2. Remove drain plug from oil pan and then drain the CVT fluid.

3. Remove drain plug gasket.

4. Remove the oil pan bolts, and then remove the oil pan and oil pan gasket.

5. Remove the magnets from the oil pan.| note | Be sure to note the location of the magnets in the oil pan before removal. |

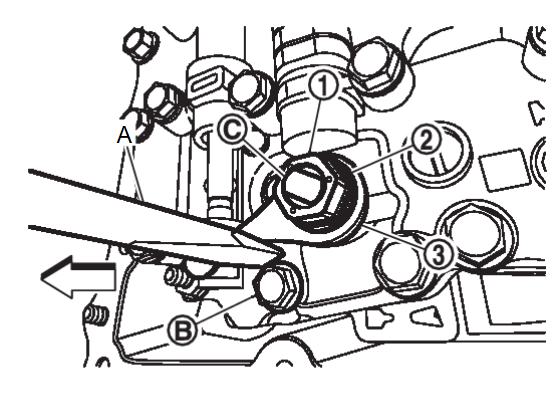

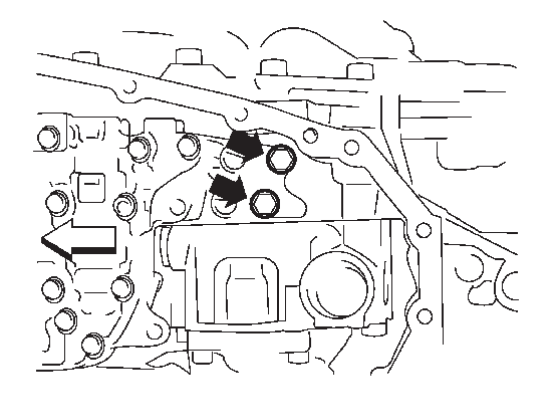

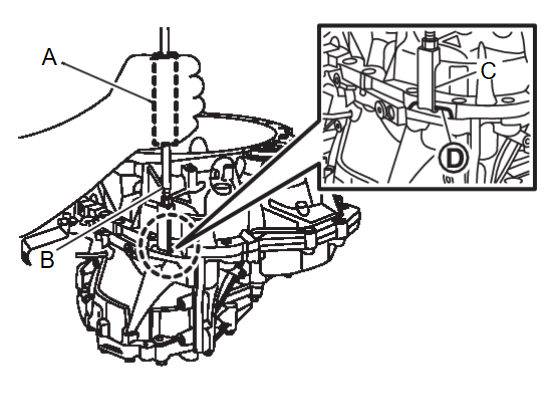

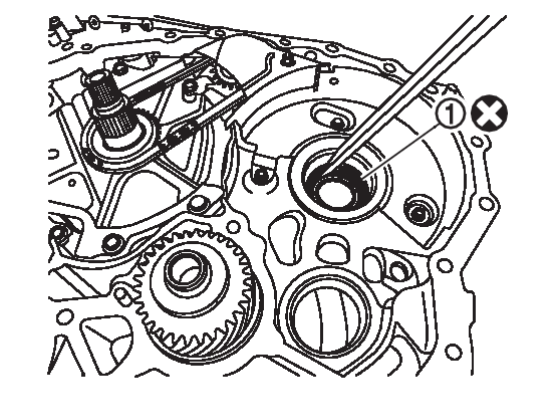

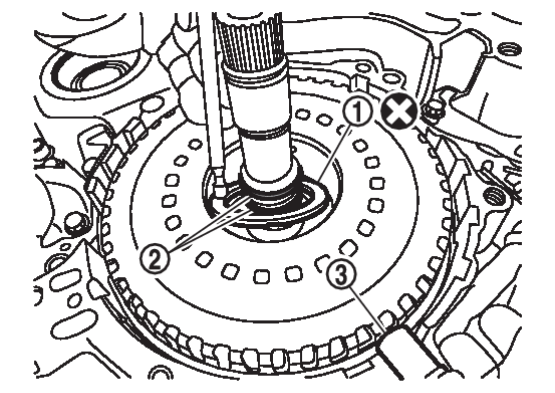

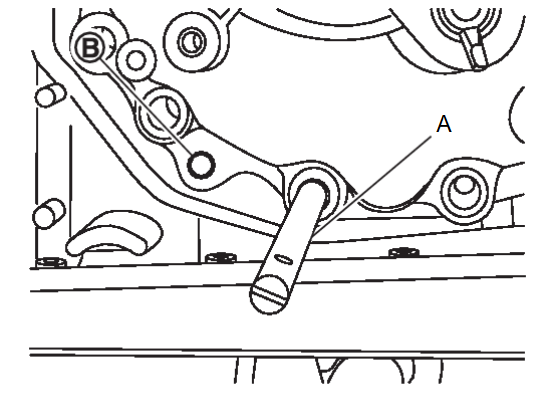

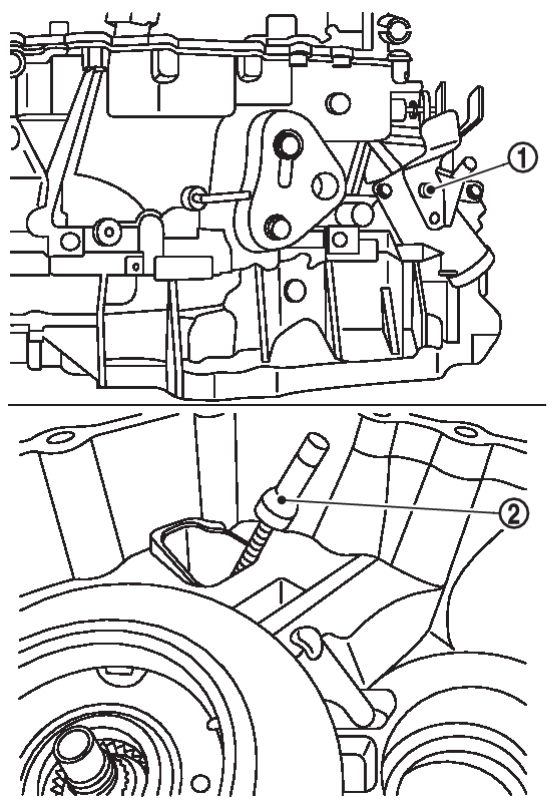

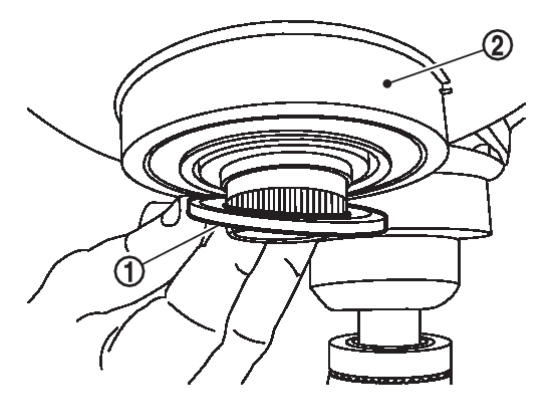

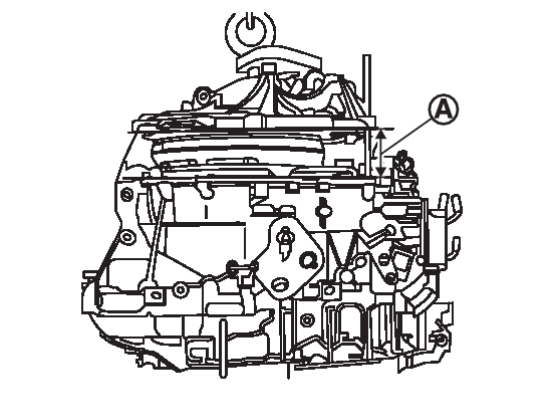

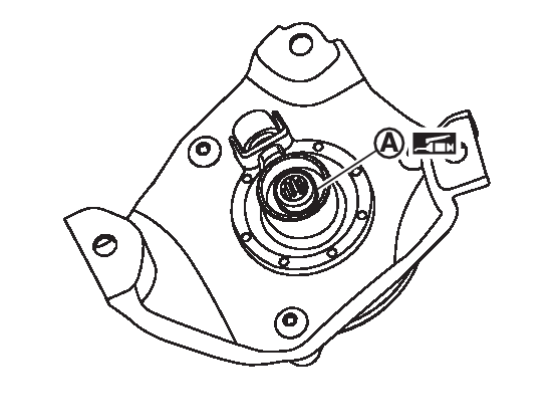

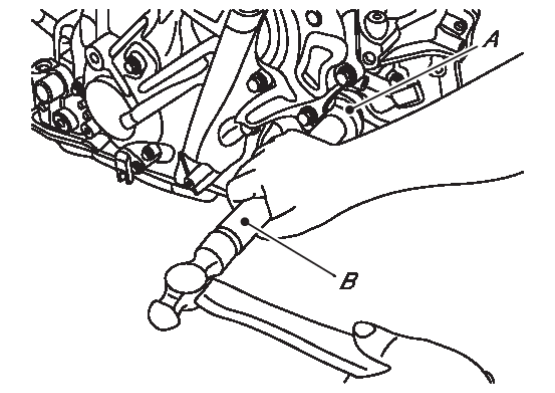

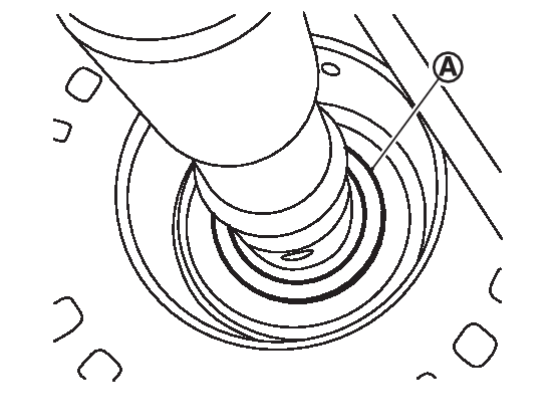

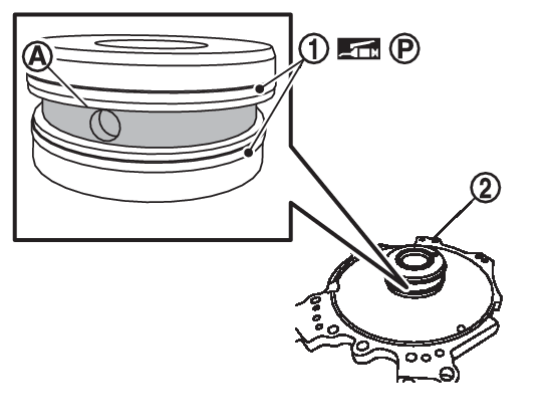

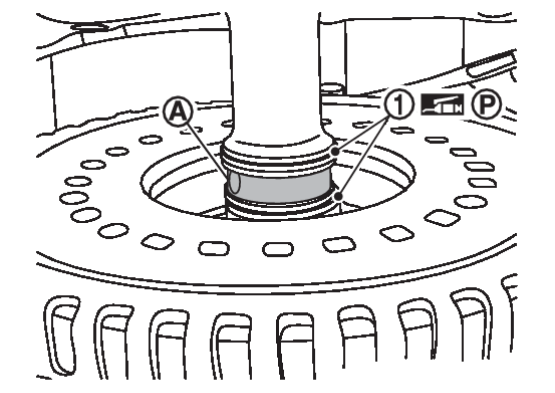

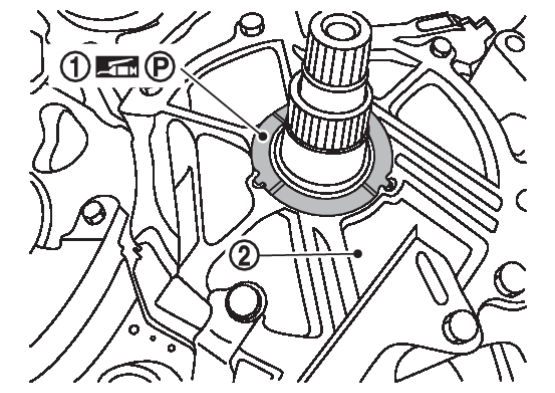

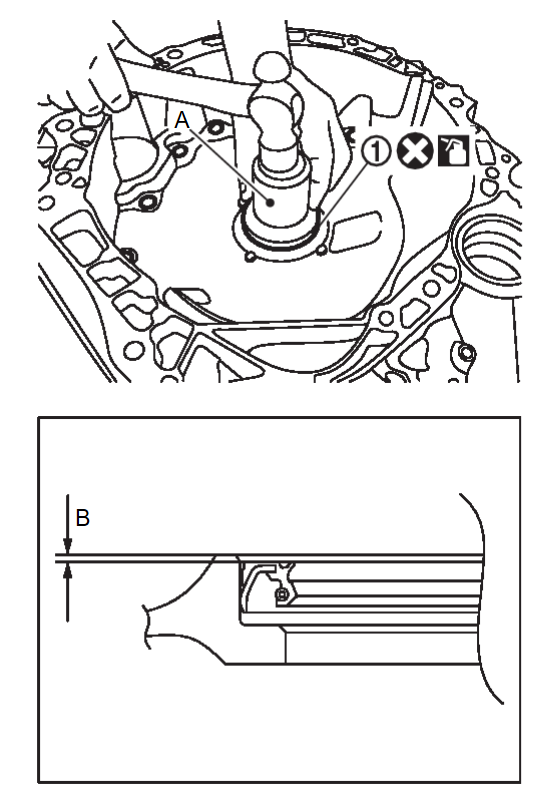

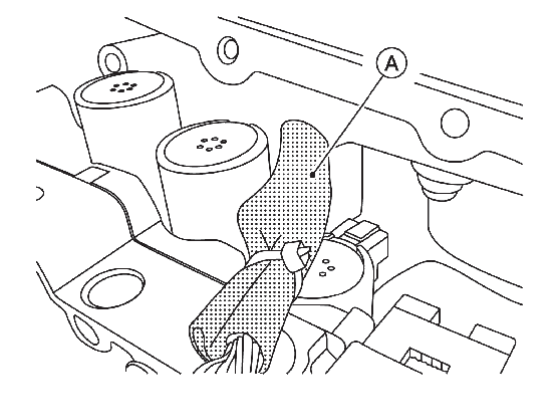

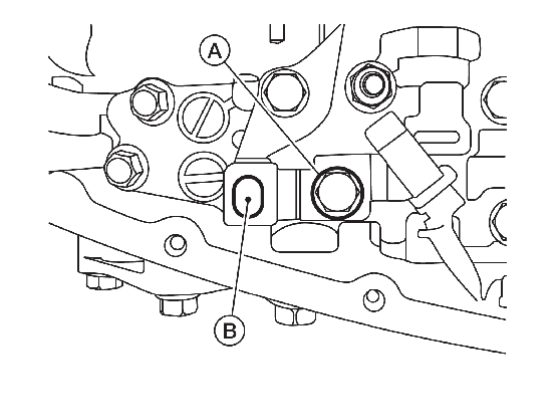

6. Use a suitable tool (A) between the manual plate  and bolt

and bolt  and remove lock nut

and remove lock nut  . Remove spring washer

. Remove spring washer  and manual plate from manual shaft

and manual plate from manual shaft  .

.| caution | - Insert suitable tool between the manual plate and bolt and remove lock nut while holding the manual plate in a fixed position.

- Be sure not to damage the control valve while using suitable tool.

|

| :Front |

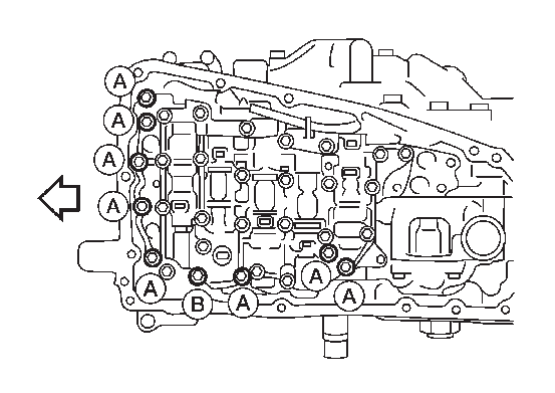

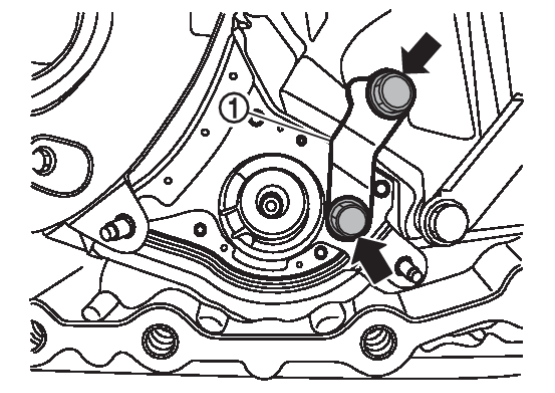

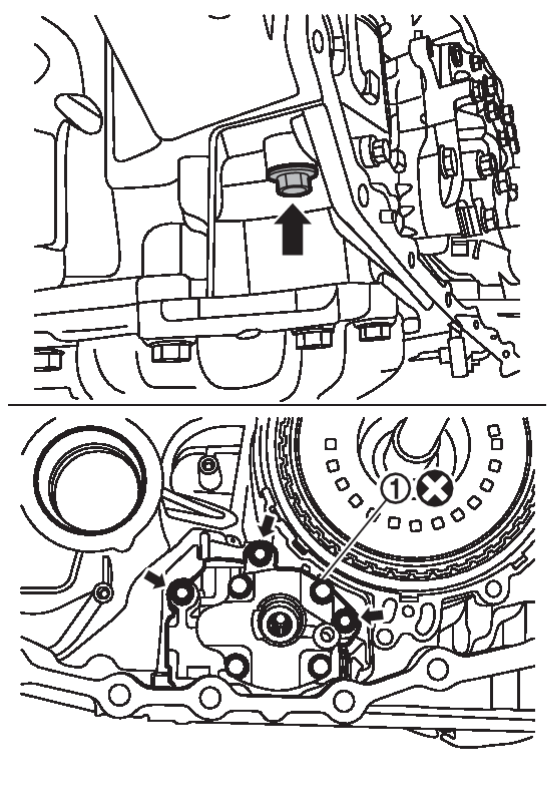

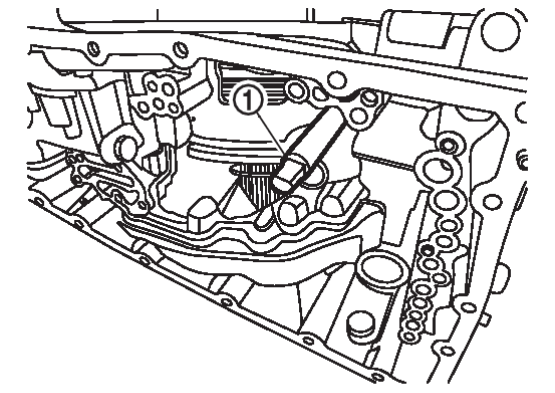

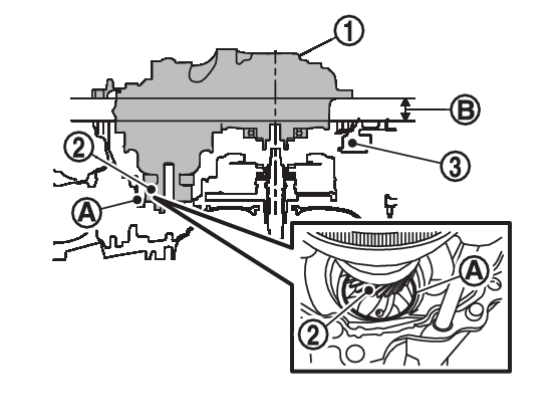

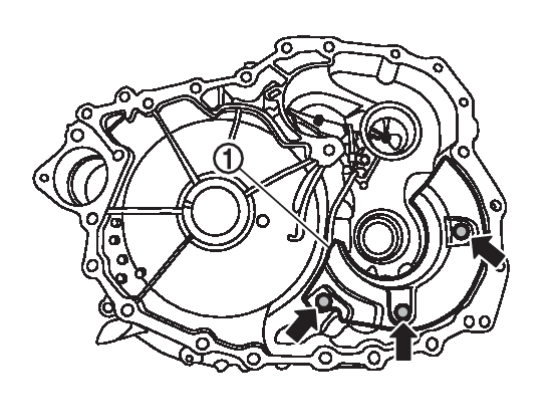

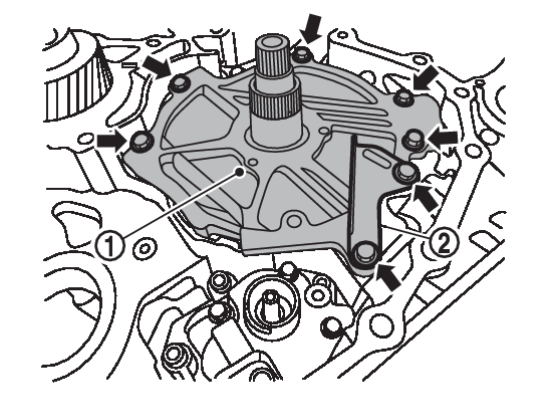

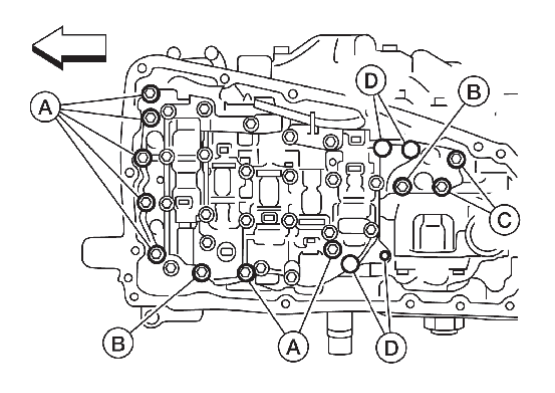

7. Remove the oil strainer assembly bolts  and remove the oil strainer assembly.

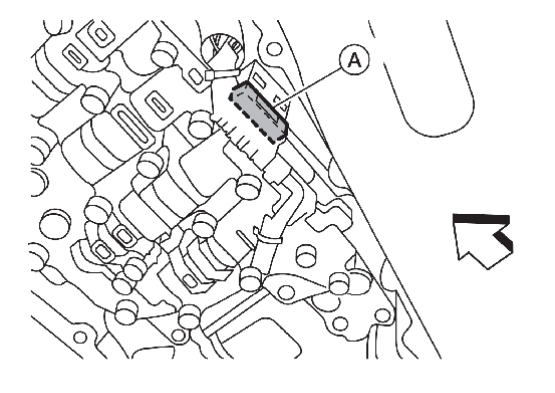

and remove the oil strainer assembly. 8. Remove CVT fluid temperature sensor bracket  and disconnect control valve harness connector

and disconnect control valve harness connector  .

. | : Bolt |

| : Front |

9. Remove bolts. | : Front |

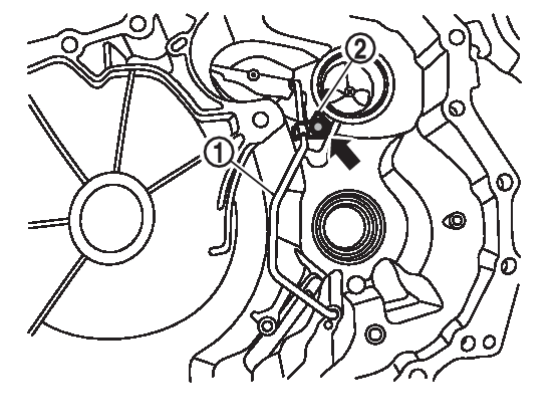

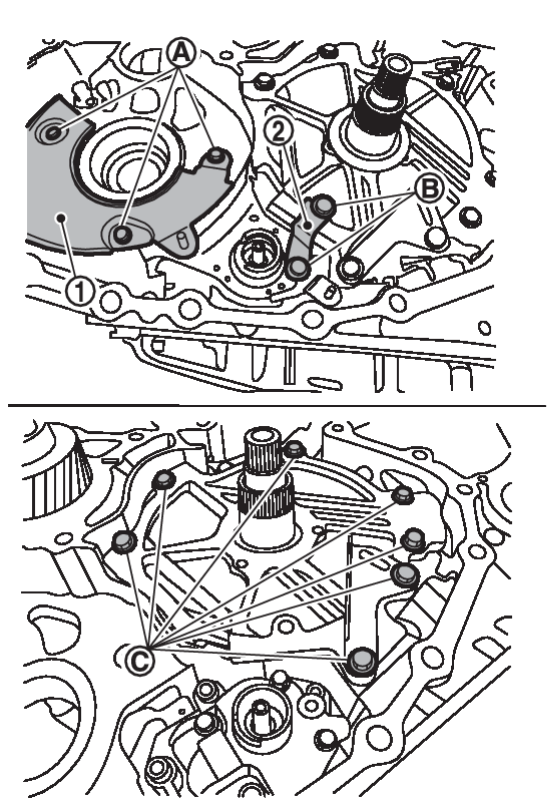

10. Disconnect control valve harness connector  .

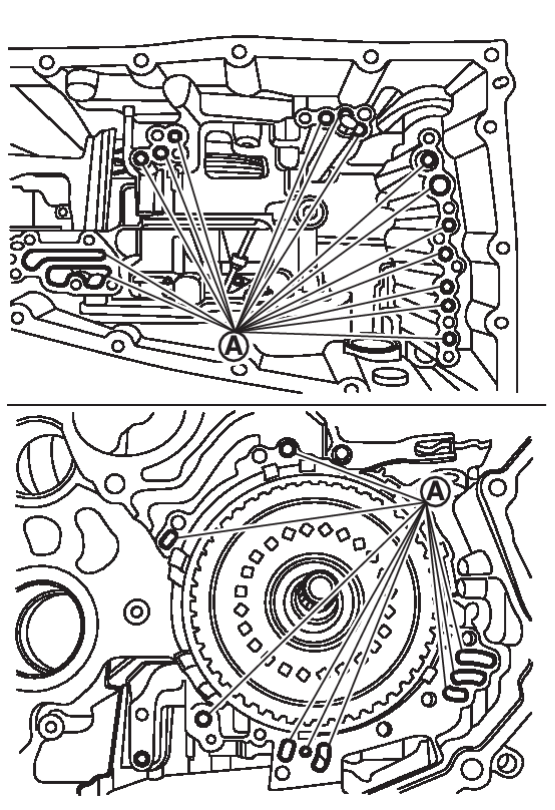

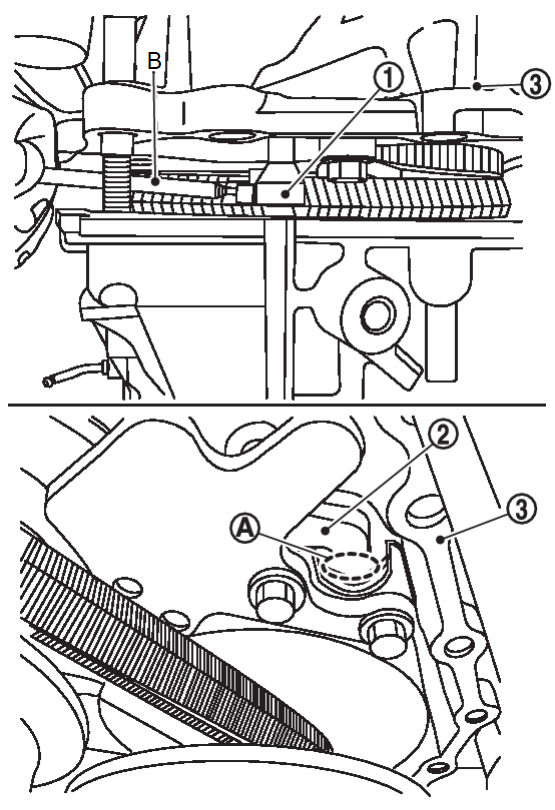

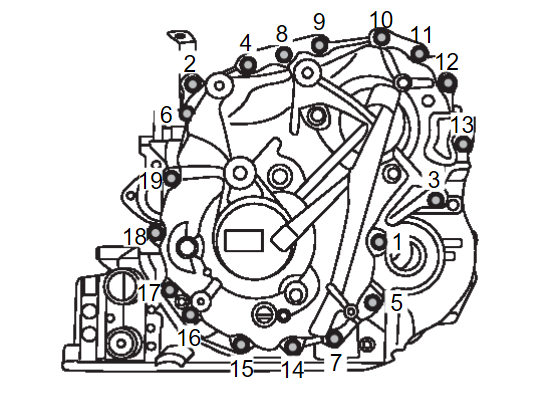

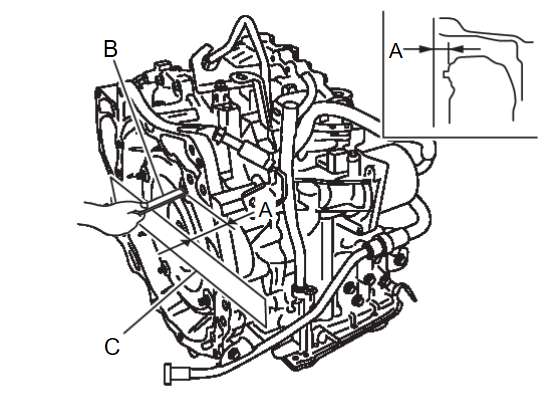

. 11. Remove the control valve bolts  and

and  , and then remove the control valve from the transaxle case.

, and then remove the control valve from the transaxle case. | : Front |

| caution | Never drop the control valve, ratio control valve and manual shaft. |

| note | Control valve bolt heads may be marked with a number "7". Bolts marked as "7" are the bolts that need to be removed in order to remove the control valve. |

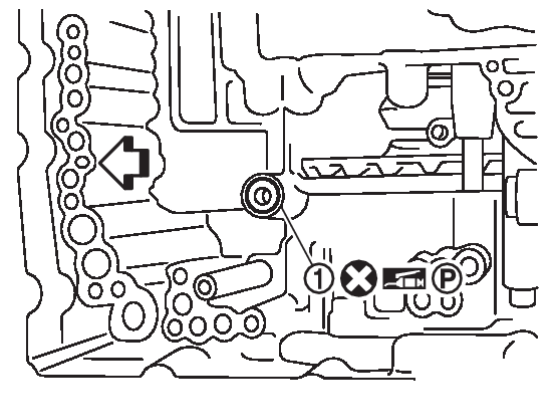

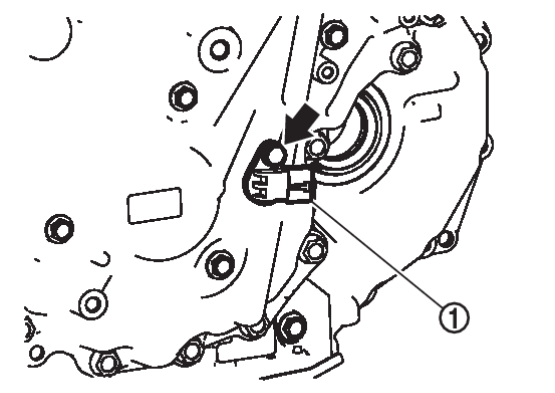

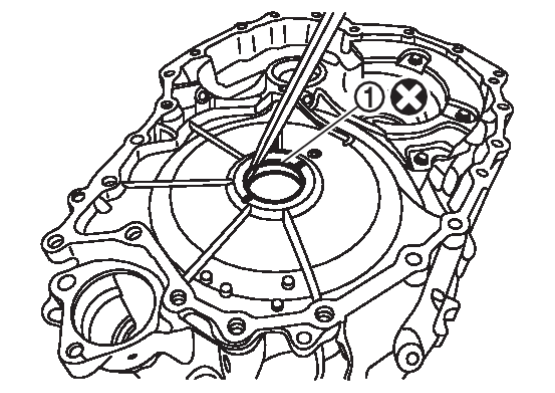

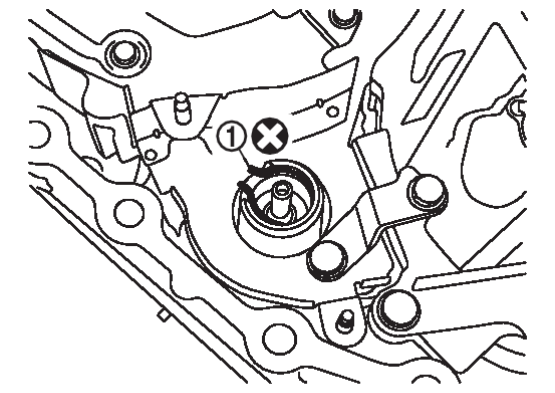

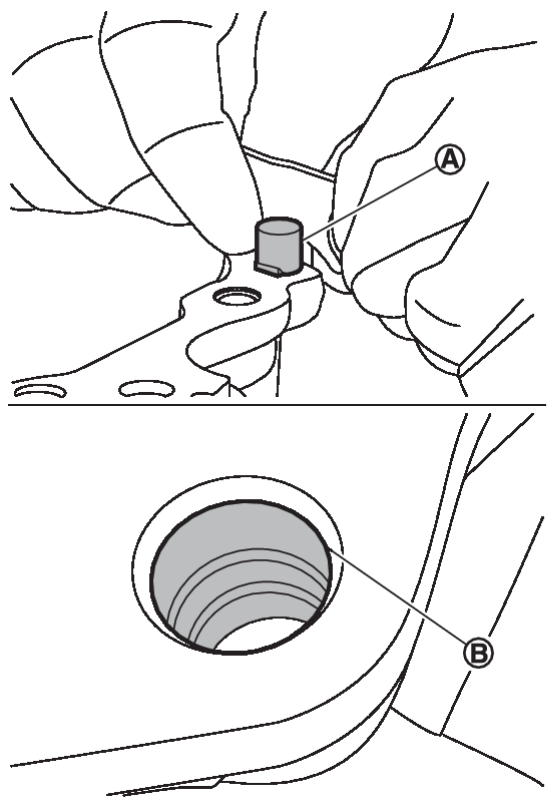

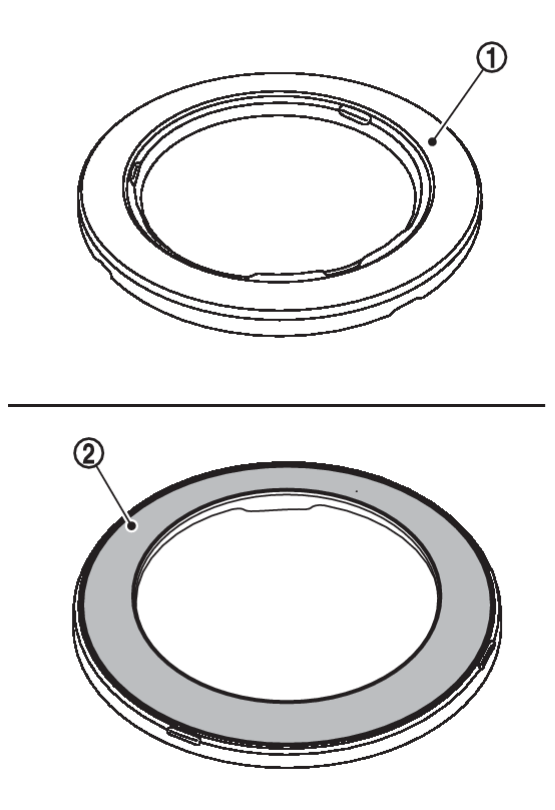

12. Remove the lip seal  from the transaxle case.

from the transaxle case. | : Front |

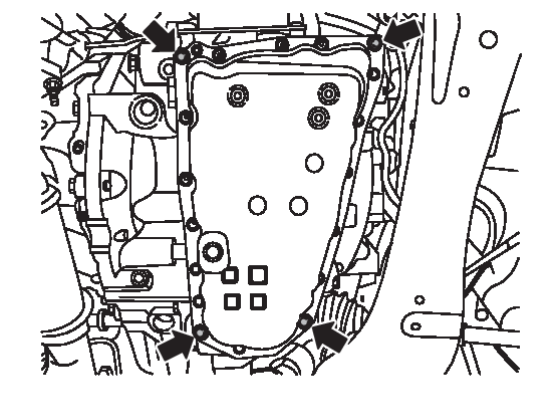

13. Temporarily install the oil pan gasket and oil pan with four oil pan bolts (  ) to corners of the oil pan, hand tight.

) to corners of the oil pan, hand tight.| note | It is not necessary for the control valve to be installed, a new one will be installed later in the service procedure. |

15. Mount the CVT on a workbench with the oil pan side down.| note | Use plastic or wood blocks to stabilize the CVT assembly on the work bench if needed. |

| caution | Be sure not to deform the oil pan. |

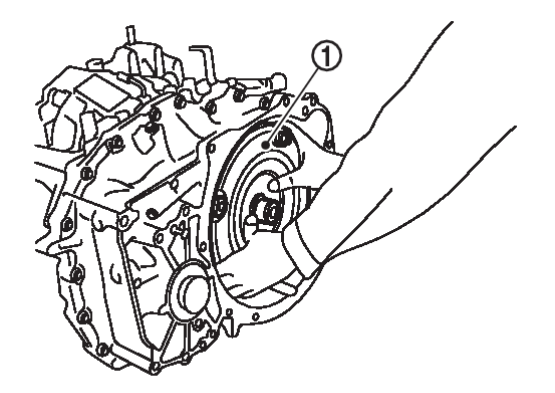

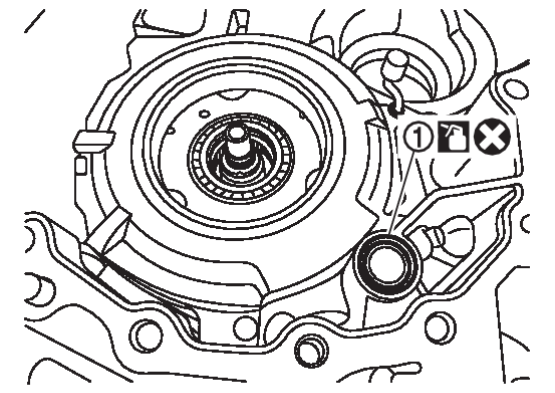

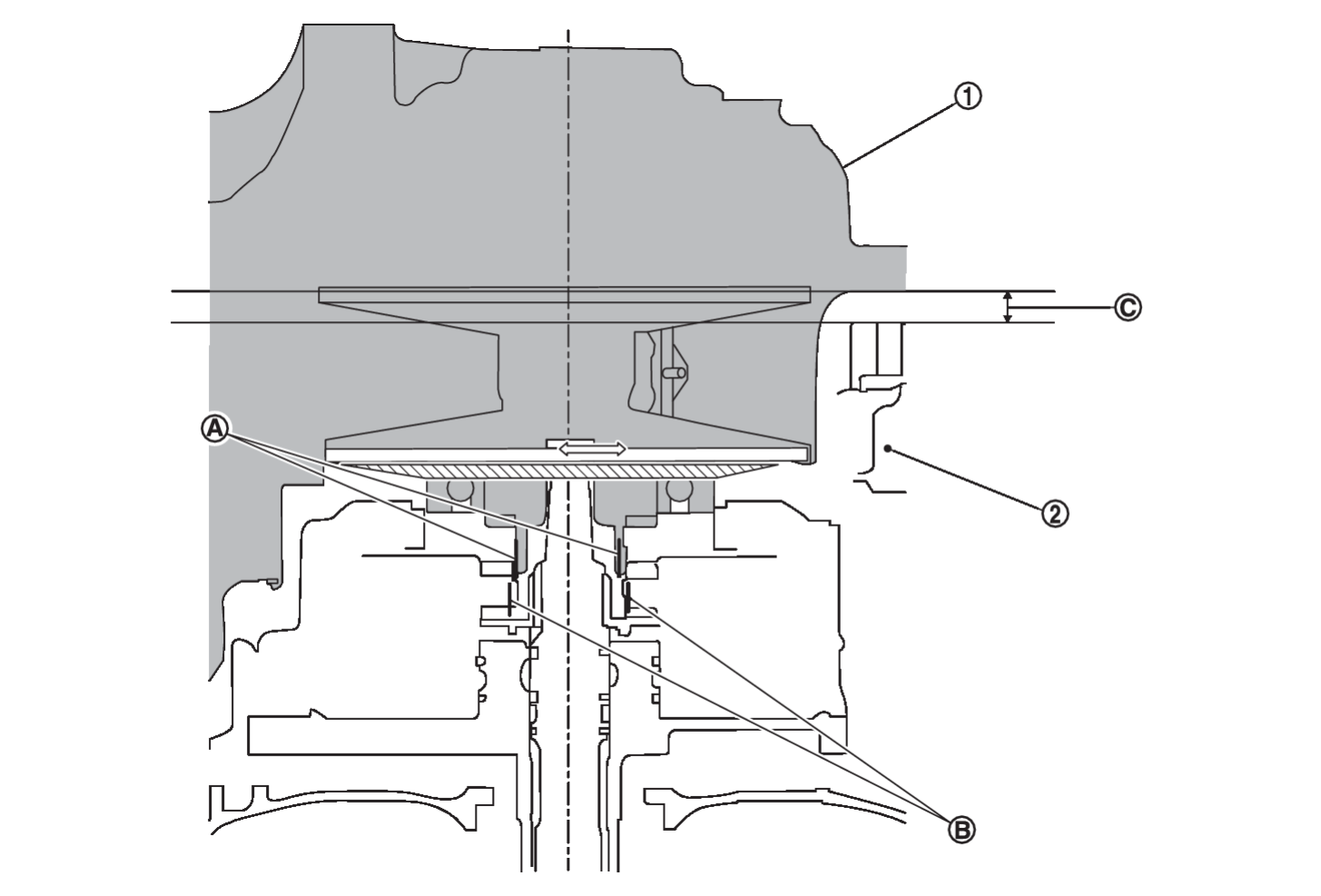

16. Remove the torque converter  .

. 17. Drain the CVT fluid out of the torque converter  .

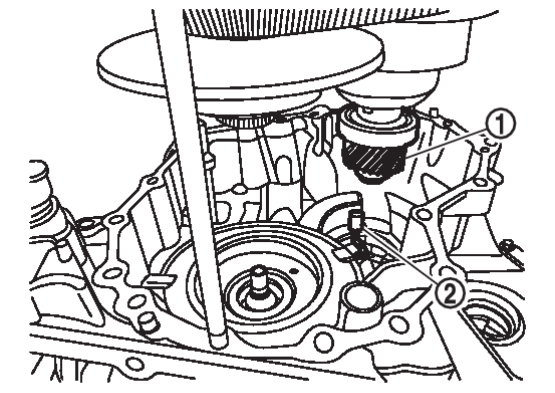

. 18. Remove mounting bolt ( ) and remove primary speed sensor

) and remove primary speed sensor  from transaxle assembly.

from transaxle assembly.| caution | Never impact the primary speed sensor when removing or installing primary speed sensor. |

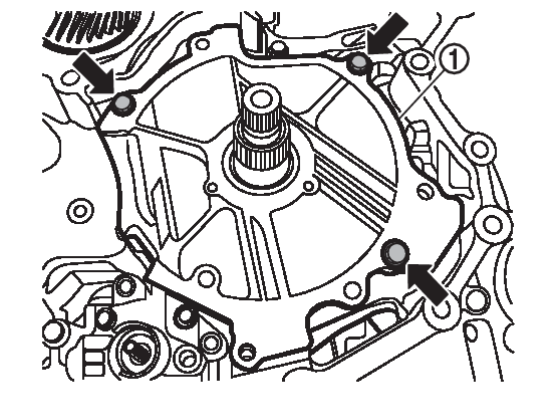

19. Remove the converter housing fixing bolts.| note | - These bolts will be replaced with new ones and will not be reused.

- Apply rust remover to the dowel pins if needed.

|

| : Front bolts |

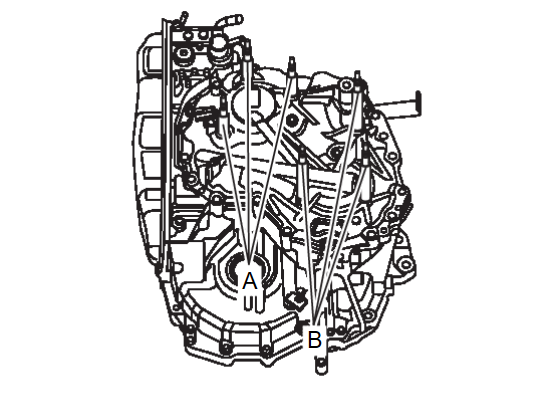

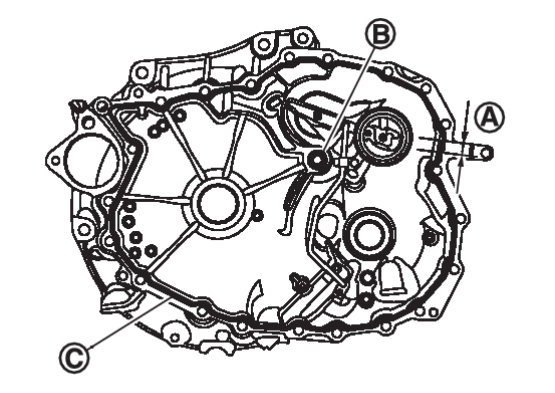

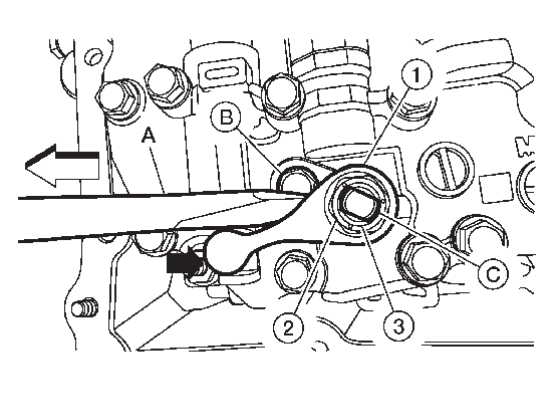

| : Back side bolts |

20. Separate and then remove the converter housing from the transaxle case. Use the slide hammer [SST: KV315J0610 (J-25721-A)] (A), slide hammer nut and bolt kit [SST: KV315J0630 (J-50255-UPD)] (B), and J-hook case separator [SST: KV315J0620 (J-51923)] (C) at the cut out areas similar to the one shown in figure. | : Cutout area (total 3 places) |

| caution | Never use a pry-bar, chisel, etc. to separate the converter housing from the transaxle case. |

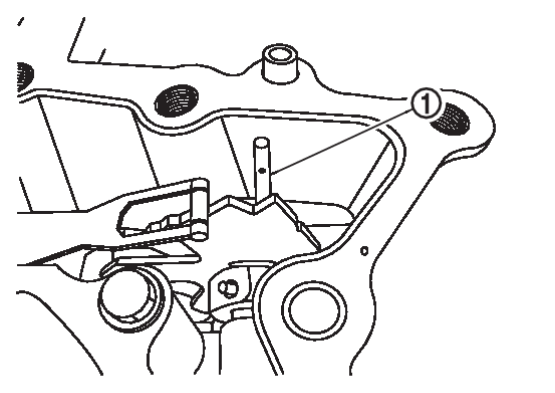

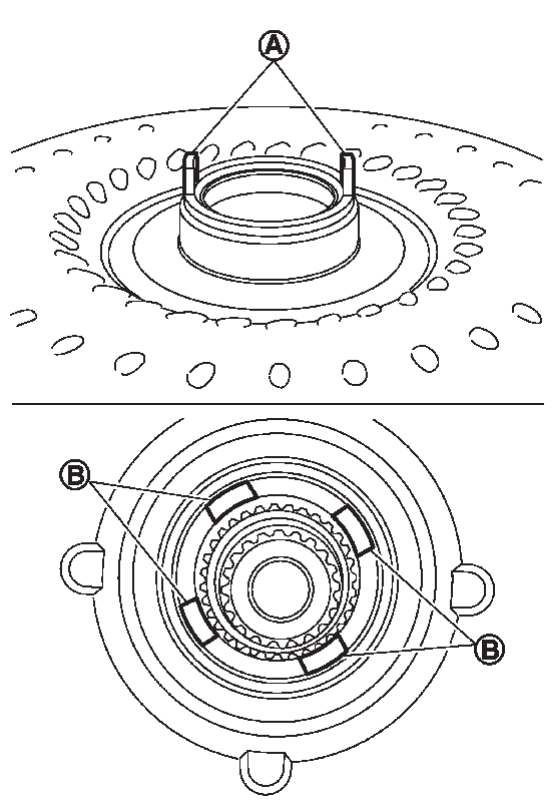

21. Check that retaining pin of manual shaft  locates on the original position.

locates on the original position. 22. Remove the O-ring  from the input shaft.

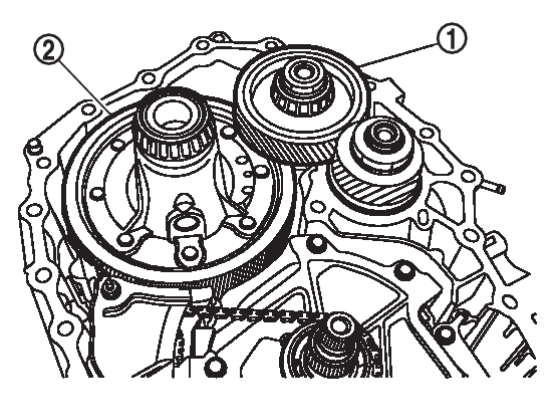

from the input shaft. 23. Carefully remove the reduction gear assembly  and the differential assembly

and the differential assembly  .

. 24. Remove the following oil seals using suitable tool:| caution | Be careful not to damage any of the seal bore surfaces. |

- Differential side oil seal

of transaxle case

of transaxle case - Converter housing oil seal

- Differential side oil seal

of converter housing

of converter housing

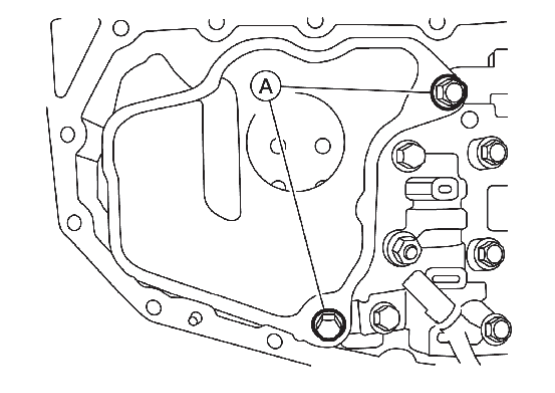

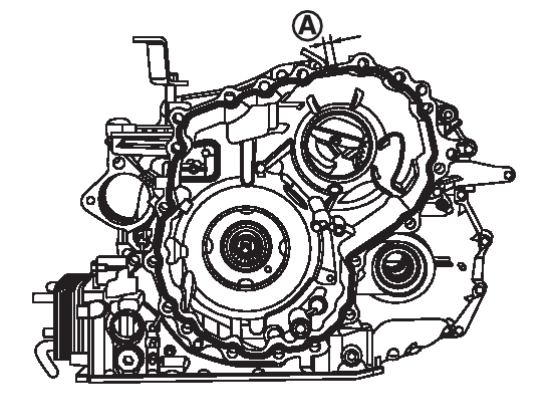

25. Remove the baffle plate (chain cover)  .

. | : Nut |

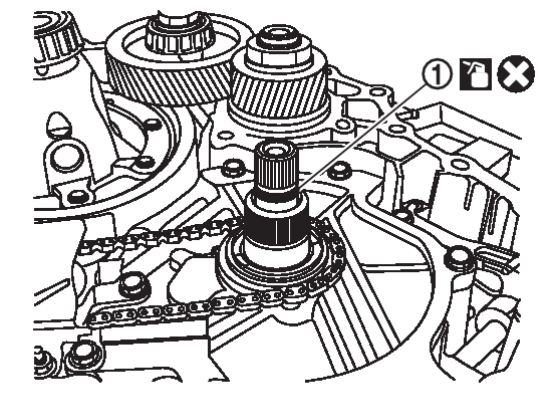

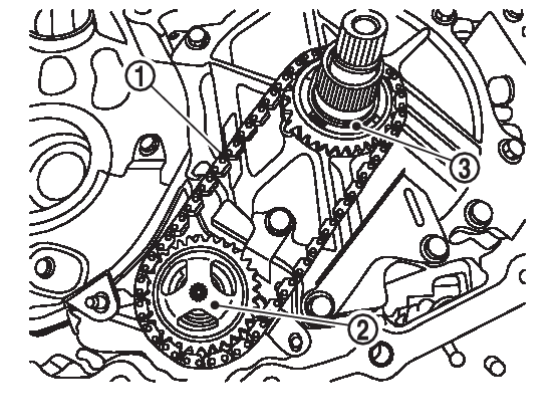

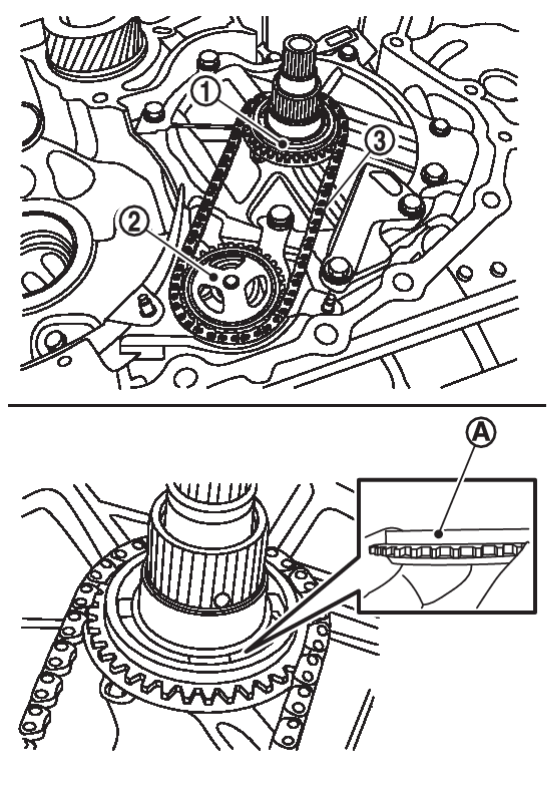

26. Remove the oil pump chain  , driven sprocket

, driven sprocket  and drive sprocket

and drive sprocket  as one assembly in the following procedure.

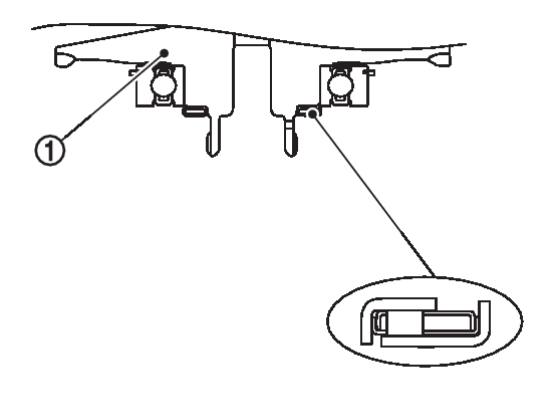

as one assembly in the following procedure.- Spread the snap ring

using snap ring pliers.

using snap ring pliers. - Lift the driven sprocket and the drive sprocket horizontally.

| caution | The drive sprocket has a specific top and bottom. Keep the sprockets and chain together after they are removed. |

27. Remove the thrust washer  .

. 28. Remove the snap ring  .

. 29. Remove the bracket  .

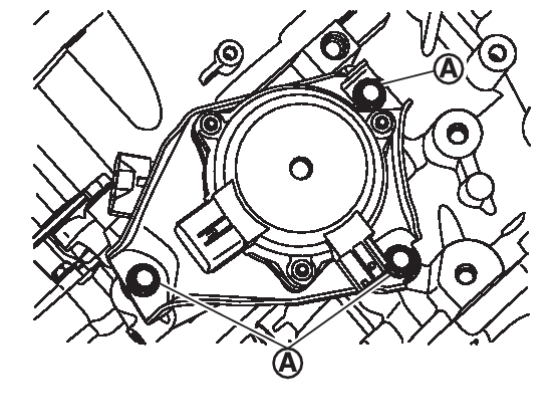

. | : Bolt |

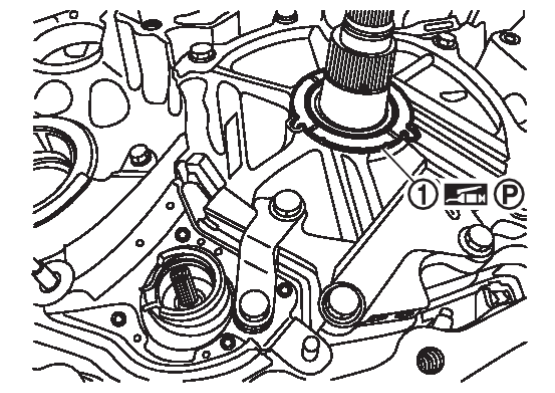

30. Remove the baffle plate  .

. | : Bolt |

31. Remove the chain guide  .

. | : Bolt |

32. Remove the dummy cover  .

. | : Bolt |

| caution | - Never grasp the input shaft and lift it.

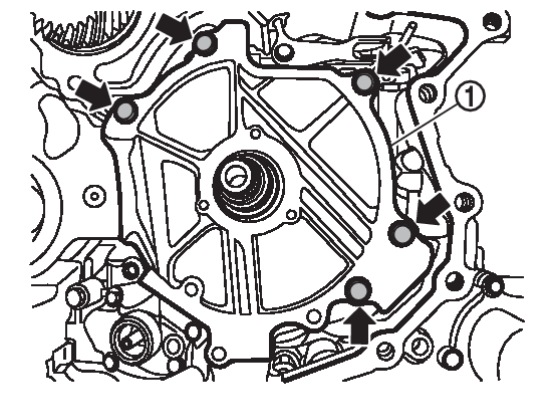

- Never remove the seal rings

. .

|

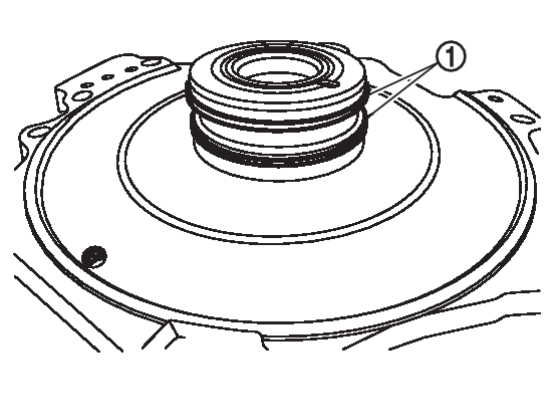

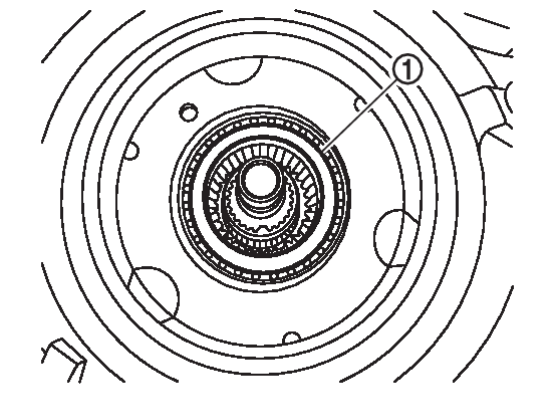

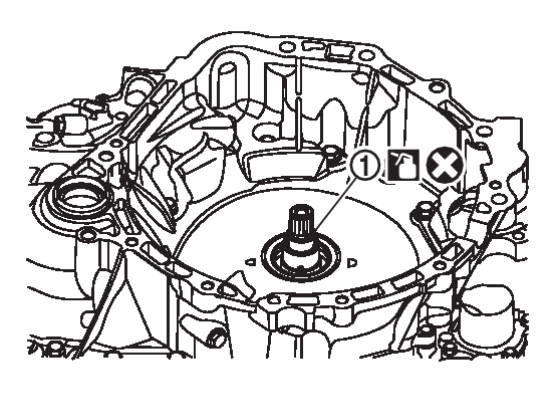

33. Remove the thrust bearing  from clutch assembly. And wipe any metallic debris off of the face of the input speed sensor

from clutch assembly. And wipe any metallic debris off of the face of the input speed sensor  .

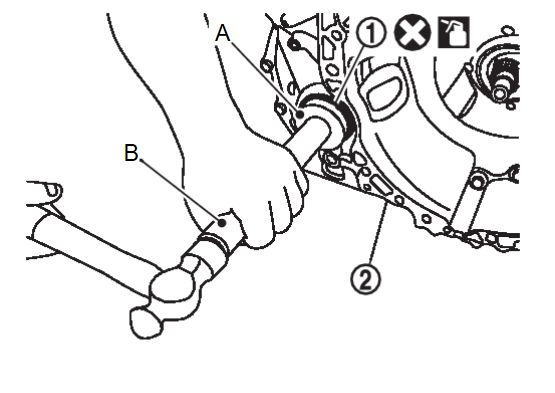

.| caution | Be careful not to damage seal rings  . . |

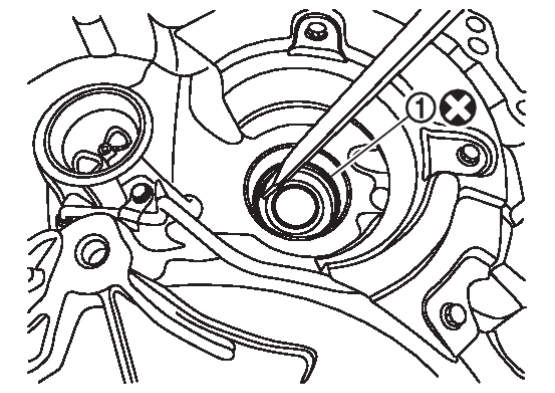

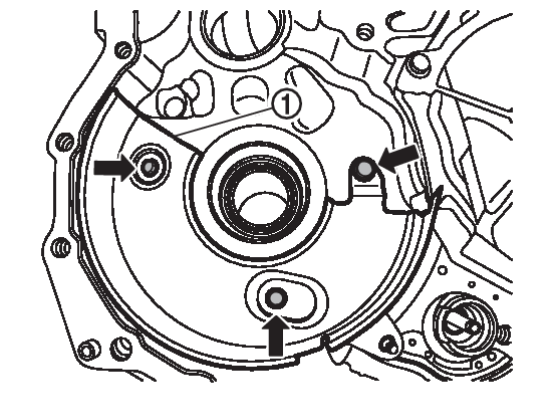

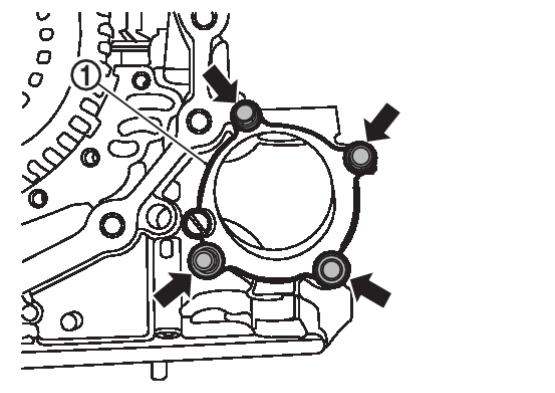

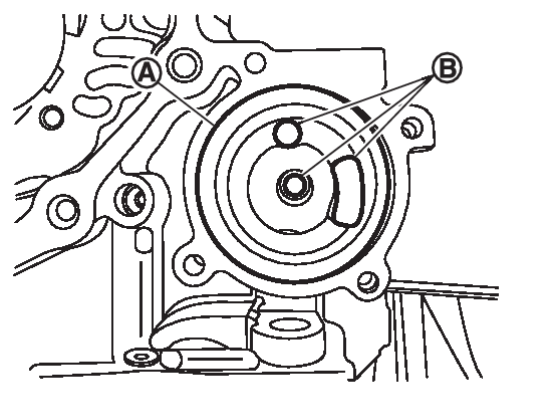

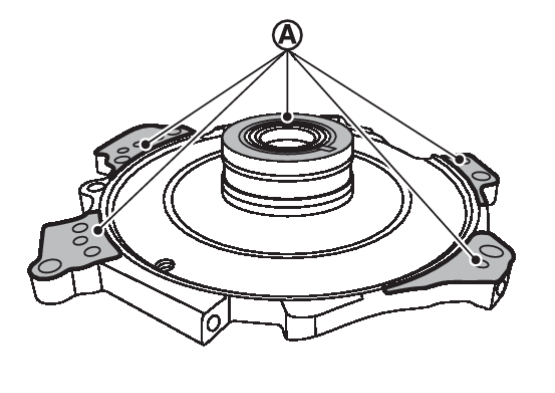

34. Remove the oil pump fixing bolts (4 pieces) and then remove the oil pump  .

. | : Bolt |

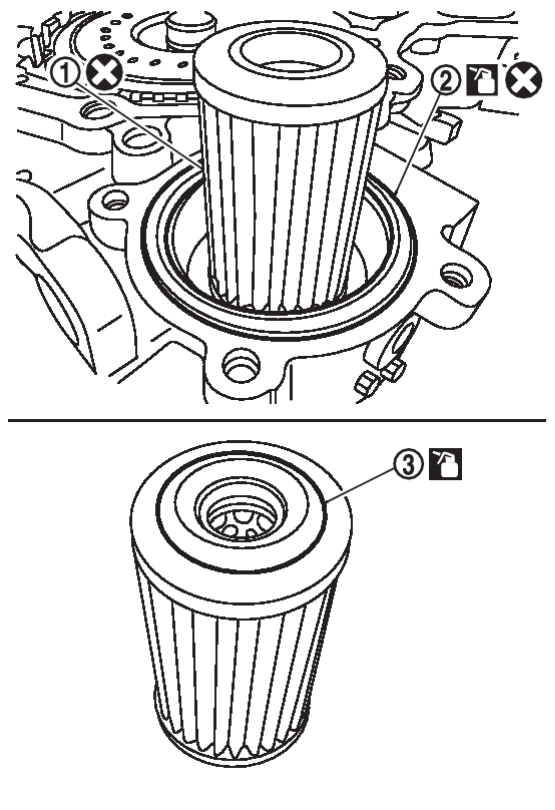

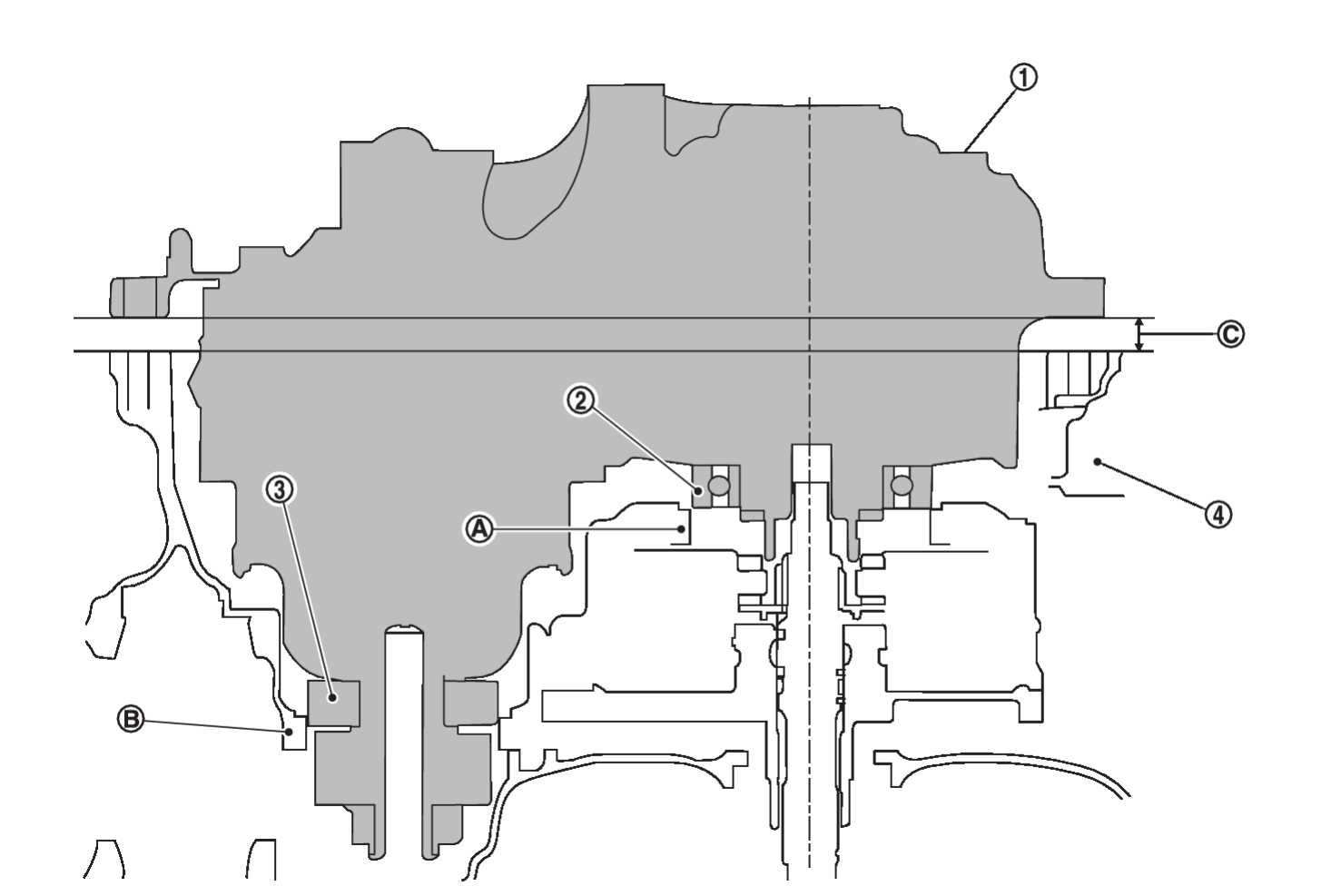

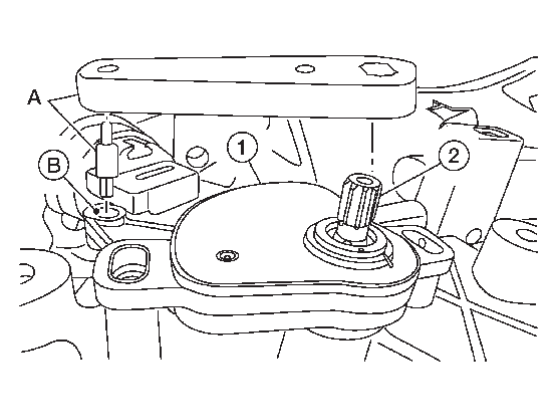

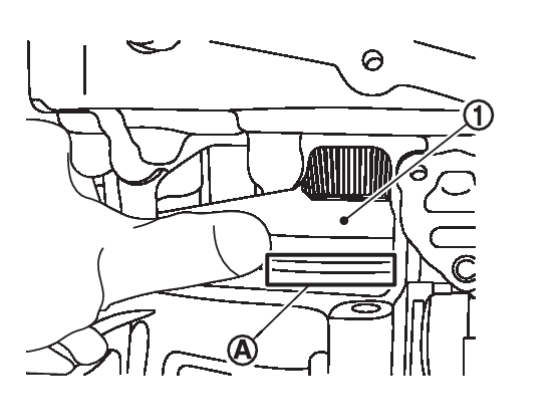

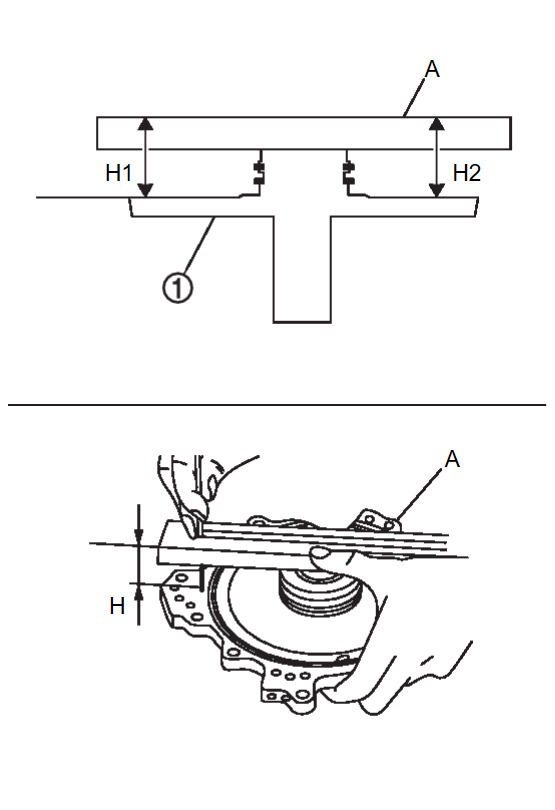

35. Remove CVT fluid filter as follows:- Remove the bolts (

) and then remove the fluid filter cover

) and then remove the fluid filter cover  .

. - Remove the CVT fluid filter

with grommet seal

with grommet seal  and O-ring

and O-ring  .

.

36. Thoroughly clean the mating surfaces of the transaxle case and torque converter housing.| note | A plastic scraper can be used. |

| caution | - Never use sanding discs, similar abrasive tools, or metal blades.

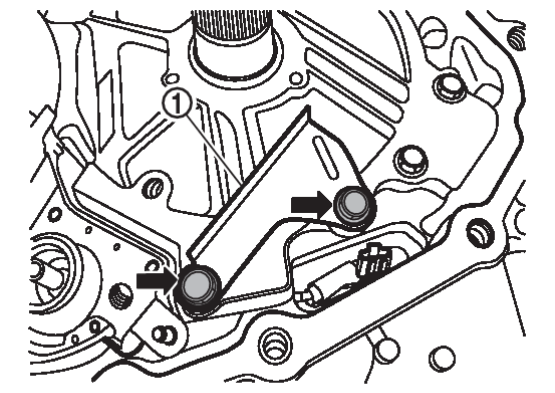

- Use parts cleaner or equivalent solvent and lint-free paper only.

- Make sure the parts cleaner or solvents used are compatible with local regulations.

- Prevent debris from entering in the CVT.

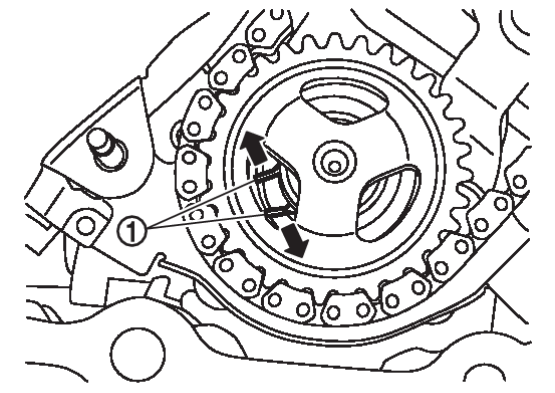

|

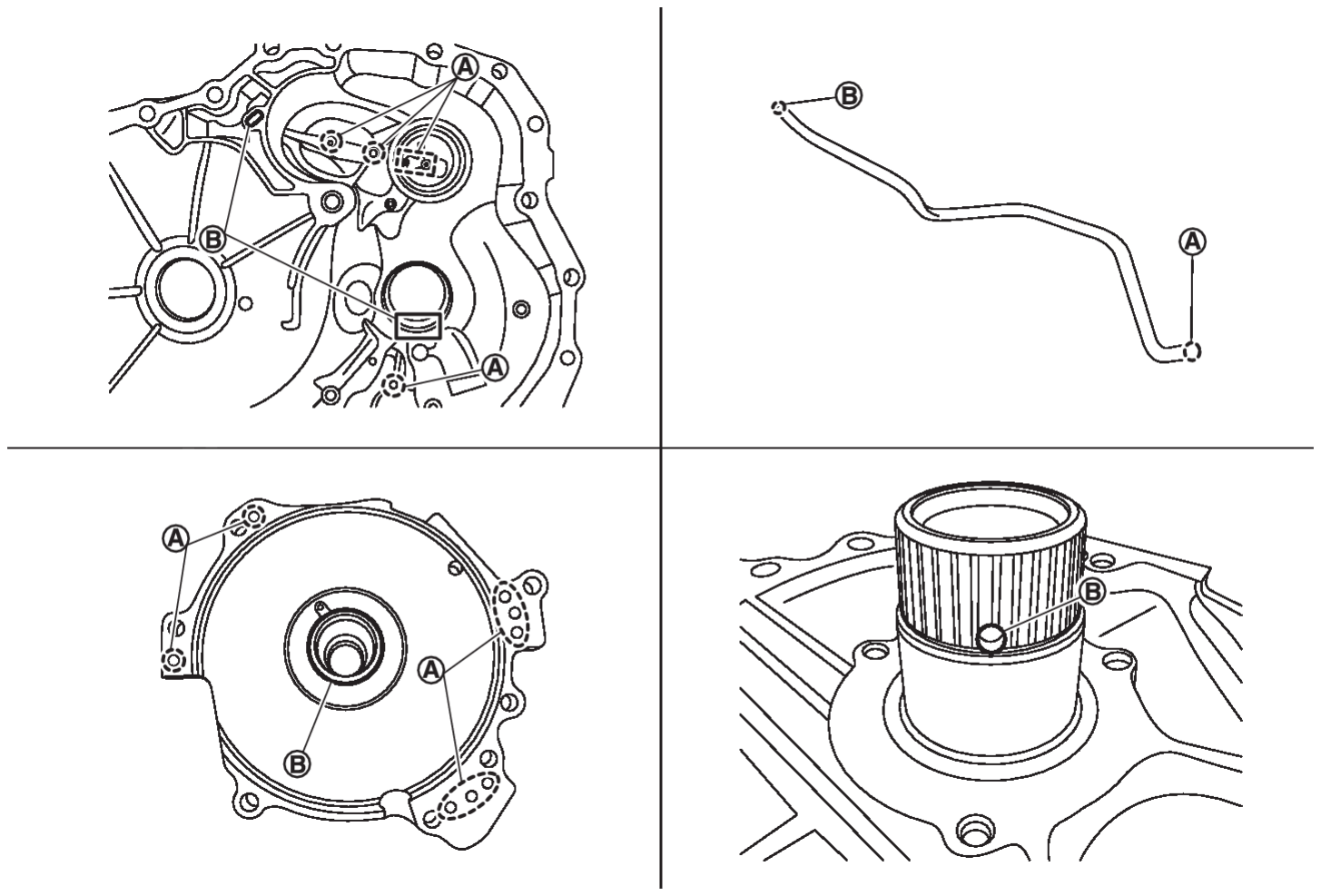

37. Make sure rust and debris have been cleaned off of dowel pins  and receiving holes

and receiving holes  .

.| note | Use small wire brush or similar tool at the inside surface of dowel pin holes. Never scrape transaxle case mating surfaces. |

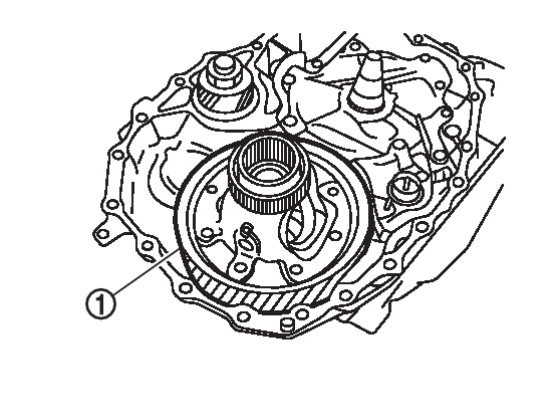

38. Clean the oil passages in the transaxle case, dummy cover, and CVT fluid filter area.| note | - Parts cleaner or a suitable cleaning solvent and compressed air will be used to clean out fluid passages in the CVT assembly.

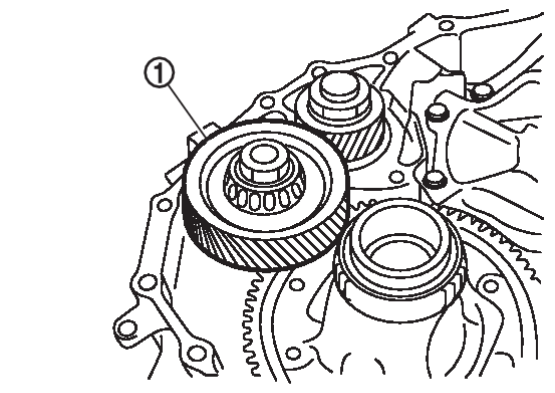

- Make sure the parts cleaner or solvents are compatible with local regulations.

|

| caution | - Wear eye / face protection when using compressed air and cleaning fluids.

- Regulate air pressure up to a maximum of 517 kpa (5.27 kg/cm2, 75 psi).

|

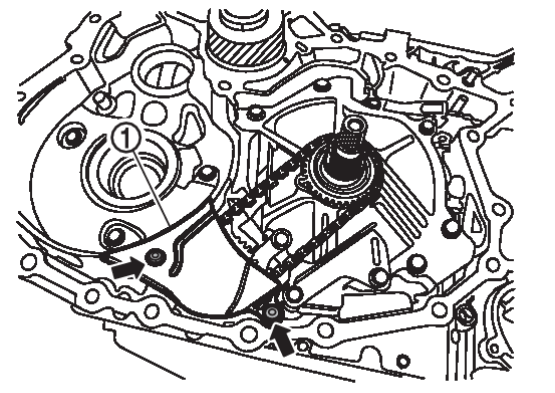

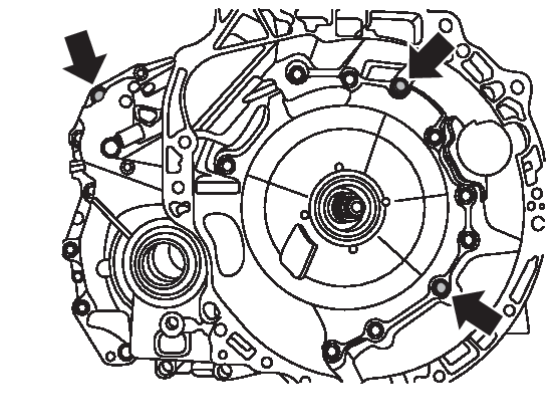

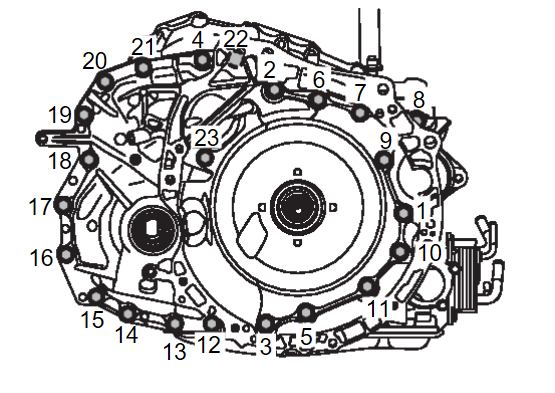

- Clean the area where the CVT fluid filter fits

and the fluid passages

and the fluid passages  to and from the filter.

to and from the filter.| caution | Make sure the old filter grommet seal is removed. |

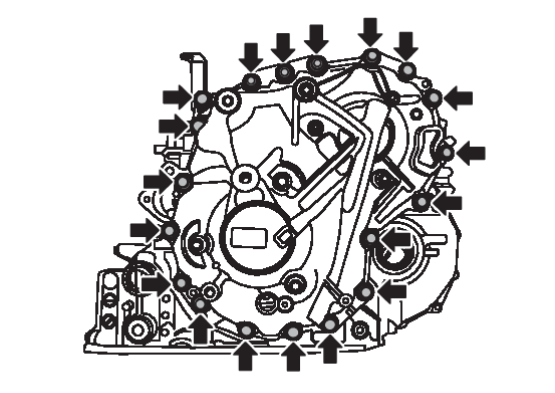

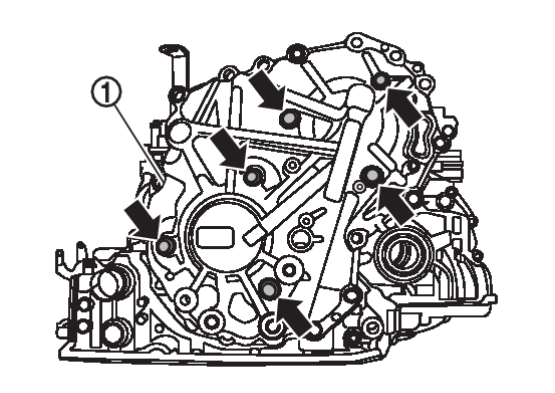

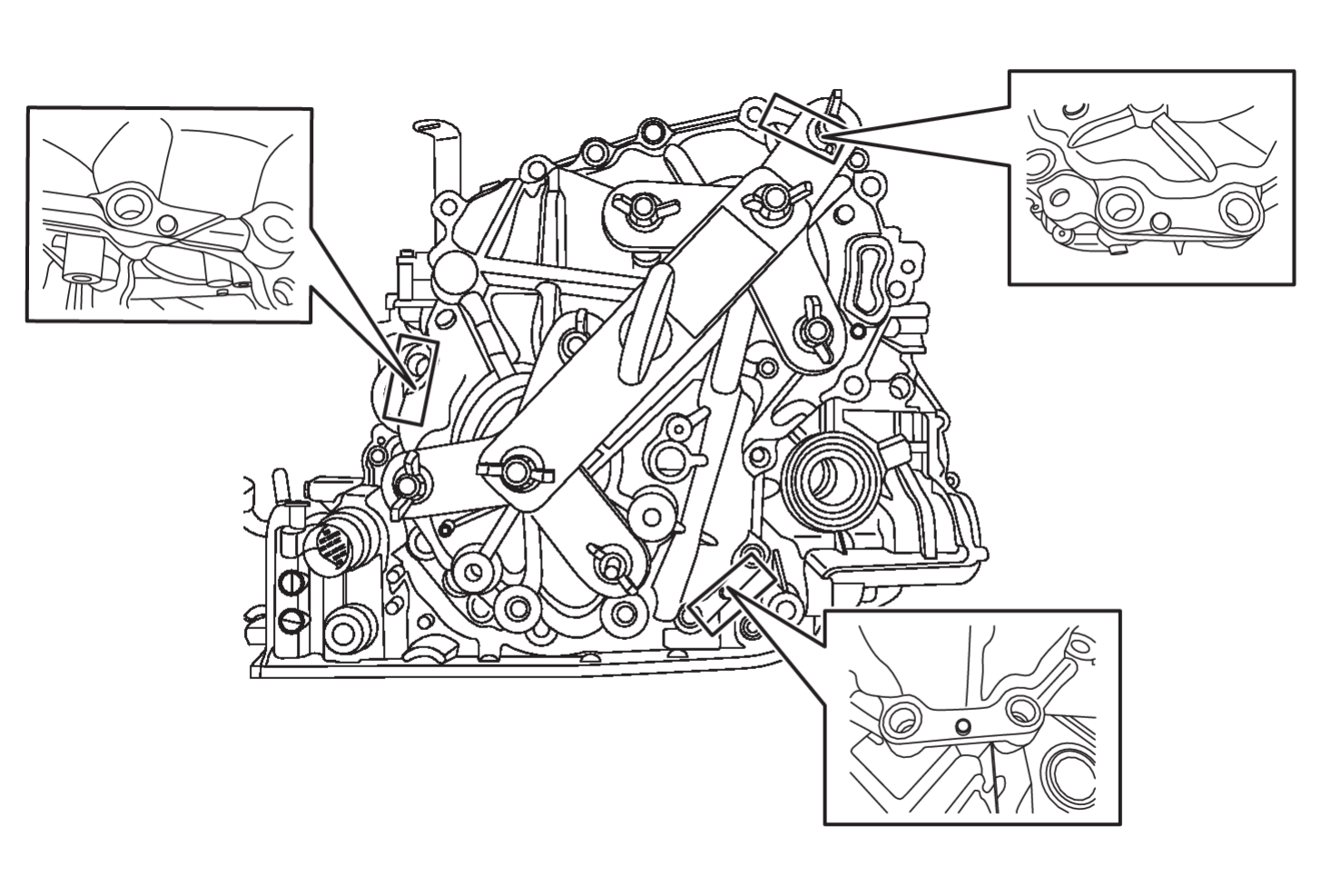

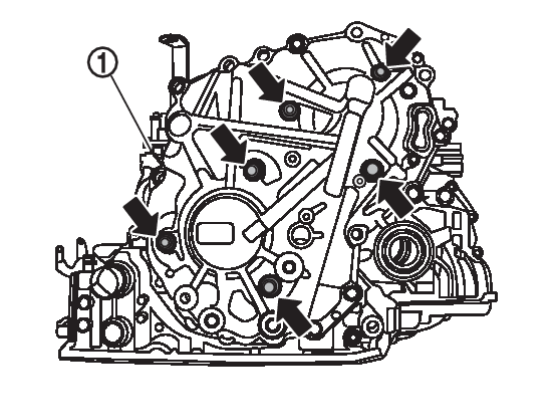

- Spray parts cleaner in all fluid passages

of the transaxle case where shown in figure.

of the transaxle case where shown in figure.| caution | Never spray parts cleaner into the clutch assembly. |

- Apply compressed air in the same passage.

| caution | Never stand in front of the passages while using compressed air. |

39. Temporarily install fluid filter cover.

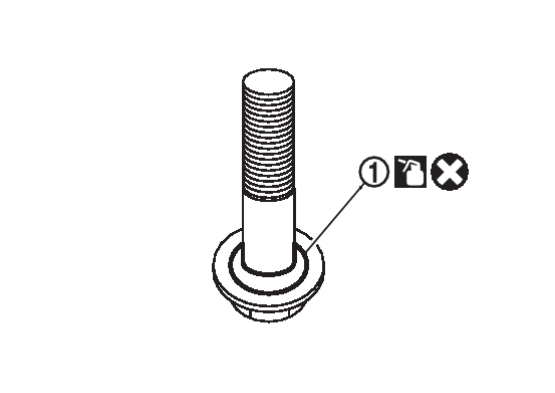

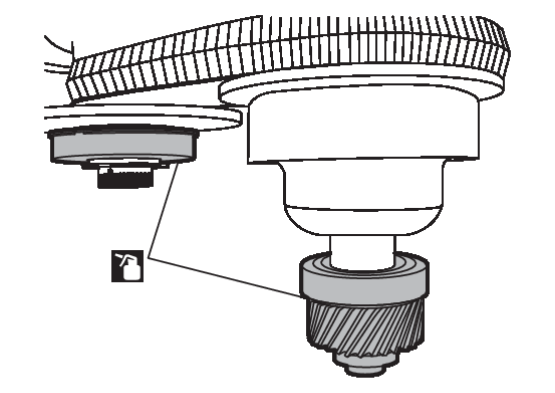

40. Install the O-ring  to the oil pump mounting bolt. (Only for the bolt installed from the outside of the transaxle case)

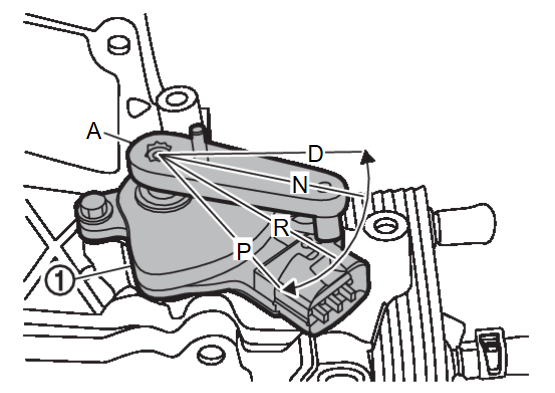

to the oil pump mounting bolt. (Only for the bolt installed from the outside of the transaxle case)| caution | - Never reuse the O-ring.

- Apply the CVT fluid to the O-ring.

|

41. Install the oil pump on the transaxle case and tighten the mounting bolts to the specified torque. (One of the oil pump retaining bolts is installed from the outside of the transaxle case in the rear part of the oil pump.) | : Bolt |

| caution | Never reuse the oil pump. |

42. Install the snap ring  .

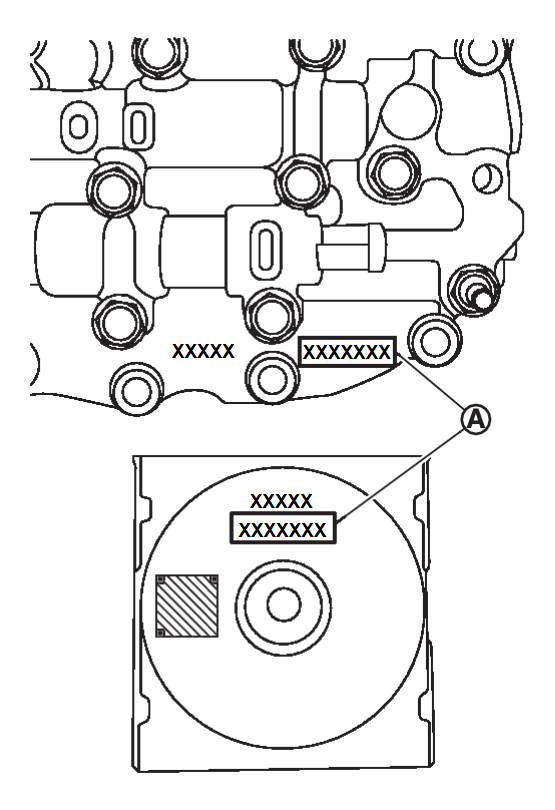

.| caution | Never reuse the oil pump snap ring. |

43. Temporarily install the dummy cover  with 3 bolts (

with 3 bolts (  ).

).| caution | - Never install the thrust bearing to the clutch assembly bore at this time.

- If cover does not seat flush, refer to trouble shooting. Refer to Trouble Shooting

. .

|

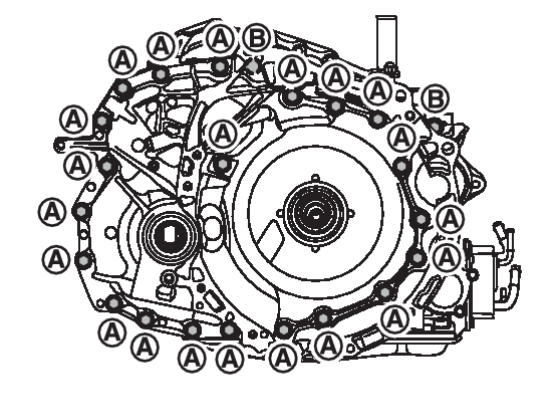

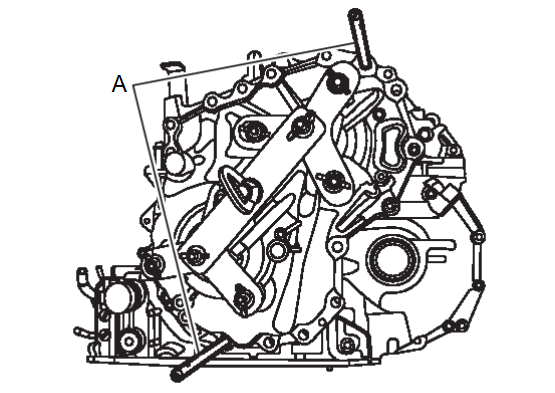

44. Temporarily install the converter housing onto the transaxle case with 3 bolts (  ).

).| caution | When fitting the CVT case surfaces, never use the bolts to draw in the case halves. Make sure the case surfaces are flush, and have no gaps prior to installing the bolts. |

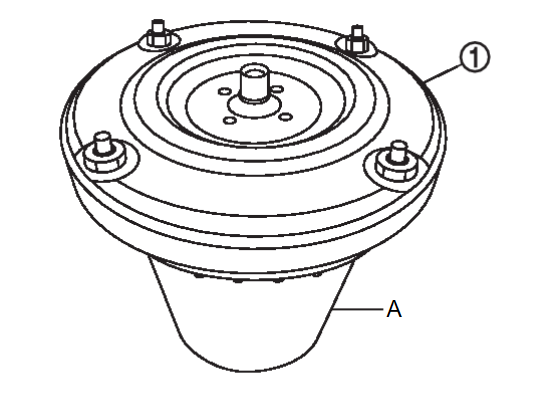

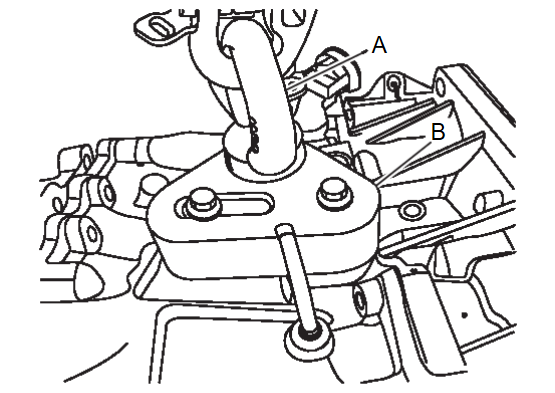

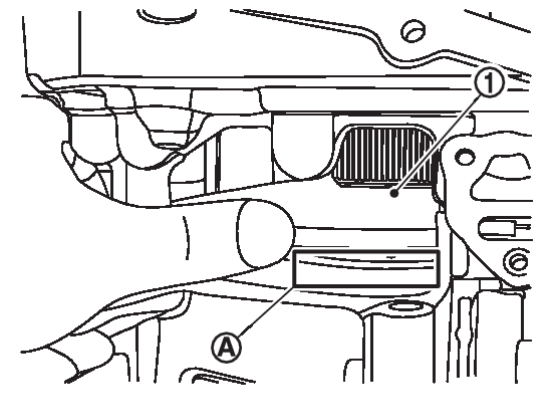

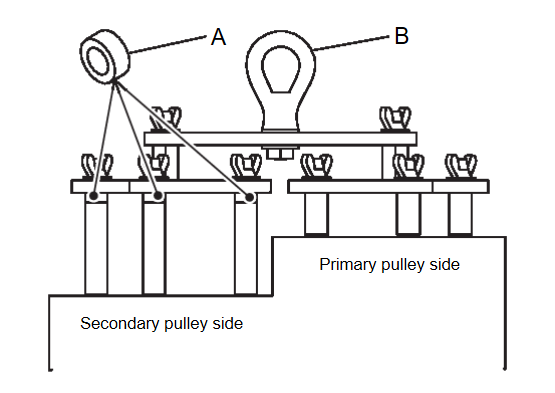

45. Reposition the CVT assembly on the work bench with the side cover side facing up.| note | - CVT lifter bracket [SST: — (J-51595)] (B) and CVT lifting eye/swivel assembly [SST: — (J-51595- 1)] (A) can be used for this step.

- Use plastic or wood blocks to stabilize the CVT assembly on the work bench if needed.

|

| caution | - Never hit the manual shaft

while repositioning the CVT; the manual shaft is longer than the oil pan mating surface. while repositioning the CVT; the manual shaft is longer than the oil pan mating surface. - Never pinch the terminal connector harness between the transaxle case and work bench or supporting block.

|

46. Rotate the primary pulley  by hand to check the pulley’s rotational characteristics.

by hand to check the pulley’s rotational characteristics.| caution | Never place fingers between the pulley and the transaxle case  . . |

| note | Remember the pulley’s rotational characteristics. This will be used as a reference after the new side cover-pulleys and belt sub-assembly (sub-assembly) have been installed. |

47. Remove the side cover fixing bolts. | : Bolt |

| note | When working with sub-assembly install, uninstall, and bracket attachment, it is critical that CVT and sub-assembly are level. |

48. Attach the CVT universal lifting fixture [SST: KV315J0100 (J-52082)] (B) with spacers [SST: — (J–52082–2)] (A) to the side cover.| note | Tighten the wing-nut bolts on the CVT universal lifting fixture [SST: KV315J0100 (J-52082)] finger tight in the following order:- Remove the pulley bracket bolts (

) from side cover ) from side cover  . . - Install medium (A) and long (B) shafts of CVT universal lifting fixture [SST: KV315J0100 (J-52082)].

- Install spacers [SST: — (J-52082-2)] (A) and CVT universal lifting fixture [SST: KV315J0100 (J-52082)] (B) to shafts.

| caution | Install CVT universal lifting (A) properly. |

|

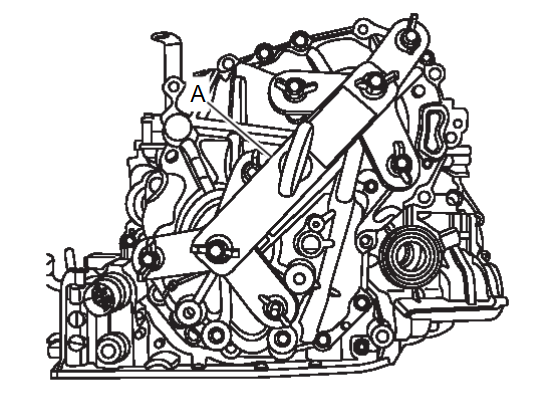

49. Attach the CVT assembly guide pins [SST: KV315J0200 (J-51959)] (A) as shown in figure.| caution | Guide pins must be placed next to dowel pins  . . |

50. Lift up the CVT universal lifting fixture [SST: KV315J0100 (J-52082)] so that the CVT assembly weight is mostly supported by the CVT universal lifting fixture and just slightly raised off of the work surface.

51. Loosen the side cover with a slide hammer at the three points.| caution | Never use a pry-bar, chisel, etc. to separate the side cover from the transaxle case. |

| note | Apply rust penetrant to the two dowel pins as needed. |

52. Lift up the CVT universal lifting fixture [SST: KV315J0100 (J-52082)] to remove the sub-assembly  from the transaxle case.

from the transaxle case. 53. Remove the CVT universal lifting fixture from the sub-assembly.| note | Check that dowel pins have remained in the transaxle case. If not, remove dowel pins from the sub-assembly and relocate back to the transaxle case. |

54. Install all six original bolts into the old sub-assembly.

55. Thoroughly clean the mating surfaces  of the CVT case that the subassembly was just separated from.

of the CVT case that the subassembly was just separated from.| caution | - Never use sanding discs, similar abrasive tools, or metal blades.

- Use parts cleaner or equivalent solvent and lint-free paper only.

- Make sure the parts cleaner or solvents used are compatible with local regulations.

- Prevent debris from entering in the CVT.

- Make sure rust and debris have been cleaned off of dowel pins and receiving holes.

- Use small wire brush or similar tool at the inside surface of dowel pin holes. Never scrape transaxle case mating surfaces.

|

| note | The CVT assembly guide pins [SST: KV315J0200 (J-51959)] can be temporarily removed for cleaning purposes. |

56. Replace the O-ring  .

.| caution | Apply CVT fluid to O-ring. |

57. Remove the thrust bearing  from the planetary carrier assembly.

from the planetary carrier assembly.| note | If not found on the planetary carrier assembly, the thrust bearing may still be attached to the primary pulley. |

58. Rotate the shift select lever  clockwise on the side of the CVT to adjust the parking rod

clockwise on the side of the CVT to adjust the parking rod  to the lowest position.

to the lowest position. 59. Remove the pulley bracket bolts (  ) from the side cover

) from the side cover  of the new sub-assembly.

of the new sub-assembly. 60. Attach the appropriate CVT universal lifting fixture [SST: KV315J0100 (J-52082)] (A) to the new sub-assembly, and then lift up sub-assembly out of the shipping box. 61. Apply Loctite 5460 on the transaxle case installation surface of the sub-assembly.| caution | - Confirm that the mating surfaces are clean before applying sealant.

- The sealant width is 2.0 mm (0.079 in).

- Check that the starting point and the ending point are about the middle between the bolts. The overlap both ends

of the bead by 3 - 5 mm (0.12 - 0.20 in). of the bead by 3 - 5 mm (0.12 - 0.20 in). - Be careful not to contact or contaminate the sealant. If the sealant has been disturbed or contaminated in any way before case assembly, thoroughly clean the mating surfaces of the transaxle case and re-apply.

|

62. Install the original thrust bearing  on the primary pulley

on the primary pulley  of the new sub-assembly.

of the new sub-assembly.| caution | - Pay close attention to the direction of the thrust bearing when installing.

| : Primary pulley |

- Apply a small amount of petroleum jelly or equivalent to the original thrust bearing to hold it in place on the primary pulley.

|

63. Apply CVT fluid to the primary pulley bearing, secondary pulley gear teeth and the secondary bearing when installing the new sub-assembly.| caution | Never drip any CVT fluid onto the sealant. |

64. Attach the CVT assembly guide pins [SST: KV315J0200 (J-51959)] (A) to transaxle case when installing the new sub-assembly.| caution | Guide pins must be installed next to dowel pins  . . |

65. Install the new sub-assembly to transaxle case.| caution | - Never allow the output gear

to hit the lubrication tube to hit the lubrication tube  when the side cover is positioned over the guide pins. when the side cover is positioned over the guide pins. - In the following steps be careful not to contact or contaminate the sealant.

- Never use hammer when installing the new sub-assembly.

|

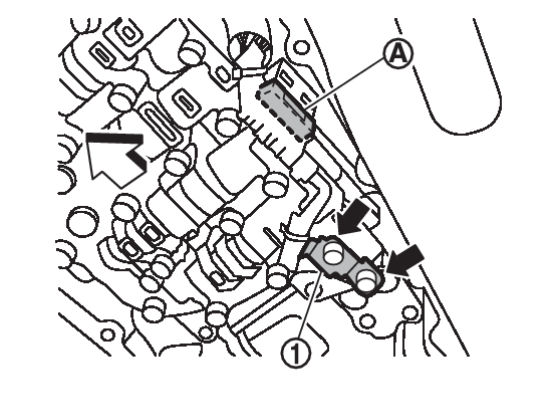

66. Remove bolts  from shift actuator and remove shift actuator.

from shift actuator and remove shift actuator. 67. Install transmission range switch adjustment tool [SST: KV381100S0 (J-52508)] (A) over manual lever  and into alignment hole

and into alignment hole  on transmission range switch

on transmission range switch  .

. 68. Confirm the parking rod operation with the following procedure.- Rotate the transmission range switch adjustment tool [SST: KV381100S0 (J-52508)] (A) counter clockwise and check that all detents for each of the P-R-N-D are detect.

| : Transmission range switch |

- Rotate the lever clockwise to return the rod back to the P position.

- If the lever does not rotate or if all detents are not detect, lift the sub-assembly and remove all sealant, and repeat from step 61.

69. Remove transmission range switch adjustment tool.

70. Apply grease evenly to the shift actuator spline  .

. 71. Install the shift actuator to the transaxle case.

72. Tighten bolts  .

. 73. Remove the CVT assembly guide pins [SST: KV315J0200 (J-51959)].

74. Install the new side cover bolts and temporary tighten them. And then, tighten the bolts to specified torque in the order shown.| caution | Never reuse the side cover bolts. |

75. Remove the CVT universal lifting fixture [SST: KV315J0100 (J-52082)].

76. Install the new pulley bracket bolts and new O-rings finger tight to side cover  .

.| caution | - Never reuse the pulley bracket bolts and the O-rings.

- Apply the CVT fluid to the O-rings.

|

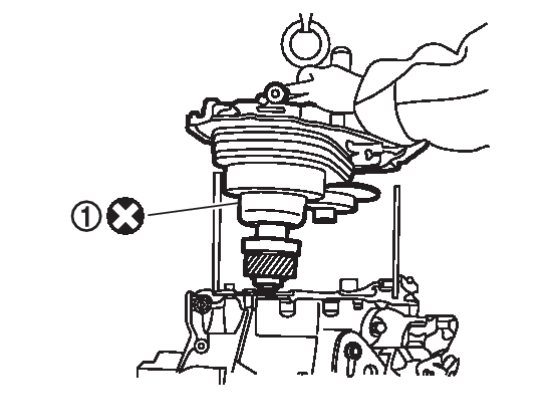

77. Check the rotational smoothness of the primary pulley ① with the following procedure.| caution | Never insert fingers between the pulley and the transaxle case  . . |

- With clean hand, access the primary pulley from the bottom of the CVT to rotate.

- Rotate the primary pulley by hand and confirm that the characteristic is the same as previously checked at step 45.

- If the rotational characteristic worse than before the sub-assembly was replaced, perform the following.

- Remove the sub-assembly from the transaxle case.

- Wipe and clean the sealant completely from both the transaxle case rim and side cover rim.

- Restart sub-assembly installation from Step 60.

78. Tighten pulley bracket bolts (  ) to the specified torque.

) to the specified torque. | : Side cover |

79. Install the differential side oil seal using the output seal installer (case side) [SST: KV31501200 (J-52281)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B).| caution | - Never reuse differential side oil seal.

- Apply CVT fluid to the differential side of oil seal lip surface.

|

80. Set the CVT on the work bench with the side cover facing down on the bench.

81. Remove the converter housing which was temporarily installed with 3 bolts (  ).

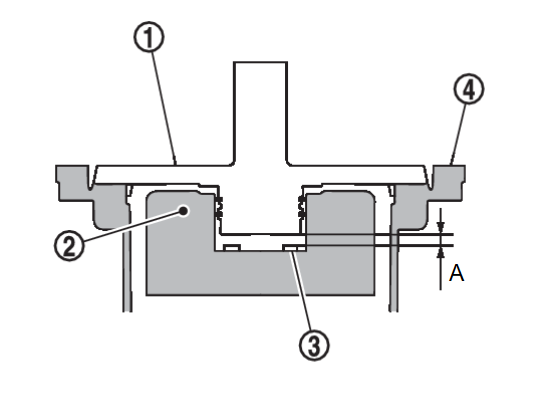

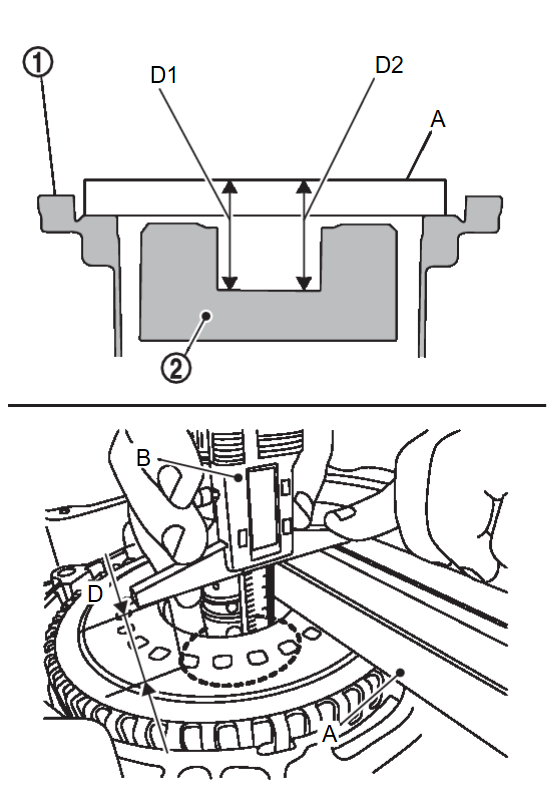

). 82. Calculate total end play with the following procedure. (Thrust bearing selection)| note | The total end play (A) must always be adjusted with thrust bearing  between the dummy cover between the dummy cover  and the forward clutch drum and the forward clutch drum  when a new sub-assembly is installed. when a new sub-assembly is installed. |

| caution | - The forward clutch is 2 - 3 mm (0.08 - 0.12 in) below the dummy cover surface.

- If the gap is more than 2 - 3 mm (0.08 - 0.12 in), the component parts may be improperly installed. Refer to Trouble Shooting

. . - If the gap is less than 2 - 3 mm (0.08 - 0.12 in), the component parts may be missing or damaged.

|

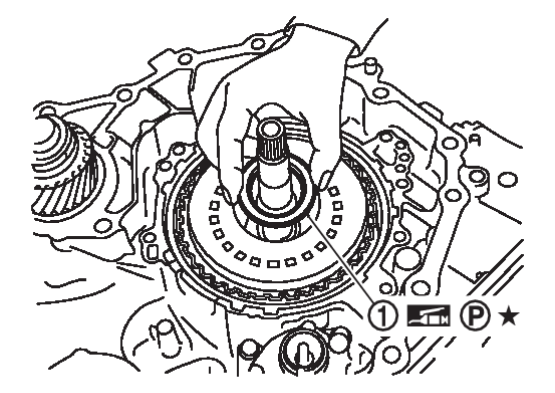

83. Install the thrust bearing  to the clutch assembly bore.

to the clutch assembly bore.| caution | - Never reuse thrust bearing.

- Apply petroleum jelly when installing the thrust bearing.

- Pay close attention to the direction of the thrust bearing when attaching it.

| : Upper side |  | : Lower side (Black surface) |

|

84. Remove the baffle plate  from the converter housing.

from the converter housing. | : Bolt |

85. Remove the bolt (  ) and then remove the lubrication tube

) and then remove the lubrication tube  and clip

and clip  .

. 86. Clean hydraulic circuit  of converter housing lubrication tube and dummy cover with parts cleaner and blowing air, check holes

of converter housing lubrication tube and dummy cover with parts cleaner and blowing air, check holes  for blowing air.

for blowing air.| caution | - Never stand in front of the passages shown while using compressed air.

- Wear eye / face protection when using compressed air and cleaning fluids.

- Regulate air pressure up to a maximum of 517 kpa(5.27 kg/cm2, 75 psi).

|

87. Install the lubrication tube  and clip

and clip  .

. 88. Install the baffle plate  to the converter housing.

to the converter housing. | : Bolt |

89. Apply petroleum jelly to the seal rings  before installing the dummy cover

before installing the dummy cover  to the transaxle case and clean the area

to the transaxle case and clean the area  .

.| caution | - Seal rings are in their appropriate slots. Carefully reposition seals as necessary.

- Seal rings must be in their correct positions during final assembly to prevent drivability issues.

|

90. Check the seal rings  of input shaft are in the correct positions and clean the area

of input shaft are in the correct positions and clean the area  .

.| caution | - Seal rings are in their appropriate slots. Carefully reposition seals as necessary.

- Seal rings must be in their correct positions during final assembly to prevent drivability issues.

|

91. Install the dummy cover  and chain guide

and chain guide  .

.| caution | - Never torque bolts (

) at this step. ) at this step. - Check that the dummy cover is fully seated on the transaxle case. If dummy cover does not seated, forward clutch may be improperly installed. Refer to Trouble Shooting

. .

|

92. Install baffle plate  and bracket

and bracket  with the related bolts finger tight. And tighten the bolts to the specified torque.

with the related bolts finger tight. And tighten the bolts to the specified torque. | : 5.9 N·m (0.6 kg-m, 52 in-lb.) |

| : 25.5 N·m (2.6 kg-m, 19 ft- lb). |

| : 19.0 N·m (1.9 kg-m, 14 ft-lb.) |

93. Install the thrust washer  onto the dummy cover

onto the dummy cover  .

.| note | Use petroleum jelly to hold the thrust washer in place. |

94. Install the drive sprocket  , driven sprocket

, driven sprocket  , and oil pump chain

, and oil pump chain  as an assembly.

as an assembly.| note | Wider edge  on the drive sprocket is facing up. on the drive sprocket is facing up. |

95. Spread the snap ring  using snap ring pliers.

using snap ring pliers. 96. Press down on the driven sprocket until it "snaps" and locks into place.

97. Pull up after install sprocket and check lockup to confirm adopt correctly.

98. Install baffle plate (chain cover)  and tighten the mounting nut.

and tighten the mounting nut. | : Nut |

99. Install the differential assembly  into the transaxle case.

into the transaxle case.| caution | - Clean differential assembly before installing.

- Apply CVT fluid to the bearings and gear teeth before installing.

|

100. Install the reduction gear assembly  into the transaxle case.

into the transaxle case.| caution | - Clean reduction gear assembly before installing.

- Apply CVT fluid to the bearings and gear teeth before installing.

|

101. Install the new CVT fluid filter  with grommet seal

with grommet seal  and O-ring

and O-ring  .

.| caution | Apply CVT fluid to the grommet seal and O-ring. |

102. Install the CVT fluid filter cover  and tighten the bolts (

and tighten the bolts (  ) to the specified torque.

) to the specified torque. 103. Check that retaining pin of manual shaft  locates on the original position.

locates on the original position. 104. Apply Loctite 5460 on the converter housing installation surface of the transaxle case.| caution | - Completely remove all moisture, oil and old sealant, etc. from the transaxle case and converter housing mounting surfaces.

- The sealant width is 2.0 mm (0.079 in).

- Check that the starting point and the ending point are about the middle between the bolts. The overlap both ends

of the bead by 3 - 5 mm (0.12 - 0.20 in). of the bead by 3 - 5 mm (0.12 - 0.20 in). - Be sure to apply, first sealant around the center bolt hole

, and next around the mating surfaces , and next around the mating surfaces  . .

|

105. Install the converter housing onto the transaxle case and temporary tighten the new converter housing bolts. And then, tighten the bolts to specified torque in the order shown.| caution | Never reuse the converter housing bolts. |

106. Install the new converter housing oil seal  evenly using the oil pump seal installer [SST: KV31500700 (J-50818)] (A)

evenly using the oil pump seal installer [SST: KV31500700 (J-50818)] (A)| caution | - Set the torque converter housing flat during installation.

- Apply CVT fluid to the seal lip surface.

- Converter housing oil seal pulling direction is used as the reference.

|

107. Install the differential side oil seal  using the output seal installer (torque converter side) [SST: KV31500910 (J-52282)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B).

using the output seal installer (torque converter side) [SST: KV31500910 (J-52282)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B). | : Converter housing |

| caution | - Never reuse differential side oil seal.

- Apply CVT fluid to the differential side oil seal lip surface.

|

108. Install the O-ring  on the input shaft.

on the input shaft.| caution | - Never reuse the O-ring.

- Apply the CVT fluid when installing the O-ring.

|

109. Install the lip seal  to the transaxle case.

to the transaxle case.| caution | - Never reuse lip seal.

- Apply petroleum jelly to lip seal.

|

| : Front |

110. Install the control valve to the transaxle case.| caution | - Never drop the control valve, ratio control valve and manual shaft.

- Ensure the harness

is correctly routed and does not get pinched. is correctly routed and does not get pinched.

|

111. Secure the control valve using bolts  ,

,  and

and  .

.| caution | Ensure the harness is correctly routed and does not get pinched. |

| note | - Leave bolt holes

blank at this step. blank at this step. - Install bolts

without the strainer bracket. without the strainer bracket.

|

| Bolt | Bolt length mm (in) | Number of bolt |

| 54 (2.13) | 7 |

| 44 (1.73) | 2 |

| 25 (0.98) | 2 |

| : Front |

112. Connect the control valve harness connector  .

. | : Front |

| caution | Securely insert the harness connector until it clicks and locks. |

113. Install the CVT fluid temperature sensor bracket to the valve body with bolt  .

.| Bolt | Bolt length mm (in) | Number of bolt |

| 54 (2.13) | 1 |

| note | Leave bolt hole  blank as it will be used to secure the oil strainer at a later step. blank as it will be used to secure the oil strainer at a later step. |

114. Install new O-ring to oil strainer assembly.| caution | - Never reuse O-ring.

- Apply CVT fluid to O-ring.

|

| note | New oil strainer come with a new O-ring already installed. |

115. Install new oil strainer with bolts  .

.| Bolt | Bolt length mm (in) | Number of bolt |

| 54 (2.13) | 2 |

116. Install the manual plate  using the steps below:.

using the steps below:. | : Front |

117. Install the spring washer  and the lock-nut

and the lock-nut  , and then tighten to the specified torque.

, and then tighten to the specified torque.| caution | To tighten nut, fix manual plate with suitable tool. |

118. Install the magnets into the oil pan in their original location.| caution | Completely clean the iron powder from the magnet area of oil pan and the magnet. |

119. Install the oil pan to the transaxle case with the following procedure.(1) Install the oil pan gasket to the oil pan.| caution | - Completely wipe out any moisture, oil, and old gasket from the oil pan gasket surface and bolt hole of oil pan and transaxle case.

- Never reuse oil pan gasket.

|

(2) Install the oil pan assembly to the transaxle case, and then temporarily tighten the oil pan bolts.

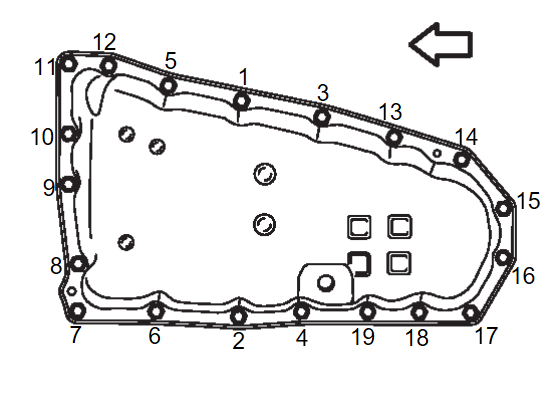

(3) Tighten the oil pan bolts in the order shown to the specified torque. | : Front |

(4) Tighten the oil pan bolts again clockwise from (1) shown to the specified torque.

120. Install drain plug gasket to drain plug.| caution | Never reuse drain plug gasket. |

121. Install drain plug to oil pan.

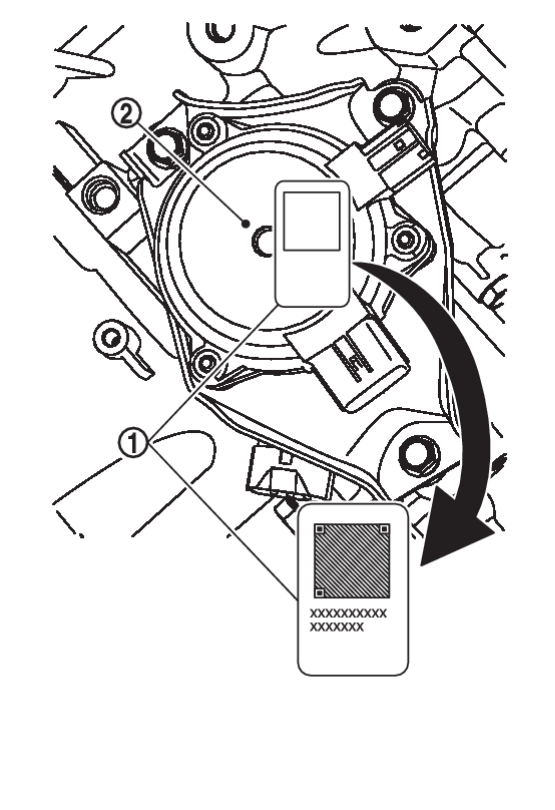

122. Install new QR code sticker  on shift actuator

on shift actuator  .

. | note | If sticker is not included with parts, contact Powertrain Call Center to report. |

123. Install the torque converter  to the transaxle in the following procedure.

to the transaxle in the following procedure.- Insert the pawl

of the torque converter to the drive sprocket hole

of the torque converter to the drive sprocket hole  on the transaxle assembly side.

on the transaxle assembly side.| caution | - Rotate the torque converter for installing torque converter.

- Never damage the bushing inside the torque converter sleeve when installing the converter housing oil seal.

|

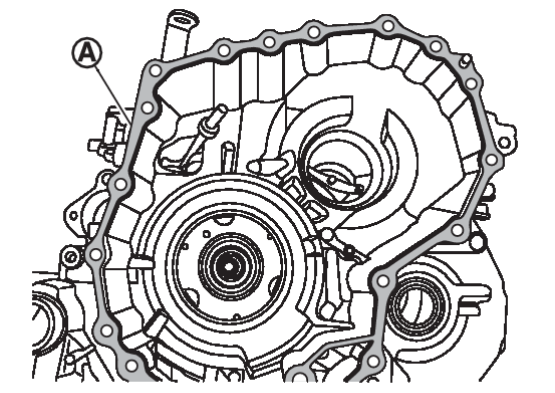

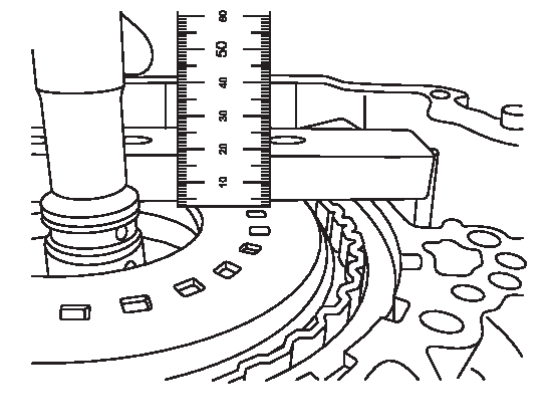

- After inserting a torque converter to the CVT, check dimension (A) with in the reference value limit.

124. Install the primary speed sensor.| caution | - Never reuse O-ring.

- Apply CVT fluid to the O-ring.

|

126. Flush the CVT fluid cooler and lines.

127. Fill the transaxle assembly with CVT fluid. Refre to Refilling .

. 128. Perform "ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE." Refer to Description .

.  .

. .

. and bolt

and bolt  and remove lock nut

and remove lock nut  . Remove spring washer

. Remove spring washer  and manual plate from manual shaft

and manual plate from manual shaft  .

. and bolt

and bolt  and remove lock nut

and remove lock nut  . Remove spring washer

. Remove spring washer  and manual plate from manual shaft

and manual plate from manual shaft  .

.

and disconnect control valve harness connector

and disconnect control valve harness connector  .

. and disconnect control valve harness connector

and disconnect control valve harness connector  .

.

.

. .

. and

and  , and then remove the control valve from the transaxle case.

, and then remove the control valve from the transaxle case. and

and  , and then remove the control valve from the transaxle case.

, and then remove the control valve from the transaxle case.

) to corners of the oil pan, hand tight.

) to corners of the oil pan, hand tight. ) to corners of the oil pan, hand tight.

) to corners of the oil pan, hand tight. .

. .

. ) and remove primary speed sensor

) and remove primary speed sensor  from transaxle assembly.

from transaxle assembly. ) and remove primary speed sensor

) and remove primary speed sensor  from transaxle assembly.

from transaxle assembly.

, driven sprocket

, driven sprocket  and drive sprocket

and drive sprocket  as one assembly in the following procedure.

as one assembly in the following procedure. , driven sprocket

, driven sprocket  and drive sprocket

and drive sprocket  as one assembly in the following procedure.

as one assembly in the following procedure. .

. .

.

from clutch assembly. And wipe any metallic debris off of the face of the input speed sensor

from clutch assembly. And wipe any metallic debris off of the face of the input speed sensor  .

. from clutch assembly. And wipe any metallic debris off of the face of the input speed sensor

from clutch assembly. And wipe any metallic debris off of the face of the input speed sensor  .

. .

. and receiving holes

and receiving holes  .

. and receiving holes

and receiving holes  .

. and the fluid passages

and the fluid passages  to and from the filter.

to and from the filter. of the transaxle case where shown in figure.

of the transaxle case where shown in figure. to the oil pump mounting bolt. (Only for the bolt installed from the outside of the transaxle case)

to the oil pump mounting bolt. (Only for the bolt installed from the outside of the transaxle case) to the oil pump mounting bolt. (Only for the bolt installed from the outside of the transaxle case)

to the oil pump mounting bolt. (Only for the bolt installed from the outside of the transaxle case)

with 3 bolts (

with 3 bolts (  ).

). with 3 bolts (

with 3 bolts (  ).

). ).

). ).

). by hand to check the pulley’s rotational characteristics.

by hand to check the pulley’s rotational characteristics. by hand to check the pulley’s rotational characteristics.

by hand to check the pulley’s rotational characteristics. .

.

.

. from the transaxle case.

from the transaxle case. from the transaxle case.

from the transaxle case. of the CVT case that the subassembly was just separated from.

of the CVT case that the subassembly was just separated from. of the CVT case that the subassembly was just separated from.

of the CVT case that the subassembly was just separated from. from the planetary carrier assembly.

from the planetary carrier assembly. from the planetary carrier assembly.

from the planetary carrier assembly. clockwise on the side of the CVT to adjust the parking rod

clockwise on the side of the CVT to adjust the parking rod  to the lowest position.

to the lowest position. clockwise on the side of the CVT to adjust the parking rod

clockwise on the side of the CVT to adjust the parking rod  to the lowest position.

to the lowest position. on the primary pulley

on the primary pulley  of the new sub-assembly.

of the new sub-assembly. on the primary pulley

on the primary pulley  of the new sub-assembly.

of the new sub-assembly. .

. and into alignment hole

and into alignment hole  on transmission range switch

on transmission range switch  .

. and into alignment hole

and into alignment hole  on transmission range switch

on transmission range switch  .

.

.

. .

. .

. between the dummy cover

between the dummy cover  and the forward clutch drum

and the forward clutch drum  when a new sub-assembly is installed.

when a new sub-assembly is installed.  to the thrust bearing installation surface of the forward clutch drum

to the thrust bearing installation surface of the forward clutch drum  .

. that contact the transaxle case and thrust beaning.

that contact the transaxle case and thrust beaning. to the installation surface on the transaxle case.

to the installation surface on the transaxle case. to the clutch assembly bore.

to the clutch assembly bore. to the clutch assembly bore.

to the clutch assembly bore. of converter housing lubrication tube and dummy cover with parts cleaner and blowing air, check holes

of converter housing lubrication tube and dummy cover with parts cleaner and blowing air, check holes  for blowing air.

for blowing air. of converter housing lubrication tube and dummy cover with parts cleaner and blowing air, check holes

of converter housing lubrication tube and dummy cover with parts cleaner and blowing air, check holes  for blowing air.

for blowing air. before installing the dummy cover

before installing the dummy cover  to the transaxle case and clean the area

to the transaxle case and clean the area  .

. before installing the dummy cover

before installing the dummy cover  to the transaxle case and clean the area

to the transaxle case and clean the area  .

. of input shaft are in the correct positions and clean the area

of input shaft are in the correct positions and clean the area  .

. of input shaft are in the correct positions and clean the area

of input shaft are in the correct positions and clean the area  .

. and chain guide

and chain guide  .

. and chain guide

and chain guide  .

. and bracket

and bracket  with the related bolts finger tight. And tighten the bolts to the specified torque.

with the related bolts finger tight. And tighten the bolts to the specified torque. and bracket

and bracket  with the related bolts finger tight. And tighten the bolts to the specified torque.

with the related bolts finger tight. And tighten the bolts to the specified torque.

onto the dummy cover

onto the dummy cover  .

. onto the dummy cover

onto the dummy cover  .

. , driven sprocket

, driven sprocket  , and oil pump chain

, and oil pump chain  as an assembly.

as an assembly. , driven sprocket

, driven sprocket  , and oil pump chain

, and oil pump chain  as an assembly.

as an assembly. on the drive sprocket is facing up.

on the drive sprocket is facing up. into the transaxle case.

into the transaxle case. into the transaxle case.

into the transaxle case. into the transaxle case.

into the transaxle case. into the transaxle case.

into the transaxle case. with grommet seal

with grommet seal  and O-ring

and O-ring  .

. with grommet seal

with grommet seal  and O-ring

and O-ring  .

. evenly using the oil pump seal installer [SST: KV31500700 (J-50818)] (A)

evenly using the oil pump seal installer [SST: KV31500700 (J-50818)] (A) evenly using the oil pump seal installer [SST: KV31500700 (J-50818)] (A)

evenly using the oil pump seal installer [SST: KV31500700 (J-50818)] (A) using the output seal installer (torque converter side) [SST: KV31500910 (J-52282)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B).

using the output seal installer (torque converter side) [SST: KV31500910 (J-52282)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B). using the output seal installer (torque converter side) [SST: KV31500910 (J-52282)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B).

using the output seal installer (torque converter side) [SST: KV31500910 (J-52282)] (A) and universal driver handle [SST: ST35325000 (J-8092)] (B).

on the input shaft.

on the input shaft. on the input shaft.

on the input shaft. to the transaxle case.

to the transaxle case. to the transaxle case.

to the transaxle case.

,

,  and

and  .

. ,

,  and

and  .

.

.

. .

.

.

. .

.

blank as it will be used to secure the oil strainer at a later step.

blank as it will be used to secure the oil strainer at a later step. using the steps below:.

using the steps below:. using the steps below:.

using the steps below:. .

.  ) of the manual valve.

) of the manual valve. and lock nut

and lock nut  .

. and tighten lock nut.

and tighten lock nut.

and the lock-nut

and the lock-nut  , and then tighten to the specified torque.

, and then tighten to the specified torque. and the lock-nut

and the lock-nut  , and then tighten to the specified torque.

, and then tighten to the specified torque. on shift actuator

on shift actuator  .

.  on shift actuator

on shift actuator  .

.  to the transaxle in the following procedure.

to the transaxle in the following procedure. to the transaxle in the following procedure.

to the transaxle in the following procedure. of the torque converter to the drive sprocket hole

of the torque converter to the drive sprocket hole  on the transaxle assembly side.

on the transaxle assembly side.

.

. .

. .

. .

. .

. .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)