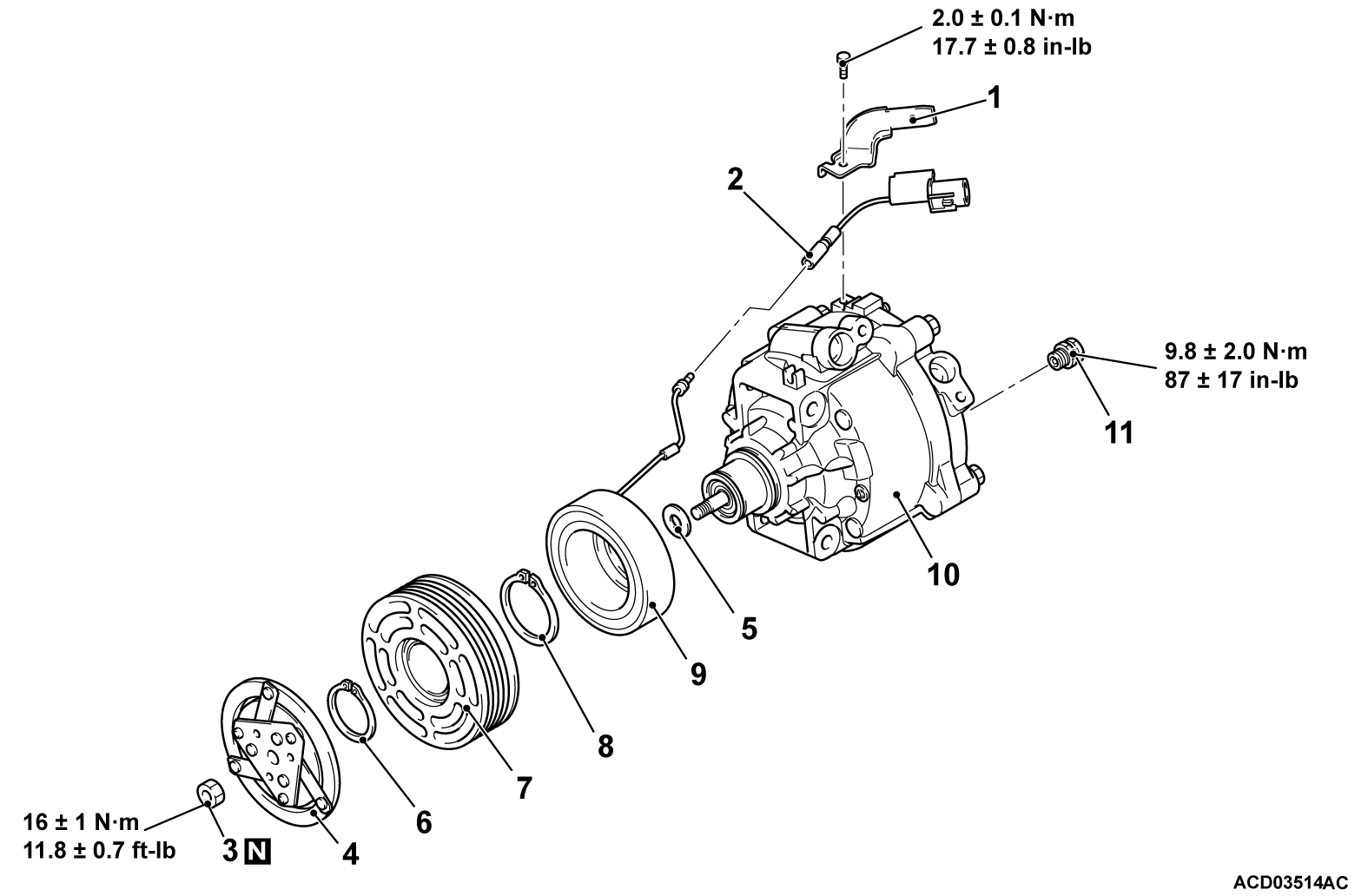

DISASSEMBLY AND ASSEMBLY

Required Special Tool:

- MB990810: Side bearing puller

- MB992623: Guide

- MB992624: Pusher

- MD999566: Claw

- MB991367: Special spanner

- MB991386: Pin

DISASSEMBLY SERVICE POINTS

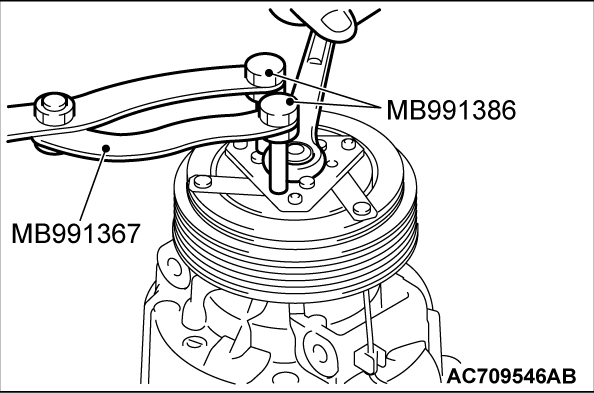

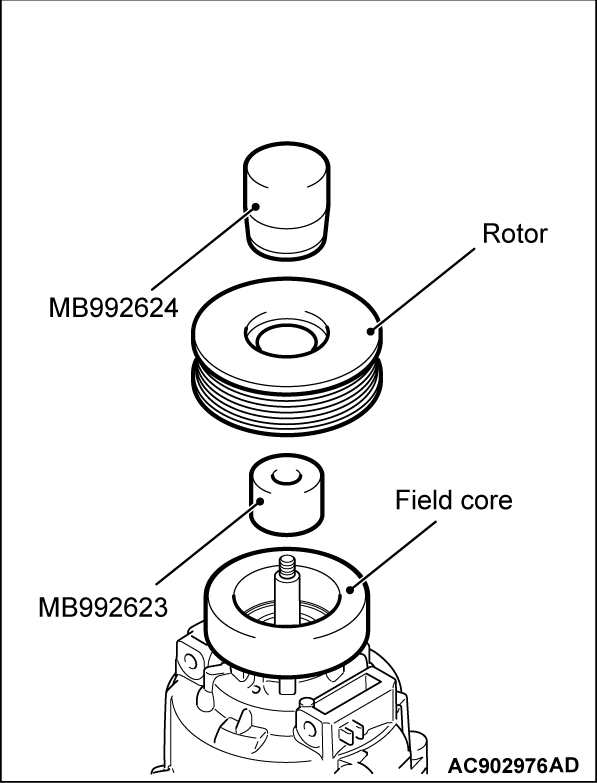

<<B>> ROTOR REMOVAL

| caution |

|

Rotor can be removed by hand, but if it is difficult to remove it, use the guide (MB992623) and the side bearing puller (MB990810) as shown.

REASSEMBLY SERVICE POINTS

>>A<< A/C COMPRESSOR HIGH PRESSURE RELIEF VALVE INSTALLATION

| caution | Be careful not to damage the O-ring when installing the high-pressure relief valve. Apply the specified refrigerating machine oil the high-pressure relief valve mounting hole before installation |

Check that O-ring is installed to the high-pressure relief and use the adjust torque wrench to install the high-pressure relief valve to the main body of the compressor.

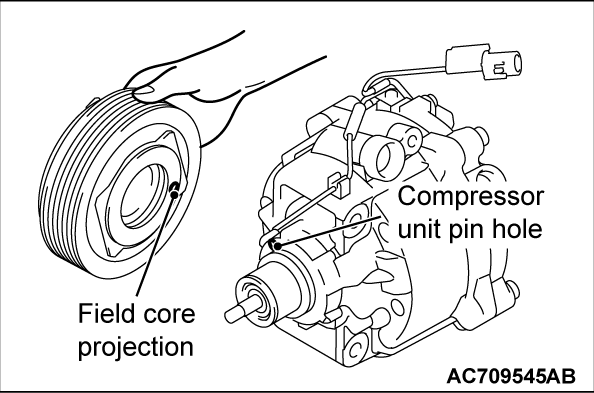

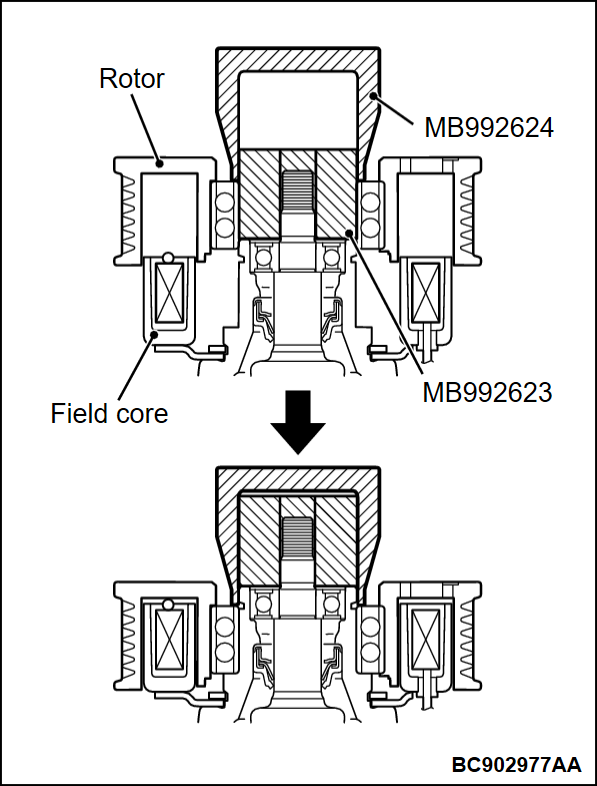

>>B<< FIELD CORE ATTACHMENT

Line up the pin hole on the compressor unit with the field core projection and attach.

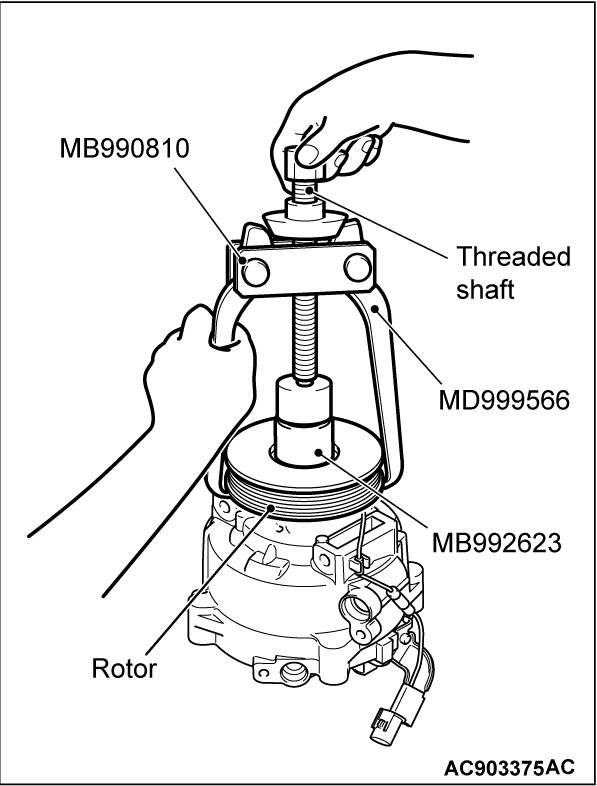

>>C<< ROTOR INSTALLATION

| caution | If the outer wheel side of rotor is pushed, an abnormal noise can be generated because the inside of rotor is damaged, therefore, always push the inner wheel side. |

Install the rotor while pushing the inner wheel side slowly using the pusher (MB992624) and guide (MB992623).

| note | Insert the rotor in a direction perpendicular to the A/C compressor. |

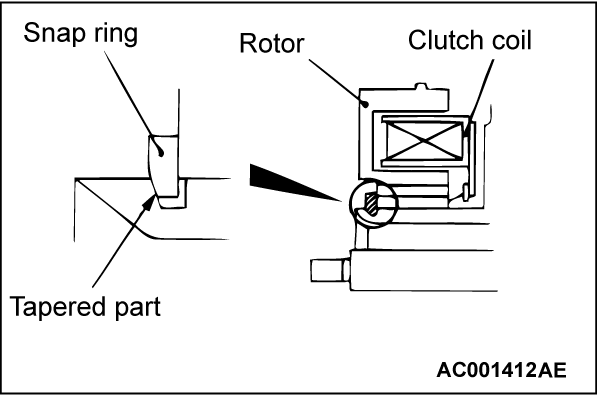

>>D<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the snap ring's tapered part is on the outside.

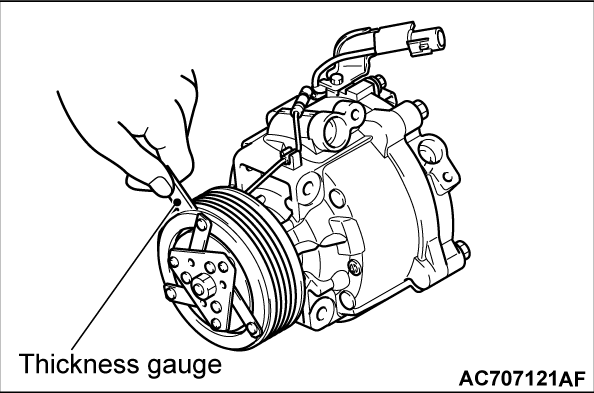

>>E<< SELF-LOCKING NUT INSTALLATION

Using a special tool, as when removing the nut, secure the armature and tighten the self-locking nut.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)