DTC P0172: System too Rich

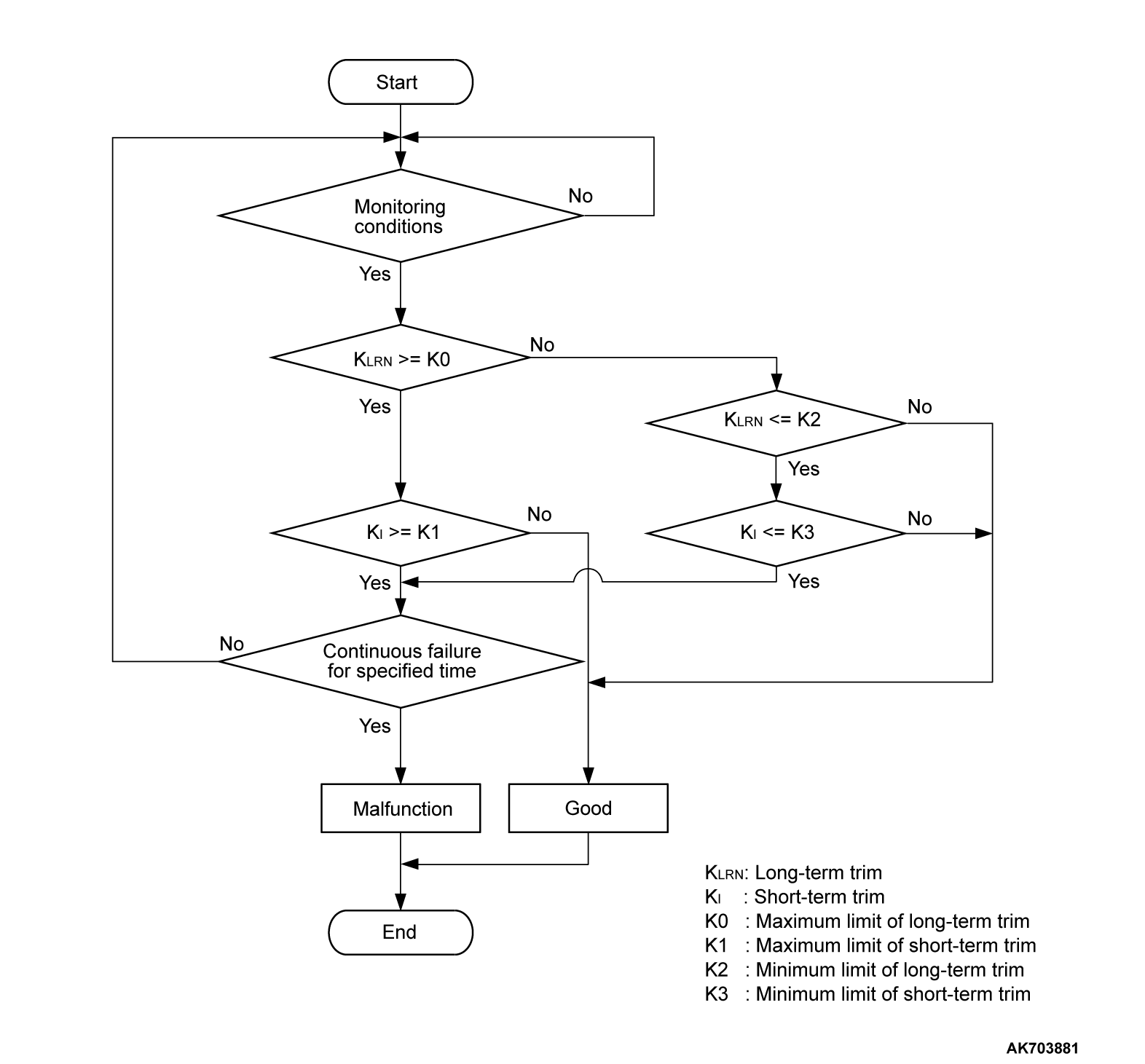

TECHNICAL DESCRIPTION

- If a malfunction occurs in the fuel system, the fuel trim value becomes too large.

- The ECM checks whether the fuel trim value is within a specified range.

DESCRIPTIONS OF MONITOR METHODS

- Air/fuel learning value (long time fuel trim) and air/fuel feedback integral value (short time fuel trim) are too rich.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Misfire monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

Check Conditions

- Under the closed loop air/fuel ratio control.

- Engine coolant temperature is more than 76°C (169°F).

- Mass airflow sensor output is more than 9 g/sec.

Judgment Criterion

- Long-term fuel trim is less than -12.5 percent for 5 seconds.

or

- Short-term fuel trim is less than -10.2 percent for 5 seconds.

Check Conditions

- Under the closed loop air/fuel ratio control.

- Engine coolant temperature is more than 76°C (169°F).

- Mass airflow sensor output is less than 9 g/sec.

Judgment Criterion

- Long-term fuel trim is less than -12.5 percent for 5 seconds.

or

- Short-term fuel trim is less than -15.2 percent for 5 seconds.

Check Conditions

- Engine coolant temperature is more than 76°C (169°F).

- Under the closed loop air/fuel ratio control.

Judgment Criterion

- Long-term fuel trim is -12.5 percent for 2 seconds.

or

- Short-term fuel trim is -25.0 percent for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Mass airflow sensor failed.

- Injector failed.

- Incorrect fuel pressure.

- Engine coolant temperature sensor failed.

- Intake air temperature sensor failed.

- Barometric pressure sensor failed.

- Manifold absolute pressure sensor failed.

- ECM failed.

DIAGNOSIS

Required Special Tool:

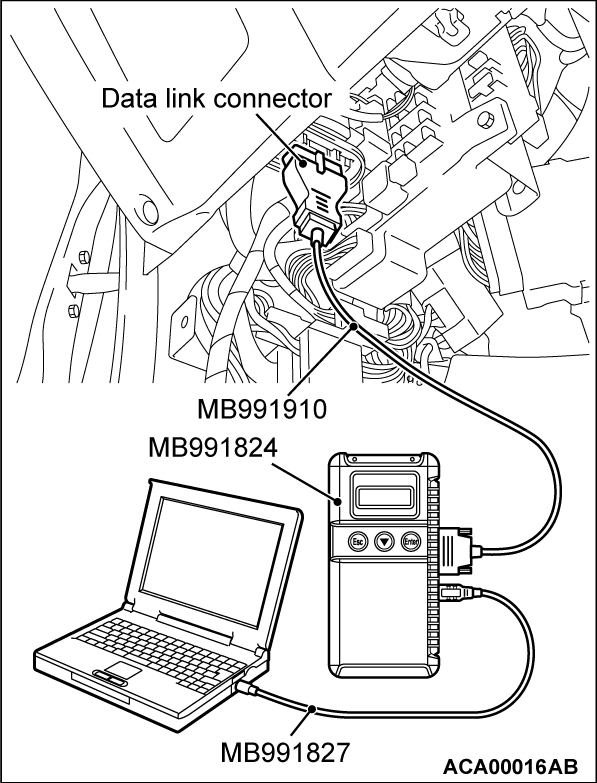

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

STEP 1. Using scan tool MB991958, check data list item 10: Mass Airflow Sensor.

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(1) Connect scan tool MB991958 to the data link connector.

(2) Start the engine and run at idle.

(3) Set scan tool MB991958 to the data reading mode for item 10, Mass Airflow Sensor.

(4) Warm up the engine to normal operating temperature: 80°C to 95°C (176°F to 203°F).

- When idling, between 1,350 and 1,670 millivolts.

- When 2,500 r/min, between 1,620 and 2,020 millivolts.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 2. Using scan tool MB991958, check data list item 5: Intake Air Temperature Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 5, Intake Air Temperature Sensor.

- The intake air temperature and temperature shown with the scan tool should approximately match.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 3. Using scan tool MB991958, check data list item 6: Engine Coolant Temperature Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 6, Engine Coolant Temperature Sensor.

- The engine coolant temperature and temperature shown with the scan tool should approximately match.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 4. Using scan tool MB991958, check data list item 8: Manifold Absolute Pressure Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the data reading mode for item 8, Manifold Absolute Pressure Sensor.

- When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg).

- When altitude is 600 m (1,969 feet), 95 kPa (28.1 in.Hg).

- When altitude is 1,200 m (3,937 feet), 88 kPa (26.0 in.Hg).

- When altitude is 1,800 m (5,906 feet), 81 kPa (23.9 in.Hg).

(3) Start the engine.

- Warm up the engine. When the engine is idling, 16 - 36 kPa (4.7 - 10.6 in.Hg).

- When the engine is suddenly revved, manifold absolute pressure varies.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

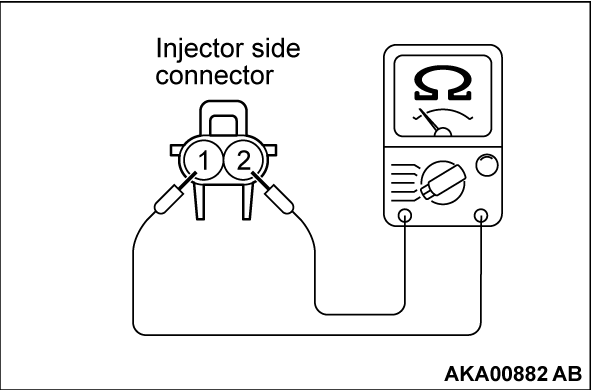

STEP 5. Check the injector.

(1) Disconnect the injector connectors B-101, B-102, B-105 and B-106.

(2) Measure the resistance between each injector side connector terminal No. 1 and No. 2.

Standard value: 10.5 - 13.5 Ω [at 20°C (68°F)]

Is the measured resistance between 10.5 and 13.5 Ω [at 20°C (68°F)]?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)