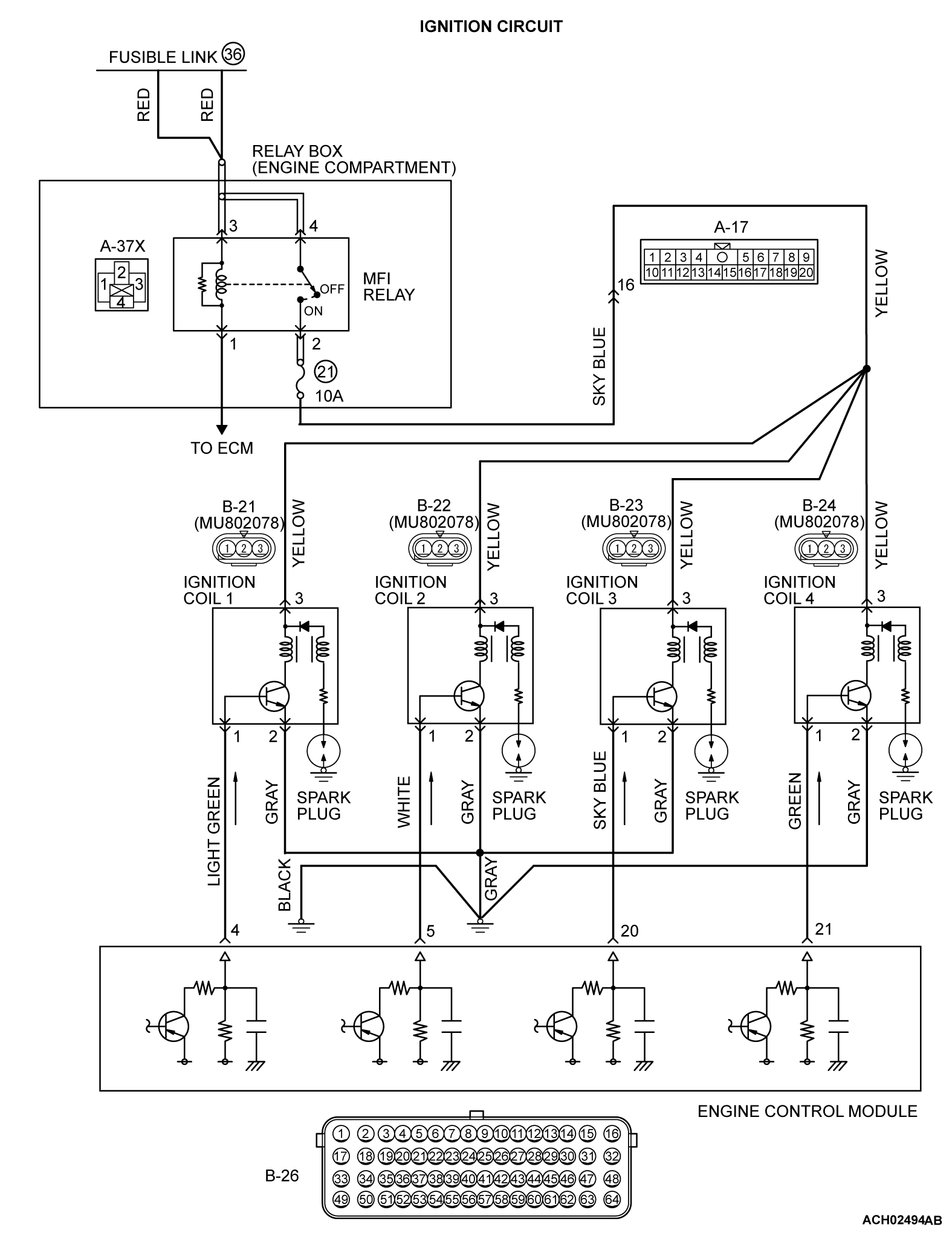

Inspection procedure 25: Ignition circuit system

CIRCUIT OPERATION

- The battery positive voltage is applied from the MFI relay (terminal No. 2) to the ignition coil (terminal No. 3) and is grounded to the vehicle body via the ignition coil (terminal No. 2).

- A power voltage of 5 V is applied to the ignition coil (terminal No. 1) from the ECM (terminal No. 4, No. 5, No. 20 and No. 21).

COMMENT

- When the ECM turn the power transistor in the unit to OFF, the battery positive voltage is applied to the power transistor in the ignition coil, resulting that the power transistor is ON. And, when the ECM turns the power transistor in the unit to ON, the power transistor in the ignition coil will be turned OFF.

- When the power transistor in the ignition coil is turned to ON with any signal from the ECM, the primary voltage will be applied through the ignition coil. When the power transistor in the ignition coil is turned OFF, the primary current is blocked and high voltage is generated in the secondary coil.

TROUBLESHOOTING HINTS (The most likely causes for this case:)

- Ignition coil failed.

- Open or shorted ignition circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

- MB9919658: Test Harness

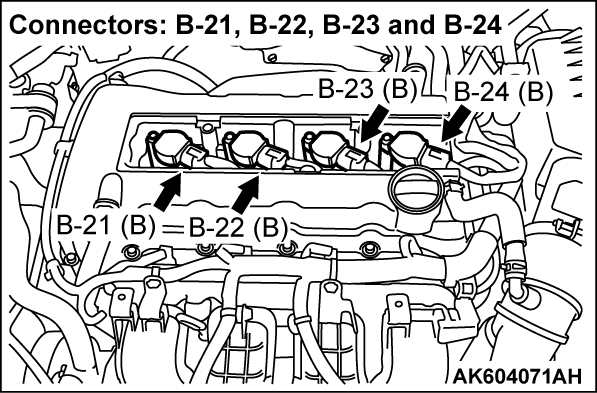

STEP 1. Check harness connector B-21, B-22, B-23 and B-24 at ignition coil for damage.

Are the harness connectors in good condition?

STEP 2. Check the ignition coil.

Refer to GROUP 16, Ignition System - On-vehicle Service - Ignition Coil Check  .

. Replace the ignition coil. Then confirm that the malfunction symptom is eliminated.

Replace the ignition coil. Then confirm that the malfunction symptom is eliminated.

.

.Are there any abnormalities?

Replace the ignition coil. Then confirm that the malfunction symptom is eliminated.

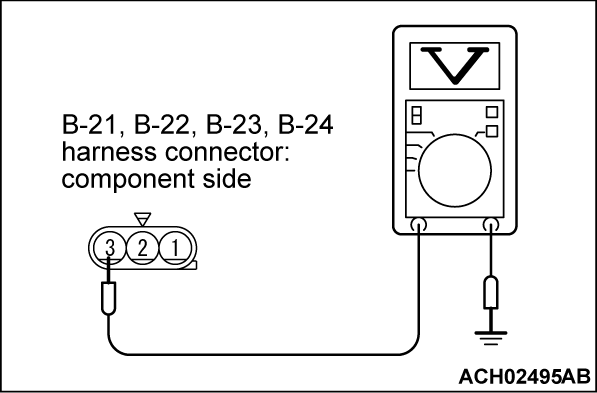

Replace the ignition coil. Then confirm that the malfunction symptom is eliminated.STEP 3. Measure the power supply voltage at ignition coil harness side connectors B-21, B-22, B-23 and B-24.

(1) Disconnect the connectors B-21, B-22, B-23 and B-24 and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 3 and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

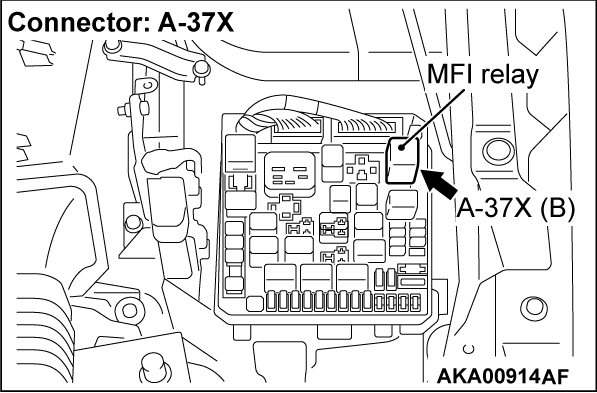

STEP 4. Check harness connector A-37X at MFI relay for damage.

Is the harness connector in good condition?

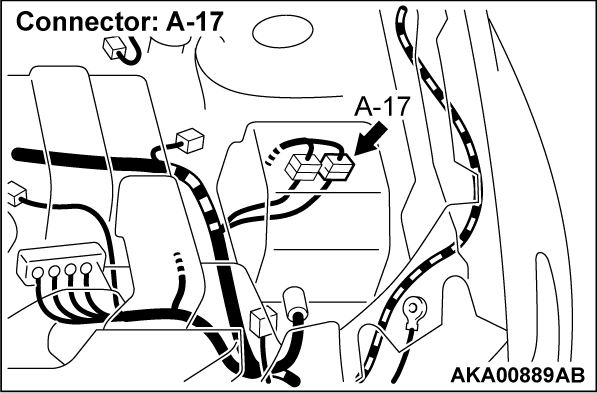

Check harness connector A-17 at intermediate connector for damage, and repair or replace as required. Refer to GROUP 00E, Harness Connector Inspection

Check harness connector A-17 at intermediate connector for damage, and repair or replace as required. Refer to GROUP 00E, Harness Connector Inspection  . If intermediate connector is in good condition, repair harness wire between MFI relay connector A-37X (terminal No. 2) and ignition coil connectors B-21, B-22, B-23 and B-24 (terminal No. 3) because of open circuit or short circuit to ground. Then confirm that the malfunction symptom is eliminated.

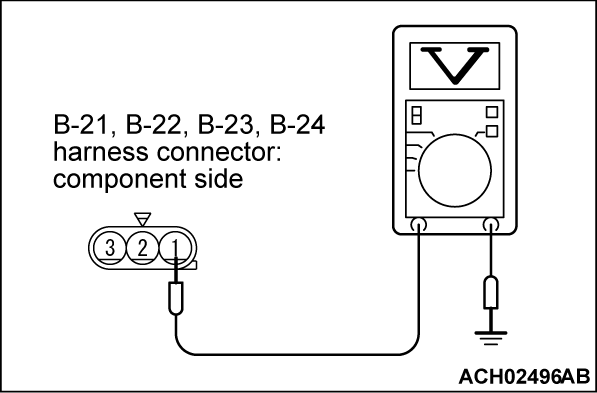

. If intermediate connector is in good condition, repair harness wire between MFI relay connector A-37X (terminal No. 2) and ignition coil connectors B-21, B-22, B-23 and B-24 (terminal No. 3) because of open circuit or short circuit to ground. Then confirm that the malfunction symptom is eliminated.STEP 5. Check the circuit at ignition coil harness side connector B-21, B-22, B-23 and B-24.

(1) Disconnect the ignition coil connectors B-21, B-22, B-23 and B-24 and connect test harness special tool MB991658 between the separated connector (All terminals should be connected).

(2) Engine: 3,000 r/min

(3) Measure the voltage between terminal No. 1 and ground.

- Voltage should be between 0.3 and 3.0 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 0.3 and 3.0 volts?

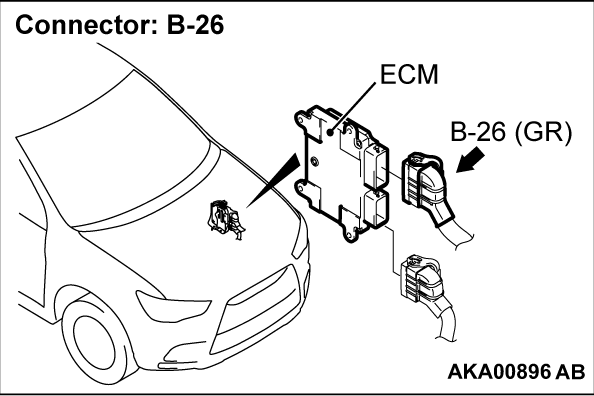

STEP 6. Check harness connector B-26 at ECM for damage.

Is the harness connector in good condition?

STEP 7. Check for open circuit and short circuit to ground between ignition coil connector and ECM connector.

- Check the harness wire between ignition coil connector B-21 (terminal No. 1) and ECM connector B-26 (terminal No. 4) at ignition coil 1.

- Check the harness wire between ignition coil connector B-22 (terminal No. 1) and ECM connector B-26 (terminal No. 5) at ignition coil 2.

- Check the harness wire between ignition coil connector B-23 (terminal No. 1) and ECM connector B-26 (terminal No. 20) at ignition coil 3.

- Check the harness wire between ignition coil connector B-24 (terminal No. 1) and ECM connector B-26 (terminal No. 21) at ignition coil 4.

Are the harness wires in good condition?

Replace the ECM (Refer to, Removal and Installation

Replace the ECM (Refer to, Removal and Installation  ). Then confirm that the malfunction symptom is eliminated.

). Then confirm that the malfunction symptom is eliminated. Repair them. Then confirm that the malfunction symptom is eliminated.

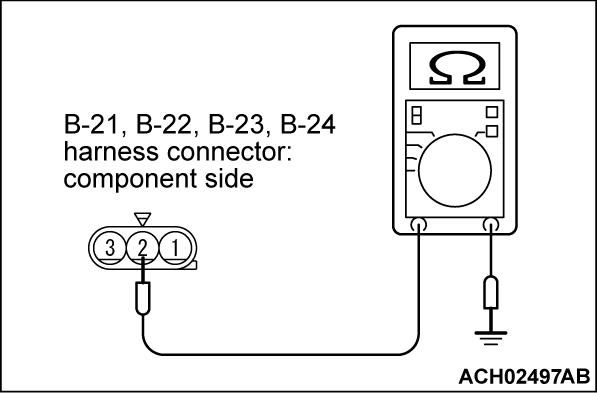

Repair them. Then confirm that the malfunction symptom is eliminated.STEP 8. Check the continuity at ignition coil harness side connector B-21, B-22, B-23 and B-24.

(1) Disconnect the connectors B-21, B-22, B-23 and B-24 and measure at the harness side.

(2) Check for the continuity between terminal No. 2 and ground.

- Continuity (2 ohms or less).

Does continuity exist?

Repair harness wire between ignition coil connectors B-21, B-22, B-23 and B-24 (terminal No. 2) and ground because of open circuit or harness damage. Then confirm that the malfunction symptom is eliminated.

Repair harness wire between ignition coil connectors B-21, B-22, B-23 and B-24 (terminal No. 2) and ground because of open circuit or harness damage. Then confirm that the malfunction symptom is eliminated.STEP 9. Check harness connector A-37X at MFI relay for damage.

Is the harness connector in good condition?

STEP 10. Check for harness damage between MFI relay connector A-37X (terminal No. 2) and ignition coil connector B-21, B-22, B-23 and B-24 (terminal No. 3)

Is the harness wire in good condition?

Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.STEP 11. Check harness connector B-26 at ECM for damage.

Is the harness connector in good condition?

STEP 12. Check for harness damage between ignition coil connector and ECM connector.

- Check the harness wire between ignition coil connector B-21 (terminal No. 1) and ECM connector B-26 (terminal No. 4) at ignition coil 1.

- Check the harness wire between ignition coil connector B-22 (terminal No. 1) and ECM connector B-26 (terminal No. 5) at ignition coil 2.

- Check the harness wire between ignition coil connector B-23 (terminal No. 1) and ECM connector B-26 (terminal No. 20) at ignition coil 3.

- Check the harness wire between ignition coil connector B-24 (terminal No. 1) and ECM connector B-26 (terminal No. 21) at ignition coil 4.

Are the harness wires in good condition?

Replace the ECM (Refer to, Removal and Installation

Replace the ECM (Refer to, Removal and Installation  ). Then confirm that the malfunction symptom is eliminated.

). Then confirm that the malfunction symptom is eliminated. Repair them. Then confirm that the malfunction symptom is eliminated.

Repair them. Then confirm that the malfunction symptom is eliminated.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)