Adjustment

ADJUSTING SHIM SELECTION

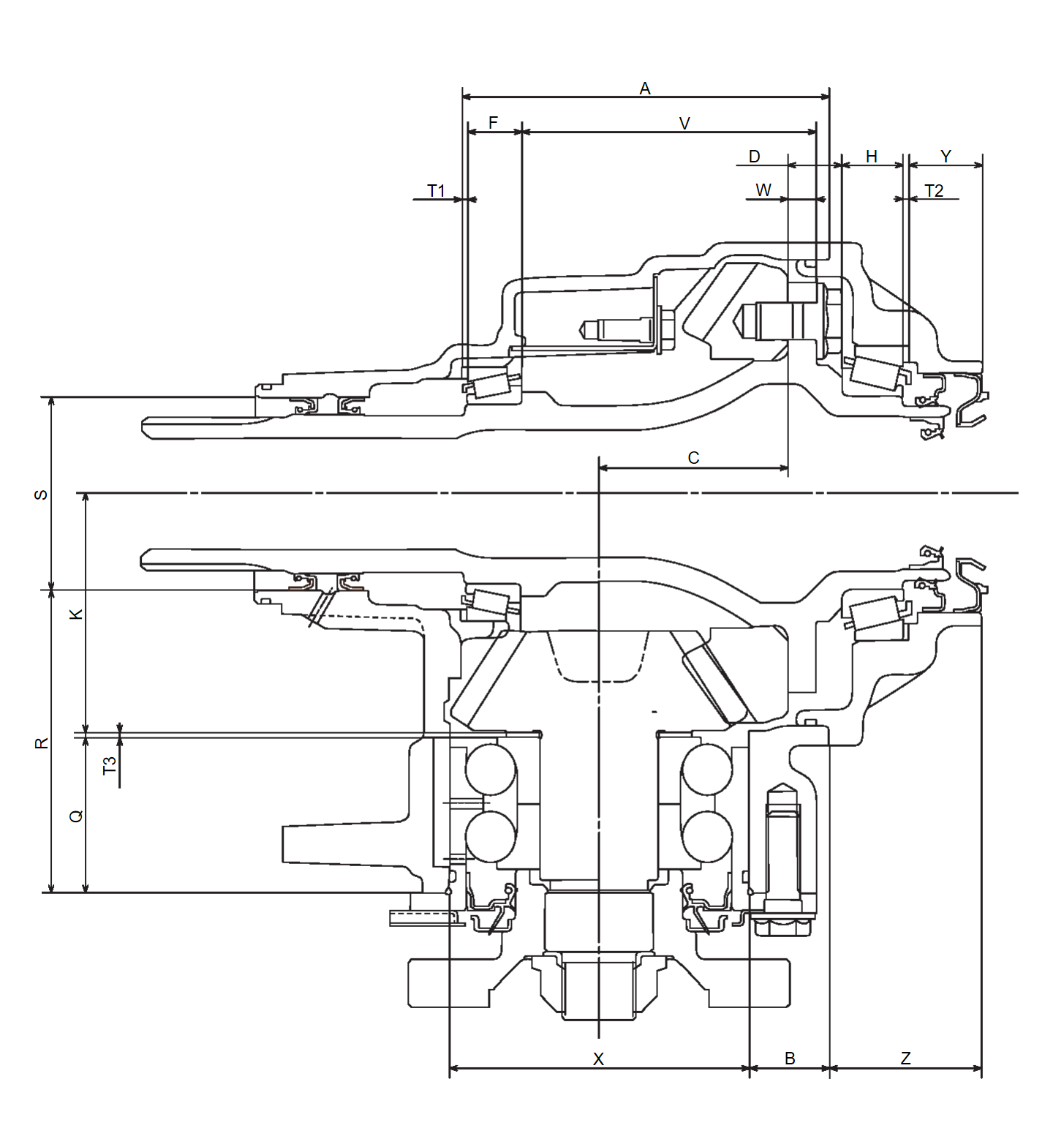

Select adjusting shim of T1, T2, and T3, respectively, by using the following equation.

T1 [Ring gear bearing adjusting shim (transfer case side)]

- T1 = A −(B +X/2) +C +W −V −F −(M/100) +0.071 mm (0.0028 in)

T2 [Ring gear bearing adjusting shim (transfer cover side)]

- T2 = −Y +Z +(B +X/2) −C −D −H +(M/100) +0.071 mm (0.0028 in)

T3 (Drive pinion adjusting shim)

- T3 = −Q +(R +S/2) −K +(O/100)

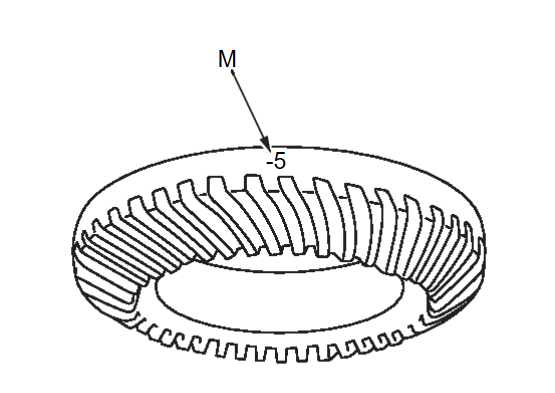

- Check dimension (M) on the ring gear side face.

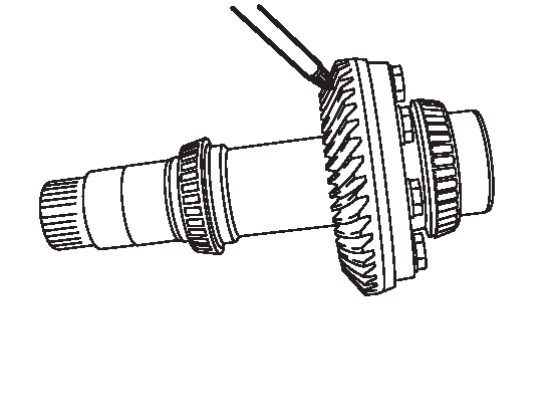

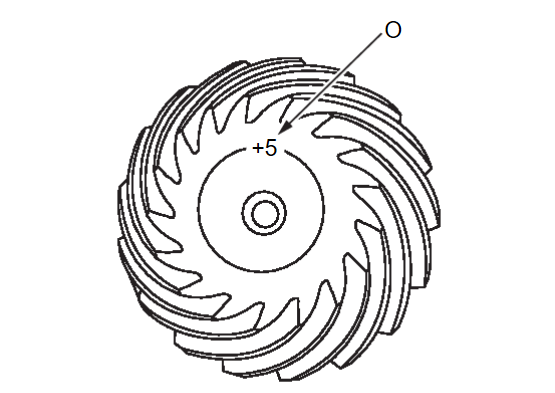

note Dimension “M” indicates the difference between the optimum engagement and standard dimensions in increments of 0.01 mm (0.0004 in) written on the ring gear side face. - Check dimension (O) on the gear end of drive pinion.

note Dimension “O” indicates the difference between the optimum engagement and the standard dimensions in increments of 0.01 mm (0.0004 in) written on the gear end of drive pinion.

PINION BEARING PRELOAD

1. Remove ring gear shaft assembly from the transfer case. Refer to Disassembly and Assembly .

.

.

.2. Rotate the companion flange back and forth from 2 to 3 times to check for unusual noise, binding, sticking, and so on.

3. Rotate the companion flange at least 20 times to check for smooth operation of the bearing.

4. While rotate drive pinion at 30 rpm, measure the pinion bearing preload with the preload gauge [SST: ST3127S000 (J-25765-A)].

| Pinion bearing preload | : Refer to Preload Torque . . |

| caution | Each rotational part should rotate smoothly with the specified transfer oil. |

| note | Preload torque differs before disassembly and after reassembly. (It differ after driving and new parts.) |

- If outside the standard, disassemble pinion bearing assembly to check and adjust each part.

TOTAL PRELOAD

1. Measure pinion bearing preload.

| caution | Check that the pinion bearing preload is within the standard. |

2. Assemble the ring gear shaft assembly to the transfer case. Refer to Disassembly and Assembly

3. Install transfer cover to check and adjust each part. Refer to Disassembly and Assembly .

.

.

.4. Rotate the companion flange at least 20 times to check for smooth operation of the bearing.

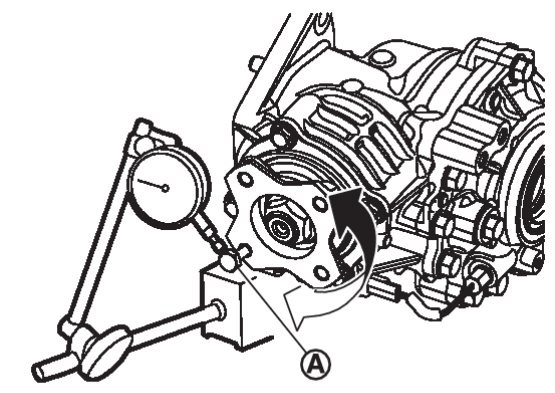

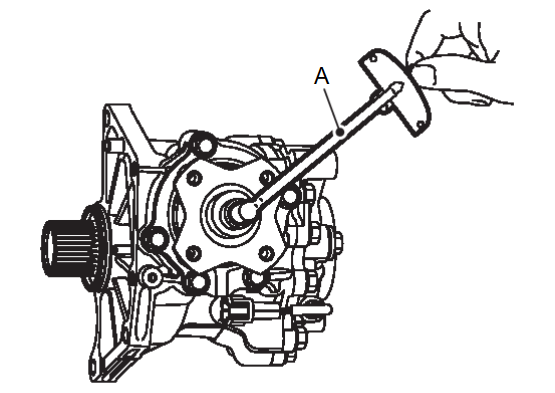

5. While rotate drive pinion at 30 rpm, measure the total preload with the preload gauge (A) [SST: ST3127S000 (J-25765-A)].

| Total preload | : Refer to Preload Torque . . |

| caution | Each rotational part should rotate smoothly with the specified transfer oil. |

| note | Preload torque differs before disassembly and after reassembly. (It differ after driving and new parts.) |

- If outside the standard, disassemble the transfer assembly to check and adjust each part. Measure it with the transfer case oil seals and transfer cover oil seals (outer/inner) removed when measuring total preload after disassembly. Then install transfer case oil seals and transfer cover oil seals.

BACKLASH

1. Install the suitable bolt to the companion flange.

3. Measure the circumference backlash of the companion flange.

| Backlash | : Refer to Backlash . . |

| note | Backlash differs before disassembly and after reassembly. (It differ after driving and new parts.) |

- If outside the standard, disassemble the transfer assembly to check and adjust each part.

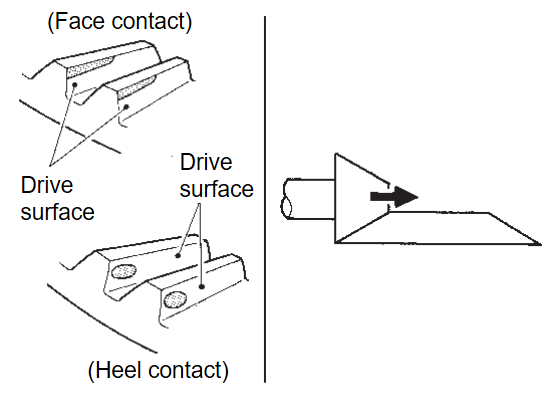

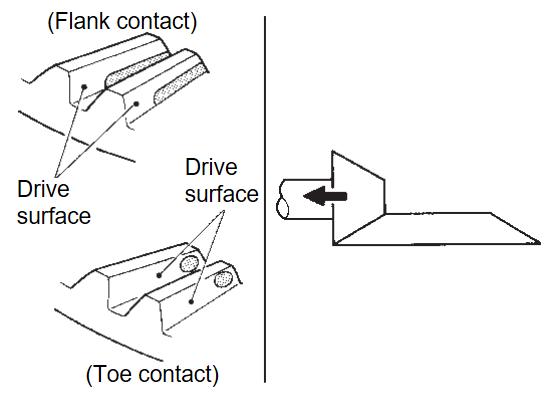

TOOTH CONTACT

1. Remove transfer cover. Refer to Disassembly and Assembly .

.

.

.2. Remove ring gear shaft assembly from transfer case. Refer to Disassembly and Assembly .

.

.

.3. Apply red lead or equivalent onto the ring gear.

| caution | Apply red lead or equivalent to both faces of 3 to 4 gears at 4 locations evenly spaced on the ring gear. |

4. Assemble ring gear shaft assembly to the transfer case. Refer to Disassembly and Assembly .

.

.

.5. Install transfer cover to check and adjust each part. Refer to Disassembly and Assembly .

.

.

.| note | At this timing, O-ring installing to transfer cover is not necessary. Install O-ring after backlash and tooth contact are checked. |

6. Remove plug from the transfer case.

7. Rotate the companion flange back and forth several times, and check the drive pinion gear to ring gear tooth contact by viewing from the plug hole.

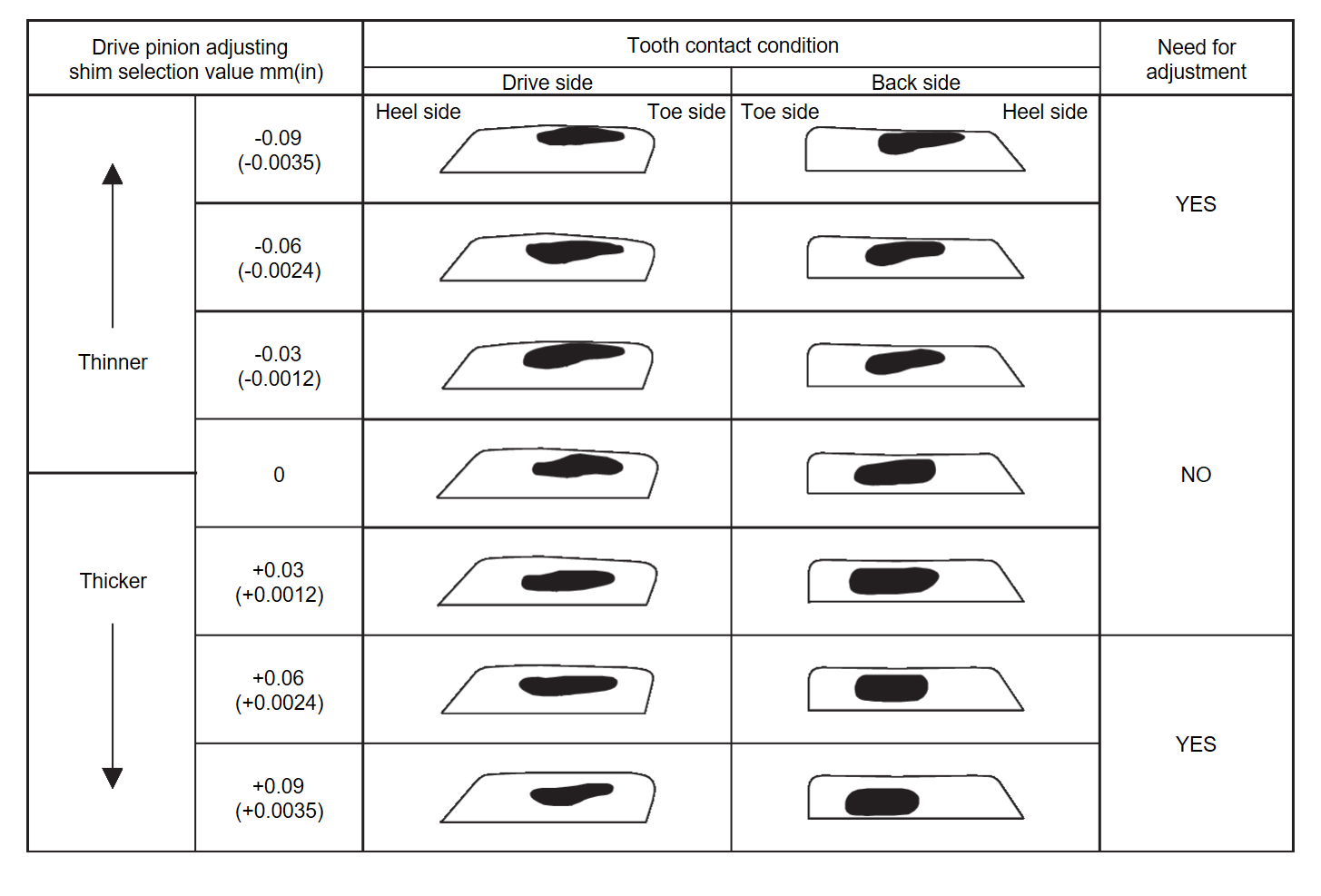

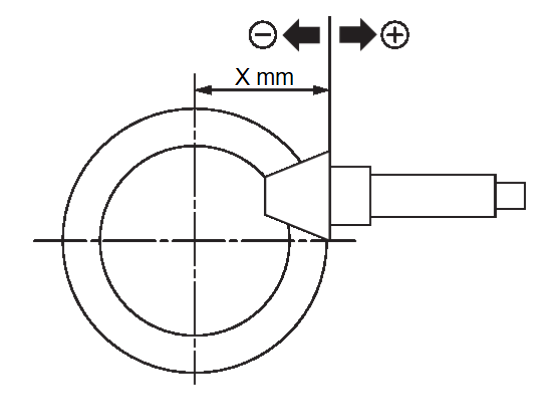

8. Follow the procedure below to adjust pinion height (dimension X) if tooth contact is improper.

| caution | If no adjusting shim with the calculated value is available, select the thicker and closest one. |

- Thicken the drive pinion adjusting shim to move the drive pinion closer to the ring gear in case of face contact or heel contact.For selecting adjusting shim, refer to the latest parts information.

caution Only one adjusting shim can be selected. - Thin the drive pinion adjusting shim to move the drive pinion farther from the ring gear in case of flank contact or toe contact.For selecting adjusting shim, refer to the latest parts information.

caution Only one adjusting shim can be selected.

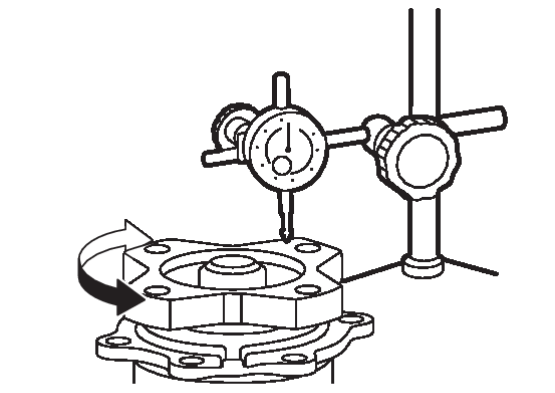

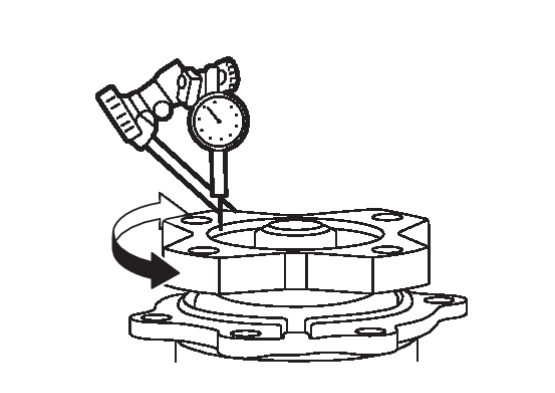

COMPANION FLANGE RUNOUT

1. Fit a dial indicator onto the companion flange face (inner side of the propeller shaft mounting bolt holes).

2. Rotate companion flange to check for runout.

| Companion flange face runout | : Refer to Companion Flange Runout . . |

4. Rotate companion flange to check for runout.

| Inner side of the companion flange runout | : Refer to Companion Flange Runout . . |

5. If the runout value is outside the runout limit, follow the procedure below to adjust.

(1) Check for runout while changing the phase between companion flange and drive pinion in 90° steps. Then search for the minimum point.

(2) Replace companion flange if runout value is still outside the limit after the phase has been changed.

(3) Adjust assembly status of the pinion bearing assembly and drive pinion, or replace pinion bearing assembly if runout is outside the standard after the companion flange is replaced.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

.

.