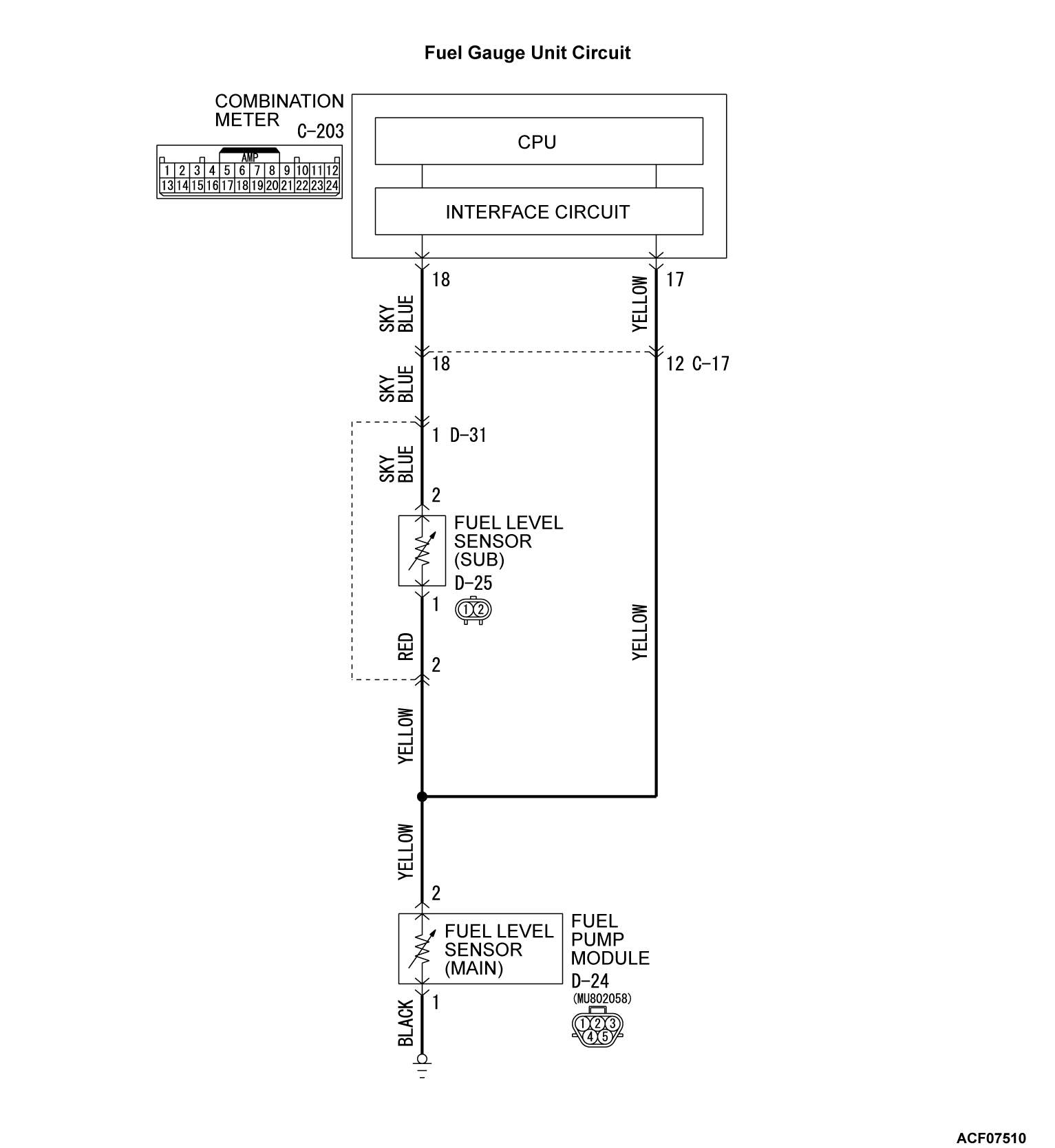

DTC B1201: Abnormal fuel information <AWD>

TROUBLE JUDGMENT

With the ignition switch at the ON position and the system voltage at 10 - 16 volts (data from ETACS-ECU), if the combination meter detects the abnormal resistance of fuel level sensor circuit for 64 seconds continuously, DTC B1201 is set.

TROUBLESHOOTING HINTS

- The fuel pump module [fuel level sensor (main)] may be defective.

- The fuel level sensor (sub) may be defective.

- The combination meter may be defective.

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

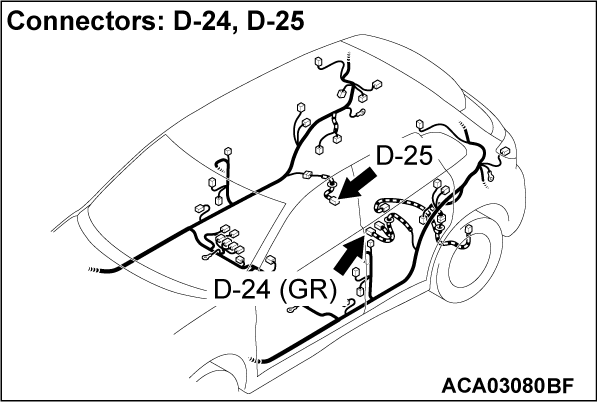

STEP 1. Check fuel pump module [fuel level sensor (main)] connector D-24 and fuel level sensor (sub) connector D-25 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is fuel pump module [fuel level sensor (main)] connector D-24 and fuel level sensor (sub) connector D-25 in good condition?

Repair the connector.

Repair the connector.STEP 2. Check the fuel level sensor.

Check to see if the fuel level sensor is normal (Refer to  ).

). Replace the fuel level sensor.

Replace the fuel level sensor.

).

).Is the check result normal?

Replace the fuel level sensor.

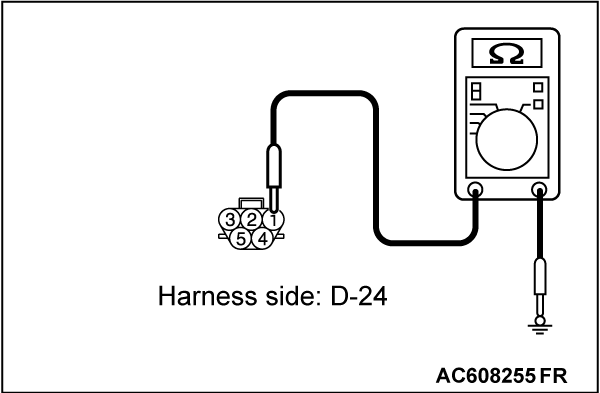

Replace the fuel level sensor.STEP 3. Measure the resistance at fuel pump module [fuel level sensor (main)] connector D-24.

(1) Disconnect fuel pump module [fuel level sensor (main)] connector D-24, and measure at the wiring harness side.

(2) Measure the resistance value between terminal 1 and ground.

- The measured value should be 2 ohm or less.

Does the measured resistance value correspond with this range?

STEP 4. Check the wiring harness between fuel pump module [fuel level sensor (main)] connector D-24 (terminal 1) and ground.

- Check the ground wire for open circuit.

Is the wiring harness between fuel pump module [fuel level sensor (main)] connector D-24 (terminal 1) and ground in good condition?

There is no action to be taken.

There is no action to be taken. Repair the wiring harness.

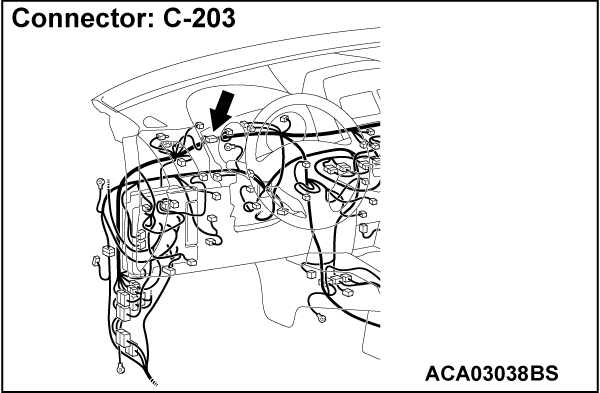

Repair the wiring harness.STEP 5. Check combination meter connector C-203 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

STEP 6. Check the wiring harness between fuel pump module [fuel level sensor (main)] connector D-24 (terminal 2) and combination meter connector C-203 (terminal 17 or 18).

- Check the communication lines for open circuit and short circuit.

| note | Also check intermediate connectors C-17 and D-31. If intermediate connectors C-17 and D-31 are damaged, repair or replace the connector as described in GROUP 00E, Harness Connector Inspection  . . |

Are the wiring harness between fuel pump module [fuel level sensor (main)] connector D-24 (terminal 2) and combination meter connector C-203 (terminal 17 or 18) in good condition?

Repair the wiring harness. The fuel gauge should work normally.

Repair the wiring harness. The fuel gauge should work normally.STEP 7. Using scan tool MB991958, perform actuator test.

- Item 03: Fuel gauge (target value): 0 →100%

- Fuel gauge shows 100 %

Is the check result normal?

Replace the combination meter.

Replace the combination meter.STEP 8. Recheck for diagnostic trouble code.

Check again if the DTC is set in the combination meter. Replace the combination meter.

Replace the combination meter. The procedure is complete.

The procedure is complete.

(1) Erase the DTC.

(2) Turn the ignition switch from "LOCK" (OFF) position to "ON" position.

(3) Check if DTC is set.

Is the DTC set?

Replace the combination meter.

Replace the combination meter. The procedure is complete.

The procedure is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)