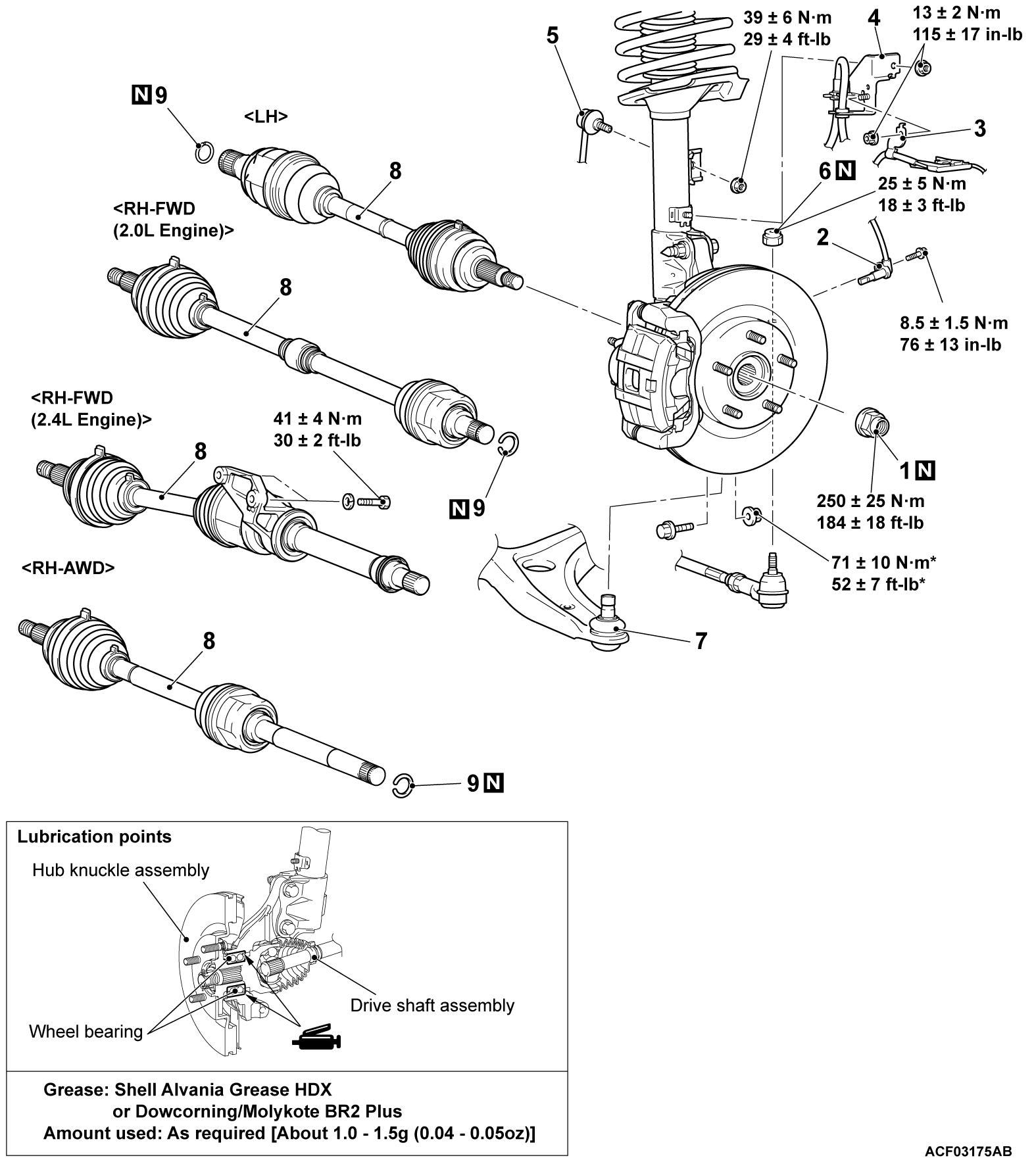

REMOVAL AND INSTALLATION

| caution |

|

Pre-removal operation | Post-installation operation |

Required Special Tools:

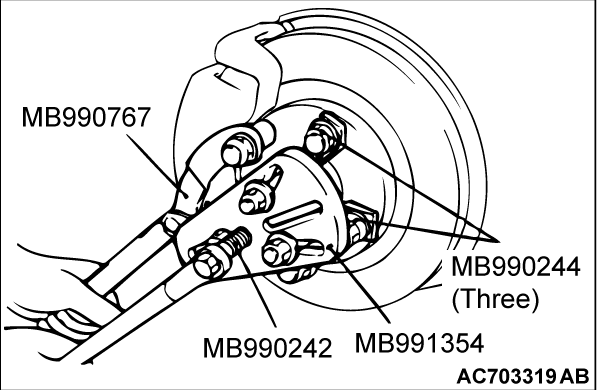

- MB990242: Puller Shaft

- MB990244: Puller Bar

- MB990767: Front Hub and Flange Yoke Holder

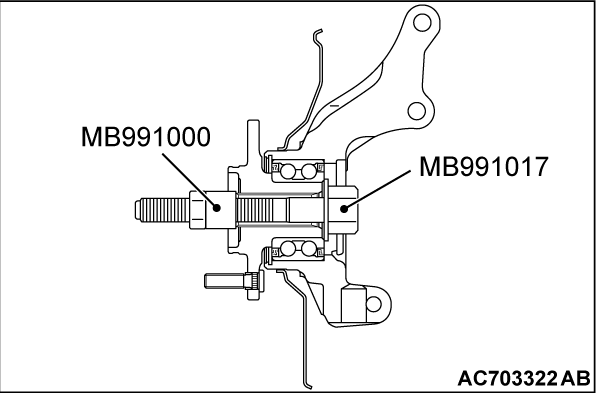

- MB991000: Spacer

- MB991017: Front Hub Remover and Installer

- MB991354: Puller Body

- MB991897 or MB992011: Ball Joint Remover

- MB992700: Lock Nut Chisel

REMOVAL SERVICE POINTS

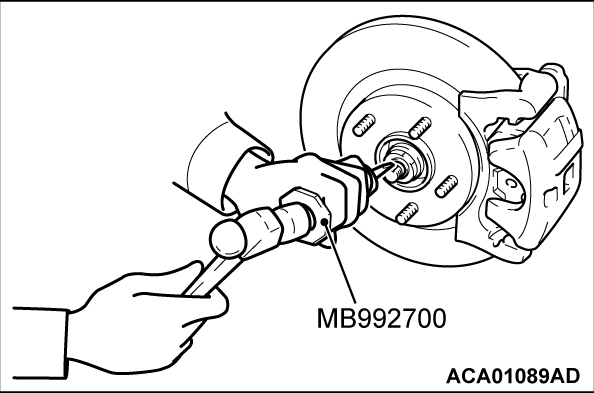

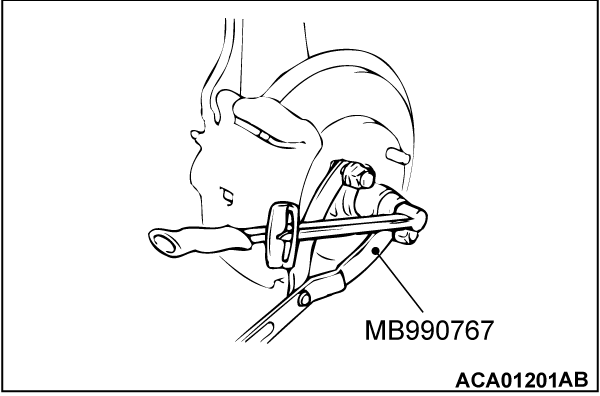

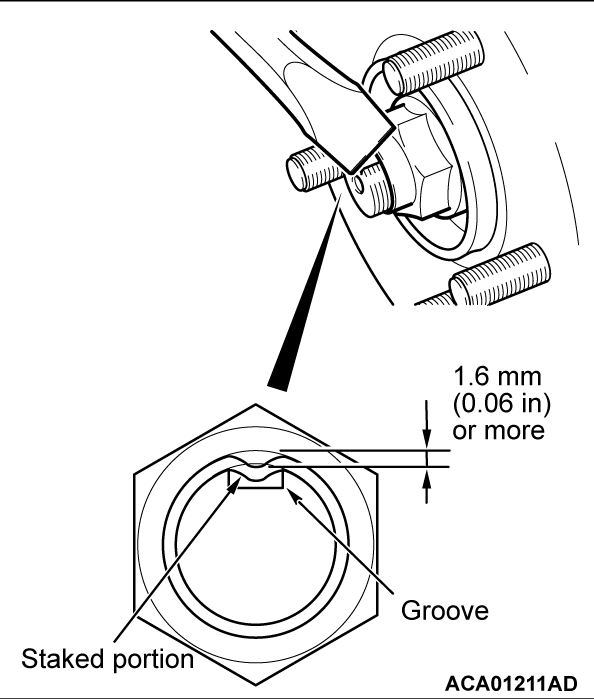

<<A>> DRIVESHAFT NUT REMOVAL

1. The staked portion of the driveshaft nut must face upwards.

2.

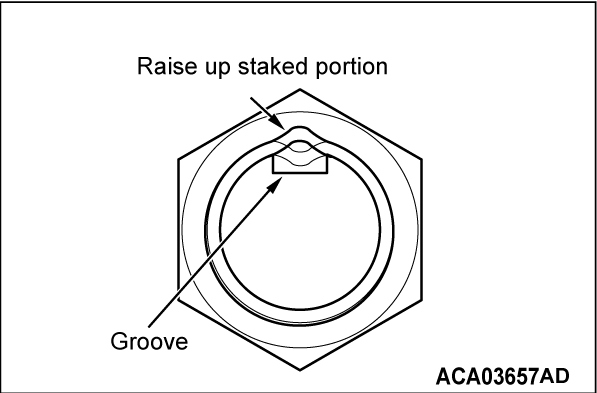

Set the special tool MB992700 in the groove of the driveshaft with its "UPPER" mark facing upwards. Then strike the staked portion of the driveshaft nut with the chisel and a hammer to raise up.

| caution |

|

3.

Raise up the staked portion of the driveshaft nut until it does not interfere with the shaft thread.

| caution | Be careful not to damage the thread of the driveshaft. |

4.

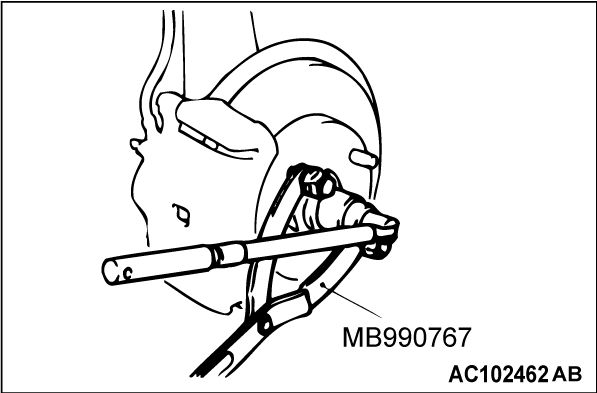

Use special tool MB990767 to counter the hub as shown in the figure to remove the driveshaft nut.

| caution |

|

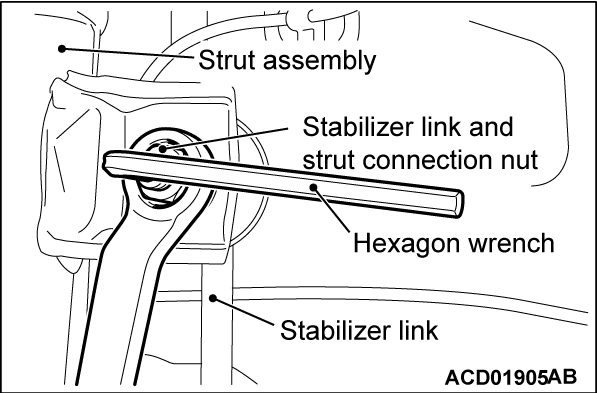

<<B>> STABILIZER LINK DISCONNECTION

Use a hexagon wrench to counterhold the stabilizer link as shown. Then use a wrench to remove the nut securing the stabilizer link to the strut.

<<C>> SELF-LOCKING NUT (TIE-ROD END CONNECTION) REMOVAL

1.

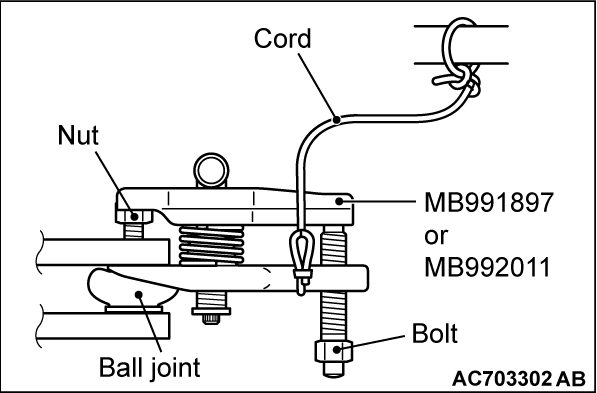

Install special tool MB991897 or MB992011, as shown in the figure.

| caution |

|

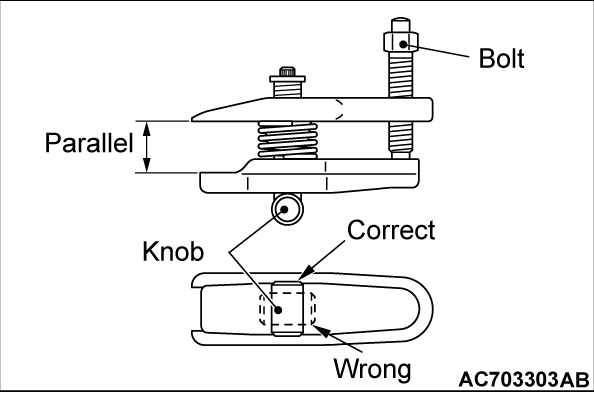

2. Turn the bolt and knob to make the special tool jaws parallel, then hand-tighten the bolt. After tightening, check that the jaws are still parallel.

| note | To adjust the special tool jaws to be parallel, set the orientation of the knob as shown in the figure. |

3. Unscrew the bolt to disconnect the ball joint.

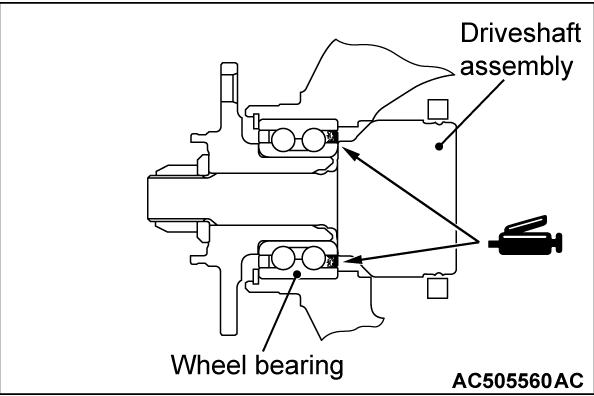

<<D>> DRIVESHAFT ASSEMBLY REMOVAL

1.

If the driveshaft is seized with the hub, use special tools MB990242 and MB990244, MB990767 and MB991354 to push the driveshaft assembly out from the hub.

| caution |

|

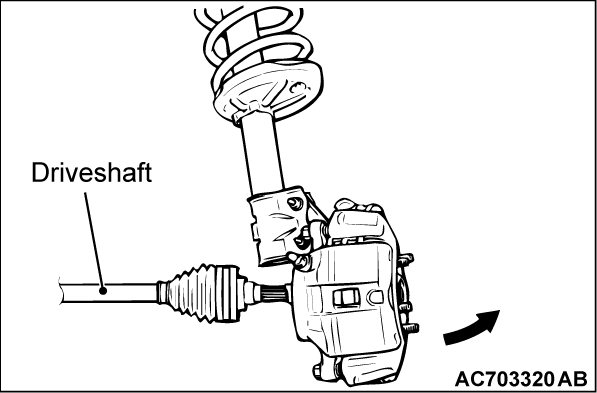

2. While pulling the lower side of the brake disk toward you, remove the driveshaft assembly from the hub.

| caution |

|

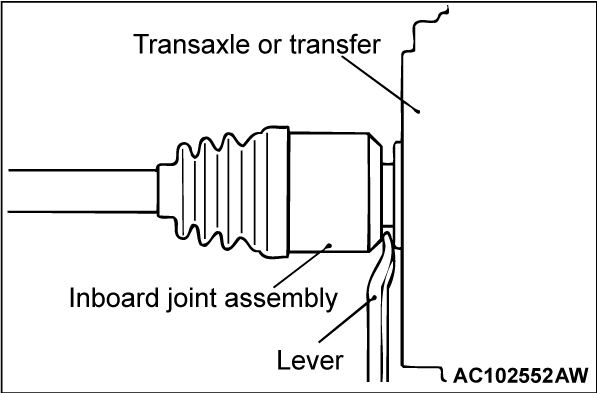

3. Insert a lever between the transaxle case or transfer and driveshaft assembly, and then pull the driveshaft assembly out from the transaxle.

| caution | Do not apply the vehicle weight to the wheel bearing with the driveshaft assembly removed. If, however, the vehicle weight shall be applied to the bearing (in order to move the vehicle), tighten the special tools MB991000 and MB991017 to the specified torque 250 ± 25 N·m (184 ± 18 ft-lb). |

INSTALLATION SERVICE POINTS

>>A<< DRIVESHAFT ASSEMBLY INSTALLATION

| caution |

|

>>B<< STABILIZER LINK CONNECTION

Use a hexagon wrench to counterhold the stabilizer link as shown. Then use a wrench to install the nut securing the stabilizer link to the strut.

>>C<< DRIVESHAFT NUT INSTALLATION

| caution |

|

1. Check the hub seated surface for damage or corrosion.Whenever solvent is used for removing the corrosion, the surface should be degreased.

2. Apply the grease as shown and then insert the drive shaft assembly into the front hub.

Specified grease: Shell Alvania Grease HDX or Dowcorning/Molykote BR2 Plus

Amount to use: As required [About 1.0 - 1.5 g (0.04 - 0.05 oz)]

3. Check that the new driveshaft nut can be turned smoothly by hand. Then tighten it until it is seated.

4. Using special tool MB990767, tighten the driveshaft nut.

Tightening torque: 250 ± 25 N·m (184 ± 18 ft-lb)

5. After tightening to the specified torque, check that the nut is seated securely.

6. Use the chisel and a hammer to stake the nut until the center in the staked portion reaches the shown dimension.

7. Finally, check that the nut is not cracked at its staked portion.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)