Inspection

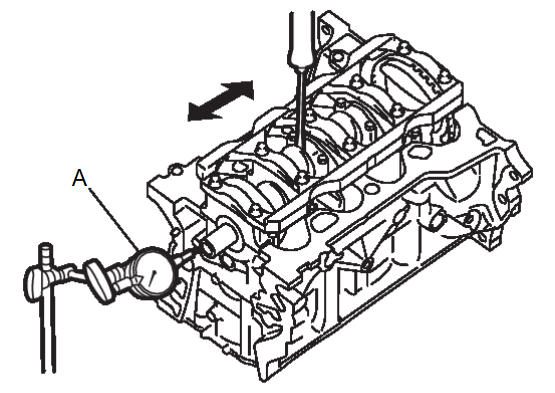

CRANKSHAFT END PLAY

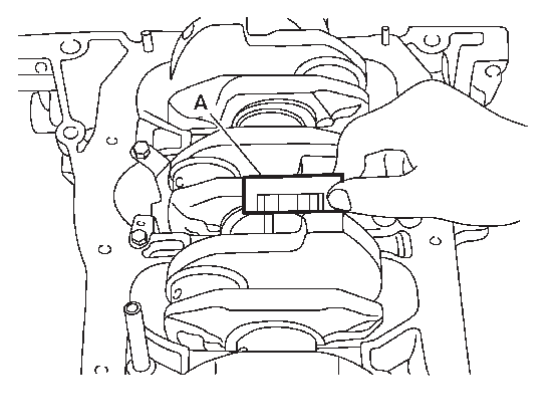

- Measure clearance between thrust bearings and crankshaft arm when crankshaft is moved fully forward or backward using suitable tool (A).

Standard and Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit replace thrust bearings and measure again. If it still exceeds limit replace crankshaft.

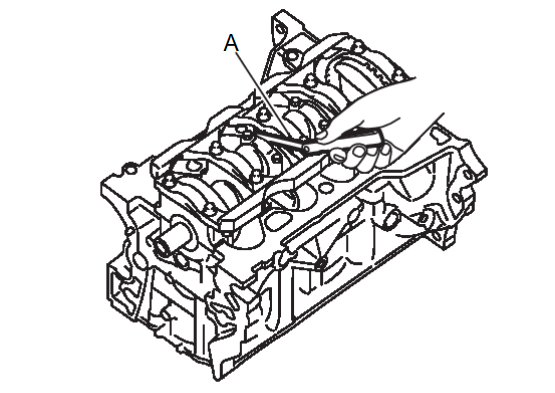

CONNECTING ROD SIDE CLEARANCE

- Measure side clearance between connecting rod and crankshaft arm using suitable tool (A).

Standard and Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit replace connecting rod and measure again. If it still exceeds limit replace crankshaft.

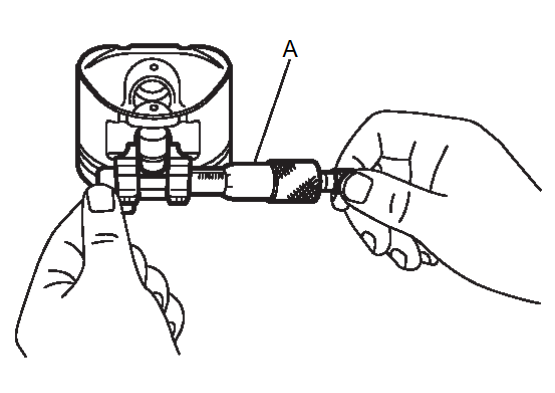

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter

- Measure inner diameter of piston pin hole using suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

.

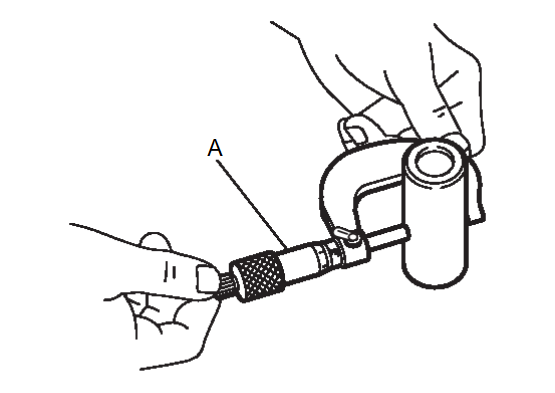

Piston Pin Outer Diameter

- Measure outer diameter of piston pin using suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

.

Piston to Piston Pin Oil Clearance

- (Piston to piston pin oil clearance) = (Piston pin hole diameter) - (Piston pin outer diameter)

Standard : Refer to CylinderBlockCylinder Block  .

. - If oil clearance value exceeds the limit replace piston and piston pin assembly.

| note | Piston is available together with piston pin as assembly. |

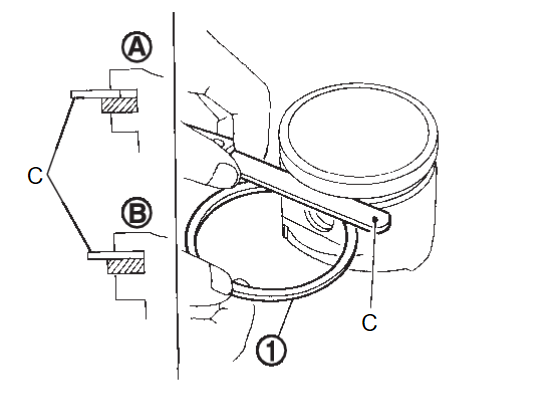

PISTON RING SIDE CLEARANCE

- Measure side clearance of piston ring

and piston ring groove using suitable tool (C).

and piston ring groove using suitable tool (C).Standard and Limit : Refer to CylinderBlockCylinder Block  .

.

: OK

: NG

1. If measured value exceeds limit replace piston ring and measure again.

2. If value still exceeds the limit replace piston.

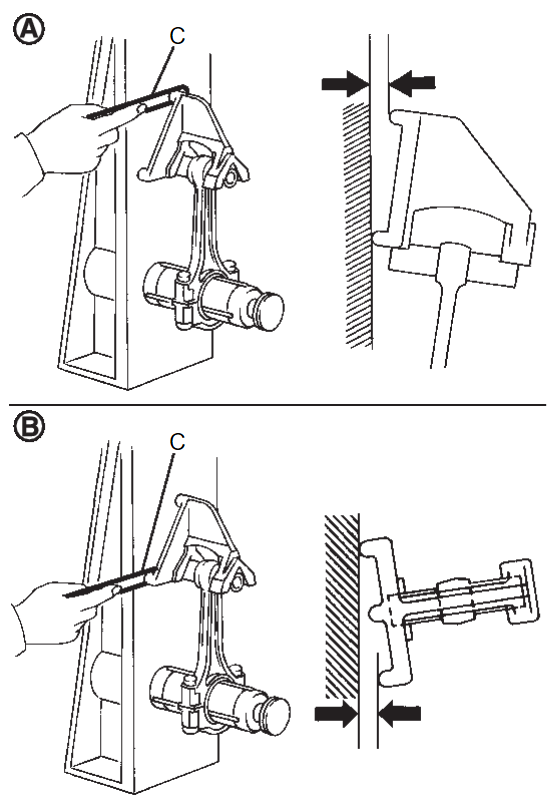

CONNECTING ROD BEND AND TORSION

- Check with a connecting rod aligner.

: Bend

: Torsion (C) : Suitable tool Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit replace connecting rod assembly.

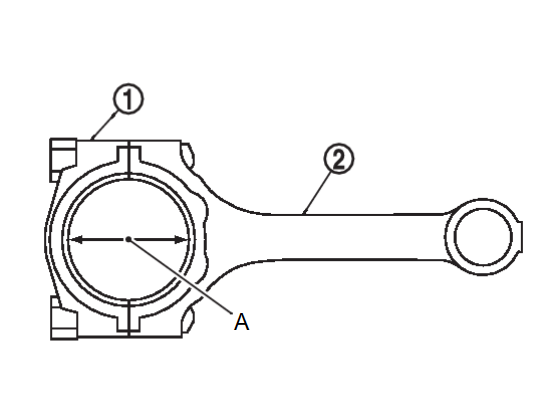

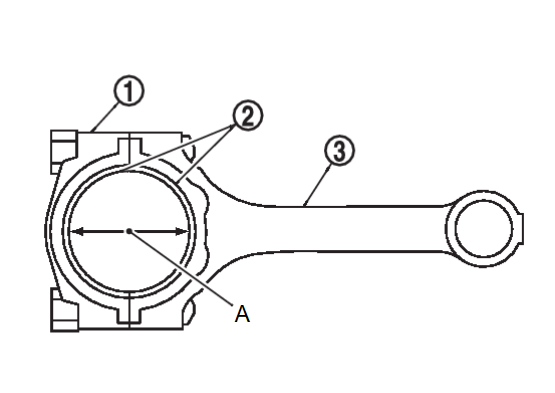

CONNECTING ROD BIG END DIAMETER

- Install connecting rod cap

without connecting rod bearing installed and tighten connecting rod bolts. Refer to Disassembly and Assembly

without connecting rod bearing installed and tighten connecting rod bolts. Refer to Disassembly and Assembly .

.

: Connecting rod (A) : Measuring direction of inner diameter - Measure inner diameter of connecting rod big end using suitable tool.

Standard : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds standard replace connecting rod assembly.

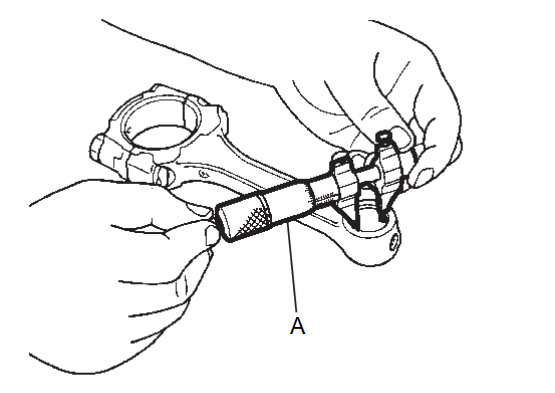

CONNECTING ROD BUSHING OIL CLEARANCE

Connecting Rod Bushing Inner Diameter

- Measure inner diameter of connecting rod bushing using suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

.

Piston Pin Outer Diameter

- Measure outer diameter of piston pin using suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

.

Connecting Rod Bushing Oil Clearance

- (Connecting rod bushing oil clearance) = (Connecting rod bushing inner diameter) - (Piston pin outer diameter)

Standard : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds standard replace connecting rod assembly and/or piston and piston pin assembly.

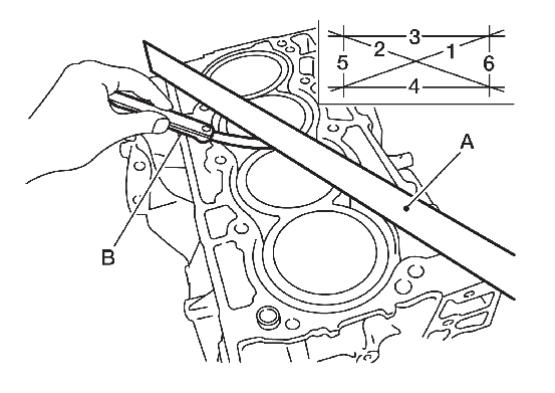

CYLINDER BLOCK TOP SURFACE DISTORTION

- Remove gasket on the cylinder block surface and also remove engine oil, scale, carbon and other contamination using suitable tool.

caution Do not allow gasket flakes to enter engine oil or engine coolant passages. - Measure distortion on cylinder block upper face at some different points in six directions using suitable tools (A/B).

Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds standard replace cylinder block.

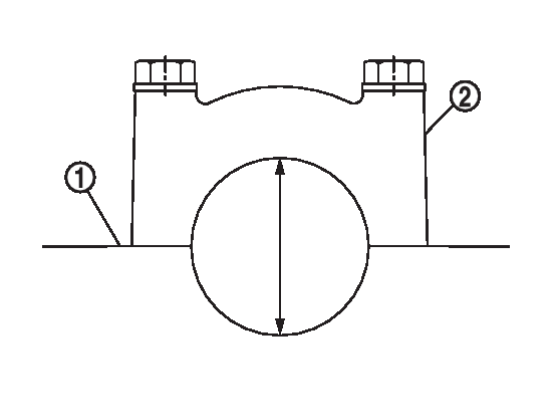

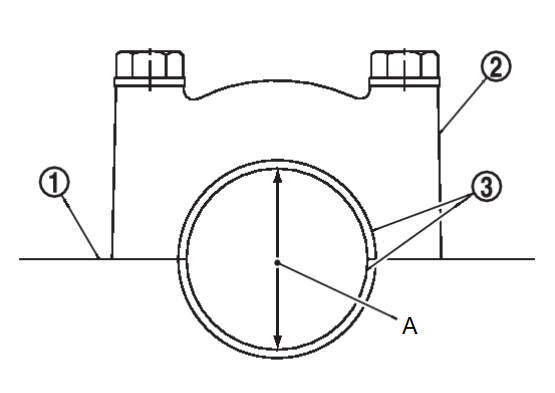

MAIN BEARING HOUSING INNER DIAMETER

- Install ladder assembly without main bearings installed and tighten ladder assembly bolts. Refer to Disassembly and Assembly

.

. - Measure inner diameter of main bearing housing using suitable tool.

Standard : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds standard replace cylinder block

and ladder assembly

and ladder assembly  .

.note Ladder assembly cannot be replaced as a single unit because it is machined together with cylinder block.

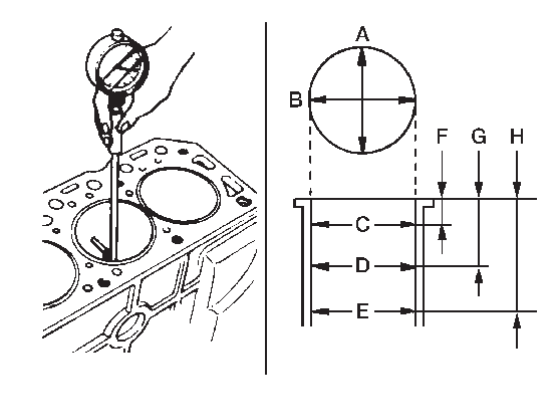

PISTON TO CYLINDER BORE CLEARANCE

Cylinder Bore Inner Diameter

- Measure cylinder bore for wear, out-of-round and taper at six different points on each cylinder using suitable tool. [(A) and (B) directions at (C), (D), and (E)] [(A) is in longitudinal direction of engine]

F : 10 mm (0.39 in) G : 75 mm (2.95 in) H : 140 mm (5.51 in) note When determining cylinder bore grade, measure the cylinder bore at (B) position. Standard: Cylinder bore inner diameter : Refer to CylinderBlockCylinder Block  .

.Limit: Out-of-round [Difference between (A) and (B)] Taper [Difference between (C) and (D)] : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit or if there are scratches and/or seizure on the cylinder inner wall hone or re-bore the cylinder inner wall.

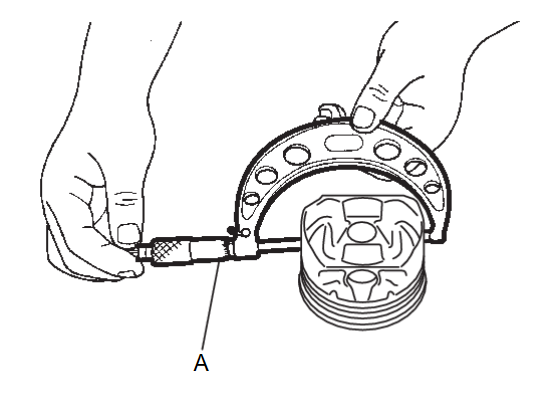

Piston Skirt Diameter

- Measure outer diameter of piston skirt with suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

.

Piston to Cylinder Bore Clearance

- (Piston to cylinder bore clearance) = (Cylinder bore inner diameter) - (Piston skirt diameter)

Standard and Limit : Refer to CylinderBlockCylinder Block  .

.

- If measured value exceeds limit replace piston and piston pin assembly..

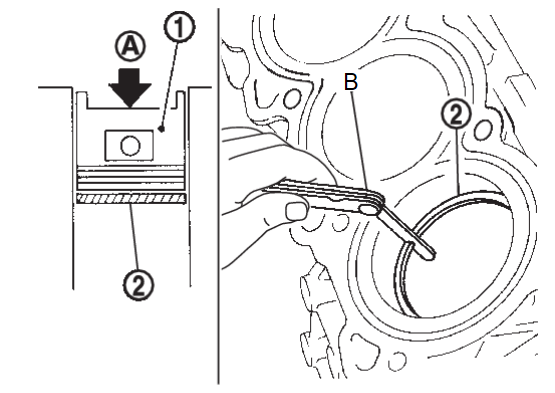

PISTON RING END GAP

- Check that cylinder bore inner diameter is within standards.

- Lubricate with new engine oil to piston

and piston ring

and piston ring  , and then insert

, and then insert  piston ring to middle of cylinder with piston and measure piston ring end gap using suitable tool (B).

piston ring to middle of cylinder with piston and measure piston ring end gap using suitable tool (B).Standard and Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit replace piston ring and measure again. If it still exceeds the limit replace cylinder block.

CRANKSHAFT MAIN JOURNAL DIAMETER

- Measure outer diameter of crankshaft main journals using suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit measure the main bearing oil clearance and use undersize bearing.

CRANKSHAFT PIN JOURNAL DIAMETER

- Measure outer diameter of crankshaft pin journal using suitable tool (A).

Standard : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit measure connecting rod bearing oil clearance and use undersize bearing.

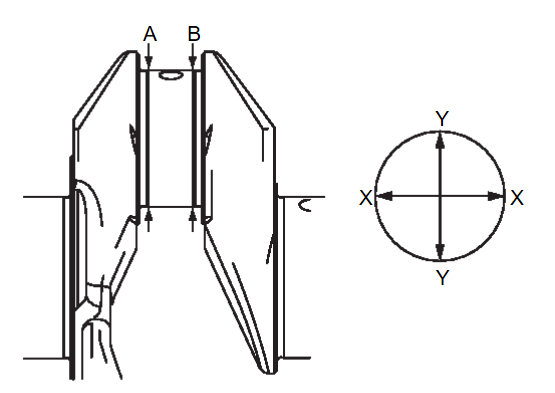

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

- Measure dimensions at four different points as shown on each main journal and pin journal using suitable tool.

- Out-of-round is indicated by the difference in dimension between (A) and (B) at (X) and (Y).

- Taper is indicated by difference in dimension between (X) and (Y) at (A) and (B).

Limit: Out-of-round [Difference between (A) and (B)] Taper [Difference between (X) and (Y)] : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit correct or replace crankshaft.

- If corrected, measure bearing oil clearance of corrected main journal and/or pin journal. Then select main bearing and/or connecting rod bearing.

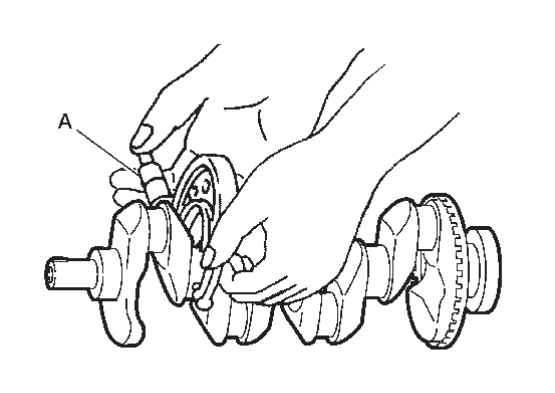

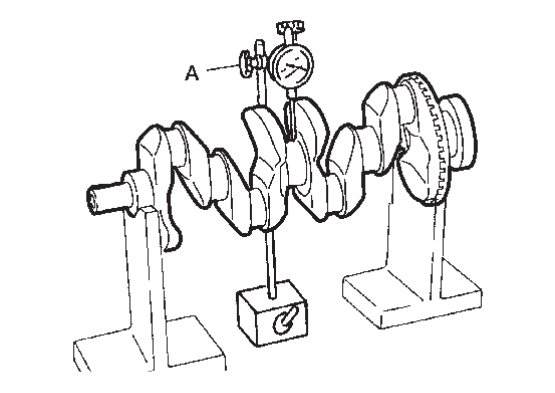

CRANKSHAFT RUNOUT

- Place V-block on precise flat table to support the journals on both ends of crankshaft.

- Place suitable tool (A) straight up on No. 3 journal.

- While rotating crankshaft, read movement of pointer on suitable tool. (Total indicator reading)

Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

- Install connecting rod bearings

to connecting rod

to connecting rod  and connecting rod bearings cap

and connecting rod bearings cap  and tighten connecting rod bolts. Refer to Disassembly and Assembly

and tighten connecting rod bolts. Refer to Disassembly and Assembly .

. - Measure inner diameter (A) of connecting rod bearing using suitable tool.

- (Bearing oil clearance) = (Connecting rod bearing inner diameter) - (Crankshaft pin journal diameter)

Standard and Limit : Refer to CylinderBlockCylinder Block  .

. - If measured value exceeds limit select proper connecting rod bearing. Use connecting rod big end diameter and crankshaft pin journal diameter to obtain specified bearing oil clearance.

Method by Using Plastigage

- Remove engine oil and dust on crankshaft pin and the surfaces of each bearing completely.

- Cut plastigage slightly shorter than bearing width and place it in crankshaft axial direction avoiding oil holes.

- Install connecting rod bearings to connecting rod and cap and tighten connecting rod bolts. Refer to Disassembly and Assembly

.

.caution Do not rotate crankshaft. - Remove connecting rod cap and bearing and using the scale (A) on the plastigage bag measure the plastigage width.

note The procedure when the measured value exceeds the limit is same as that described in the “Method by Calculation”.

MAIN BEARING OIL CLEARANCE

Method by Calculation

- Install main bearings

to cylinder block

to cylinder block  and ladder assembly

and ladder assembly  and tighten ladder assembly bolts. Refer to Disassembly and Assembly

and tighten ladder assembly bolts. Refer to Disassembly and Assembly .

. - Measure the inner diameter (A) of main bearing with bore gauge.

- (Bearing oil clearance) = (Main bearing inner diameter) - (Crankshaft main journal diameter)

| Standard and Limit | : Refer to CylinderBlockCylinder Block . . |

- If measured value exceeds limit select proper main bearing. Use main bearing inner diameter and crankshaft main journal diameter to obtain specified bearing oil clearance. Refer to Disassembly and Assembly

.

.

Method by Using Plastigage

- Remove engine oil and dust on crankshaft main journal and surfaces of each bearing completely.

- Cut plastigage slightly shorter than bearing width and place it in crankshaft axial direction avoiding oil holes.

- Install main bearings on cylinder block and ladder assembly and tighten ladder assembly bolts. Refer to Disassembly and Assembly

.

.caution Do not rotate crankshaft. - Remove ladder assembly and bearings and using the scale (A) on the plastigage bag measure the plastigage width.

note The procedure when measured value exceeds the limit is same as that described in “Method by Calculation”.

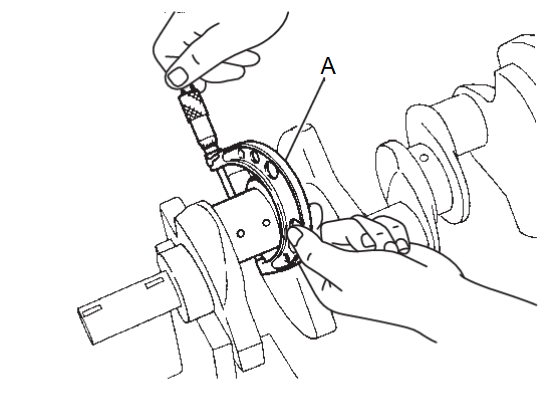

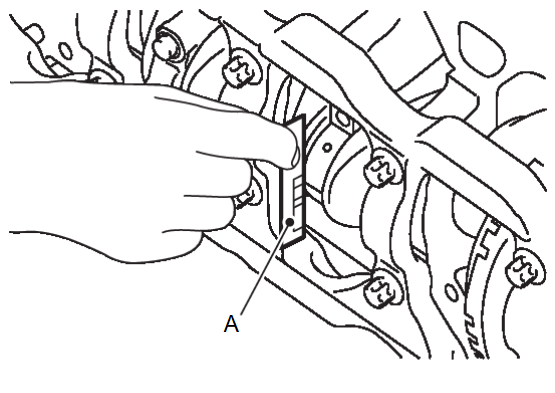

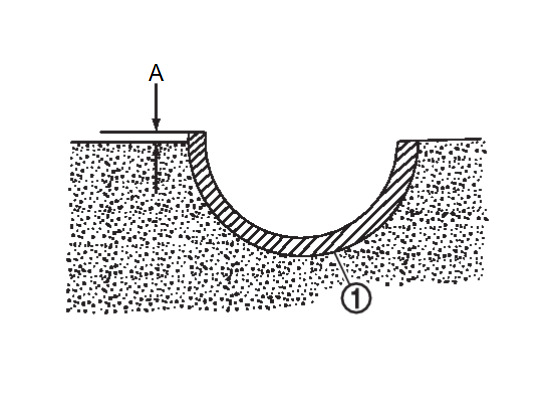

MAIN BEARING CRUSH HEIGHT

- When ladder assembly is removed after being tightened to specified torque with main bearings

installed, tip end of bearing must protrude (A). Refer to Disassembly and Assembly

installed, tip end of bearing must protrude (A). Refer to Disassembly and Assembly .

.A : Example Standard: There must be crush height. - If standard is not met, replace main bearings.

CONNECTING ROD BEARING CRUSH HEIGHT

- When connecting rod bearing cap is removed after being tightened to specified torque with connecting rod bearings

installed, tip end of bearing must protrude (A). Refer to Disassembly and Assembly

installed, tip end of bearing must protrude (A). Refer to Disassembly and Assembly .

.A : Example Standard: There must be crush height. - If standard is not met, replace connecting rod bearings.

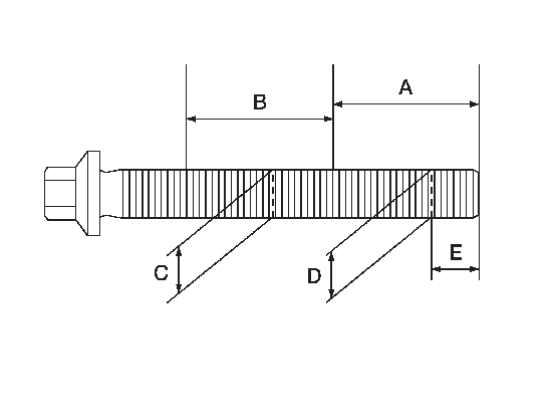

LADDER ASSEMBLY BOLT OUTER DIAMETER

- Measure outer diameters (C) and (D) at positions shown.

A : 30 mm (1.18 in) B : 20 mm (0.79 in) E : 10 mm (0.39 in) - If reduction appears in (B) range, regard it as (C).

Limit [(D) - (C)] : 0.13 mm (0.0051 in) - If measured value exceeds limit (a large difference in dimensions) replace ladder assembly bolt with new one.

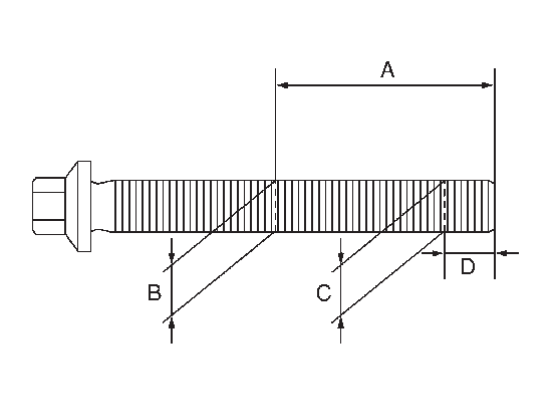

CONNECTING ROD BOLT OUTER DIAMETER

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)