DIAGNOSTIC ITEM 1: Diagnose when the scan tool cannot receive the data sent by ETACS-ECU

| caution | When servicing a CAN bus line, ground yourself by touching a metal object such as an unpainted water pipe. If you fail to do so, a component connected to the CAN bus line may be damaged. |

FUNCTION

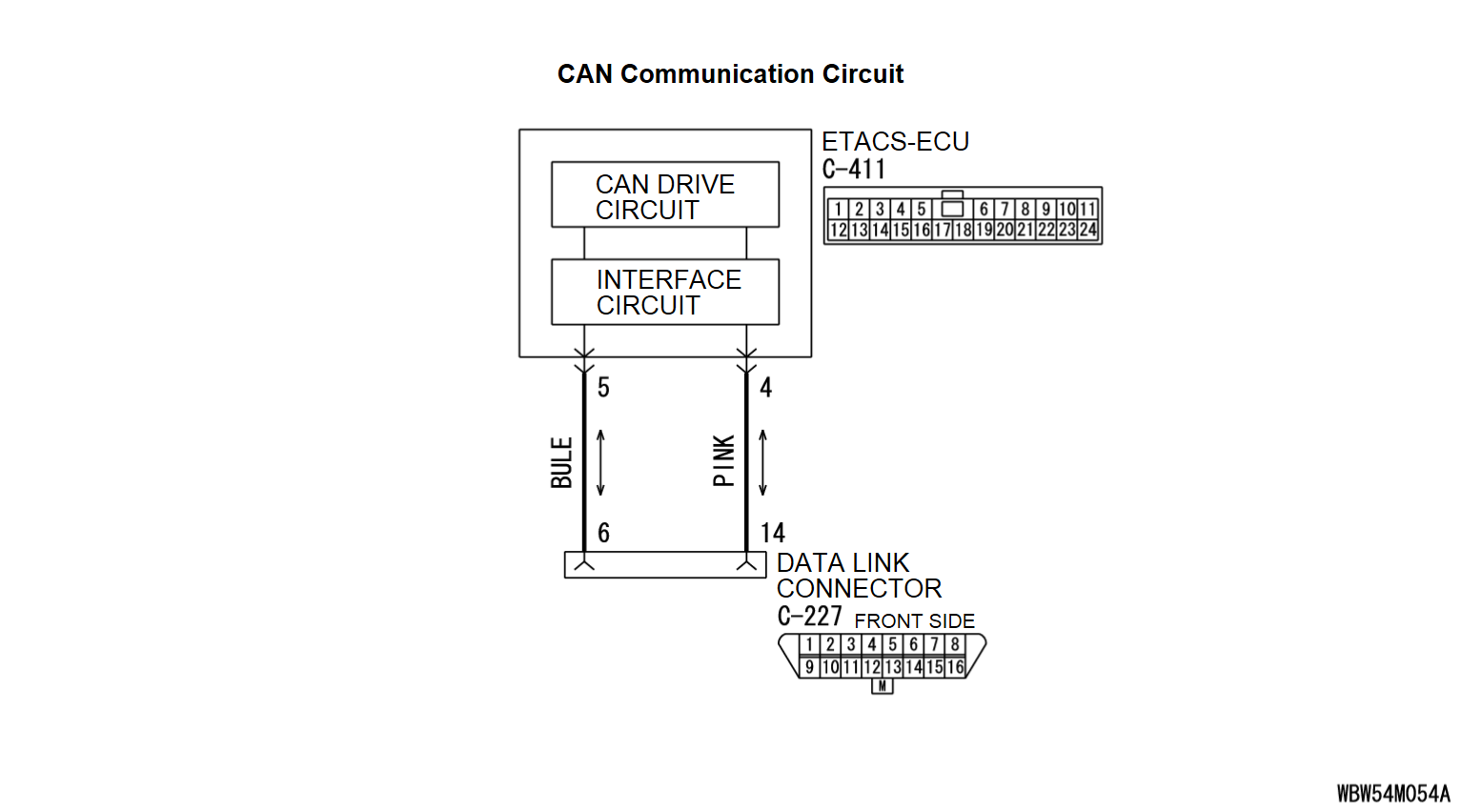

When the CAN bus diagnosis is carried out, the scan tool communicates with the ETACS-ECU. If a communication flag is not set for the ETACS-ECU, the ETACS-ECU will be diagnosed as a communication error.

TROUBLE JUDGMENT CONDITIONS

If a communication flag is not set for the ETACS-ECU, the Scan Tool determines that there is a failure.

TROUBLESHOOTING HINTS

- Malfunction of the connector (data link connector or ETACS-ECU connector improperly connected)

- Malfunction of the wiring harness (open circuit, short to ground, short to power supply between the data link connector and the ETACS-ECU connector, line-to-line short, or power supply to the ETACS-ECU)

- Malfunction of ETACS-ECU

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

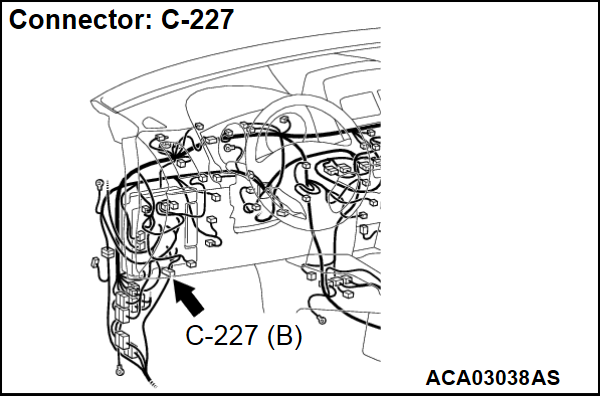

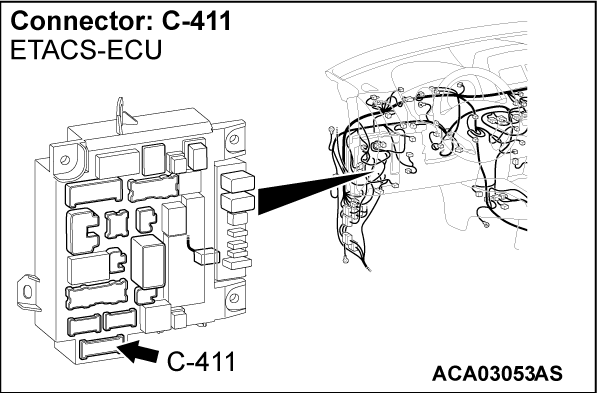

STEP 1. Check data link connector C-227 and ETACS-ECU connector C-411 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

| caution | The strand end of the twisted wire should be within 10 cm (4 inches) from the connector. For details refer to  . . |

Are data link connector C-227 and ETACS-ECU connector C-411 in good condition?

Repair the damaged parts.

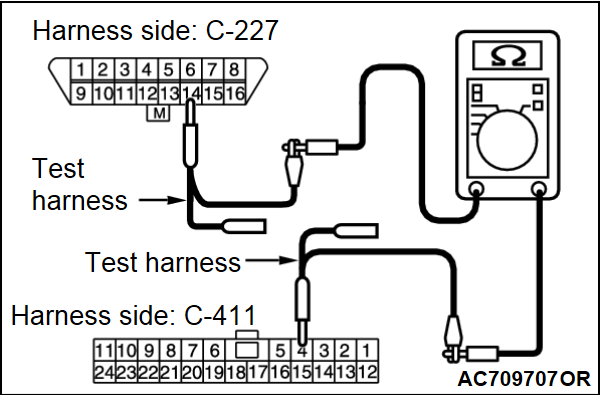

Repair the damaged parts.STEP 2. Check the wiring harness between data link connector C-227 and ETACS-ECU connector C-411 for open circuit.

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

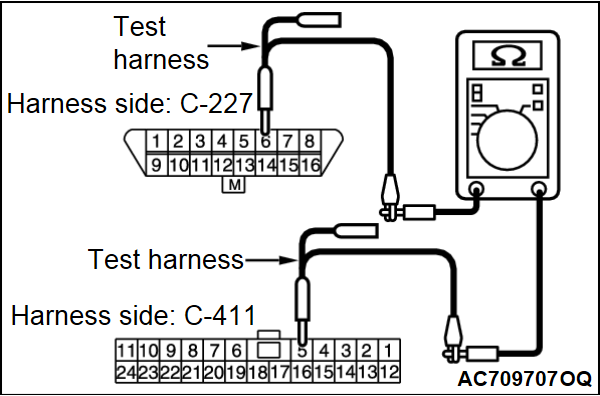

(1) Disconnect the scan tool and ETACS-ECU connector C-411, and check the wiring harness.

(2) Check the wiring harness between data link connector C-227 (terminal No.6) and ETACS-ECU connector C-411 (terminal No.5) <CAN_H>

OK: Continuity exists (2 ohms or less)

(3) Check the wiring harness between data link connector C-227 (terminal No.14) and ETACS-ECU connector C-411 (terminal No.4) <CAN_L>

OK: Continuity exists (2 ohms or less)

Is the wiring harness between data link connector C-227 and ETACS-ECU connector C-411 in good condition?

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.

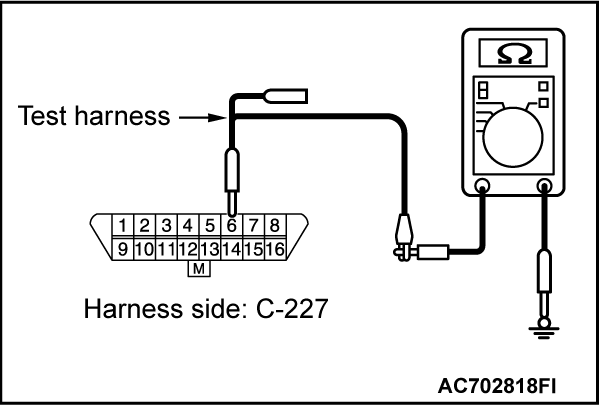

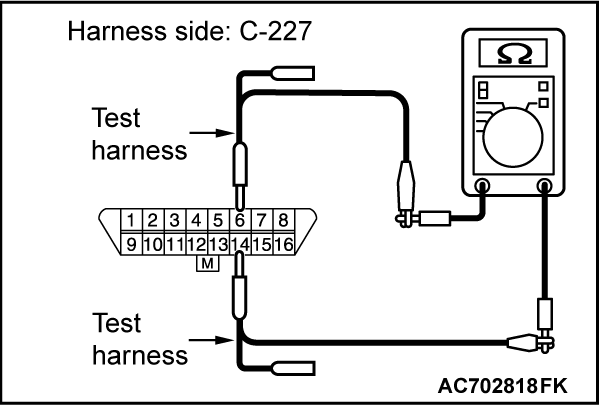

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.STEP 3. Check the wiring harness between data link connector C-227 and ETACS-ECU connector C-411 for a short to ground. Measure the resistance at data link connector C-227.

| caution | Disconnect the negative battery terminal. For details refer to  . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the scan tool and ETACS-ECU connector C-411, and measure the resistance at the wiring harness side of data link connector C-227.

(2) Measure the resistance between data link connector terminal 6 and body ground. <CAN_H>

OK: 1 kΩ or more

(3) Measure the resistance between data link connector terminal 14 and body ground. <CAN_L>

OK: 1 kΩ or more

Do all the resistances measure 1 kΩ or more?

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.

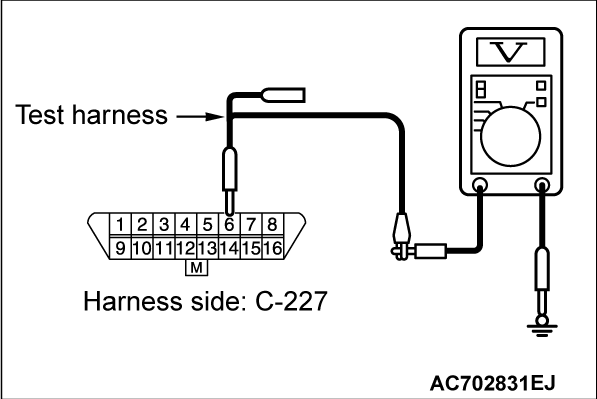

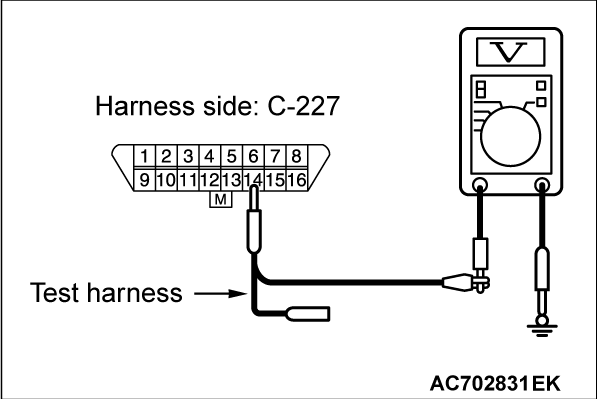

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.STEP 4. Check the wiring harness between data link connector C-227 and ETACS-ECU connector C-411 for a short to the power supply. Measure the voltage at data link connector C-227.

| caution | Disconnect the negative battery terminal. For details refer to  . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the scan tool and ETACS-ECU connector C-411, and measure the resistance at the wiring harness side of data link connector C-227.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between data link connector terminal 6 and body ground. <CAN_H>

OK: 1 volts or less

(4) Measure the voltage between data link connector terminal 14 and body ground. <CAN_L>

OK: 1 volts or less

Do all the voltage measure 5 volts or less?

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.

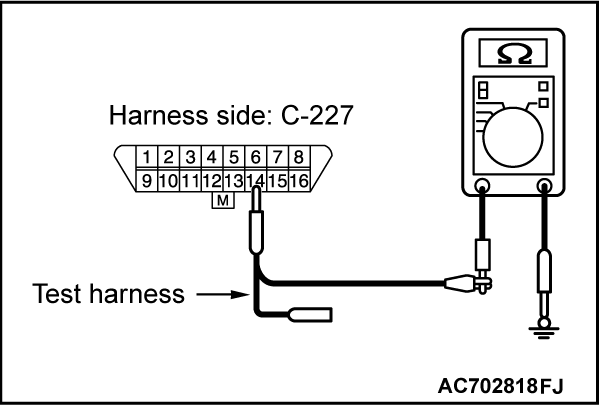

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.STEP 5. Check the wiring harness between data link connector C-227 and ETACS-ECU connector C-411 for line-to-line short. Measure the resistance at data link connector C-227.

| caution | Disconnect the negative battery terminal. For details refer to  . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the scan tool and ETACS-ECU connector C-411, and measure the resistance at the wiring harness side of data link connector C-227.

(2) Measure the resistance between data link connector terminal 6 and 14.

OK: No continuity

Is the check result normal?

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.

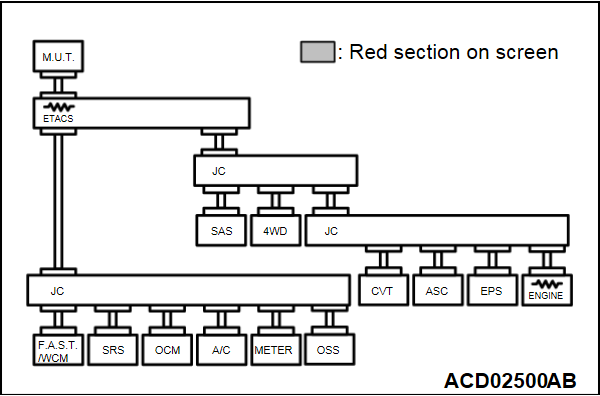

Repair the wiring harness between data link connector C-227 and ETACS-ECU connector C-411.STEP 6. Using scan tool MB991958, diagnose the CAN bus line.

(1)

| caution | To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958. |

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose CAN bus lines, and check if the scan tool screen is as shown in the illustration.

Does the scan tool screen correspond to the illustration?

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use Troubleshooting/inspection Service Points - How to Cope with Intermittent Malfunction  ).

). Replace the ETACS-ECU.

Replace the ETACS-ECU.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)