DISASSEMBLY AND ASSEMBLY

Required Special Tools:

- MB992209: Bellows Band Clipping Tool

- MB992249: Variable Spanner

DISASSEMBLY SERVICE POINT

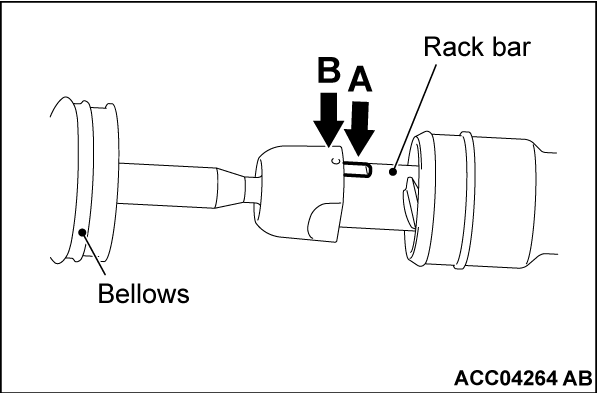

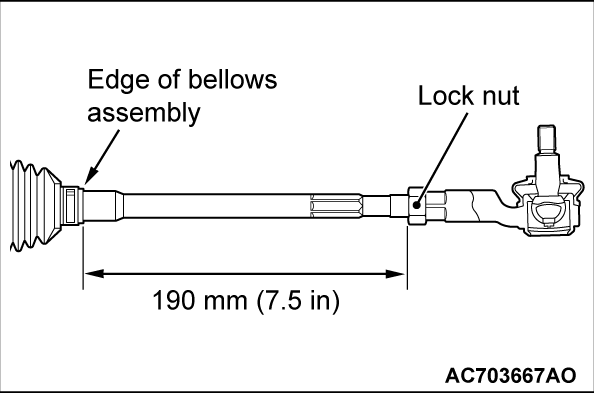

<<A>> TIE-ROD REMOVAL

1.

Fold the left bellows back, and then use a spanner to counterhold the flats (A) on the rack end.

| caution | Be careful not to damage the rack bar and the teeth surface. |

2. Apply the special tool "variable spanner" MB992249 to the B portion as shown to remove the tie rod.

| note | There are not flats on the right rack bar. Therefore, counterhold the left rack end even when you remove the right tie rod. |

ASSEMBLY SERVICE POINTS

>>A<< TIE-ROD INSTALLATION

1.

Fold the left bellows back, and then use a spanner to counterhold the flats (A) on the rack end.

| caution | Be careful not to damage the rack bar and the teeth surface. |

2. Apply the special tool "variable spanner" MB992249 to the B portion as shown to tighten the tie rod to the specified torque.

Tightening torque: 84 ± 14 N·m (62 ± 10 ft-lb)

| note | There are not flats on the right rack bar. Therefore, counterhold the left rack end even when you install the right tie rod. |

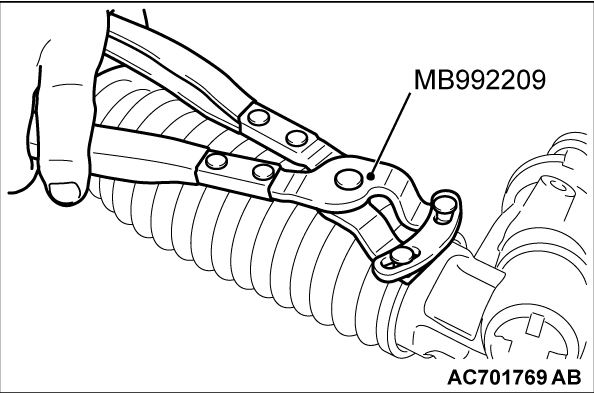

>>B<< BAND INSTALLATION

1.

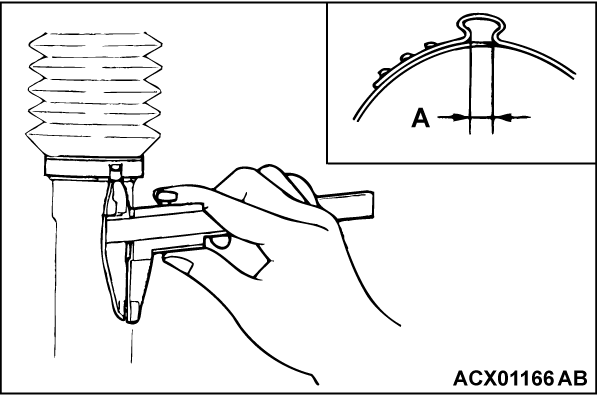

Use special tool MB992209 to crimp the bellows band.

| caution |

|

2. Check that crimped width (A) is within the standard value.

Standard value (A): 2.4 - 2.8 mm (0.10 - 0.11 inch)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)