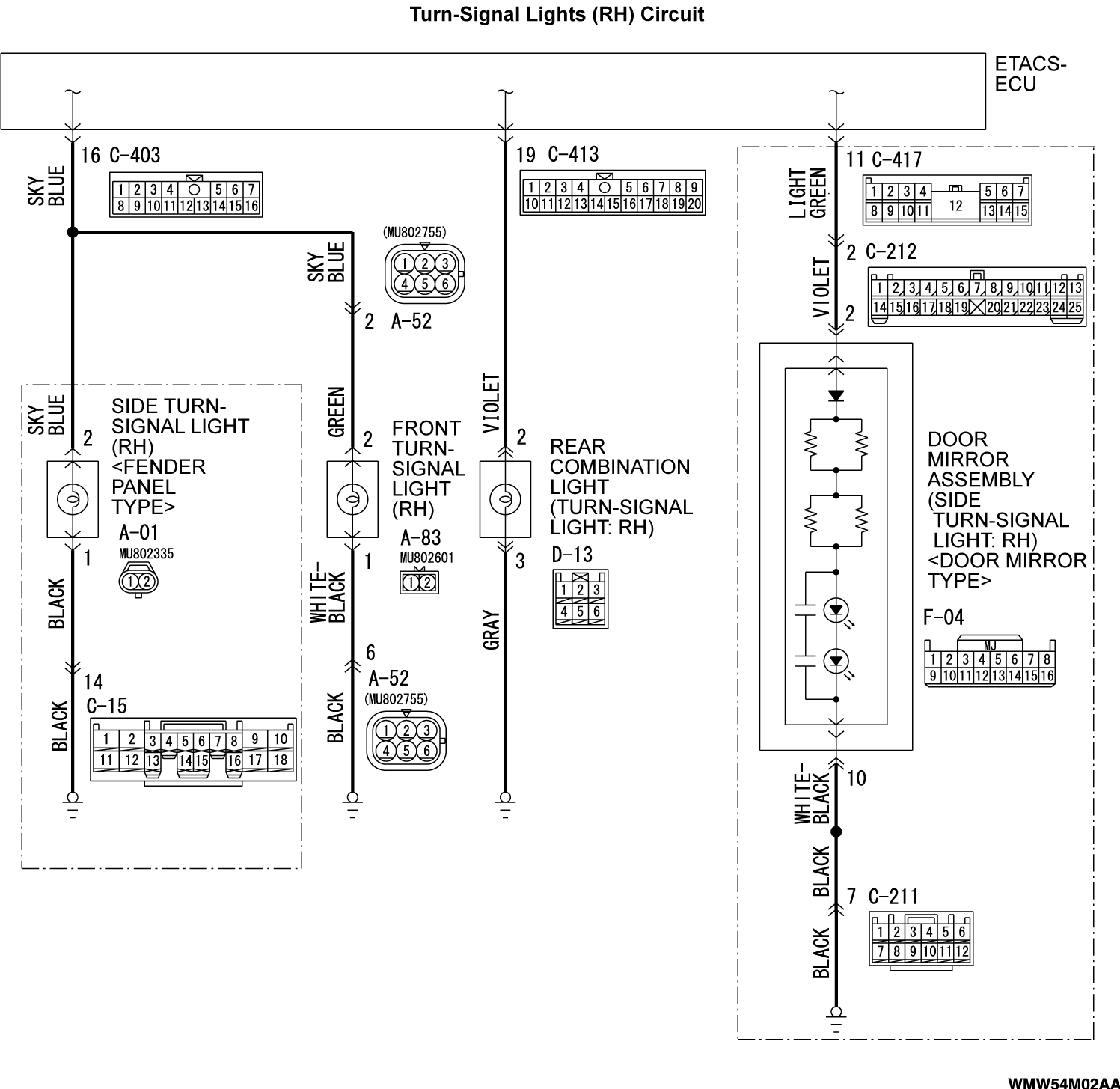

DTC B16A4: Blown turn-signal light (RH) bulb

| caution | Whenever the ECU is replaced, ensure that the power supply circuit, the ground circuit and the communication circuit are normal. |

DIAGNOSTIC FUNCTION

When the right bulb of turn-signal light is blown, the ETACS-ECU sets DTC B16A4.

TECHNICAL DESCRIPTION (COMMENT)

The ETACS-ECU sets DTC B16A4 under the following conditions.

- If there is a malfunction to the right turn-signal light bulb, the blown right bulb counter counts once when the illumination of hazard or turn-signal light (right side) is attempted.

- If the blown right bulb counter reaches "3," DTC B16A4 is set.

TROUBLESHOOTING HINTS

- Malfunction of turn-signal light bulb (right side)

- Malfunction of the ETACS-ECU

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB992006: Extra fine probe

- MB991223: Harness set

STEP 1. Bulb check.

Check whether the bulb of turn-signal light which does not illuminate is normal. Replace the bulb of turn-signal light which does not illuminate.

Replace the bulb of turn-signal light which does not illuminate.

Is the check result normal?

Replace the bulb of turn-signal light which does not illuminate.

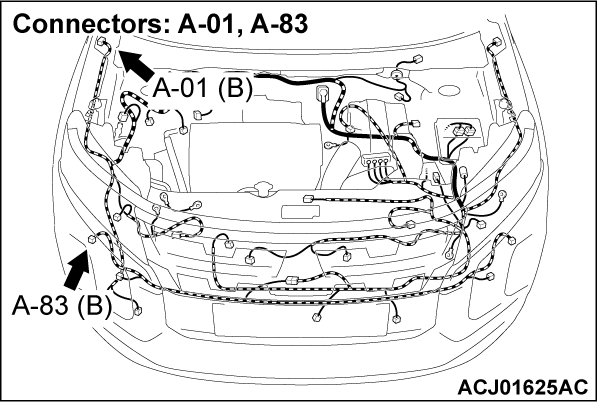

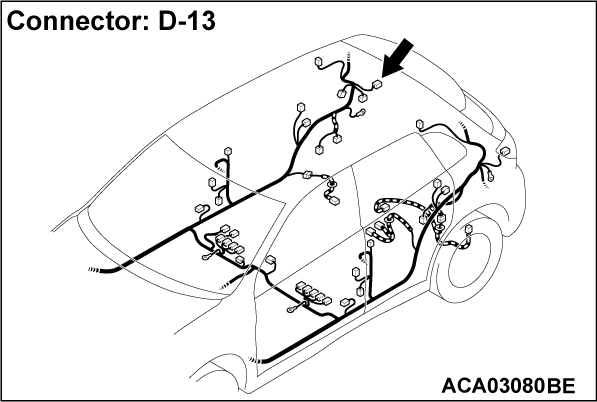

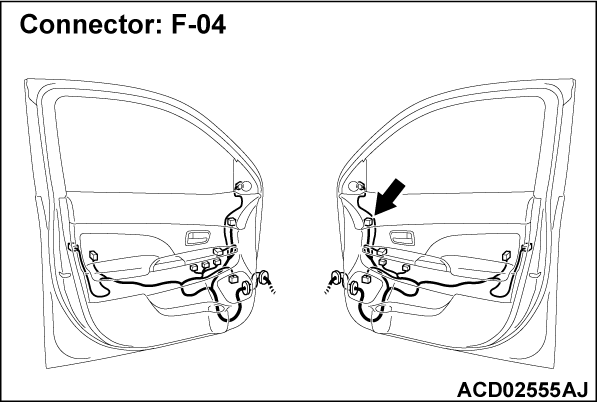

Replace the bulb of turn-signal light which does not illuminate.STEP 2. Check front turn-signal light (RH) connector A-83 <front>, side turn-signal light (RH) connector A-01 <side (fender panel type)>, door mirror assembly (RH) connector F-04 <side (door mirror type)>, rear combination light (RH) connector D-13 <rear> for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Are front turn-signal light (RH) connector A-83 <front>, side turn-signal light (RH) connector A-01 <side (fender panel type)>, door mirror assembly (RH) connector F-04 <side (door mirror type)>, rear combination light (RH) connector D-13 <rear> in good condition?

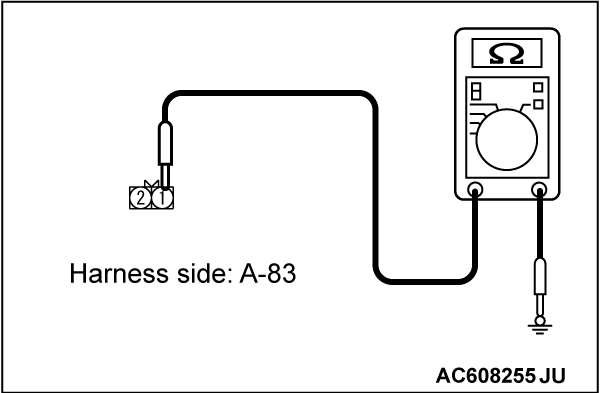

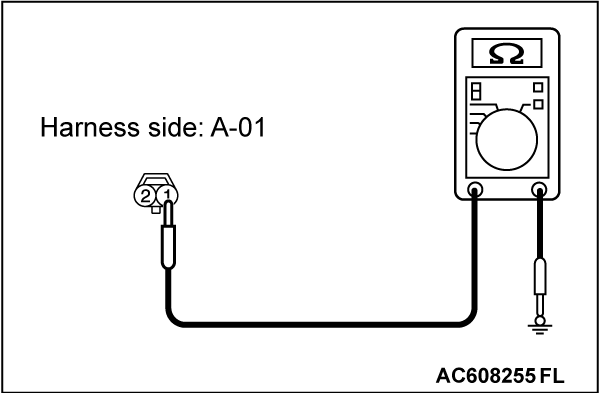

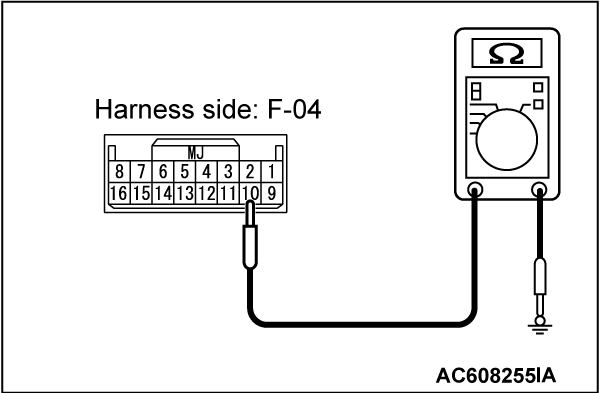

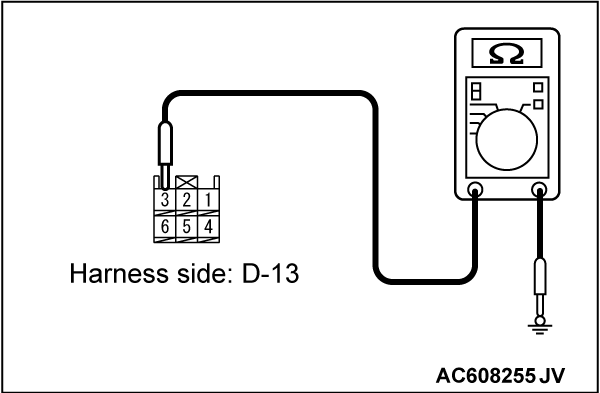

STEP 3. Resistance measurement at front turn-signal light (RH) connector A-83 <front>, side turn-signal light (RH) connector A-01 <side (fender panel type)>, door mirror assembly (RH) connector F-04 <side (door mirror type)>, rear combination light (RH) connector D-13 <rear>.

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Measure the resistance between the connector terminal of light which does not illuminate and body ground.

- Measure the resistance between the front turn-signal light (RH) connector A-83 (terminal 1) and body ground. <Front>

- Measure the resistance between the side turn-signal light (RH) connector A-01 (terminal 1) and body ground. <side (fender panel type)>

- Measure the resistance between the door mirror assembly (RH) connector F-04 (terminal 10) and body ground. <side (door mirror type)>

- Measure the resistance between the rear combination light (RH) connector D-13 (terminal 3) and body ground.

OK: The measured value should be continuity exists (2 ohm or less).

Does the measured resistance value correspond with this range?

STEP 4. Check the wiring harness between front turn-signal light (RH) connector A-83 (terminal 1) <front>, side turn-signal light (RH) connector A-01 (terminal 1) <side (fender panel type)>, door mirror assembly (RH) connector F-04 (terminal 10) <side (door mirror type)>, rear combination light (RH) connector D-13 (terminal 3) <rear> and ground.

- Check the ground wires for open circuit.

Are the wiring harness between front turn-signal light (RH) connector A-83 (terminal 1) <front>, side turn-signal light (RH) connector A-01 (terminal 1) <side (fender panel type)>, door mirror assembly (RH) connector F-04 (terminal 10) <side (door mirror type)>, rear combination light (RH) connector D-13 (terminal 3) <rear> and ground in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

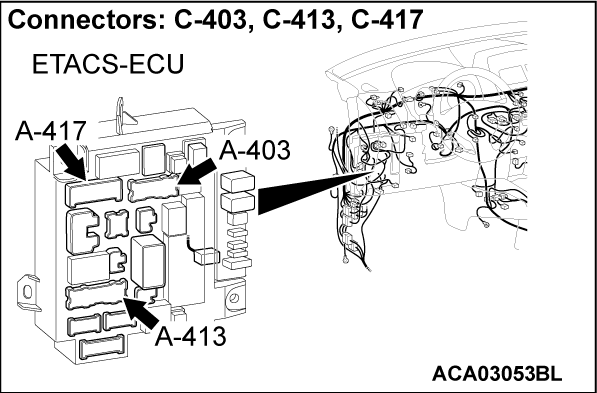

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 5. Check ETACS-ECU connectors C-403 <front or side (fender panel type)>, C-417 <side (door mirror type)> and C-413 <rear> for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Are ETACS-ECU connectors C-403 <front or side (fender panel type)>, C-417 <side (door mirror type)> and C-413 <rear> in good condition?

STEP 6. Check the wiring harness between front turn-signal light (RH) connector A-83 (terminal 2) <front>, side turn-signal light (RH) connector A-01 (terminal 2) <side (fender panel type)>, door mirror assembly (RH) connector F-04 (terminal 2) <side (door mirror type)>, rear combination light (RH) connector D-13 (terminal 2) <rear> and ETACS-ECU connector C-403 (terminal 16) <front or side (fender panel type)>, C-417 (terminal 11) <side (door mirror type)> or C-413 (terminal 19) <rear>.

- Check the power supply line for open circuit.

Are the wiring harness between front turn-signal light (RH) connector A-83 (terminal 2) <front>, side turn-signal light (RH) connector A-01 (terminal 2) <side (fender panel type)>, door mirror assembly (RH) connector F-04 (terminal 2) <side (door mirror type)>, rear combination light (RH) connector D-13 (terminal 2) <rear> and ETACS-ECU connector C-403 (terminal 16) <front or side (fender panel type)>, C-417 (terminal 11) <side (door mirror type)> or C-413 (terminal 19) <rear> in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary.STEP 7. Using scan tool MB991958, Check whether the diagnostic trouble code is set again.

(1)

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(2) Turn the ignition switch to the "ON" position.

(3) Erase the DTC.

(4) Turn the ignition switch from "LOCK" (OFF) position to "ON" position.

(5) Check if DTC is set.

Is the DTC set?

Replace the ETACS-ECU.

Replace the ETACS-ECU. The procedure is complete.

The procedure is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)