DTC P0451: Evaporative Emission Control System Pressure Sensor Range/Performance

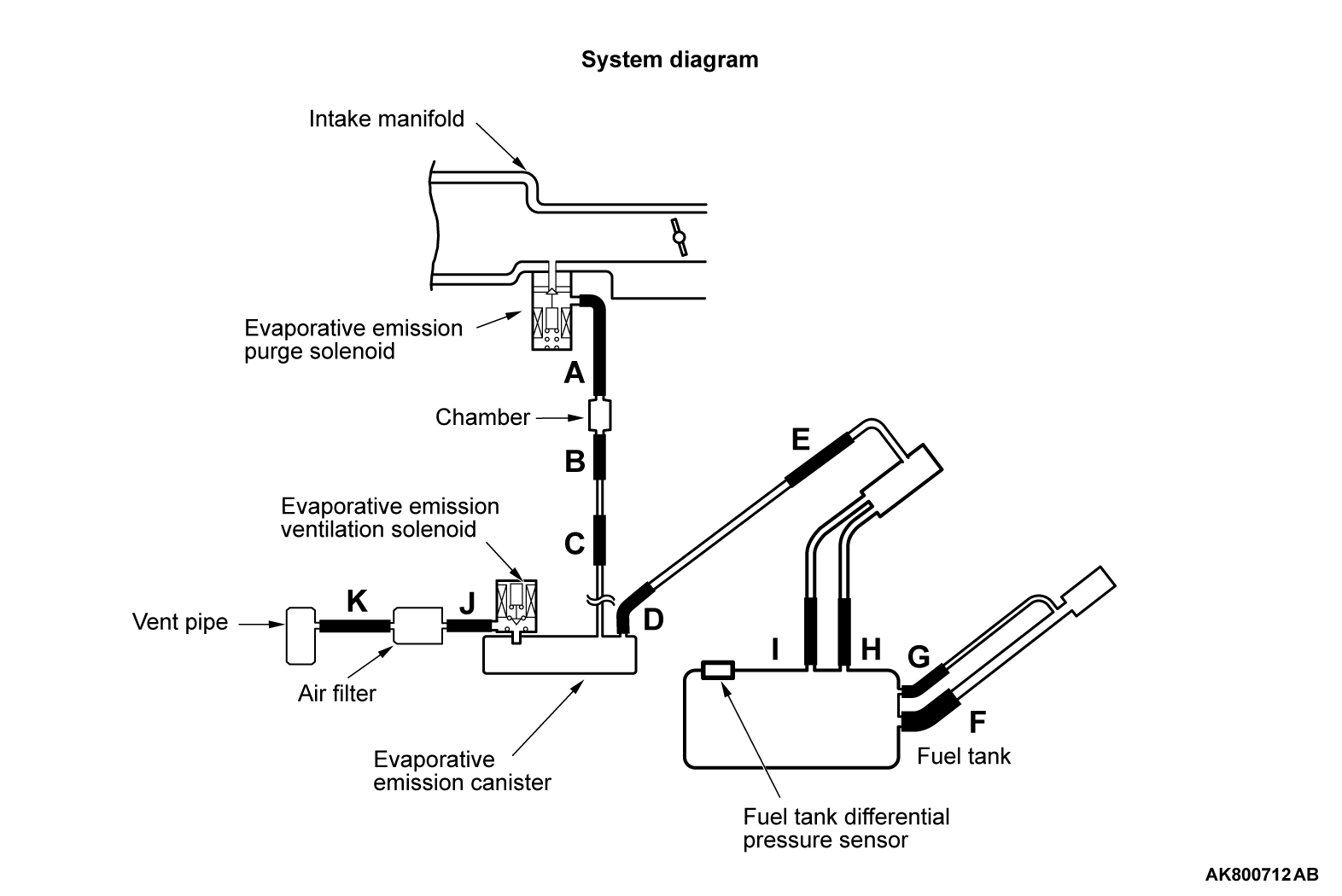

CIRCUIT OPERATION

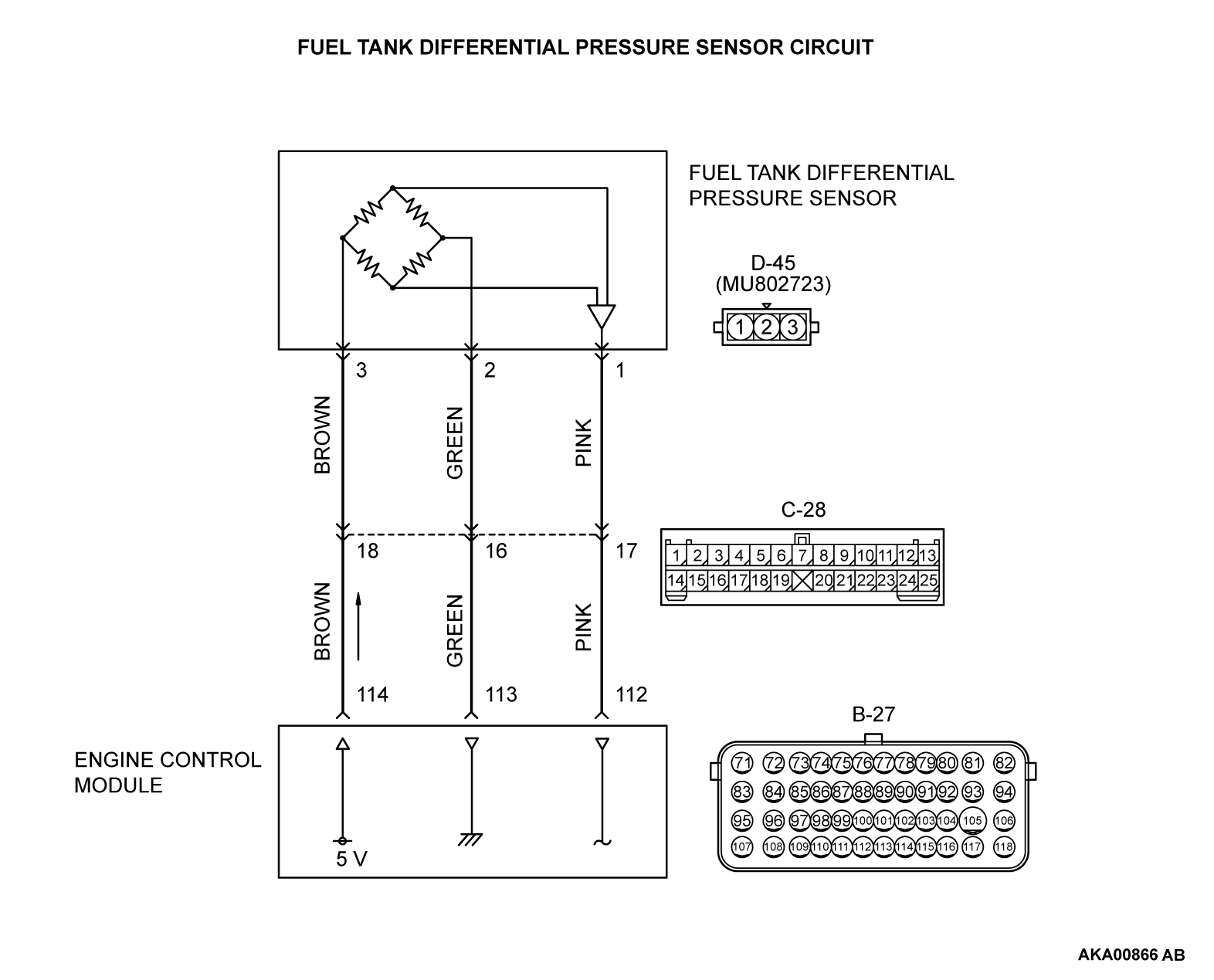

- The ECM (terminal No. 114) supplies a 5 volts reference signal to the fuel tank differential pressure sensor (terminal No. 3). The fuel tank differential pressure sensor (terminal No. 2) is grounded through the ECM (terminal No. 113).

- The fuel tank differential pressure sensor (terminal No. 1) returns a voltage signal to the ECM (terminal No. 112) that is proportional to the pressure in the fuel tank.

TECHNICAL DESCRIPTION

- The ECM monitors the fuel tank differential pressure sensor signal voltage.

- The ECM determines whether the fuel tank differential pressure sensor signal voltage is within normal operating parameters.

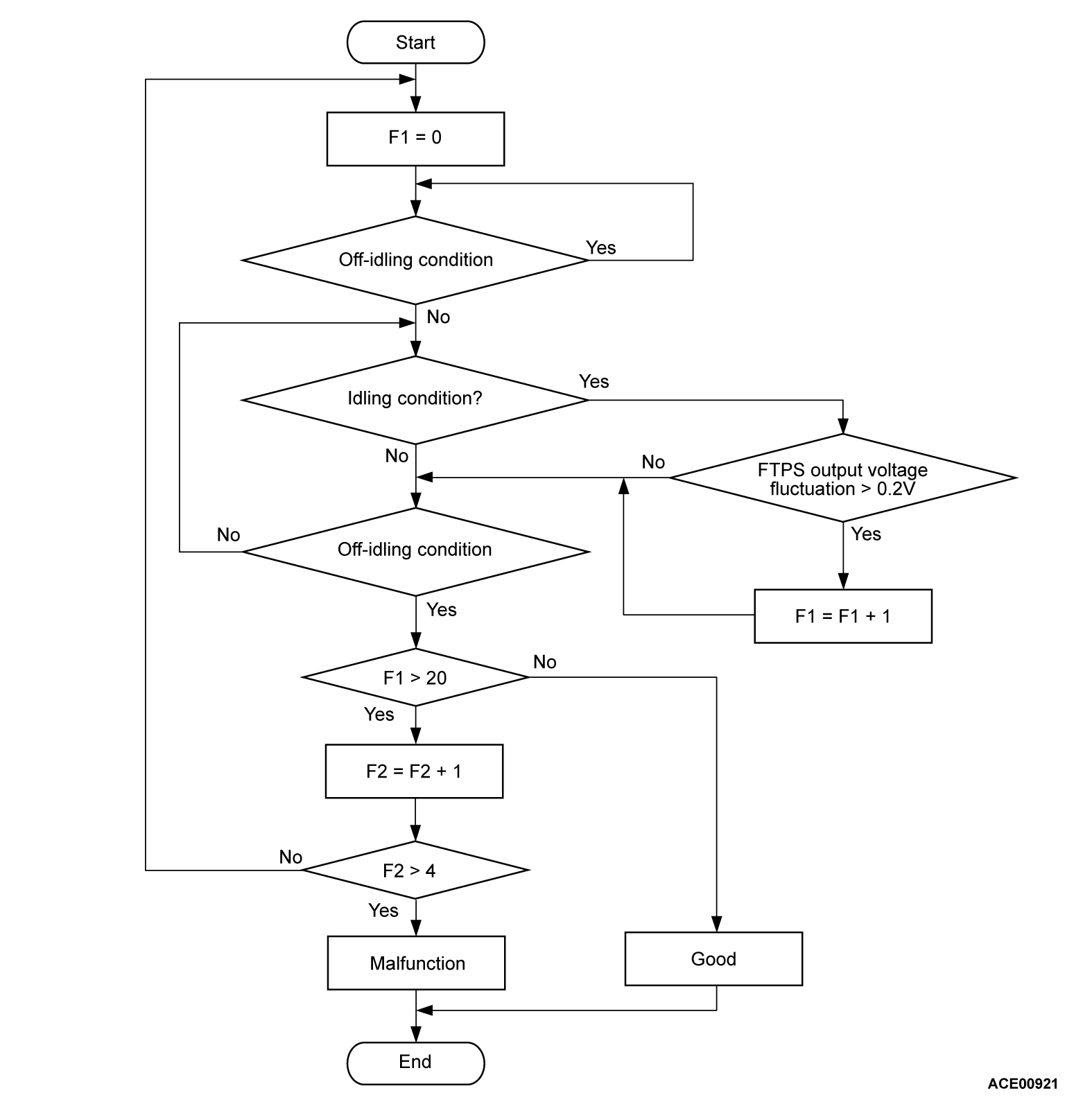

DESCRIPTIONS OF MONITOR METHODS

- Detect malfunction if change of fuel tank differential pressure sensor output voltage during idling stays large during specified go/stop operations.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Evaporative emission purge solenoid monitor

- Evaporative emission ventilation solenoid monitor

- Fuel temperature sensor monitor

- Fuel level sensor monitor

Sensor (The sensors below are determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Accelerator pedal position sensor

Check Conditions

- Accelerator pedal is not depressed.

- Vehicle speed is less than 1.5 km/h (1 mph).

note The conditions for deviating from idling operation are as follows: - Vehicle speed is more than 50 km/h (31 mph).

Judgment Criteria

- The drastic pressure fluctuation is detected 20 times or more per engine idling, which is that the fuel tank differential pressure sensor output voltage is 0.2 volt or more.

- The condition described above is consecutively detected 4 times under the normal driving conditions.

note If the number of sudden pressure fluctuations does not reach 20 times during any one period of engine idling, or if the ignition switch is turned OFF, the counter will reset to 0.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Fuel tank differential pressure sensor failed.

- Fuel tank differential pressure sensor circuit harness damage or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

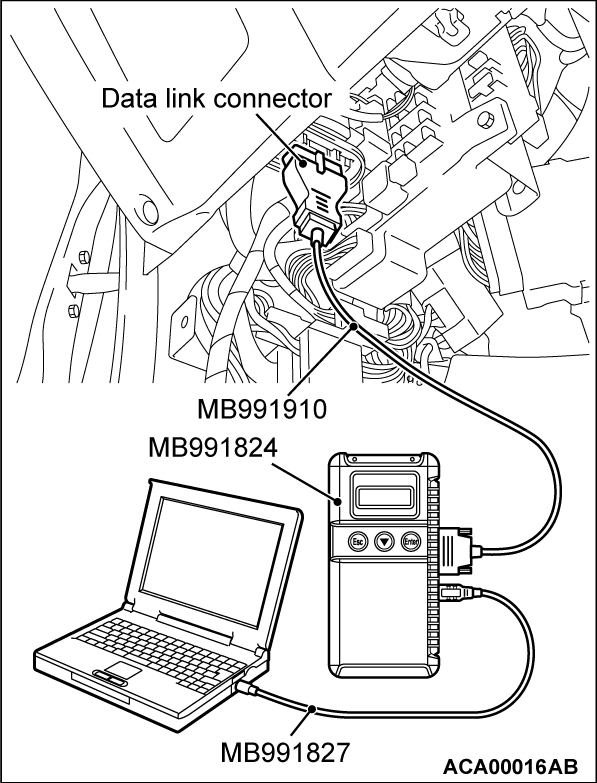

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, check data list item 52: Fuel Tank Differential Pressure Sensor.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

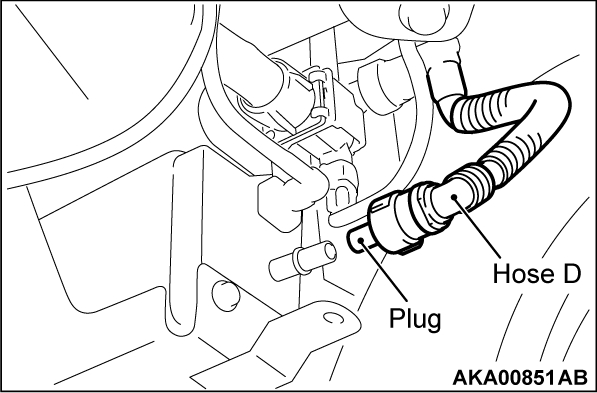

(2) Plug the disconnected end of hose D.

(3) Turn the ignition switch to the "ON" position.

(4) Remove the fuel cap.

(5) Set scan tool MB991958 to the data reading mode for item 52, Fuel Tank Differential Pressure Sensor.

- Output voltage should be between 1,500 and 3,500 millivolts.

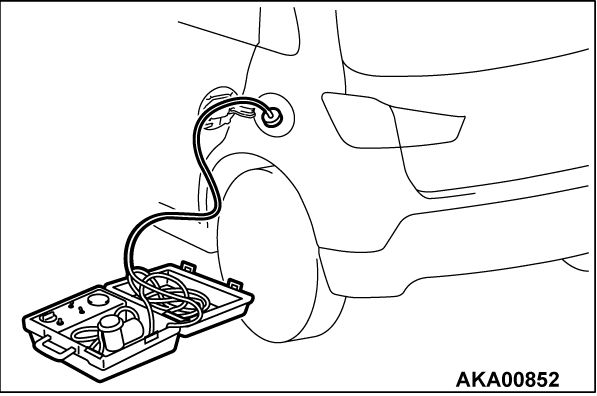

(6) Connect the evaporative emission system pressure pump (Miller number 6872A) to the fuel tank filler tube by using fuel tank adapter (MLR-8382) and pressurize the fuel tank.

- The fuel tank pressure reading should increase.

(7) Turn the ignition switch to the "LOCK" (OFF) position.

(8) Remove the evaporative emission system pressure pump (Miller number 6872A) and the fuel tank adapter (MLR-8382), and reinstall the fuel cap.

(9) Connect hose D to the evaporative emission canister.

Is the sensor operating properly?

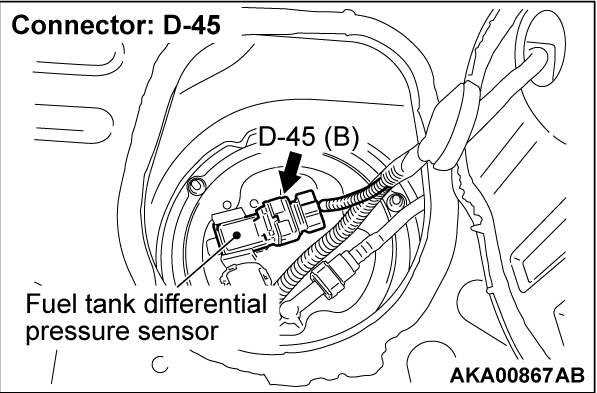

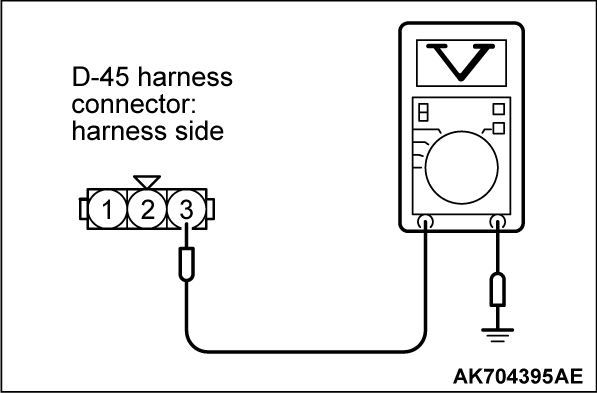

STEP 2. Measure the sensor supply voltage at fuel tank differential pressure sensor connector D-45 by backprobing.

(1) Do not disconnect the connector D-45.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 3 and ground by backprobing.

- Voltage should be between 4.9 and 5.1 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 4.9 and 5.1 volts?

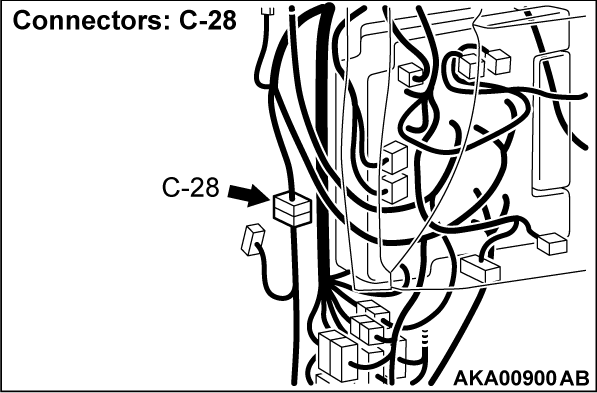

STEP 3. Check harness connector D-45 at fuel tank differential pressure sensor and harness connector B-27 at ECM for damage.

Are the harness connectors in good condition?

STEP 4. Check for harness damage between fuel tank differential pressure sensor connector D-45 (terminal No. 3) and ECM connector B-27 (terminal No. 114).

| note | Check harness after checking intermediate connector C-28. If intermediate connector is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  . Then go to Step 11 . Then go to Step 11 . . |

Is the harness wire in good condition?

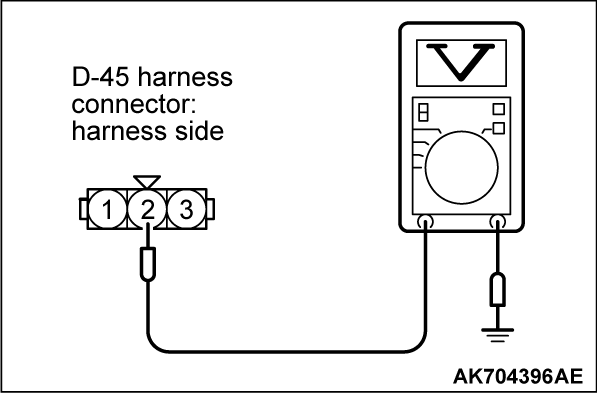

STEP 5. Measure the ground voltage at fuel tank differential pressure sensor connector D-45 by backprobing.

(1) Do not disconnect the connector D-45.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal No. 2 and ground by backprobing.

- Voltage should be 0.5 volt or less.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage 0.5 volt or less?

STEP 6. Check harness connector D-45 at fuel tank differential pressure sensor and harness connector B-27 at ECM for damage.

Are the harness connectors in good condition?

STEP 7. Check for harness damage between fuel tank differential pressure sensor connector D-45 (terminal No. 2) and ECM connector B-27 (terminal No. 113).

| note | Check harness after checking intermediate connector C-28. If intermediate connector is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  . Then go to Step 11 . Then go to Step 11 . . |

Is the harness wire in good condition?

STEP 8. Check harness connector D-45 at fuel tank differential pressure sensor and harness connector B-27 at ECM for damage.

Are the harness connectors in good condition?

STEP 9. Check for harness damage between fuel tank differential pressure sensor connector D-45 (terminal No. 1) and ECM connector B-27 (terminal No. 112).

| note | Check harness after checking intermediate connector C-28. If intermediate connector is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  . Then go to Step 11 . Then go to Step 11 . . |

Is the harness wire in good condition?

STEP 10. Replace the fuel tank differential pressure sensor.

(1) Replace the fuel tank differential pressure sensor.

(2) Carry out test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 16  .

.

.

.(3) Check the diagnostic trouble code (DTC).

Is DTC P0451 set?

The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)