INSPECTION PROCEDURE 5: Blower Air Amount cannot be Changed.

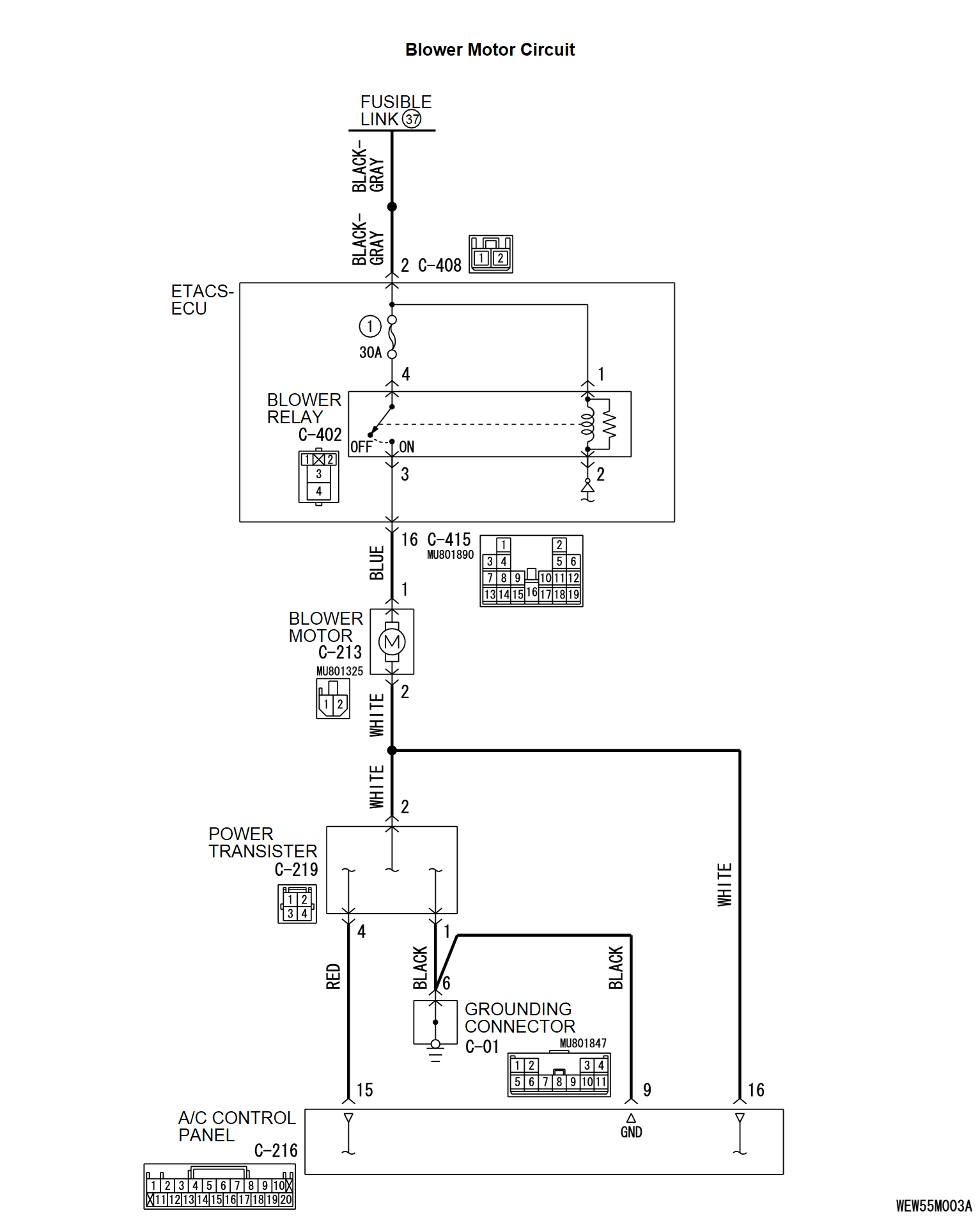

CIRCUIT OPERATION

If the blower motor speed cannot be changed, the power transistor circuit is suspected.

TROUBLESHOOTING HINTS

- Malfunction of the power transistor

- Malfunction of the A/C control panel

- Damaged wiring harness or connectors

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

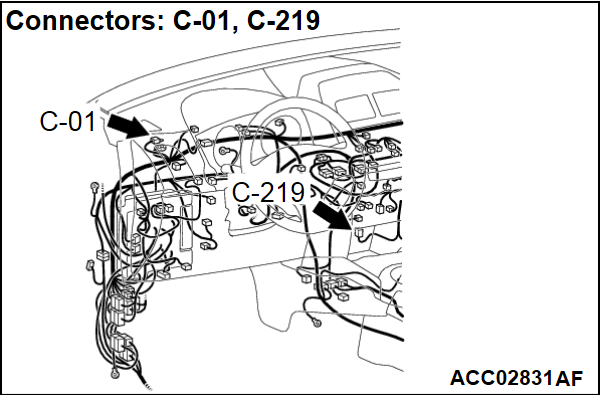

STEP 1. Check power transistor connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is power transistor connector C-219 in good condition?

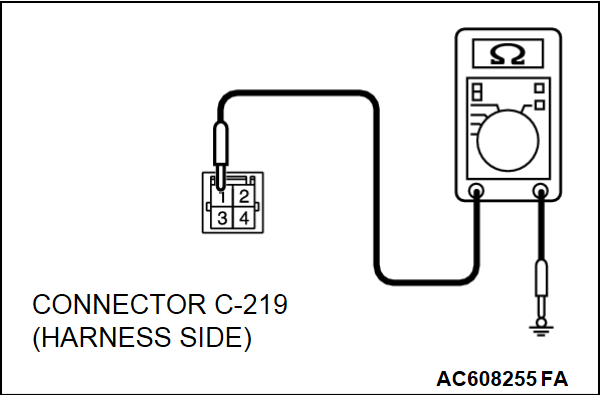

STEP 2. Measure the resistance at power transistor connector C-219.

(1) Disconnect power transistor connector C-219, and measure the resistance at the wiring harness side.

(2) Measure the resistance value between terminal 1 and ground.

OK: The measured value should be 2 ohms or less

Does the measured resistance value correspond with this range?

STEP 3. Check grounding connector C-01 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is grounding connector C-01 in good condition?

STEP 4. Check the wiring harness between power transistor connector C-219 (terminal 1) and grounding connector C-01 (terminal 6), between grounding connector C-01 (terminal 6) and A/C control panel connector C-216 (terminal 9).

- Check the power transistor ground line for open circuit.

Is the wiring harness between power transistor connector C-219 (terminal 1) and grounding connector C-01 (terminal 6), between grounding connector C-01 (terminal 6) and A/C control panel connector C-216 (terminal 9) good condition?

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent Malfunctions

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent Malfunctions  .

. Repair the wiring harness. The blower motor should operate normally.

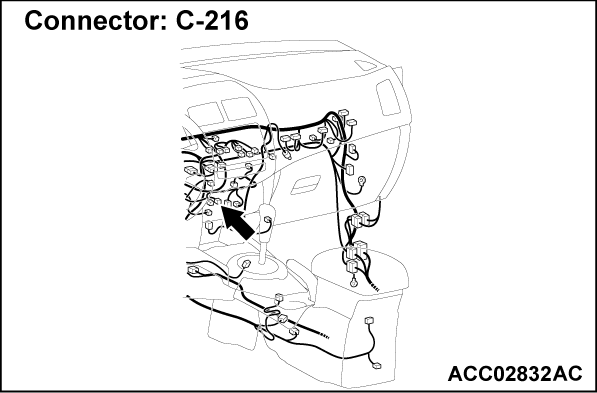

Repair the wiring harness. The blower motor should operate normally.STEP 5. Check A/C control panel connector C-216 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Is A/C control panel connector C-216 in good condition?

STEP 6. Check the wiring harness between A/C control panel connector C-216 (terminals 16 and 15) and power transistor connector C-219 (terminals 2 and 4).

- Check the A/C control panel signal line for open and short circuit.

Is the wiring harness between A/C control panel connector C-216 (terminals 16 and 15) and power transistor connector C-213 (terminals 2 and 4) in good condition?

Repair the wiring harness. The blower motor should operate normally.

Repair the wiring harness. The blower motor should operate normally.STEP 7. Replace the power transistor and check the trouble symptom again

Check the trouble symptom again. The procedure is complete.

The procedure is complete. Replace the A/C control panel.

Replace the A/C control panel.

Is the check result satisfactory?

The procedure is complete.

The procedure is complete. Replace the A/C control panel.

Replace the A/C control panel.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)