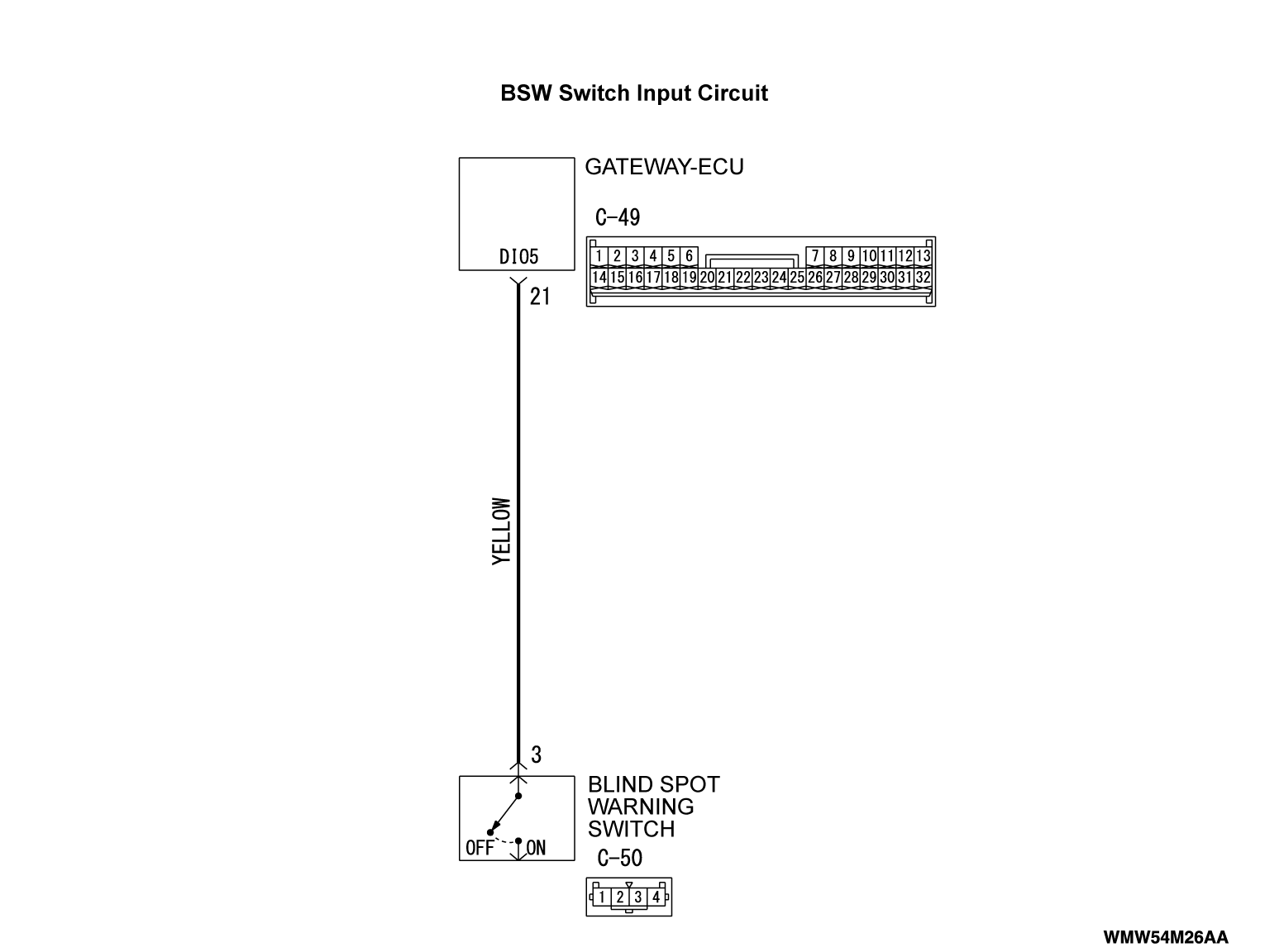

DTC C2321 BSW SW input malfunction

| caution | Before replacing the ECU, ensure that the power supply circuit, the ground circuit and the communication circuit are normal. |

OPERATION

BSW-ECU (master) receives a signal from the blind spot warning switch via CAN communication with the gateway-ECU.

CHECK CONDITION

When all of the conditions below are satisfied:

- Ignition switch is in the ON position.

- BSW-ECU (master) system voltage is at 9 to 16 volts.

DIAGNOSTIC FUNCTION AND JUDGMENT CRITERIA

If the gateway-ECU detects the blind spot warning switch pressed state for 60 seconds or more continuously, the BSW-ECU (master) sets DTC C2321.

TROUBLESHOOTING HINTS

- The blind spot warning switch (stuck on) may be defective

- The gateway-ECU may be defective

- The BSW-ECU (master) may be defective

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

STEP 1. Using scan tool (M.U.T.-III) other system data list

Using the gateway-ECU data list, check the blind spot warning switch signal.

(1)

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Check the input signals from the blind spot warning switch.

- When the blind spot warning switch is pressed.

|

- When the blind spot warning switch is not pressed.

|

OK: Normal condition is displayed.

Is the check result normal?

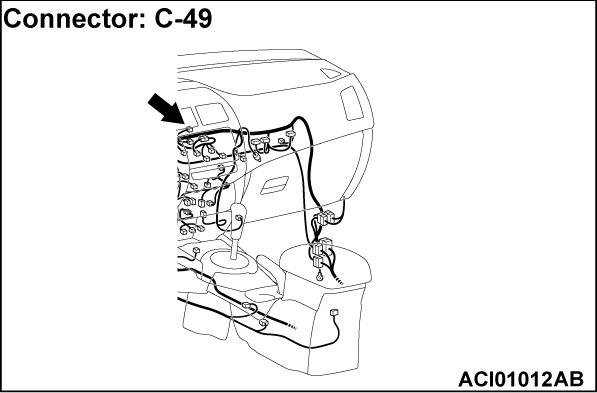

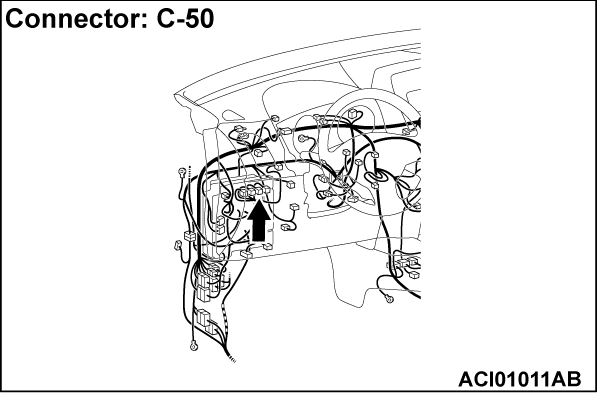

STEP 2. Connectors check: gateway-ECU connector C-49, blind spot warning switch connector C-50.

Are gateway-ECU connector C-49 and blind spot warning switch connector C-50 in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 3. Check the wiring harness between gateway-ECU connector C-49 (terminal No. 21) and blind spot warning switch connector C-50 (terminal No. 3).

- Check the input line for short and open circuit.

Is the wiring harness between Gateway-ECU connector C-49 (terminal 21) and blind spot warning switch connector C-50 (terminal 3) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 4. Check the blind spot warning switch.

Refer to blind spot warning switch Inspection  .

. Replace the blind spot warning switch.

Replace the blind spot warning switch.

.

.Is the check result normal?

Replace the blind spot warning switch.

Replace the blind spot warning switch.STEP 5. Using scan tool (M.U.T.-III) other system data list

Using the gateway-ECU data list, check the blind spot warning switch signal.

Intermittent malfunction is suspected (Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent Malfunction

Intermittent malfunction is suspected (Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the gateway-ECU.

Replace the gateway-ECU.

- When the blind spot warning switch is pressed.

|

- When the blind spot warning switch is not pressed.

|

OK: Normal condition is displayed.

Is the check result normal?

Intermittent malfunction is suspected (Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent Malfunction

Intermittent malfunction is suspected (Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the gateway-ECU.

Replace the gateway-ECU.STEP 6. Check whether the DTC is set again.

Check again if the DTC is set in the BSW-ECU (master). Replace the BSW-ECU (master).

Replace the BSW-ECU (master).

(1) Erase the DTC.

(2) Turn the ignition switch from the "LOCK" (OFF) position to the "ON" position.

(3) Check if the DTC is set.

Is the DTC set?

Replace the BSW-ECU (master).

Replace the BSW-ECU (master).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)