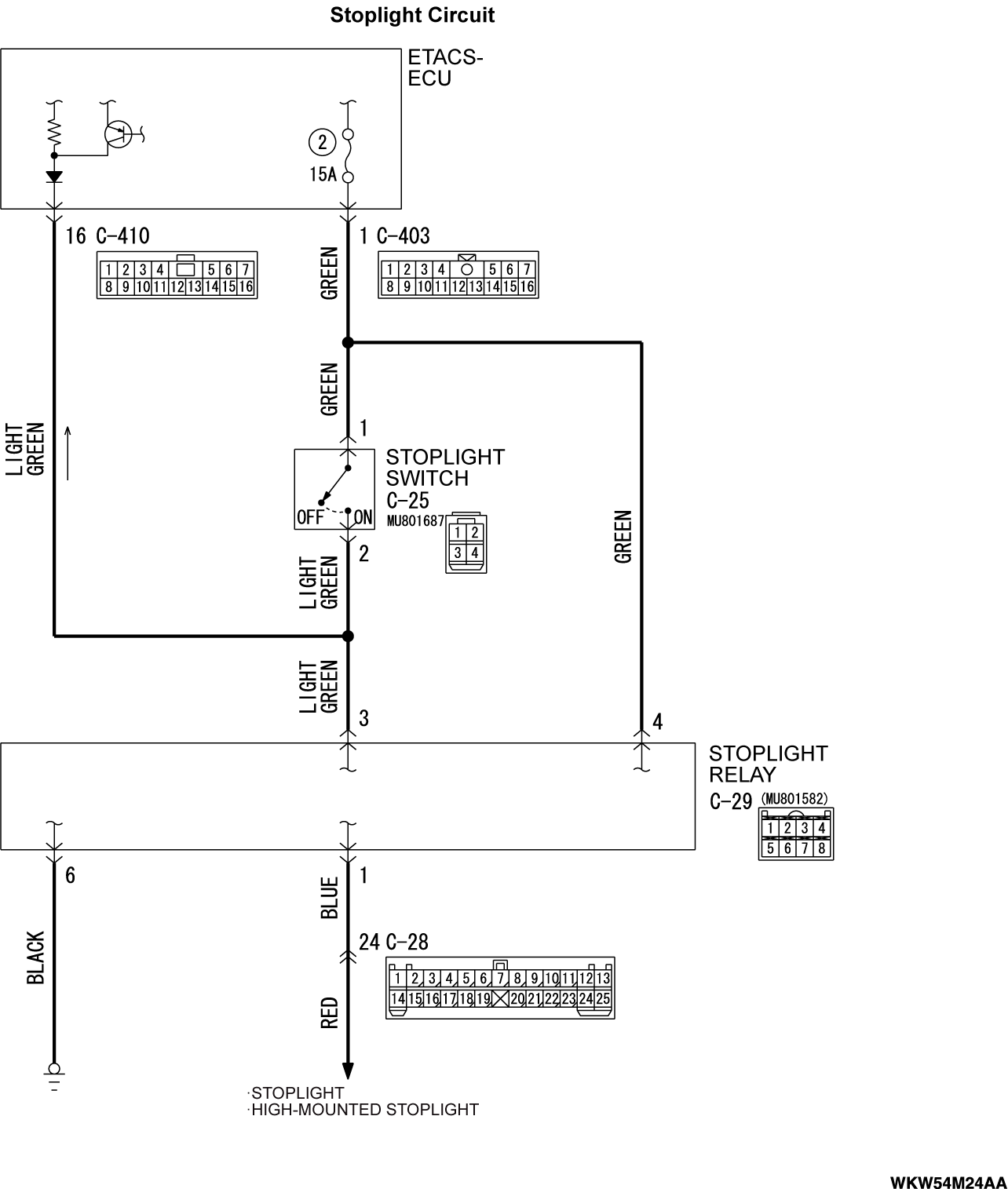

Inspection Procedure 3: Stoplight does not illuminate or go out normally. <Vehicles with stop light relay>

COMMENTS ON TROUBLE SYMPTOM

If the stoplights do not illuminate or go out normally, the stoplight relay power supply, ground circuit system, stoplight switch, or the stoplight relay * may be defective.

| note | *: The stoplight relay cannot be inspected because it is a semiconductor relay. |

PROBABLE CAUSES

- Malfunction of stoplight switch

- Malfunction of stoplight relay

- Damaged harness wires and connectors

DIAGNOSIS

Required Special Tools:

- MB992006: Extra fine probe

- MB991223: Harness set

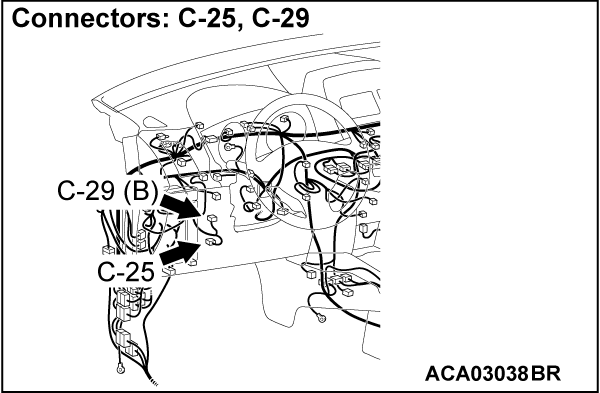

STEP 1. Check stoplight relay connector C-29 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

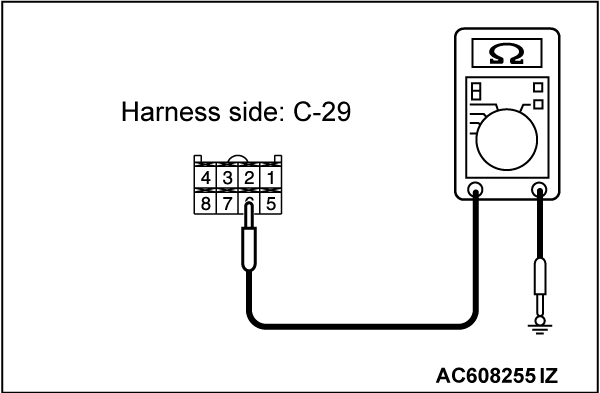

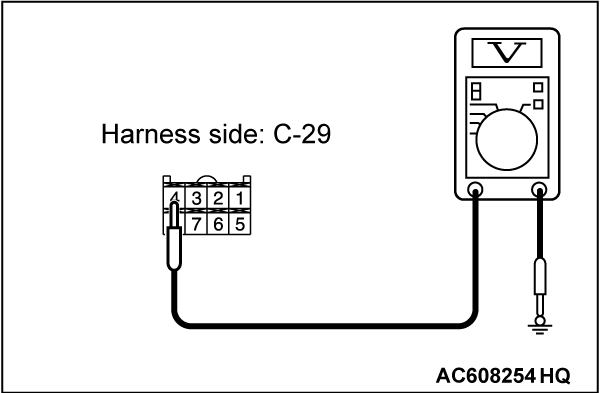

STEP 2. Resistance measurement at stoplight relay connector C-29.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Measure the resistance between stoplight relay connector C-29 (terminal No. 6) and the body ground.

OK: The measured value should be continuity exists (2 ohms or less).

Does the measured resistance value correspond with this range?

STEP 3. Check the wiring harness between stoplight relay connector C-29 (terminal No. 6) and ground.

Check the ground line for open circuit. The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction  ).

). Repair the wiring harness.

Repair the wiring harness.

Is the wiring harness between stoplight relay connector C-29 (terminal No. 6) and ground in good condition?

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction  ).

). Repair the wiring harness.

Repair the wiring harness.STEP 4. Check the stoplight switch.

Check the stoplight switch. Refer to GROUP 35A - Brake Pedal  .

. Replace the stoplight switch.

Replace the stoplight switch.

.

.Is the stoplight switch in good condition?

Replace the stoplight switch.

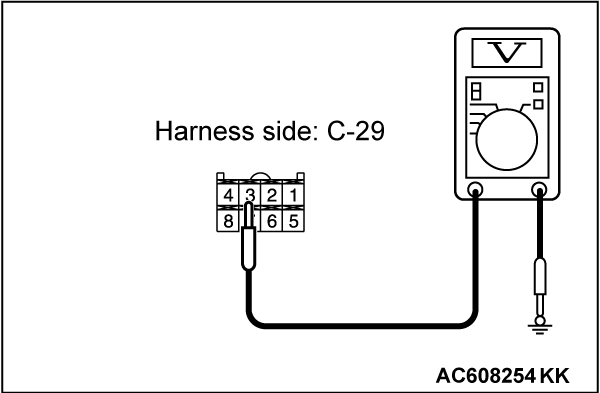

Replace the stoplight switch.STEP 5. Check the battery power supply circuit to the stoplight relay. Measure the voltage at stoplight relay connector C-29.

(1) Disconnect stoplight relay connector C-29 measure the voltage available at the wiring harness side of the connector.

(2) Measure the voltage between stoplight relay connector C-29 terminal 4 and ground.

- The voltage should measure approximately 12 volts (battery positive voltage).

(3) Stoplight switch: ON

(4) Measure the voltage between stoplight relay connector terminal No. 3 and the body ground.

- The voltage should measure approximately 12 volts (battery positive voltage).

Is the measured voltage approximately 12 volts (battery positive voltage)?

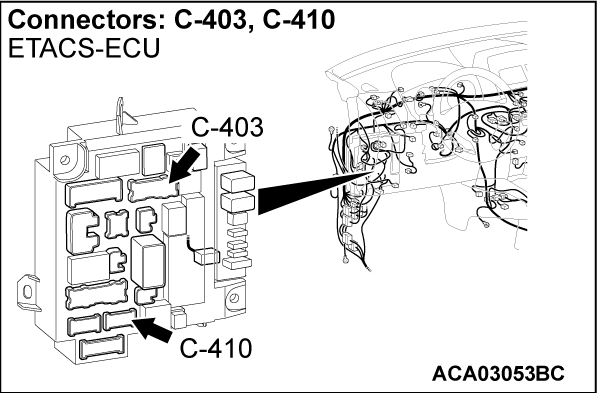

STEP 6. Check ETACS-ECU connector C-403 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

STEP 7. Check the wiring harness between stoplight relay connector C-29 (terminal No. 3/4) and ETACS-ECU connector C-403 (terminal No. 1).

- Check the power supply line (battery supply) for open circuit and short circuit.

Is the wiring harness between stoplight relay connector C-29 (terminal No. 3/4) and ETACS-ECU connector C-403 (terminal No. 1) in good condition?

Repair the wiring harness.

Repair the wiring harness.STEP 8. Check ETACS-ECU connectors C-410 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

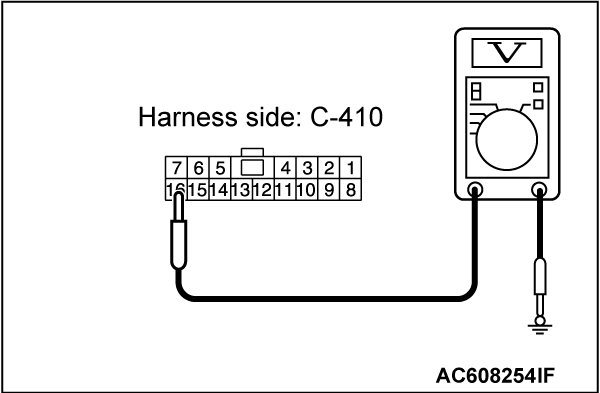

STEP 9. Check the battery power supply circuit to the ETACS-ECU. Measure the voltage at ETACS-ECU connector C-410.

(1) Disconnect connector measure the voltage available at the wiring harness side of the connector.

(2) Disconnecting the ETACS-ECU connector C-410.

(3) Stoplight switch: ON

(4) Measure the voltage between ETACS-ECU connector C-410 terminal No. 16 and the body ground.

- The voltage should measure approximately 12 volts (battery positive voltage).

Is the measured voltage approximately 12 volts (battery positive voltage)?

STEP 10. Check the wiring harness between ETACS-ECU connector C-410 (terminal No. 16) and stoplight relay connector C-29 (terminal No. 3).

- Check the signal line for short circuit.

Is the wiring harness between ETACS-ECU connector C-410 (terminal No. 16) and stoplight relay connector C-29 (terminal No. 3) in good condition?

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points, How to Cope with Intermittent Malfunction  ).

). Repair the wiring harness.

Repair the wiring harness.STEP 11. Check the wiring harness between stoplight relay connector C-29 (terminal No. 1) and intermediate connector C-28 (terminal No. 24).

Check the communication line for open or short circuit. Repair the wiring harness.

Repair the wiring harness.

Is the wiring harness between stoplight relay connector C-29 (terminal No. 1) and intermediate connector C-28 (terminal No. 24) in good condition?

Repair the wiring harness.

Repair the wiring harness.STEP 12. Retest the system

Check that the stoplight illuminates normally. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the stoplight relay.

Replace the stoplight relay.

Does the stoplight relay work normally?

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the stoplight relay.

Replace the stoplight relay.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)