DTC No. P0C43-00 Coolant Temperature Sensor Rationality Diagnosis

MONITOR EXECUTION

- Once per driving cycle (During the BMU activation)

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- BMU monitor

Sensor (The sensor below is determined to be normal)

- Refrigerant temperature sensor

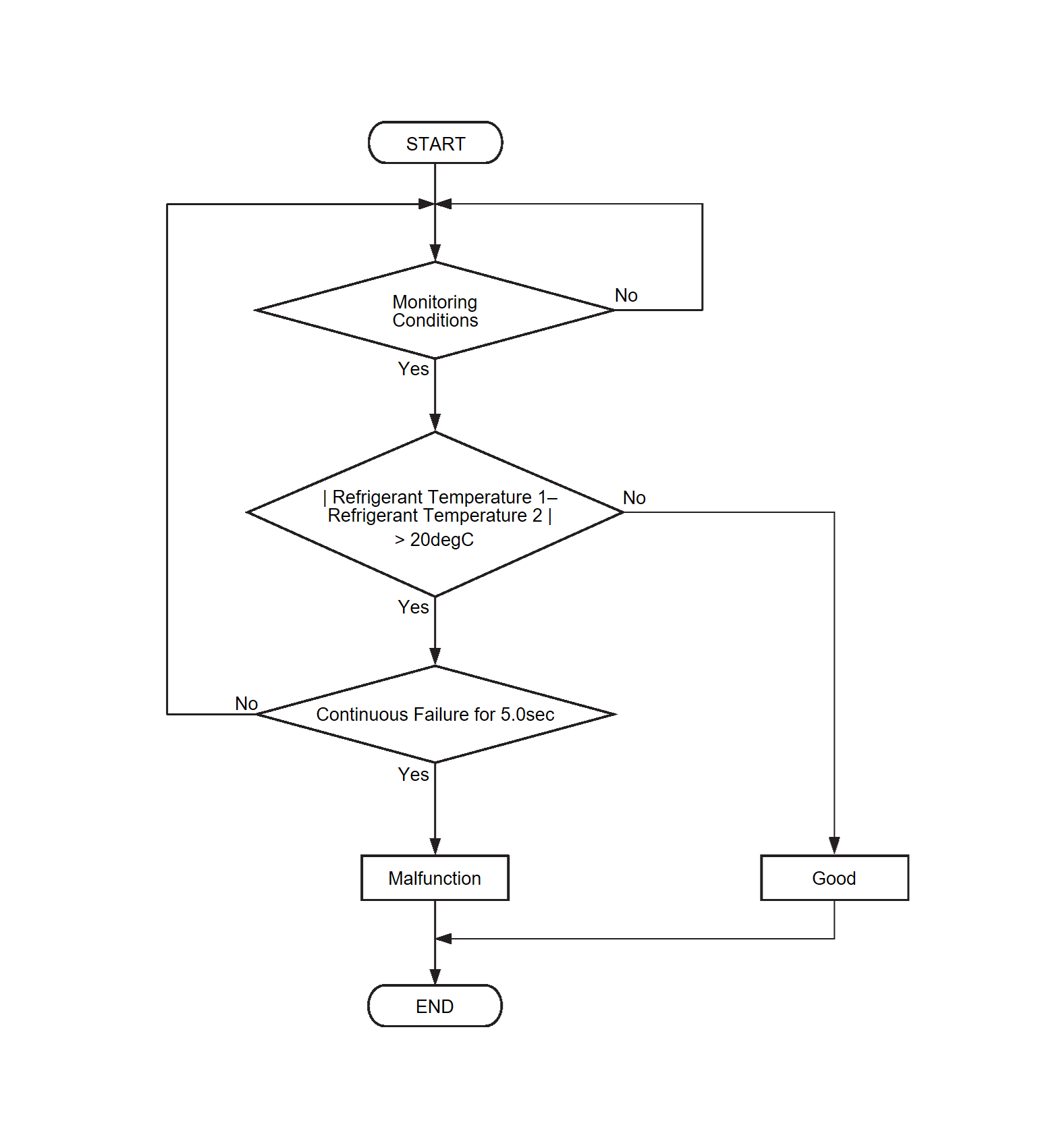

DTC SET CONDITIONS

Check Condition

- Battery Management Unit (BMU) power supply voltage is more than 7.578 volts.

- Electric motor switch: ON

- Time after above conditions satisfy is less than 1 second.

- The soaking time is 6 hours or more. (Electric motor switch: OFF)

- The soaking time is 300 seconds or more. (Electric motor switch: OFF and ECU sleep)

Judgment Criterion

- The temperature difference between the drive battery refrigerant temperature sensor No. 1 and drive battery refrigerant temperature sensor No. 2 exceeds 20°C (68°F) for 5 seconds or more.

OBD-II DRIVE CYCLE PATTERN

- Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE

.

.

TROUBLESHOOTING HINTS

- Damaged wiring harness and connectors

- Malfunction of the drive battery cooler pipe assembly

- Malfunction of BMU

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991223: Wiring harness set

- MB992006: Extra fine probe

1.Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE .

.

.

.(2) Check the DTC.

Is the DTC set?

The trouble can be an intermittent malfunction (Refer to General Information - How to Use Troubleshooting/Inspection Service Points, How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

The trouble can be an intermittent malfunction (Refer to General Information - How to Use Troubleshooting/Inspection Service Points, How to Cope with Intermittent Malfunctions HOW TO COPE WITH INTERMITTENT MALFUNCTIONS ).

).2.Drive battery control wiring harness check (Drive battery refrigerant temperature sensor signal line)

(1) Disassemble the drive battery (Refer to SERVICE PROCEDURE ).

).

).

).(2) Check the following harness for short to ground circuit and open circuit.

- Between the BMU connector (terminal No. 24) and the drive battery cooler pipe assembly connector (terminal No. 1)

- Between the BMU connector (terminal No. 21) and the drive battery cooler pipe assembly connector (terminal No. 7)

Is the check result normal?

3.Drive battery control wiring harness check (Drive battery refrigerant temperature sensor signal line)

Check the following wiring harness for damage.

- Between the BMU connector (terminal No. 24) and the drive battery cooler pipe assembly connector (terminal No. 1)

- Between the BMU connector (terminal No. 21) and the drive battery cooler pipe assembly connector (terminal No. 7)

Is the check result normal?

4.Drive battery control wiring harness check (Drive battery refrigerant temperature sensor ground line)

Check the following wiring harness for open circuit.

- Between the BMU connector (terminal No. 23) and the drive battery cooler pipe assembly connector (terminal No. 2)

- Between the BMU connector (terminal No. 22) and the drive battery cooler pipe assembly connector (terminal No. 8)

Is the check result normal?

5.Drive battery refrigerant temperature sensor check

Check the drive battery refrigerant temperature sensor check (Refer to DRIVE BATTERY COOLANT TEMPERATURE SENSOR CHECK ).

). Replace the BMU (Refer to BATTERY MANAGEMENT UNIT (BMU) REMOVAL AND INSTALLATION

Replace the BMU (Refer to BATTERY MANAGEMENT UNIT (BMU) REMOVAL AND INSTALLATION ). Then,

). Then,

Replace the drive battery cooler pipe assembly (Refer to SERVICE PROCEDURE

Replace the drive battery cooler pipe assembly (Refer to SERVICE PROCEDURE ). Then,

). Then,

).

).Is the check result normal?

Replace the BMU (Refer to BATTERY MANAGEMENT UNIT (BMU) REMOVAL AND INSTALLATION

Replace the BMU (Refer to BATTERY MANAGEMENT UNIT (BMU) REMOVAL AND INSTALLATION ). Then,

). Then,

Replace the drive battery cooler pipe assembly (Refer to SERVICE PROCEDURE

Replace the drive battery cooler pipe assembly (Refer to SERVICE PROCEDURE ). Then,

). Then,

6.Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE .

.

.

.(2) Check the DTC.

Is the DTC set?

Retry the troubleshooting.

Retry the troubleshooting. The procedure is complete.

The procedure is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)