EVAPORATIVE EMISSION PURGE SOLENOID CHECK

1. Remove the inlet manifold from the evaporative emission (EVAP) purge solenoid valve.

| note | When disconnecting the vacuum hose, always place an identification mark so that it can be reconnected at its original position. |

2. Remove the EVAP purge solenoid valve from the intake manifold.

3. Disconnect the harness connector.

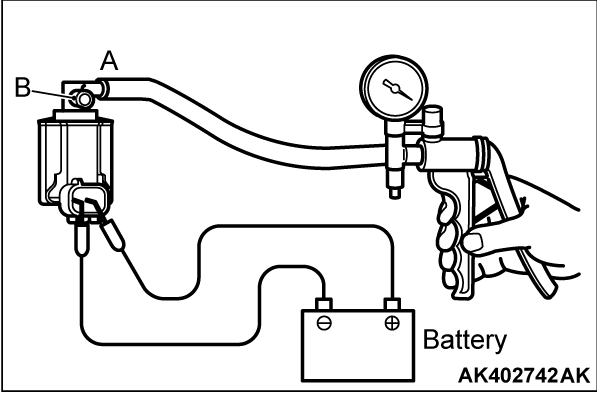

4. Connect a hand vacuum pump to nipple (A) of the EVAP purge solenoid (refer to the illustration at left).

5. As described in the chart below, check airtightness by applying a vacuum with voltage applied directly from the battery to the EVAP purge solenoid valve and without applying voltage.

| Jumper wire | Nipple "B" state | Normal state |

| Connected | Opened | Negative pressure leaks |

| Closed | Negative pressure maintained | |

| Disconnected | Opened | Negative pressure maintained |

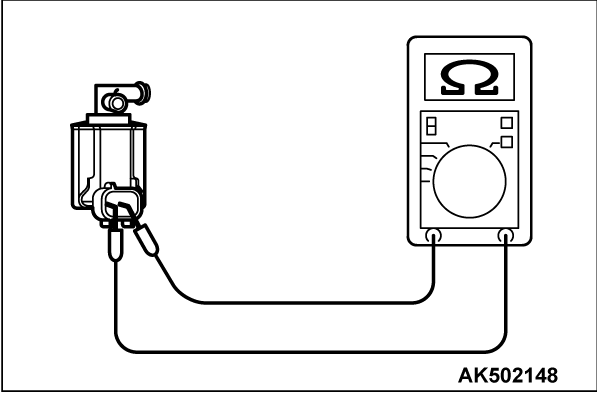

6. Measure the resistance between the terminals of the EVAP purge solenoid.

Standard value: 22 - 26 Ω [at 20°C (68°F)]

7. Replace the solenoid if airtightness or resistance is out of specification.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)