Inspection procedure 23: Fuel pump system

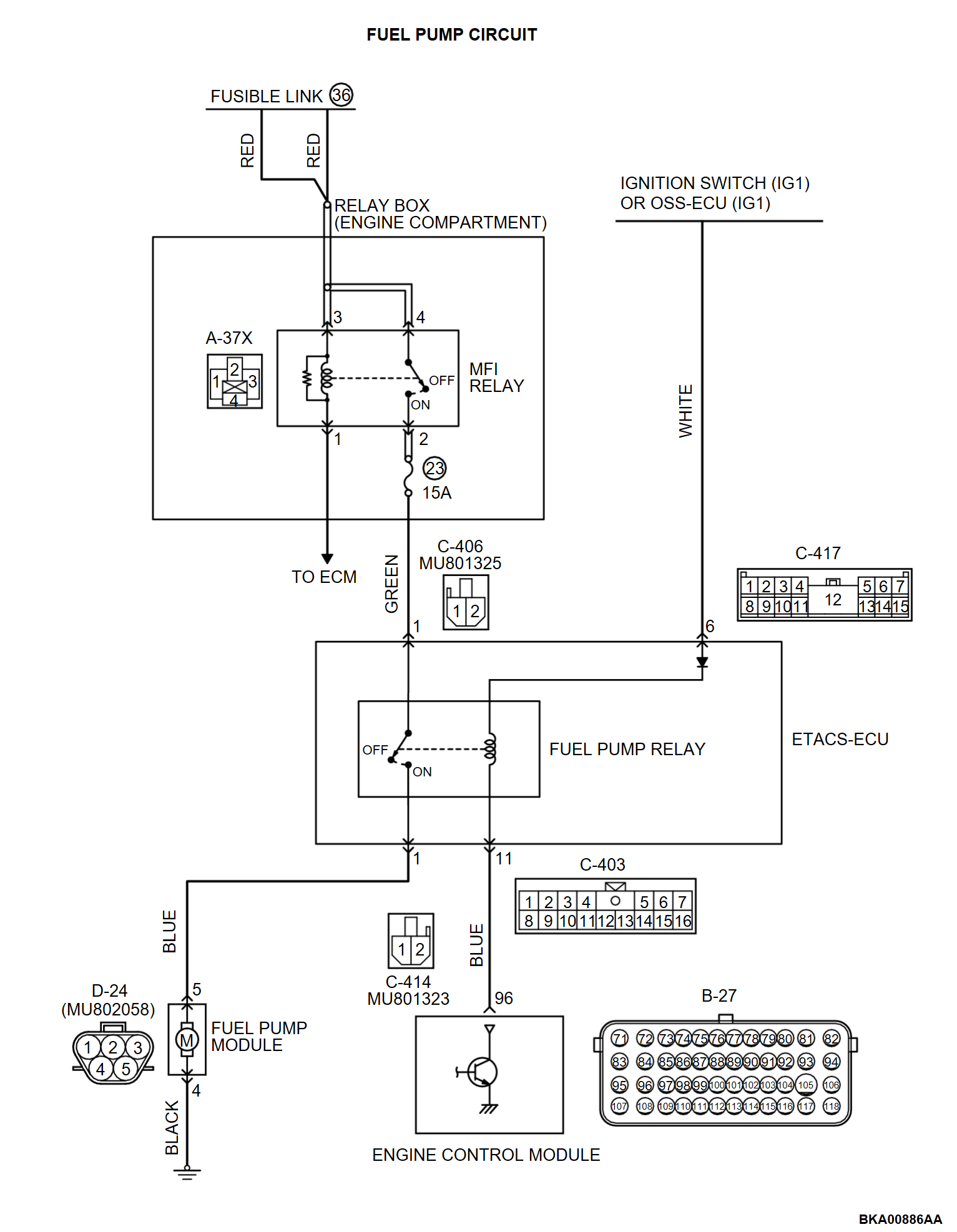

CIRCUIT OPERATION

- The fuel pump drive power is supplied from MFI relay (terminal No. 2) to fuel pump relay (C-406 ETACS-ECU connector terminal No. 1) in the ETACS-ECU.

- The battery positive voltage is applied by the ignition switch to the fuel pump coil (C-417 ETACS-ECU connector terminal No. 6) in the ETACS-ECU. The ECM turns "ON" the relay by turning "ON" the power transistor in the unit so as to conduct power to the fuel pump relay coil (via the C-403 ETACS-ECU connector terminal No. 11).

- When the fuel pump relay is turned "ON", the battery positive voltage will be supplied from the fuel pump relay (C-414 ETACS-ECU connector terminal No. 1) to the fuel pump.

COMMENT

- When the ignition switch ON signal is inputted into the ECM, the ECM turns ON the fuel pump relay. This causes the battery voltage to be supplied to the fuel pump.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Fuel pump relay failed.

- Fuel pump failed.

- Open or shorted fuel pump circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

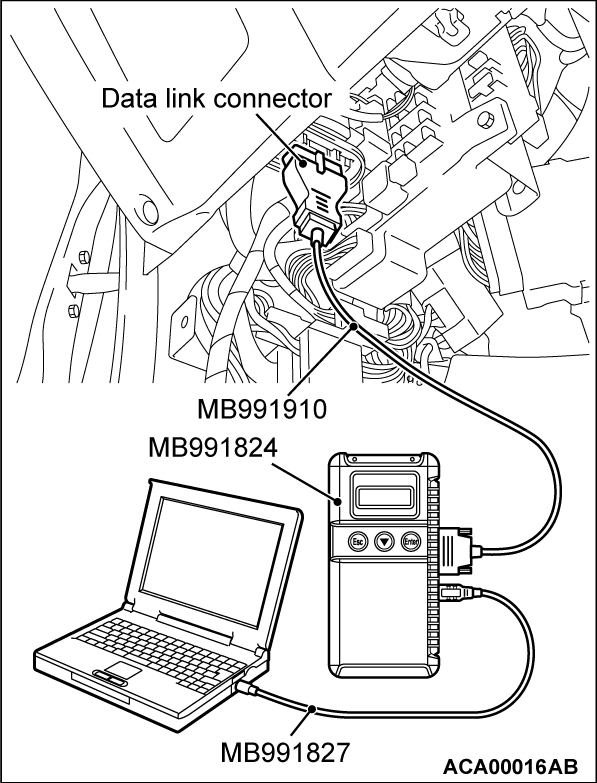

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, check actuator test item 9: Fuel Pump.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool MB991958 to the actuator test mode for item 9, Fuel Pump.

- An operation sound of the fuel pump should be heard.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the fuel pump operating properly?

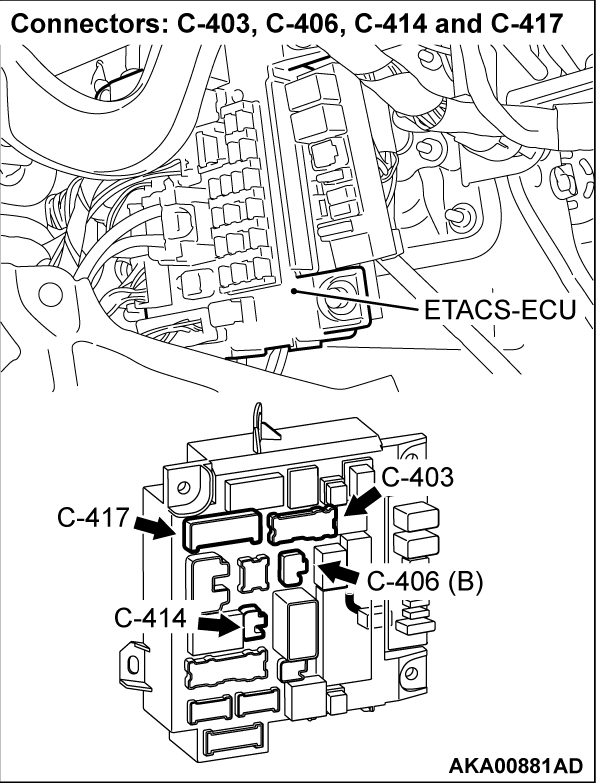

STEP 2. Check harness connector C-317, C-403, C-406 and C-414 at ETACS-ECU for damage.

Are the harness connectors in good condition?

STEP 3. Check the fuel pump relay.

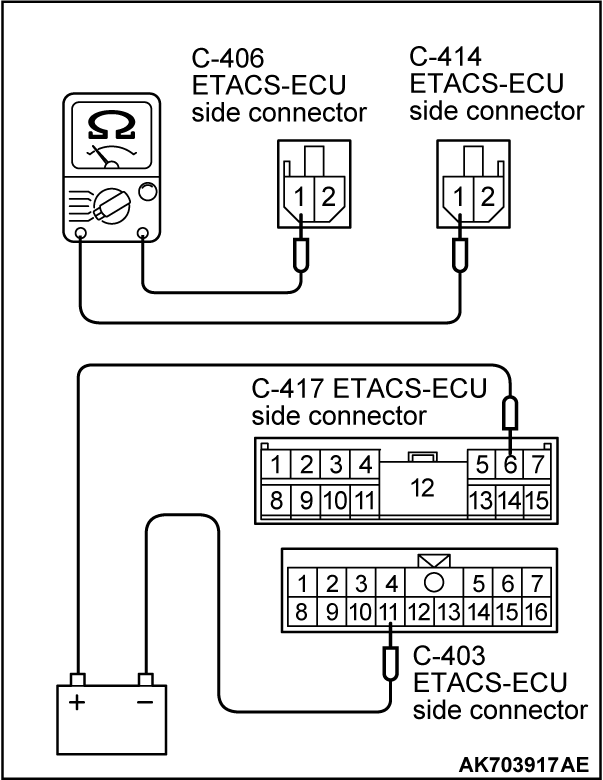

(1) Remove the ETACS-ECU.

(2) Use jumper wires to connect C-417 ETACS-ECU terminal No. 6 to the positive battery terminal and C-403 ETACS-ECU terminal No. 11 to the negative battery terminal.

(3) Check for continuity between the C-406 ETACS-ECU terminal No. 1 and C-414 ETACS-ECU terminal No. 1 while connecting and disconnecting the jumper wire at the negative battery terminal.

- Continuity (2 ohms or less). <Negative battery terminal connected>

- Should be open loop. <Negative battery terminal disconnected>

(4) Install the ETACS-ECU.

Is the measured resistance normal?

Replace the ETACS-ECU. Then confirm that the malfunction symptom is eliminated.

Replace the ETACS-ECU. Then confirm that the malfunction symptom is eliminated.STEP 4. Check harness connector B-27 at ECM for damage.

Is the harness connector in good condition?

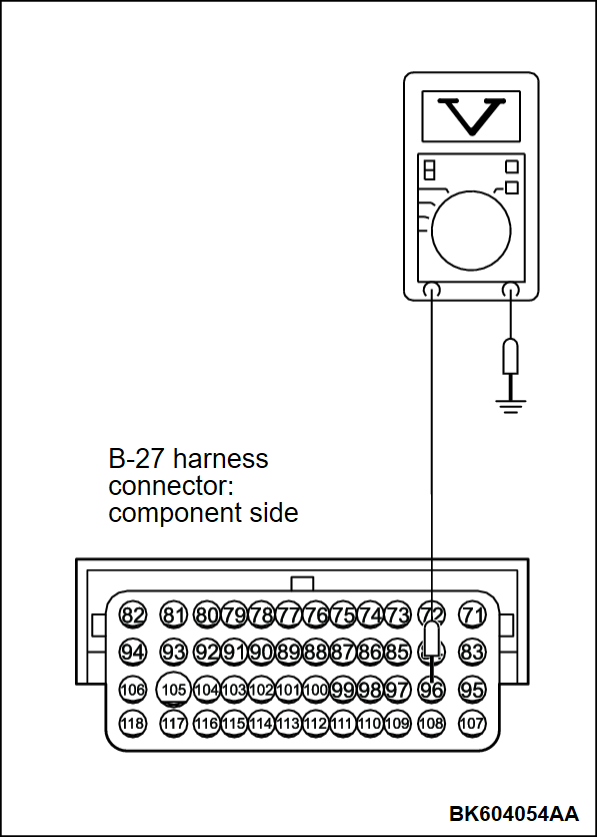

STEP 5. Measure the power supply voltage at ECM harness side connector B-27.

(1) Disconnect the connector B-27 and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 96 and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

Repair harness wire between ETACS-ECU connector C-403 (terminal No. 11) and ECM connector B-27 (terminal No. 96) because of open circuit or short circuit to ground. Then confirm that the malfunction symptom is eliminated.

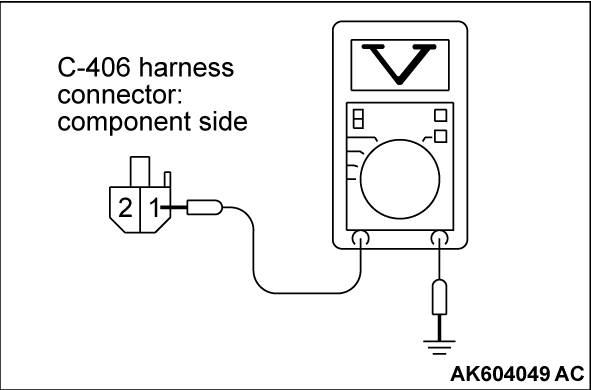

Repair harness wire between ETACS-ECU connector C-403 (terminal No. 11) and ECM connector B-27 (terminal No. 96) because of open circuit or short circuit to ground. Then confirm that the malfunction symptom is eliminated.STEP 6. Measure the power supply voltage at ETACS-ECU harness side connector C-406.

(1) Disconnect the connector C-406 and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 1 and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

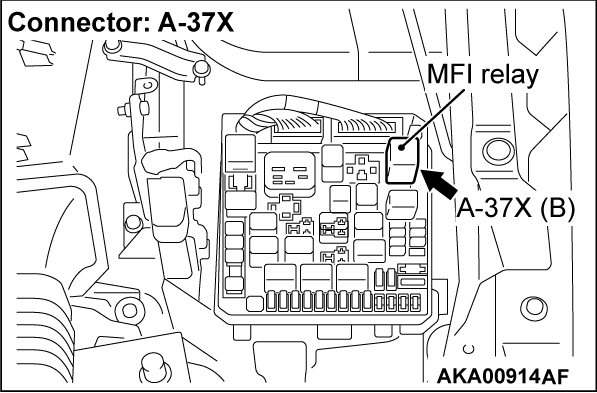

STEP 7. Check harness connector A-37X at MFI relay for damage.

Is the harness connector in good condition?

Repair harness wire between MFI relay connector A-37X (terminal No. 2) and ETACS-ECU connector C-406 (terminal No. 1) because of open circuit or short circuit to ground. Then confirm that the malfunction symptom is eliminated.

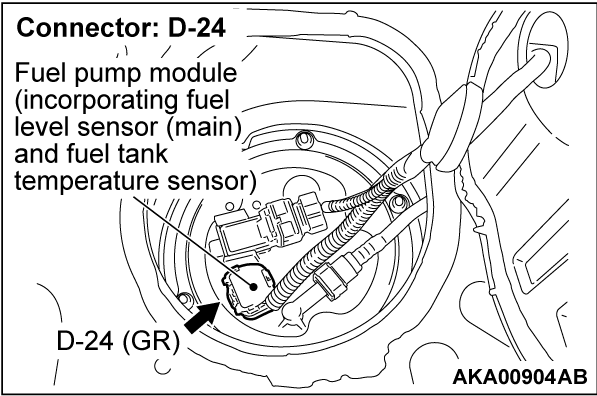

Repair harness wire between MFI relay connector A-37X (terminal No. 2) and ETACS-ECU connector C-406 (terminal No. 1) because of open circuit or short circuit to ground. Then confirm that the malfunction symptom is eliminated.STEP 8. Check harness connector D-24 at fuel pump for damage.

Is the harness connector in good condition?

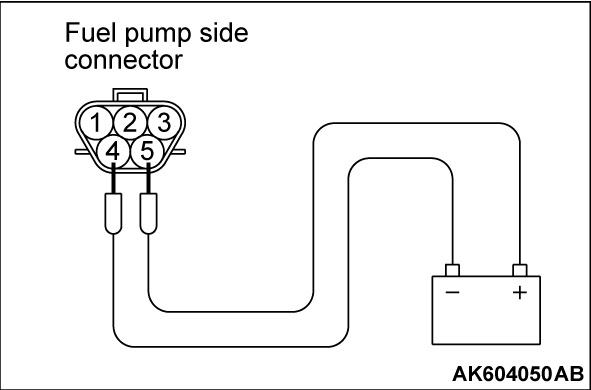

STEP 9. Check the fuel pump operation.

(1) Disconnect fuel pump connector D-24.

(2) Use jumper wires to connect fuel pump terminal No. 5 to the positive battery terminal and terminal No. 4 to the negative battery terminal.

- An operating sound of the fuel pump should be heard.

Is the fuel pump operating properly?

Replace the fuel pump. Then confirm that the malfunction symptom is eliminated.

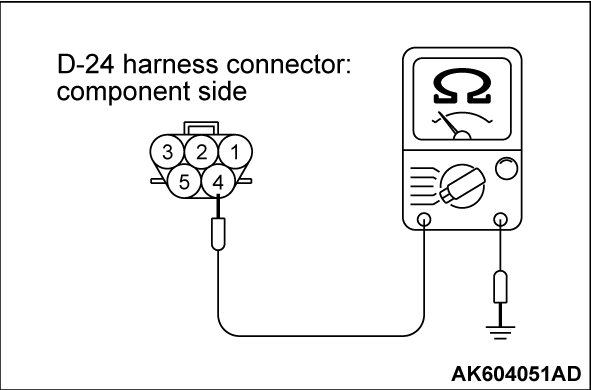

Replace the fuel pump. Then confirm that the malfunction symptom is eliminated.STEP 10. Check the continuity at fuel pump harness side connector D-24.

(1) Disconnect the connector D-24 and measure at the harness side.

(2) Check for the continuity between terminal No. 4 and ground.

- Continuity (2 ohms or less).

Does continuity exist?

Repair harness wire between fuel pump connector D-24 (terminal No. 4) and ground because of open circuit or harness damage. Then confirm that the malfunction symptom is eliminated.

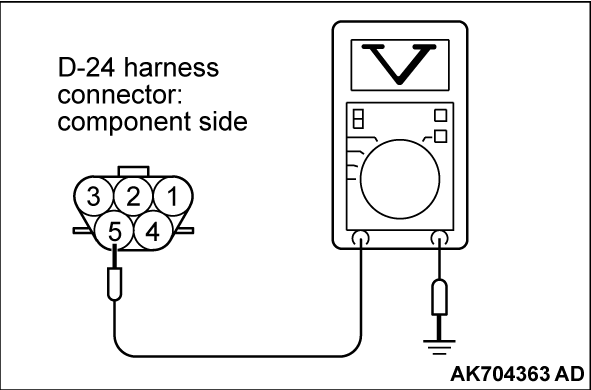

Repair harness wire between fuel pump connector D-24 (terminal No. 4) and ground because of open circuit or harness damage. Then confirm that the malfunction symptom is eliminated.STEP 11. Measure the power supply voltage at fuel pump harness side connector D-24.

(1) Disconnect the connector D-24 and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 5 and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

STEP 12. Check for open circuit and short circuit to ground between ETACS-ECU connector C-414 (terminal No. 1) and fuel pump connector D-24 (terminal No. 5).

Is the harness wire in good condition?

Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.STEP 13. Check for harness damage between ETACS-ECU connector C-403 (terminal No. 11) and ECM connector B-27 (terminal No. 96).

Is the harness wire in good condition?

Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.STEP 14. Using scan tool MB991958, check actuator test item 9: Fuel Pump.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the actuator test mode for item 9, Fuel Pump.

- An operation sound of the fuel pump should be heard.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the fuel pump operating properly?

STEP 15. Check harness connector A-37X at MFI relay for damage.

Is the harness connector in good condition?

STEP 16. Check for harness damage between MFI relay connector A-37X (terminal No. 2) and ETACS-ECU connector C-406 (terminal No. 1).

Is the harness wire in good condition?

Repair harness wire between ETACS-ECU connector C-414 (terminal No. 1) and fuel pump connector (terminal No. 5) because of harness damage. Then confirm that the malfunction symptom is eliminated.

Repair harness wire between ETACS-ECU connector C-414 (terminal No. 1) and fuel pump connector (terminal No. 5) because of harness damage. Then confirm that the malfunction symptom is eliminated. Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)