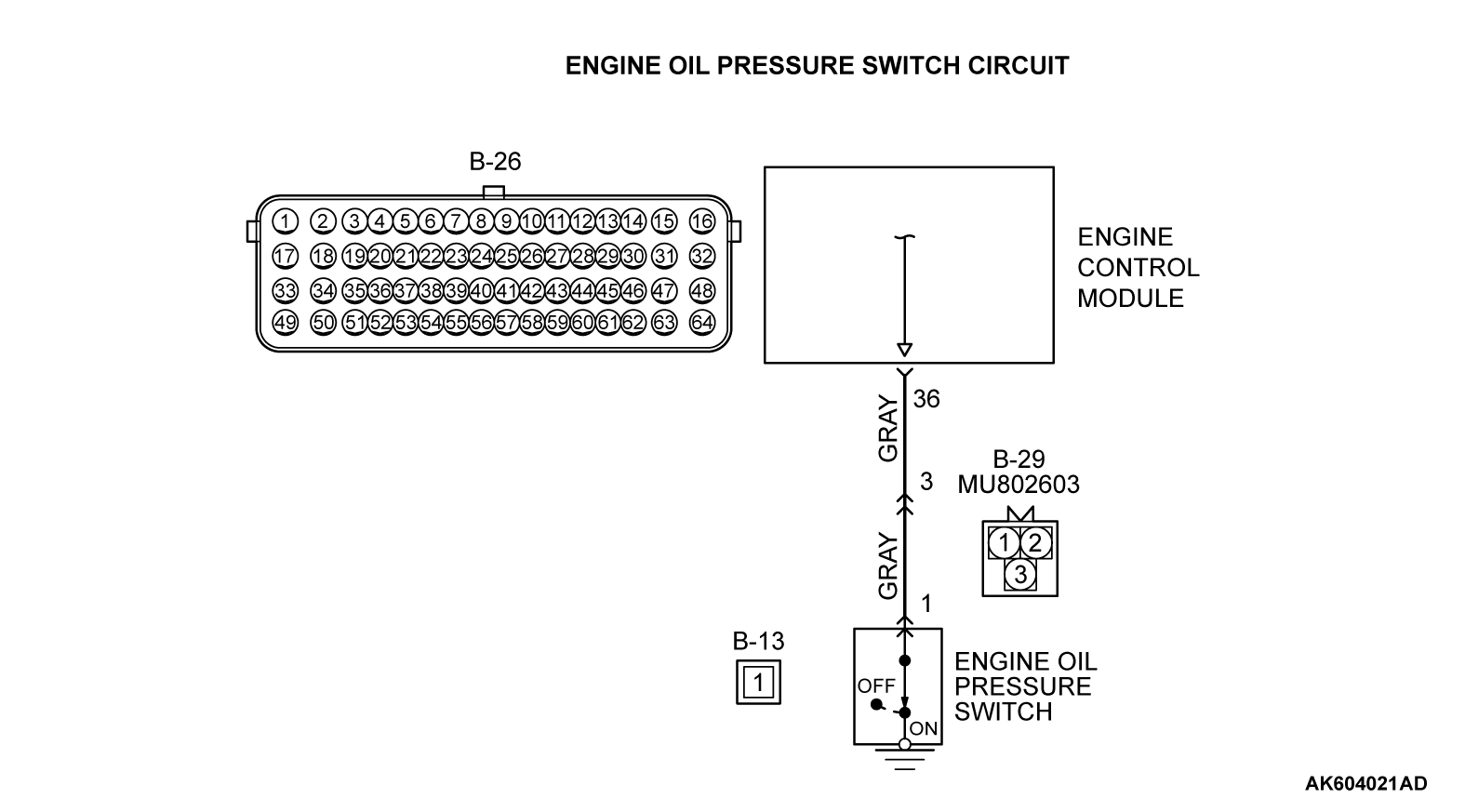

Inspection procedure 27: Engine oil pressure switch system

CIRCUIT OPERATION

- Battery voltage is applied to the engine oil pressure switch (terminal No. 1) from the ECM (terminal No. 36).

COMMENT

- Detect the engine oil pressure conditions and enter the result into the ECM. After starting the engine if the engine oil pressure rises to higher than the given pressure, the engine oil pressure switch turns OFF. Under this condition the ECM sends the command of turning off the oil warning lamp to the combination meter via CAN.

TROUBLESHOOTING HINTS (The most likely causes for this case:)

- Engine oil pressure switch failed.

- Open or shorted engine oil pressure switch circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

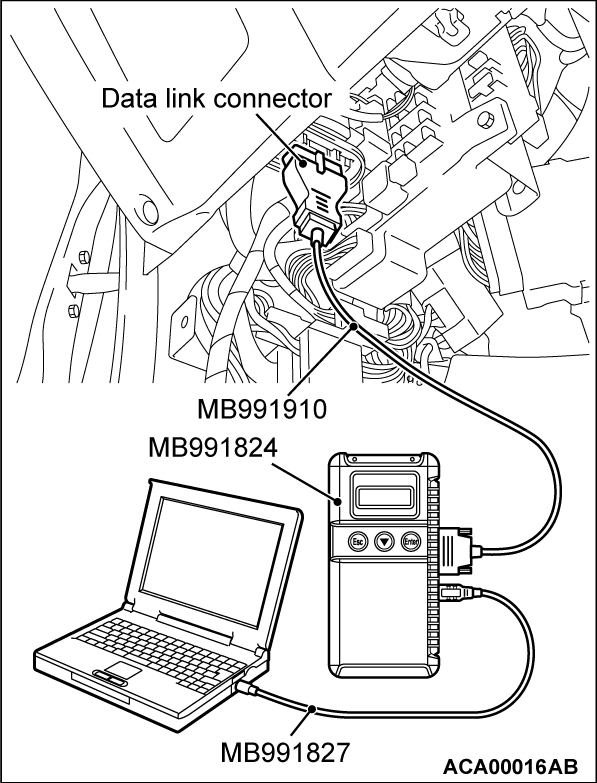

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

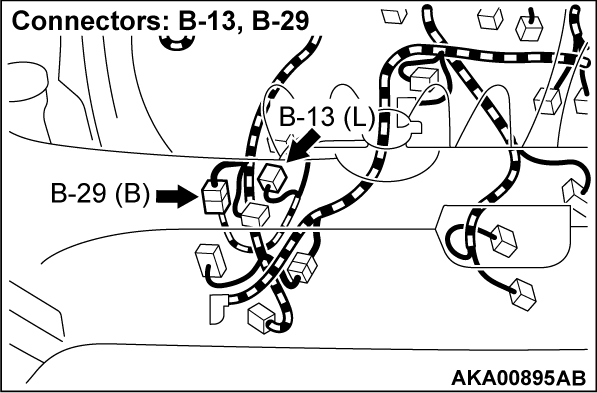

STEP 1. Check harness connector B-13 at engine oil pressure switch for damage.

Is the harness connector in good condition?

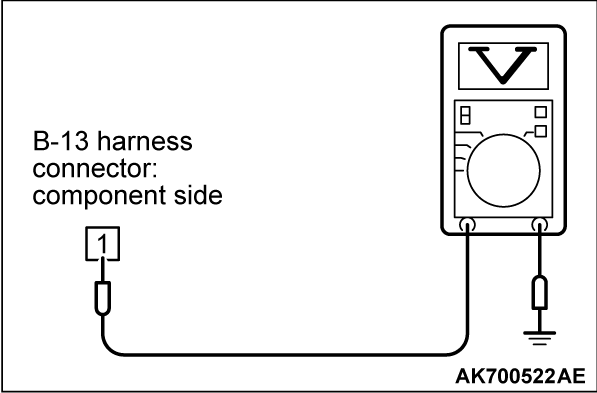

STEP 2. Measure the power supply voltage at engine oil pressure switch harness side connector B-13.

(1) Disconnect the connector B-13 and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 1 and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

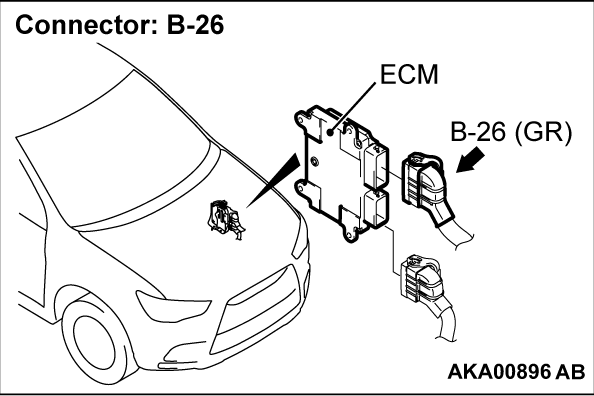

STEP 3. Check harness connector B-26 at ECM for damage.

Is the harness connector in good condition?

STEP 4. Check for open circuit and short circuit to ground between ECM connector B-26 (terminal No. 36) and engine oil pressure switch connector B-13 (terminal No. 1)

Is the harness wire in good condition?

Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.STEP 5. Using scan tool MB991958, check data list item 90: Engine Oil Pressure Switch.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool MB991958 to the data reading mode for item 90, Engine Oil Pressure Switch.

- When the engine is stopped, "ON" should be displayed.

- When the engine is idling, "OFF" should be displayed.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the operating properly?

STEP 6. Check harness connector B-26 at ECM for damage.

Is the harness connector in good condition?

STEP 7. Check for harness damage between ECM connector B-26 (terminal No. 36) and engine oil pressure switch connector B-13 (terminal No. 1)

Is the harness wire in good condition?

Replace the engine oil pressure switch. Then confirm that the malfunction symptom is eliminated.

Replace the engine oil pressure switch. Then confirm that the malfunction symptom is eliminated. Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)