DTC B210A: +B power supply (low input)

DTC B210B: +B power supply (high input)

DTC B210B: +B power supply (high input)

TROUBLE JUDGMENT

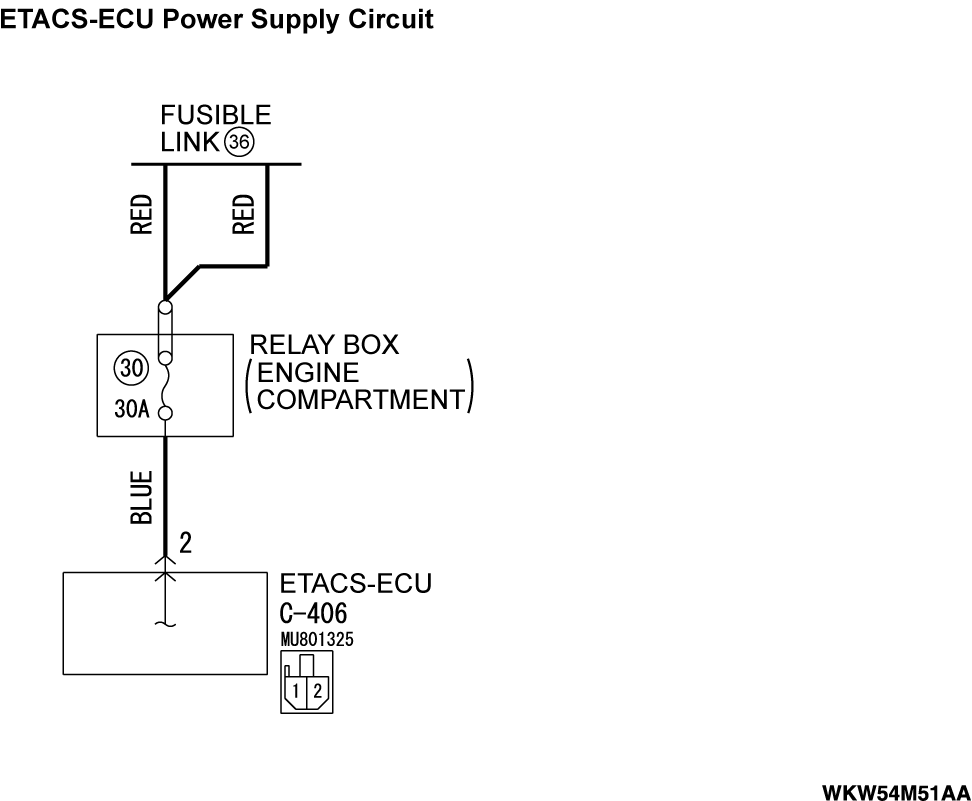

The ETACS-ECU sets DTC B210A if the power supply fuse voltage decreases to the specified value or less, and sets DTC B210B if the power supply fuse voltage increases to the specified value or more. However, when the status returns to normal, the ETACS-ECU automatically erases DTCs B210A and B210B.

TECHNICAL DESCRIPTION (COMMENT)

The power supply fuse or the ETACS-ECU may have a problem.

TROUBLESHOOTING HINTS

- The power supply fuse may be defective.

- The ETACS-ECU may be defective.

- The battery may be defective.

- The generator may be defective.

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

STEP 2. Wiring harness check between C-406 ETACS-ECU connector and fuse No. 30.

Check the power supply line for short circuit. Replace the fuse No.30.

Replace the fuse No.30. A short circuit may be present in the power supply circuit. Repair the wiring harness between ETACS-ECU connector C-406 terminal 2 and fuse No. 30, and replace fuse No. 30.

A short circuit may be present in the power supply circuit. Repair the wiring harness between ETACS-ECU connector C-406 terminal 2 and fuse No. 30, and replace fuse No. 30.

Is the check result normal?

Replace the fuse No.30.

Replace the fuse No.30. A short circuit may be present in the power supply circuit. Repair the wiring harness between ETACS-ECU connector C-406 terminal 2 and fuse No. 30, and replace fuse No. 30.

A short circuit may be present in the power supply circuit. Repair the wiring harness between ETACS-ECU connector C-406 terminal 2 and fuse No. 30, and replace fuse No. 30.STEP 3. Battery check

STEP 4. Charging system check

Refer to GROUP 16 - Output Current Test  .

. Repair or replace the charging system component(s).

Repair or replace the charging system component(s).

.

.Is the charging system in good condition?

Repair or replace the charging system component(s).

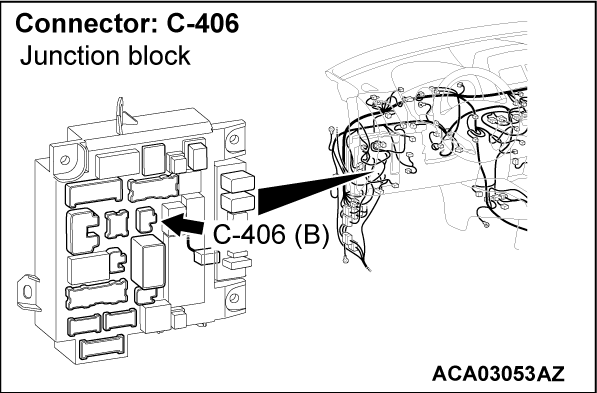

Repair or replace the charging system component(s).STEP 5. Check ETACS-ECU connector C-406 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is ETACS-ECU connector C-406 in good condition?

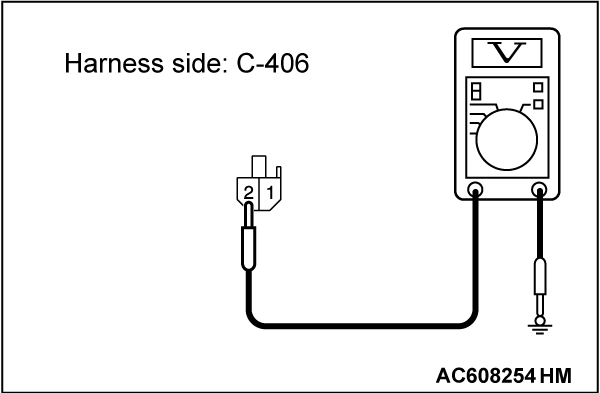

STEP 6. Check the battery power supply circuit to the ETACS-ECU. Measure the voltage at ETACS-ECU connector C-406.

(1) Disconnect ETACS-ECU connector C-406 and measure the voltage available at the wiring harness side of the connector.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Measure the voltage between terminal 2 and ground.

- The voltage should measure approximately 12 volts (battery positive voltage).

Is the measured voltage approximately 12 volts (battery positive voltage)?

STEP 7. Check the wiring harness between ETACS-ECU connector C-406 (terminal 2) and the fusible link (36).

Check the power supply line for open circuit. No action is necessary and testing is complete.

No action is necessary and testing is complete. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

Is the wiring harness between ETACS-ECU connector C-406 (terminal 2) and the fusible link (36) in good condition?

No action is necessary and testing is complete.

No action is necessary and testing is complete. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 8. Using scan tool MB991958, check data list.

Check the power supply fuse voltage. Replace the ETACS-ECU.

Replace the ETACS-ECU.

(1)

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(2) Check the ETACS data list.

- Turn the ignition switch to the "LOCK" (OFF) position.

|

Does the scan tool MB991958 display the item "voltage sensing of IOD Line" is normal condition?

Replace the ETACS-ECU.

Replace the ETACS-ECU.STEP 9. Recheck for diagnostic trouble code.

Check again if the DTC is set in the ETACS-ECU. Replace the ETACS-ECU.

Replace the ETACS-ECU.

(1) Erase the DTC.

(2) Turn the ignition switch from "LOCK" (OFF) position to "ON" position.

(3) Check if DTC is set.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the DTC set?

Replace the ETACS-ECU.

Replace the ETACS-ECU.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)