Disassembly and Assembly

DISASSEMBLY

1. Remove drain plug and gasket from transfer cover, and drain gear oil.

2. Remove filler plug and gasket from transfer cover.

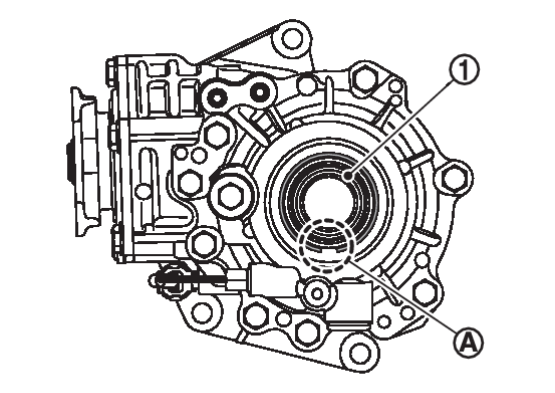

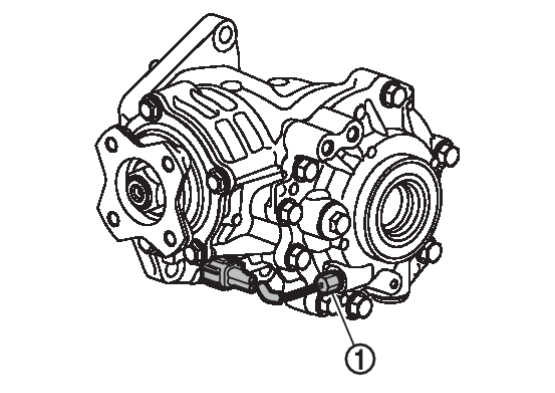

3. Remove transfer oil temperature sensor  .

.

.

.| caution |

|

6. Remove O-ring from transfer cover.

| caution |

|

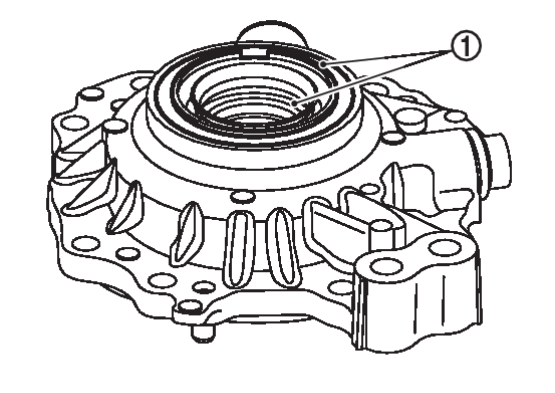

7. Lightly tap the metal part of oil seals  with pin punch etc. from back side of transfer cover to remove transfer cover oil seal (outer/inner).

with pin punch etc. from back side of transfer cover to remove transfer cover oil seal (outer/inner).

with pin punch etc. from back side of transfer cover to remove transfer cover oil seal (outer/inner).

with pin punch etc. from back side of transfer cover to remove transfer cover oil seal (outer/inner).| caution | When removing, never damage the transfer cover by scooping it out with a tool. |

8. Remove ring gear bearing adjusting shim (transfer cover side)  and ring gear bearing outer race (transfer cover side)

and ring gear bearing outer race (transfer cover side)  .

.

and ring gear bearing outer race (transfer cover side)

and ring gear bearing outer race (transfer cover side)  .

.9. Perform inspection after disassembly. Refer to InspectionInspection .

.

.

.ASSEMBLY

1. Select the ring gear bearing adjusting shim (transfer cover side). Refer to Adjustment .

.

.

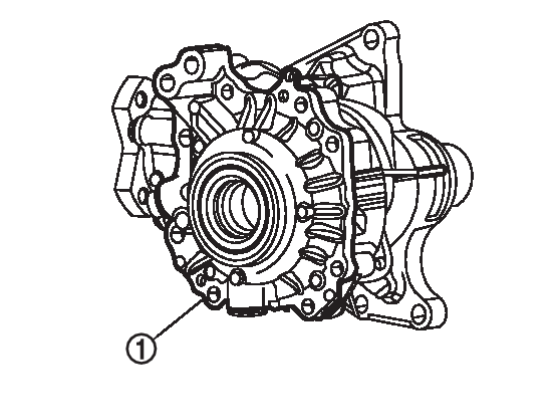

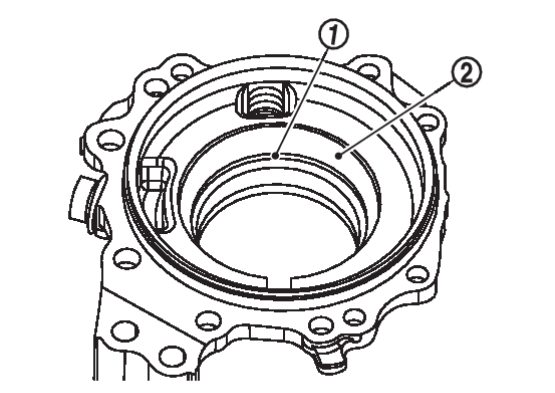

.2. Install the selected ring gear bearing adjusting shim (transfer cover side)  and ring gear bearing outer race (transfer cover side)

and ring gear bearing outer race (transfer cover side)  using a drift (commercial service tool).

using a drift (commercial service tool).

and ring gear bearing outer race (transfer cover side)

and ring gear bearing outer race (transfer cover side)  using a drift (commercial service tool).

using a drift (commercial service tool).| caution |

|

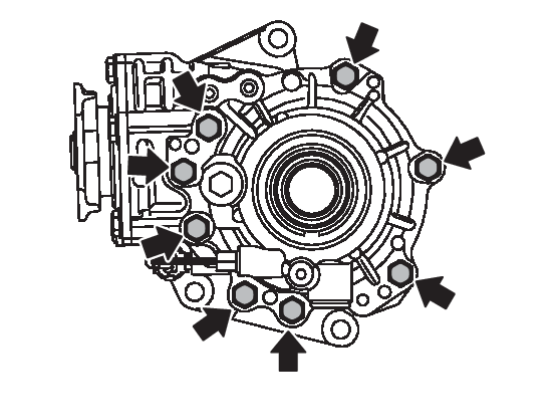

3. Install the transfer cover to the transfer case, and apply anti-corrosive oil onto thread and seats on the mounting bolts. Then tighten mounting bolts to the specified torque.

- For tightening torque, refer to Exploded View

.

.

| note | At this timing, O-ring installing to transfer cover is not necessary. Install O-ring after tooth contact is checked. |

4. Check backlash, tooth contact, total preload and companion flange runout. Refer to Adjustment .

.

.

.| caution | Measure the total preload without oil seals of transfer cover and transfer case. |

5. Remove transfer cover to install O-ring.

6. Install O-ring to the transfer cover.

| caution |

|

7. Install the transfer cover to the transfer case, and apply anti-corrosive oil onto thread and seats on the mounting bolts. Then tighten mounting bolts to the specified torque.

- For tightening torque, refer to Exploded View

.

.

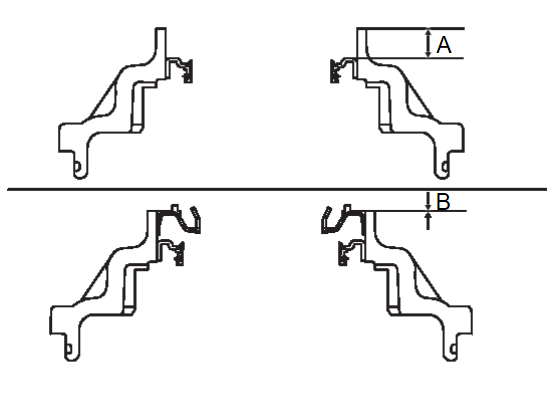

8. Using drift (commercial service tool), install transfer cover oil seal (outer/inner) with the directions below.

| A | : Installation dimension for transfer cover oil seal (inner) |

| B | : Installation dimension for transfer cover oil seal (outer) |

| Dimension | |

| A | : 10.3 +0.6/-0 mm (0.406 +0.024/-0 in) |

| B | : 0 +0.6/-0 mm (0 +0.024/-0 in) |

| note | The positive value is deeper than the transfer cover end face. |

| caution |

|

9. Install gasket onto transfer oil temperature sensor  and install them to transfer cover.

and install them to transfer cover.

and install them to transfer cover.

and install them to transfer cover.- For tightening torque, refer to Exploded View

.

.

| caution |

|

10. Install gasket onto drain plug and install them to transfer cover.

- For tightening torque, refer to Exploded View

.

.

| caution | Never reuse gasket. |

11. Install gasket onto filler plug and install them to transfer cover.

- For tightening torque, refer to Exploded View

.

.

| caution |

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

is located on the lower side.

is located on the lower side.