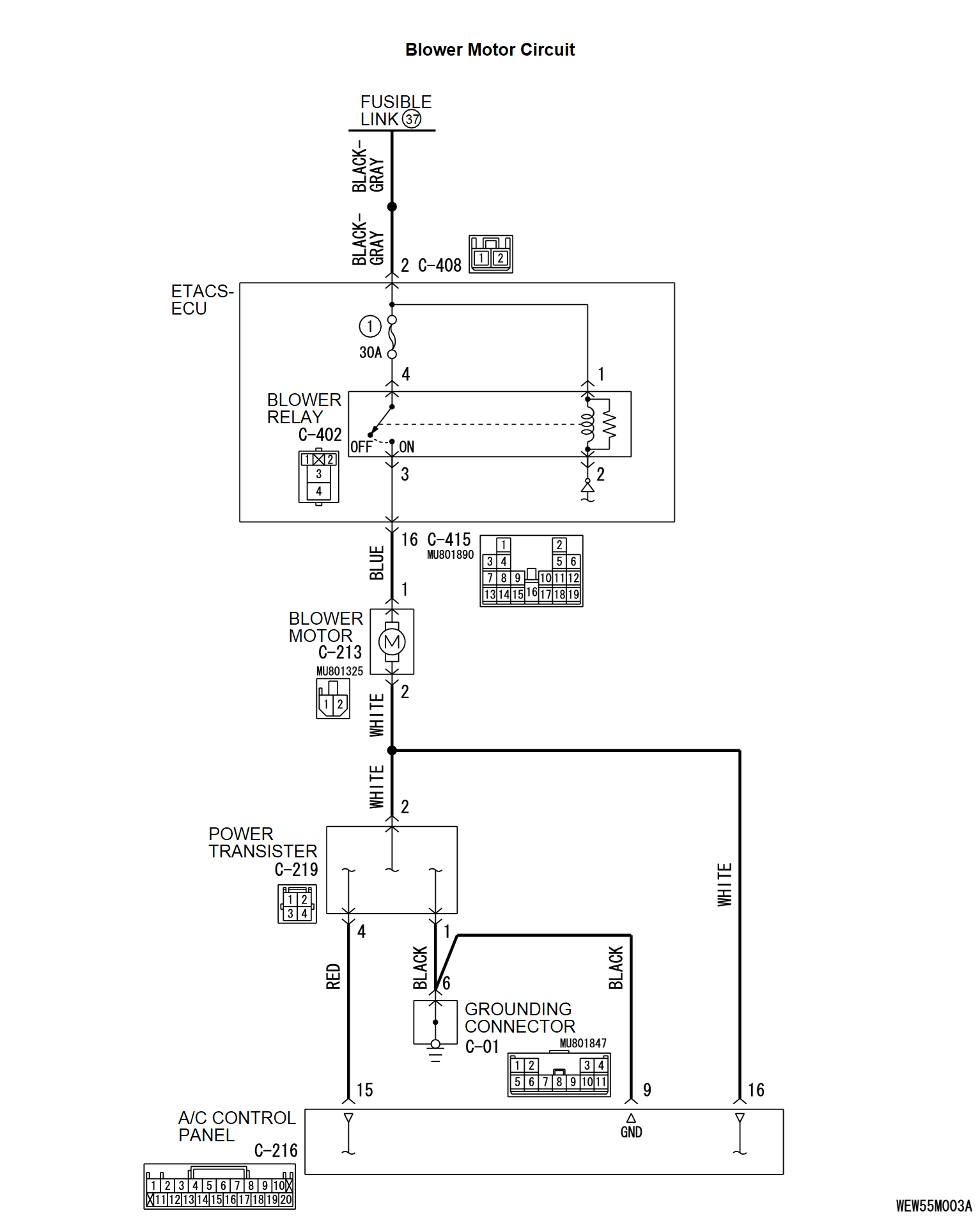

INSPECTION PROCEDURE 9: Blower Motor power supply system.

TECHNICAL DESCRIPTION (COMMENT)

If the voltage is not supplied to the blower motor, the blower relay system may be failed.

TROUBLESHOOTING HINTS

- Malfunction of the ETACS-ECU

- Malfunction of the blower relay

- Damaged wiring harness or connectors

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

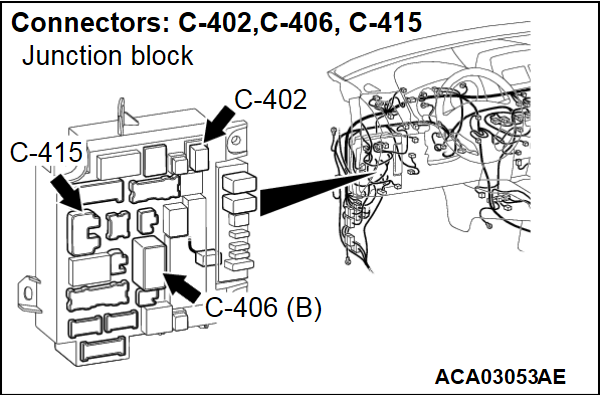

STEP 1. Check blower relay connector C-402 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is blower relay connector C-402 in good condition?

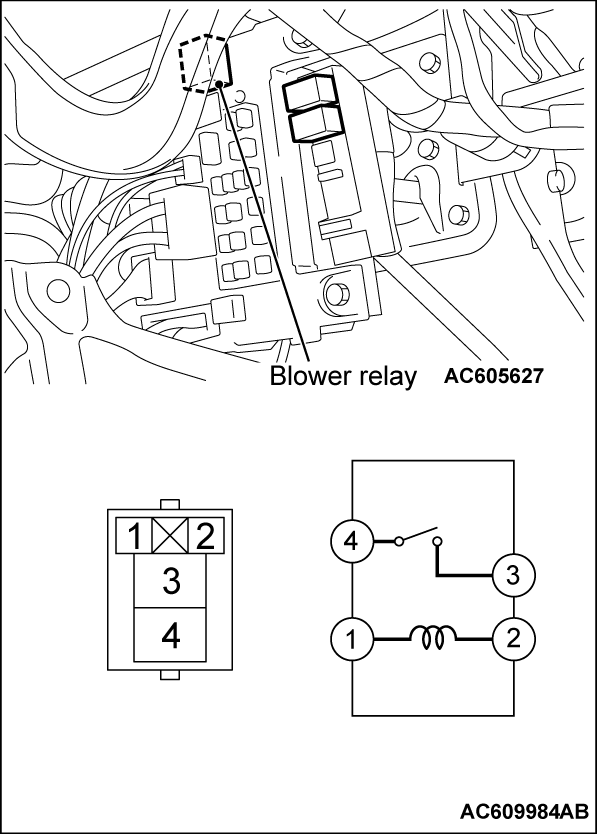

STEP 2. Check the blower relay continuity.

Follow the table below to check the blower relay for continuity.

Replace the rear window defogger relay.

Replace the rear window defogger relay.

|

Is the blower relay in good condition?

Replace the rear window defogger relay.

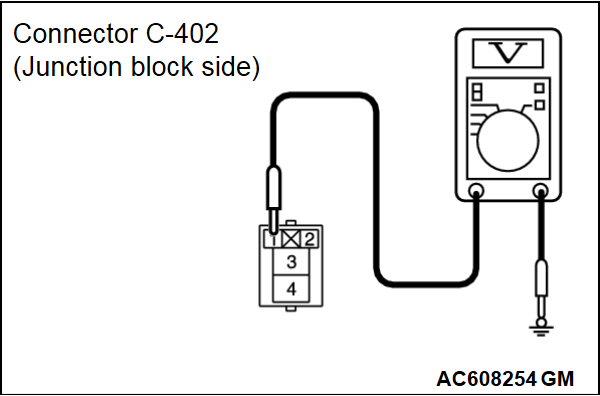

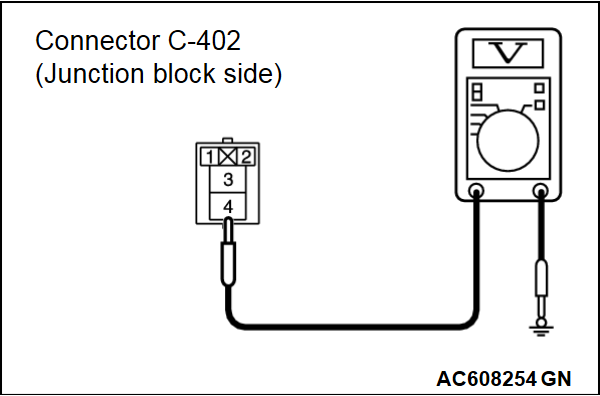

Replace the rear window defogger relay.STEP 3. Measure the voltage at blower relay connector C-402.

(1) Disconnect blower relay connector C-402, and measure the voltage at the junction block side.

(2) Measure the voltage between terminals 1 and ground.

- The measured value should be approximately 12 volts (battery positive voltage).

(3) Measure the voltage between terminals 4 and ground.

- The measured value should be approximately 12 volts (battery positive voltage).

Is the measured voltage approximately 12 volts?

STEP 4. Check the wiring harness between blower relay connector C-402 (terminals 1 and 4) and the fusible link (37).

- Check the blower relay power supply line for open circuit.

Is the wiring harness between blower relay connector C-402 (terminals 1 and 4) and the fusible link (37) in good condition?

STEP 5. Check blower relay connector C-402 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is blower relay connector C-402 in good condition?

STEP 6. Check the wiring harness between blower relay connector C-402 (terminal 3) and blower motor connector C-213 (terminal 1).

- Check the blower motor power supply line for open circuit.

Is the wiring harness between blower relay connector C-402 (terminal 3) and blower motor connector C-213 (terminal 1) in good condition?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)