DTC B16A7: Taillight (RH) circuit short <Short circuit in the taillight control circuit>

| caution | Whenever the ECU is replaced, ensure that the power supply circuit, the ground circuit and the communication circuit are normal. |

TROUBLE JUDGMENT

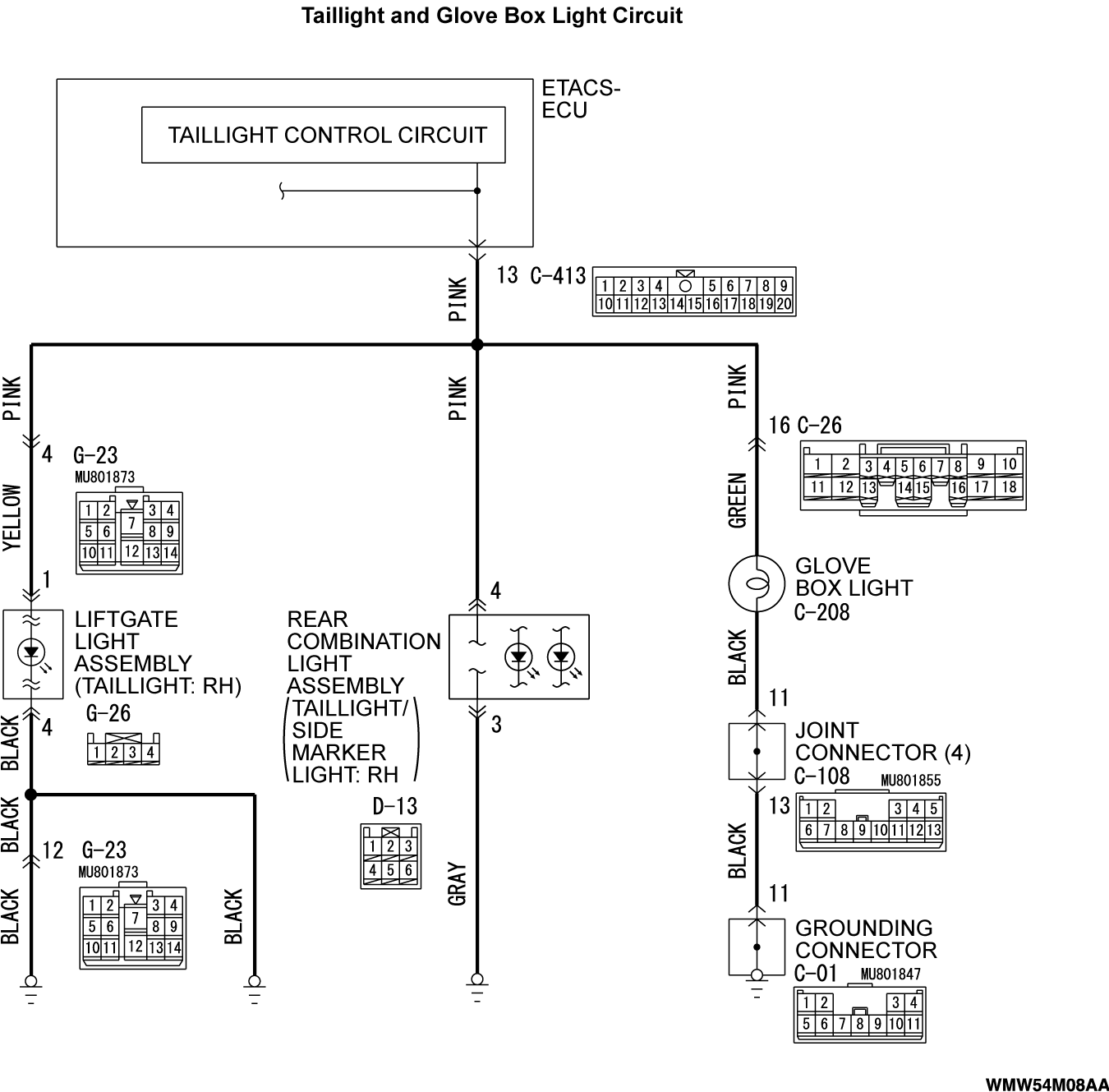

When the short circuit is detected in the following light circuit, the ETACS-ECU sets DTC No. B16A7.

- Taillight

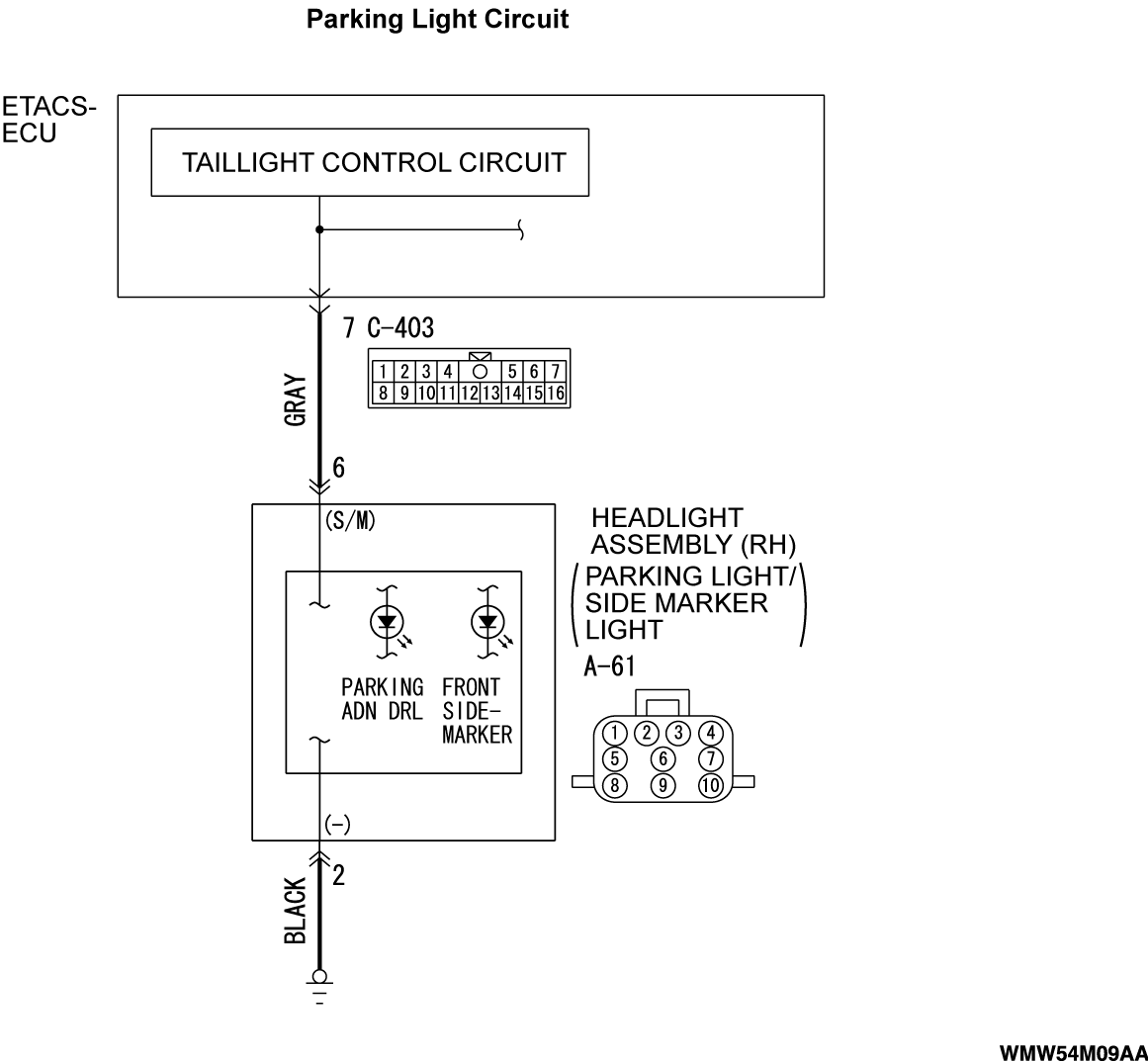

- Parking light

- Glove box light

- Front side-marker light

- Rear side-marker light

TECHNICAL DESCRIPTION (COMMENT)

The problem detection of each light is made based on the digital feed back signal (input signal to ETACS-ECU) which operates the each light. When the ignition switch is ON, the ETACS-ECU determines the each light circuit state from the load placed on the line. After 100 ms has elapsed since the start of the check, the ETACS-ECU performs a sampling with each 10 ms. If an abnormality is detected, it increases the counter by 2, and when no abnormality is detected, it decreases the counter by 1. Once the counter reaches "10," the ETACS-ECU sets DTC No. B16A7 if the load is detected on the line.

TROUBLESHOOTING HINTS

- The headlight assembly (RH) may be defective. <Parking light/front side-marker light>

- The rear combination light unit (RH) may be defective. <Taillight/rear side-marker light>

- The liftgate light unit (RH) may be defective. <Taillight>

- The glove box light bulb may be defective.

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector.

- The ETACS-ECU may be defective.

DIAGNOSIS

Required Special Tools:

- MB992006: Extra fine probe

- MB991223: Harness set

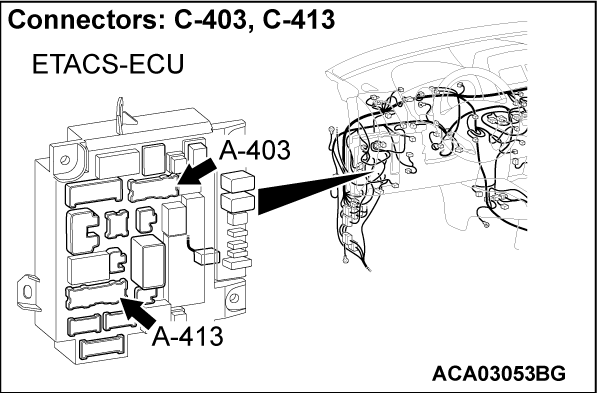

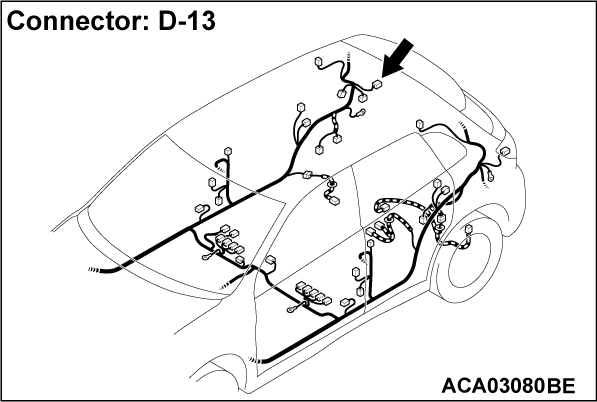

STEP 1. Check ETACS-ECU connector C-413, rear combination light (taillight/rear side-marker light: RH) connector D-13 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is ETACS-ECU connector C-413, rear combination light (taillight/rear side-marker light: RH) connector D-13 in good condition?

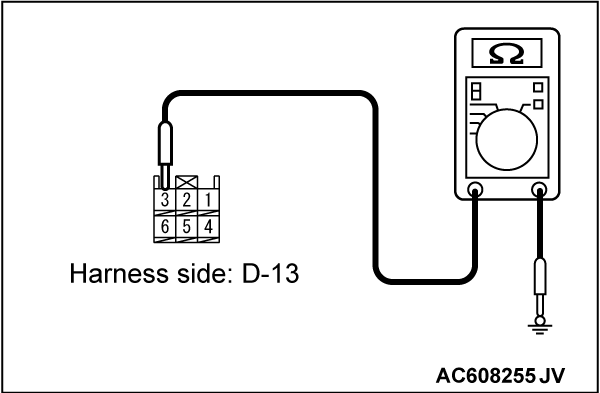

STEP 2. Check the ground circuit to the rear combination light (taillight/rear side-marker light: RH). Measure the resistance at rear combination light (taillight/rear side-marker light: RH) connector D-13.

(1) Disconnect rear combination light (taillight/rear side-marker light: RH) connector D-13 and measure the resistance available at the wiring harness side of the connector.

(2) Measure the resistance value between rear combination light (taillight/rear side-marker light: RH) connector D-13 terminal 3 and ground.

- The resistance should be 2 ohms or less.

Is the measured resistance 2 ohms or less?

STEP 3. Check the wiring harness between rear combination light (taillight/rear side-marker light: RH) connector D-13 (terminal 3) and the ground.

Check the ground wires for open circuit. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

Is the wiring harness between rear combination light (taillight/rear side-marker light: RH) connector D-13 (terminal 3) and the ground in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 4. Check the wiring harness between rear combination light (taillight/rear side-marker light: RH) connector D-13 (terminal 4) and ETACS-ECU connector C-413 (terminal 13).

- Check the power supply line for open circuit and short circuit.

Is the wiring harness between rear combination light (taillight/rear side-marker light: RH) connector D-13 (terminal 4) and ETACS-ECU connector C-413 (terminal 13) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 5. Using scan tool MB991958, check whether the diagnostic trouble code is set again.

Check again if the DTC is set in the ETACS.

(1) Erase the DTC.

(2) Lighting operation of a taillight is performed.

(3) Check if DTC is set.

Is the DTC set?

STEP 6. Using scan tool MB991958, check whether the diagnostic trouble code is set again.

Check again if the DTC is set in the ETACS. Replace the rear combination light unit (RH).

Replace the rear combination light unit (RH).

(1) Erase the DTC.

(2) Disconnect the rear combination light (taillight/rear side-marker light: RH) connector.

(3) Lighting operation of a taillight is performed.

(4) Check if DTC is set.

Is the DTC set?

Replace the rear combination light unit (RH).

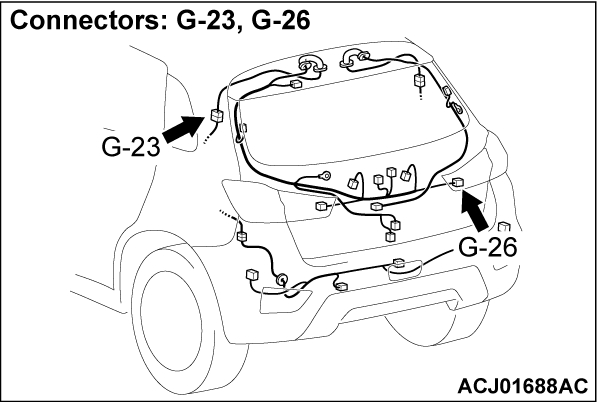

Replace the rear combination light unit (RH).STEP 7. Check ETACS-ECU connector C-413, liftgate light (taillight: RH) connector G-26 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is connector in good condition?

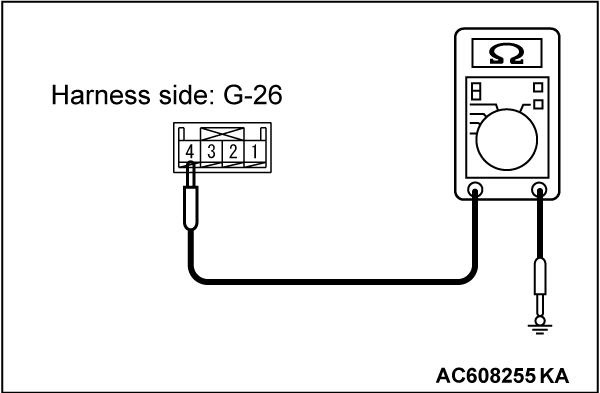

STEP 8. Check the ground circuit to the liftgate light (taillight: RH). Measure the resistance at liftgate light (taillight: RH) connector G-26.

(1) Disconnect liftgate light (taillight: RH) connector G-26 and measure the resistance available at the wiring harness side of the connector.

(2) Measure the resistance value between liftgate light (taillight: RH) connector G-26 terminal 4 and ground.

- The resistance should be 2 ohms or less.

Is the measured resistance 2 ohms or less?

STEP 9. Check the wiring harness between liftgate light (taillight: RH) connector G-26 (terminal 4) and ground.

- Check the ground wires for open circuit.

Is the wiring harness between liftgate light (taillight: RH) connector G-26 (terminal 4) and the ground in good condition?

STEP 10. Check the wiring harness between liftgate light (taillight: RH) connector G-26 (terminal 1) and ETACS-ECU connector C-413 (terminal 13).

- Check the power supply line for open circuit and short circuit.

Is the wiring harness between liftgate light (taillight: RH) connector G-26 (terminal 1) and ETACS-ECU connector C-413 (terminal 13) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 11. Using scan tool MB991958, check whether the diagnostic trouble code is set again.

Check again if the DTC is set in the ETACS.

(1) Erase the DTC.

(2) Lighting operation of a taillight is performed.

(3) Check if DTC is set.

Is the DTC set?

STEP 12. Using scan tool MB991958, check whether the diagnostic trouble code is set again.

Check again if the DTC is set in the ETACS. Replace the liftgate light unit (RH).

Replace the liftgate light unit (RH).

(1) Erase the DTC.

(2) Disconnect the liftgate light (taillight: RH) connector.

(3) Lighting operation of a taillight is performed.

(4) Check if DTC is set.

Is the DTC set?

Replace the liftgate light unit (RH).

Replace the liftgate light unit (RH).STEP 13. Connector check.

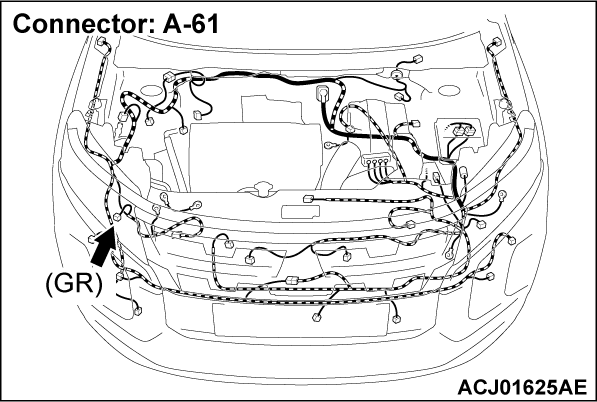

- Headlight assembly (parking light/front side-marker light: RH) connector A-61

- ETACS-ECU connector C-403

Is connector in good condition?

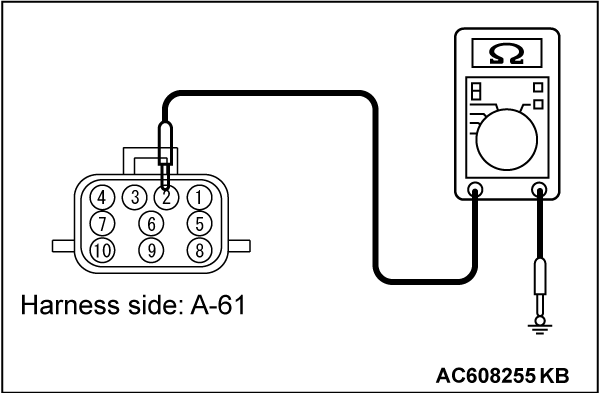

STEP 14. Resistance measurement.

(1) Disconnect headlight assembly (parking light/front side-marker light: RH) connector A-61 and measure the resistance available at the wiring harness side of the connector.

(2) Measure the resistance value between headlight assembly (parking light/front side-marker light: RH) connector A-61 terminal No. 2 and ground.

- The resistance should be 2 ohms or less.

Is the measured resistance 2 ohms or less?

STEP 15. Check the wiring harness between headlight assembly (parking light/front side-marker light: RH) connector A-61 (terminal No. 2) and the ground.

- Check the ground wires for open circuit.

Is the wiring harness between headlight assembly (parking light/front side-marker light: RH) connector A-61 (terminal No. 2) and the ground in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 16. Check the wiring harness between headlight assembly (parking light/front side-marker light: RH) connector A-61 (terminal No. 6) and the ETACS-ECU connector C-403 (terminal No. 7).

- Check the power supply line for open circuit and short circuit.

Is the wiring harness between headlight assembly (parking light/front side-marker light: RH) connector A-61 (terminal No. 6) and the ETACS-ECU connector C-403 (terminal No. 7) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 17. Using scan tool MB991958, check whether the DTC is set again.

(1) Erase the DTC.

(2) Lighting operation of a taillight is performed.

(3) Check if DTC is set.

Is the DTC set?

STEP 18. Using scan tool MB991958, check whether the DTC is set again.

(1) Erase the DTC.

(2) Disconnect the headlight assembly (parking light/front side-marker light: RH) connector.

(3) Lighting operation of a taillight is performed.

(4) Check if DTC is set.

Is the DTC set?

Replace the headlight body (RH).

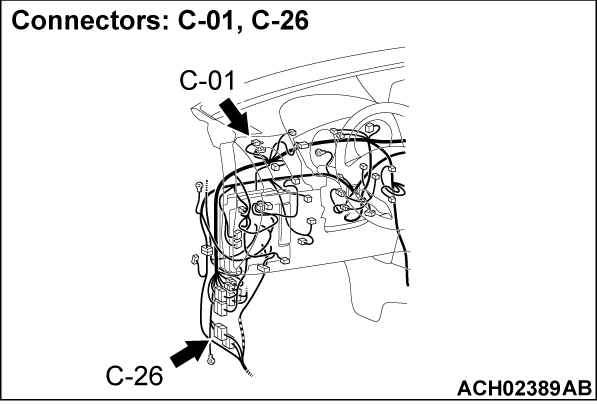

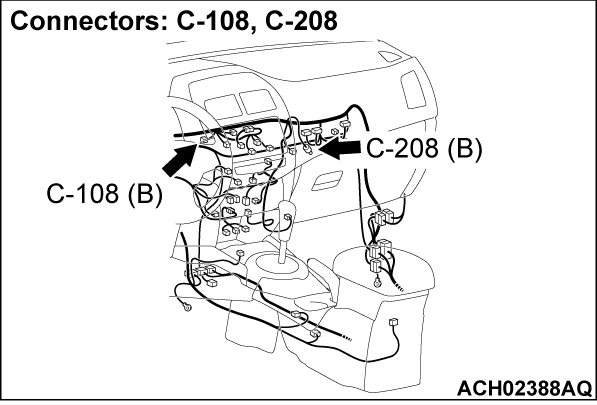

Replace the headlight body (RH).STEP 19. Check glove box light connector C-208, ETACS-ECU connector C-413 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

STEP 20. Check the glove box light bulb.

Check the continuity at the glove box light bulb to confirm whether it is normal.

Is the check result normal?

STEP 21. Check the wiring harness between glove box light connector C-208 and the ETACS-ECU connector C-413 (terminal No. 13).

- Check the power supply line for open circuit and short circuit.

Is the wiring harness between glove box light connector C-208 and the ETACS-ECU connector C-413 (terminal No. 13) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 22. Check the wiring harness between glove box light connector C-208 and the ground.

Check the ground wires for open circuit. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

Is the wiring harness between glove box light connector C-208 and the ground in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 23. Using scan tool MB991958, check whether the diagnostic trouble code is set again.

(1) Erase the DTC.

(2) Lighting operation of a taillight is performed.

(3) Check if DTC is set.

Is the DTC set?

Replace the ETACS-ECU.

Replace the ETACS-ECU.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)