INSPECTION PROCEDURE: Liftgate Lock Release Handle Signal is not Received.

| caution | Before replacing the ECU, ensure that the power supply circuit, the ground circuit and the communication circuit are normal. |

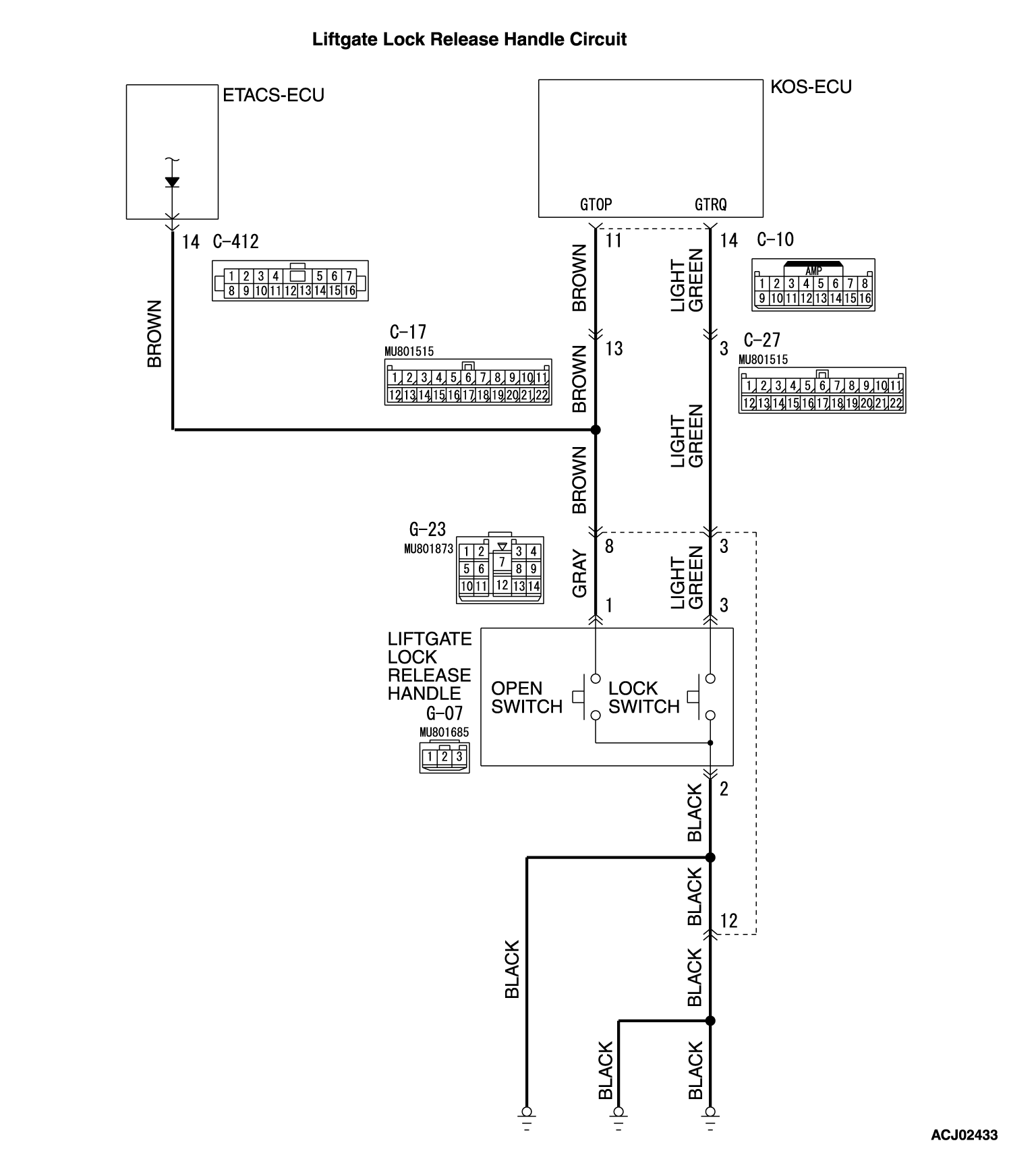

CIRCUIT OPERATION

The ETACS-ECU operates the liftgate according to signal from the liftgate lock release handle.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the liftgate will not work normally. If the signal is not normal, the liftgate lock release handle or the ETACS-ECU may be defective.

TROUBLESHOOTING HINTS

- The liftgate lock release handle may be defective

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

- The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

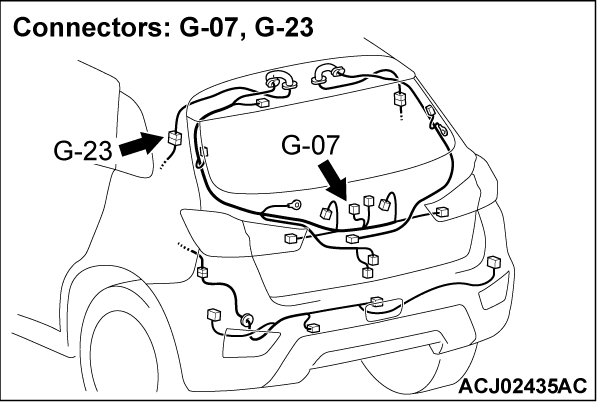

STEP 1. Check liftgate lock release handle connector G-07 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is liftgate lock release handle connector G-07 in good condition?

STEP 2. Check the liftgate lock release handle.

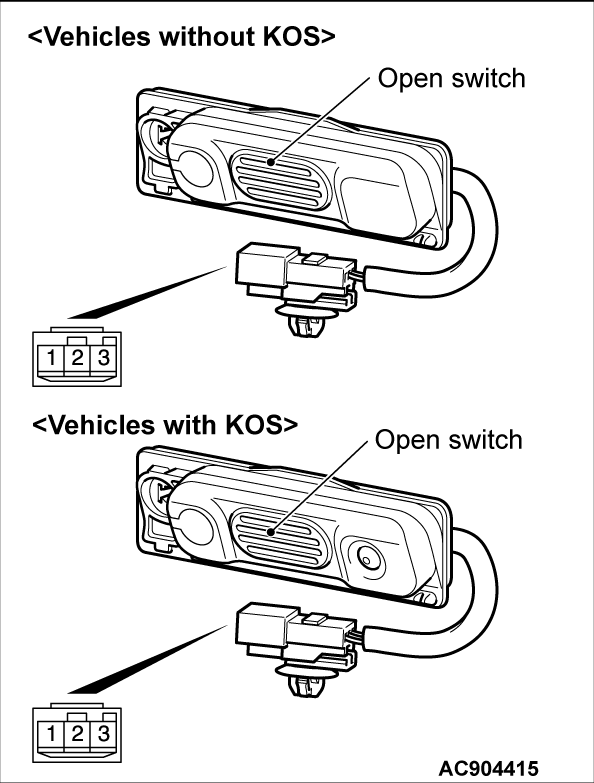

Remove the liftgate lock release handle. Refer to GROUP 42A, Liftgate Handle and Latch  . Then check continuity between the switch terminals.

. Then check continuity between the switch terminals.

Repair the liftgate lock release handle. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

Repair the liftgate lock release handle. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

. Then check continuity between the switch terminals.

. Then check continuity between the switch terminals.<LIFTGATE OPEN SWITCH (VEHICLES WITHOUT KOS)>

|

<LIFTGATE OPEN SWITCH (VEHICLES WITH KOS)>

|

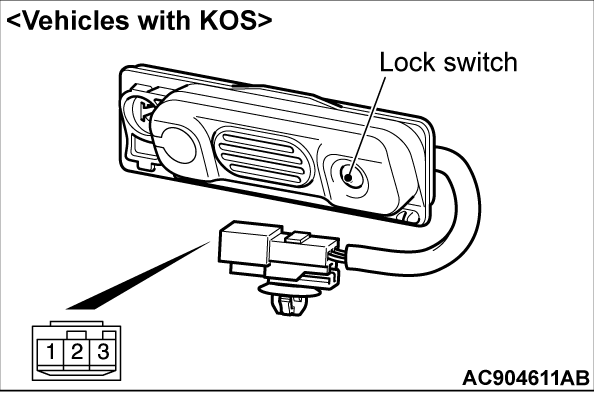

<LIFTGATE LOCK SWITCH (VEHICLES WITH KOS)>

|

Is the liftgate lock release handle in good condition?

Repair the liftgate lock release handle. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

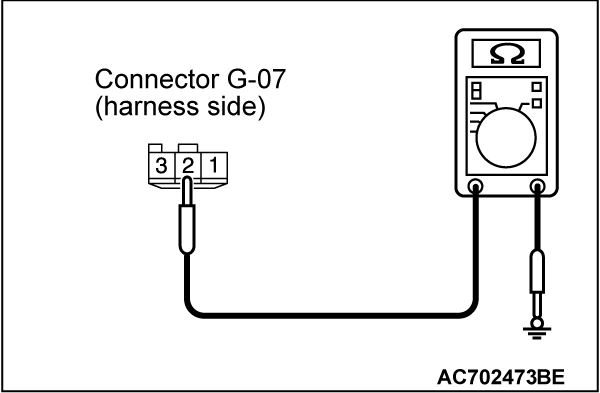

Repair the liftgate lock release handle. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.STEP 3. Check the ground circuit to the liftgate lock release handle. Measure the resistance at liftgate lock release handle connector G-07.

(1) Disconnect liftgate lock release handle connector G-07 and measure the resistance on the wiring harness side of the connector.

(2) Measure the resistance value between terminal 2 and ground.

- The resistance should be 2 ohms or less.

Is the measured resistance 2 ohms or less?

STEP 4. Check the wiring harness between liftgate lock release handle connector G-07 (terminal 2) and ground.

- Check the power supply line for open circuit and short circuit.

Is the wiring harness between liftgate lock release handle connector G-07 (terminal 2) and ground in good condition?

No action is necessary and testing is complete.

No action is necessary and testing is complete. The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

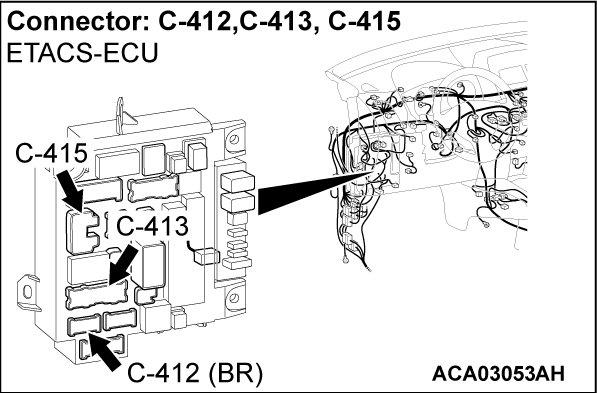

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.STEP 5. Check ETACS-ECU connector C-412 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is ETACS-ECU connector C-412 in good condition?

STEP 6. Check the wiring harness between liftgate lock release handle connector G-07 (terminal 1) and ETACS-ECU connector C-412 (terminal 14).

- Check the power supply line for open circuit and short circuit.

Is the wiring harness between liftgate lock release handle connector G-07 (terminal 1) and ETACS-ECU connector C-412 (terminal 14) in good condition?

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair the wiring harness as necessary. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.STEP 7. Using scan tool MB991958, check data list.

Check the signals related to the liftgate lock release handle operation. No action is necessary and testing is complete.

No action is necessary and testing is complete. Replace the ETACS-ECU. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

Replace the ETACS-ECU. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

(1)

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(2) Turn the ignition switch to the "ON" position.

(3) Check the data list of the ETACS.

- Liftgate lock release handle: From OFF to ON

|

(4) Turn the ignition switch to the "LOCK" (OFF) position.

OK: Normal condition is displayed.

Is the check result normal?

No action is necessary and testing is complete.

No action is necessary and testing is complete. Replace the ETACS-ECU. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.

Replace the ETACS-ECU. If the liftgate lock release handle operates normally, a correct signal is sent from the liftgate lock release handle.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)