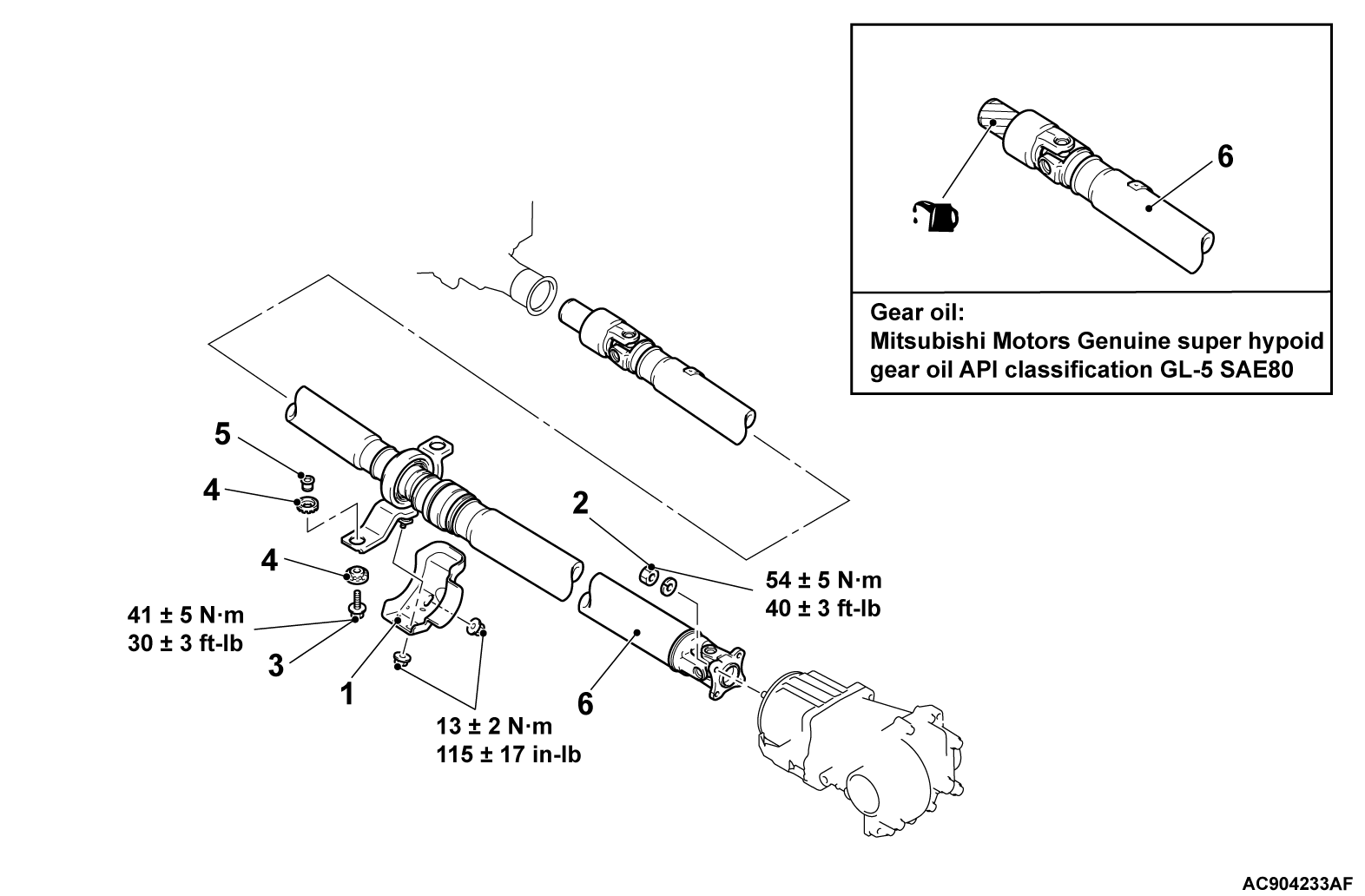

REMOVAL AND INSTALLATION

Pre-removal and Post-installation operation |

REMOVAL SERVICE POINTS

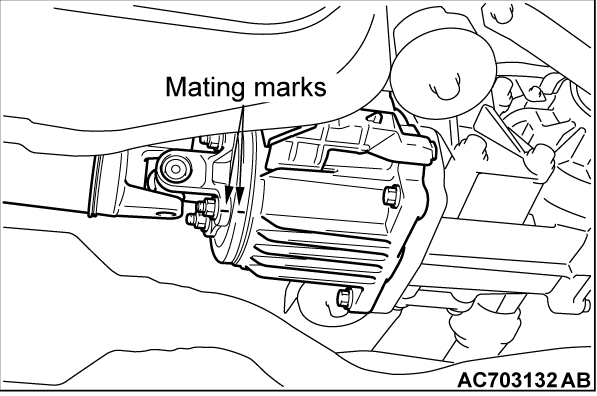

<<A>> FLANGE YOKE AND ELECTRONIC CONTROL COUPLING CONNECTING NUT REMOVAL

Put mating marks on the flange yoke and the electronic control coupling.

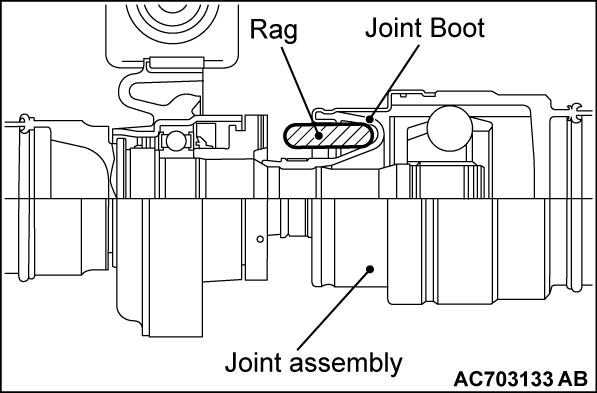

<<B>> PROPELLER SHAFT ASSEMBLY REMOVAL

1.

Insert a waste or similar materials into the joint boots, and remove the propeller shaft assembly by aligning the front propeller shaft with the rear shaft.

| caution | If the joint assembly is bent, it may be damaged when pinching the joint boots. |

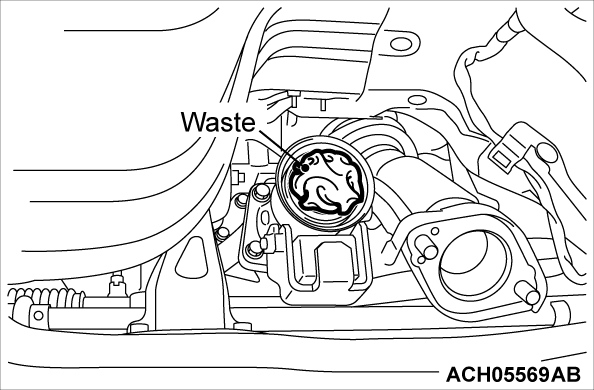

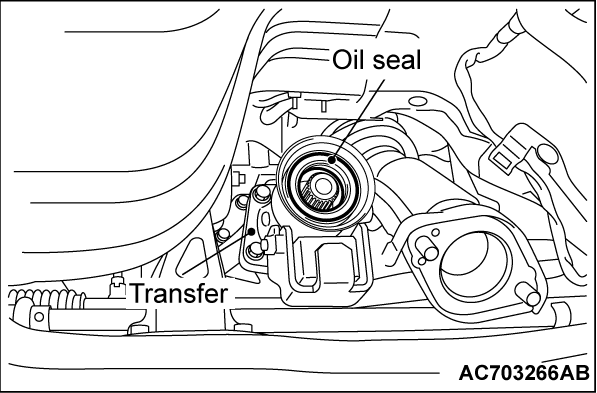

2. Using a lint-free waste cloth, cover the transfer case to prevent the entry of foreign materials.

INSTALLATION SERVICE POINTS

>>A<< PROPELLER SHAFT ASSEMBLY INSTALLATION

| caution |

|

>>B<< FLANGE YOKE AND ELECTRONIC CONTROL COUPLING CONNECTING NUT INSTALLATION

If the propeller shaft is reused, align the mating marks and install the connecting nuts.

Tightening torque: 54 ± 5 N·m (40 ± 3 ft-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)