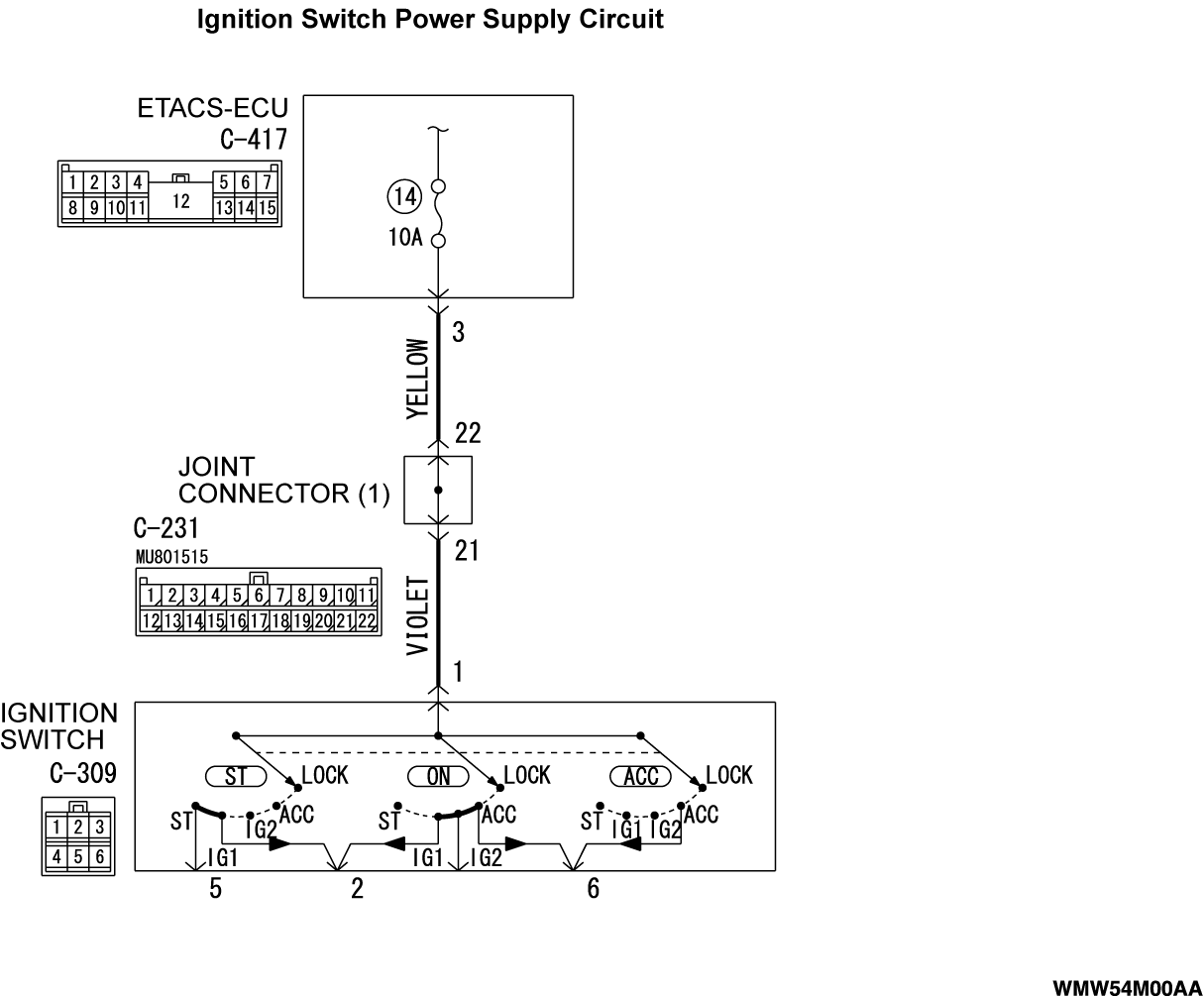

Inspection Procedure 2: Defective power supply system of the ignition switch

TECHNICAL DESCRIPTION (COMMENT)

When the power supply system of ignition switch has a problem, none of the equipment and system connected to the ignition switch works even if the ignition switch is operated.

TROUBLESHOOTING HINTS

- The ignition switch may be defective

- The fuse No.14 may be defective

- The ETACS-ECU may be defective

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB992006: Extra fine probe

- MB991223: Harness set

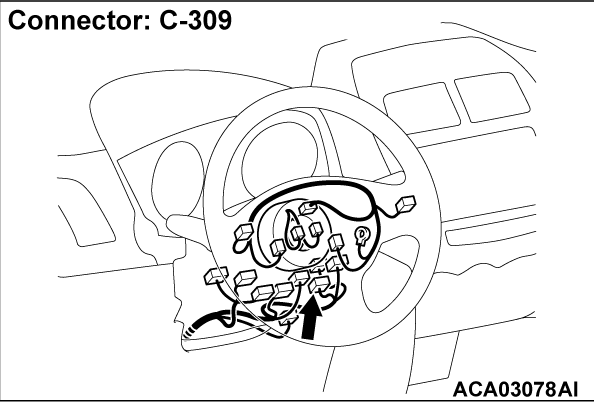

STEP 1. Check ignition switch connector C-309 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

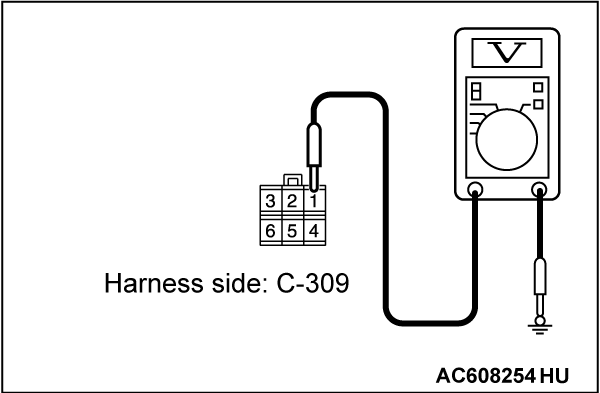

STEP 2. Check the battery power supply circuit to the ignition switch. Measure the voltage at ignition switch connector C-309.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Measure the voltage between terminal 1 and ground.

- The voltage should measure approximately 12 volts (battery positive voltage).

Is the measured voltage approximately 12 volts (battery positive voltage)?

STEP 3. Check the fuse No.14.

Is the check result normal?

Replace the fuse No.14. (Check that there is not a short to ground in the circuit of lower reaches before replacing. If there are any problems, replace the fuse after the circuit of lower reaches is repaired.)

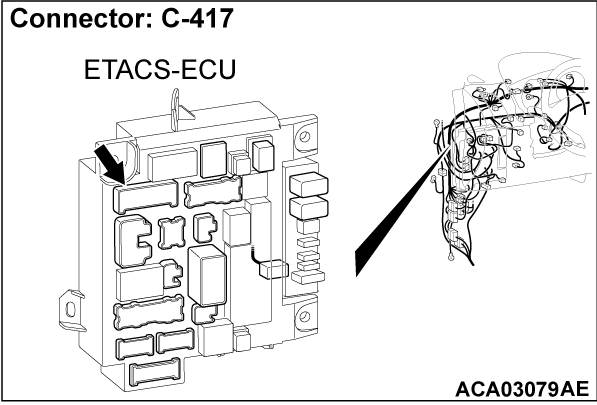

Replace the fuse No.14. (Check that there is not a short to ground in the circuit of lower reaches before replacing. If there are any problems, replace the fuse after the circuit of lower reaches is repaired.)STEP 4. Check ETACS-ECU connector C-417 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

STEP 5. Check the wiring harness between ignition switch connector C-309 (terminal 1) and ETACS-ECU connector C-417 (terminal 3).

- Check the battery power supply line for open circuit.

| note | Before the wiring harness check, check the joint connector C-231, and repair them if necessary. |

Is the check result normal?

Repair the wiring harness.

Repair the wiring harness.STEP 6. Check the ignition switch.

Remove the ignition switch. Then check continuity between the switch terminal.

Replace the ignition switch.

Replace the ignition switch.

|

Is the ignition switch in good condition?

Replace the ignition switch.

Replace the ignition switch.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)