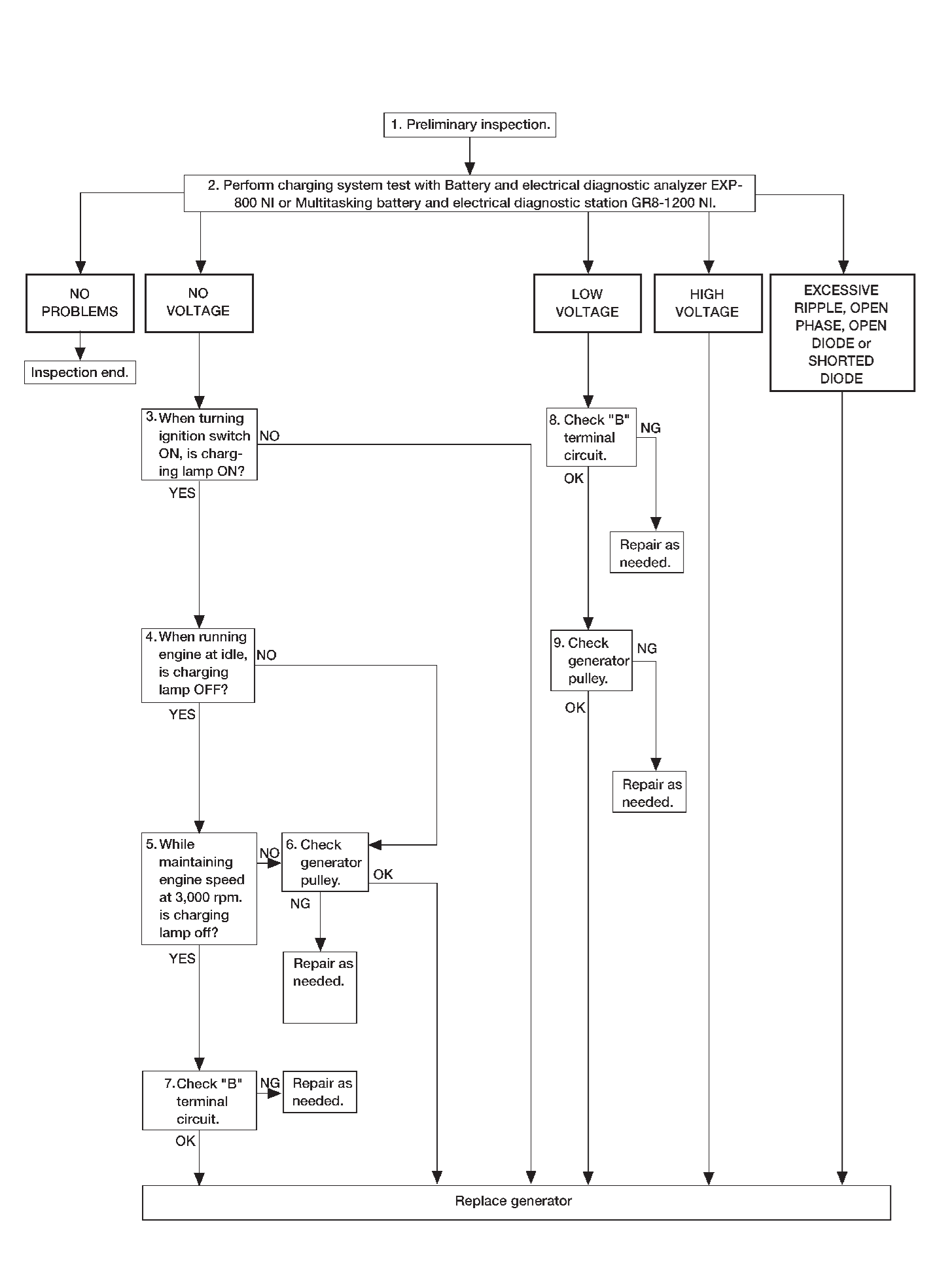

Work Flow (With EXP-800 NI or GR8-1200 NI)

CHARGING SYSTEM DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To test the charging system, use the following special service tools:

- EXP-800 NI Battery and electrical diagnostic analyzer

- GR8-1200 NI Multitasking battery and electrical diagnostic station

| note | Refer to the applicable Instruction Manual for proper charging system diagnosis procedures. |

DETAILED FLOW

| note | To ensure a complete and thorough diagnosis, the 12V battery, starter motor and generator test segments must be done as a set from start to finish. |

2.DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

Perform the charging system test using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI. Refer to the applicable Instruction Manual for proper testing procedures. PROBLEMSCharging system is normal and will also show “DIODE RIPPLE” test result.

PROBLEMSCharging system is normal and will also show “DIODE RIPPLE” test result.

Test result

PROBLEMSCharging system is normal and will also show “DIODE RIPPLE” test result.

PROBLEMSCharging system is normal and will also show “DIODE RIPPLE” test result. : Replace generator. Refer to Removal and Installation .

.

.

. : Replace generator. Refer to Removal and Installation . Perform “DIODE RIPPLE” test again using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI to confirm repair.

. Perform “DIODE RIPPLE” test again using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI to confirm repair.

. Perform “DIODE RIPPLE” test again using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI to confirm repair.

. Perform “DIODE RIPPLE” test again using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI to confirm repair. 3.INSPECTION WITH CHARGE WARNING LIGHT (IGNITION SWITCH IS ON)

Ignition switch ON. Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

.

Does the charge warning light illuminate?

Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

.4.INSPECTION WITH CHARGE WARNING LIGHT (IDLING)

5.INSPECTION WITH CHARGE WARNING LIGHT (ENGINE AT 3,000 RPM)

6.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to InspectionInspection .

. Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

. Repair as needed.

Repair as needed.

.

.Is generator pulley normal?

Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

. Repair as needed.

Repair as needed.7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure .

. Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

. Repair as needed.

Repair as needed.

.

.Is “B” terminal circuit normal?

Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

. Repair as needed.

Repair as needed.8.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure .

. Repair as needed.

Repair as needed.

.

.Is “B” terminal circuit normal?

Repair as needed.

Repair as needed.9.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to InspectionInspection .

. Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

. Repair as needed.

Repair as needed.

.

.Is generator pulley normal?

Replace generator. Refer to Removal and Installation

Replace generator. Refer to Removal and Installation .

. Repair as needed.

Repair as needed.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)