DTC P062F: Internal Control Module EEPROM Error

TECHNICAL DESCRIPTION

- ECM stored the information such as the idle learned value and so on in the memory of ECM.

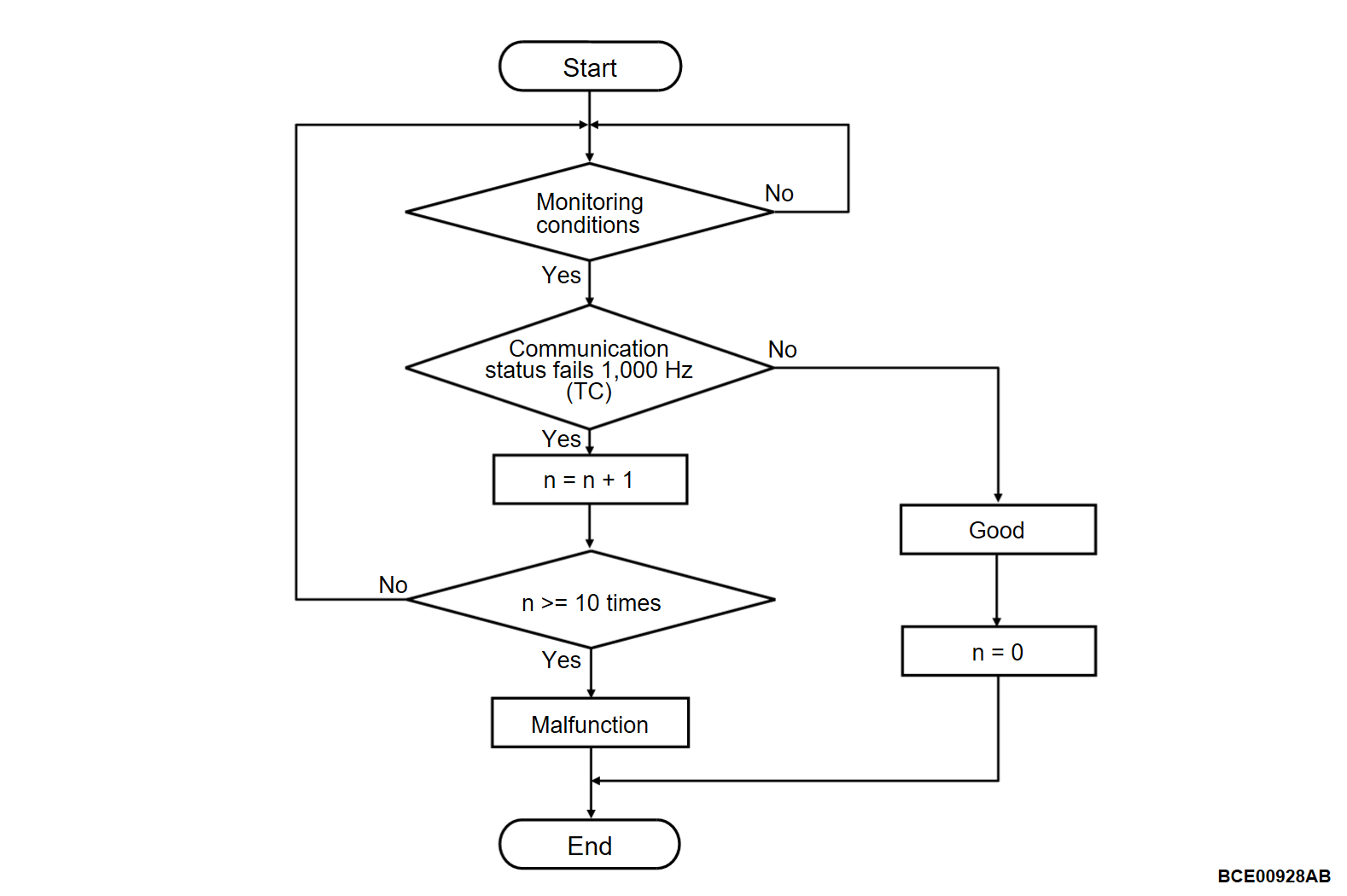

DESCRIPTIONS OF MONITOR METHODS

- To check whether the information such as the idle learned value and so on is stored in the memory of ECM.

MONITOR EXECUTION

- Once per driving cycle

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Condition

- Ignition switch is "ON" position.

Judgment Criterion

- The latest data that was flashed while the ignition switch was in "LOCK" (OFF) position are not stored correctly.

FAIL-SAFE AND BACKUP FUNCTION

- None

OBD-II DRIVE CYCLE PATTERN

- None.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- ECM failed.

DIAGNOSIS

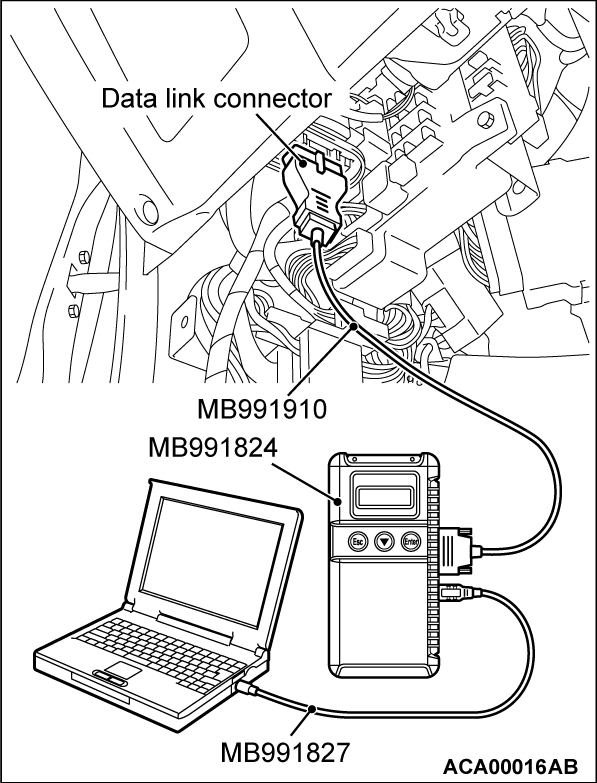

Required Special Tool:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, read the diagnostic trouble code (DTC).

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) After the DTC has been deleted, read the DTC again.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is DTC P062F set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)