This bulletin supersedes SR-18-002REV, to revise the ordering part number for the brake fluid and the approximate brake fluid (in fluid ounces). Revisions are italicized and indicated by  .

.

|

SUBJECT: PARKING BRAKE CORROSION - SAFETY RECALL CAMPAIGN - REVISED |

No: SR-18-002REVII |

||||||||||||||||||

|

DATE: June 2018 |

|||||||||||||||||||

|

MODEL: See Below |

|||||||||||||||||||

|

CIRCULATE TO: |

[ X ] GENERAL MANAGER |

[ X ] PARTS MANAGER |

[ X ] TECHNICIAN |

||||||||||||||||

|

[ X ] SERVICE ADVISOR |

[ X ] SERVICE MANAGER |

[ X ] WARRANTY PROCESSOR |

[ X ] SALES MANAGER |

||||||||||||||||

|

This bulletin supersedes SR-18-002REV, to revise the ordering part number for the brake fluid and the approximate brake fluid (in fluid ounces). Revisions are italicized and indicated by |

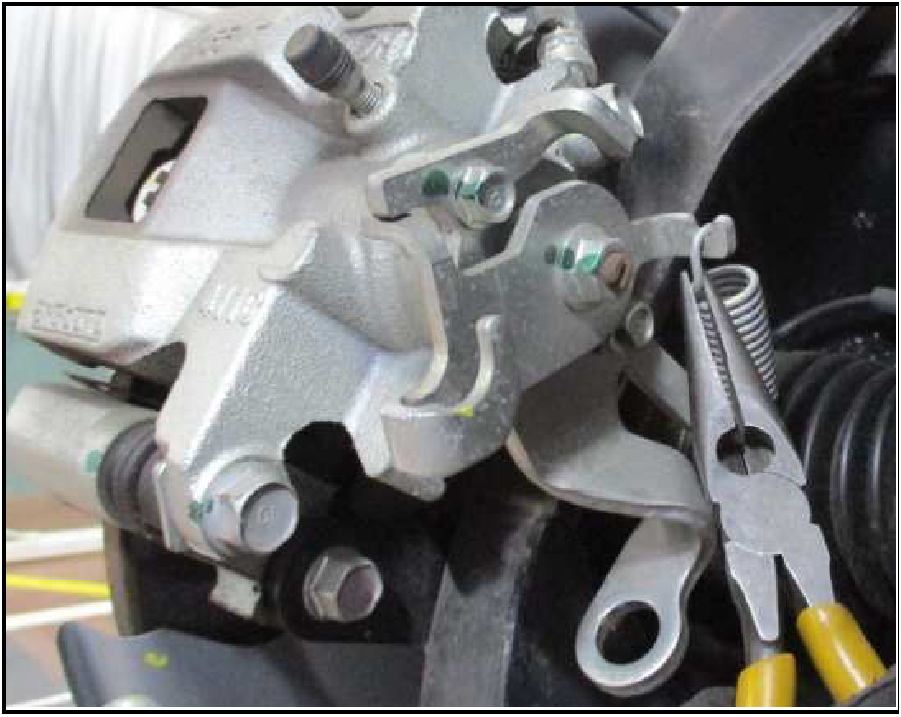

This campaign bulletin instructs dealers to inspect the rear brake calipers and, if necessary, replace the parking brake boot and lever or the brake caliper body. On certain affected vehicles, the dealer must also replace the piston assembly and piston boot.

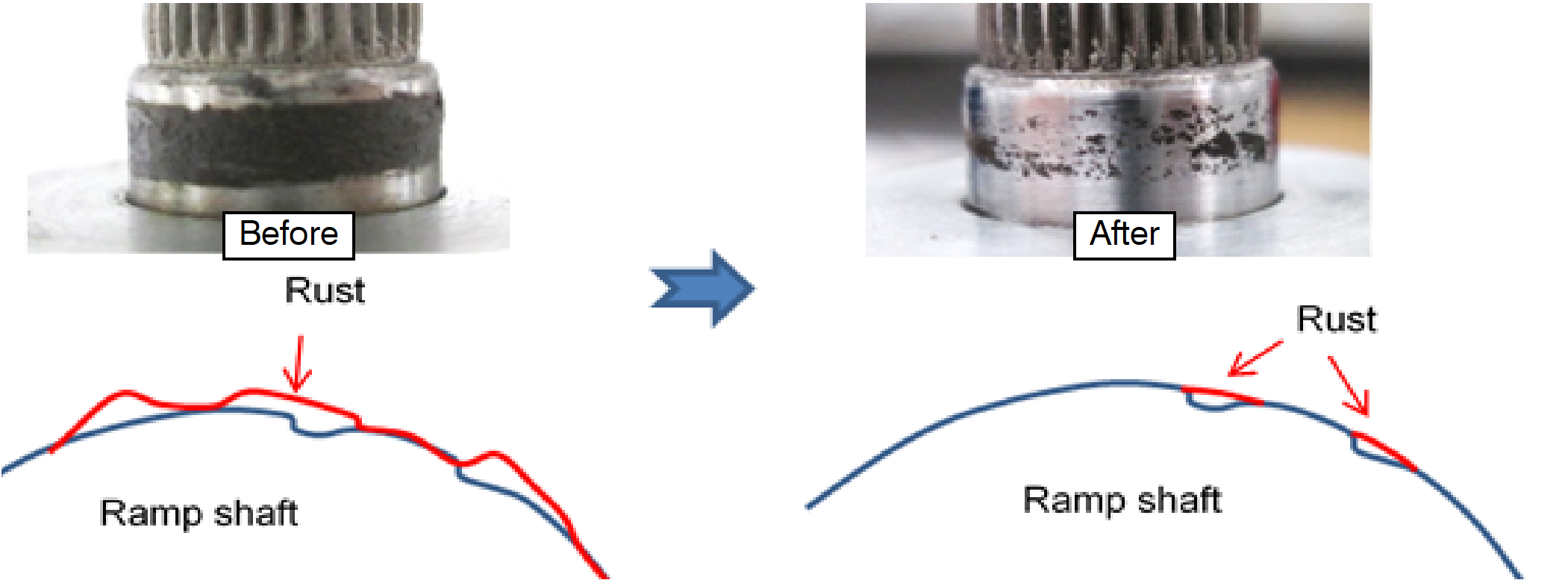

(A) Due to insufficient rust prevention to the operating shaft of the parking brake and insufficient sealing performance of the rear brake caliper lever boot, water may penetrate the brake caliper lever boot and the parking brake operating shaft, causing caliper body and/or parking brake operating shaft corrosion. As a result, the operating shaft may bind, causing the rear brakes to drag and/or decrease parking brake performance.

(B) Due to an inappropriate manufacturing process, the automatic adjuster in the rear brake caliper, with built-in parking brake, may not work. If the automatic adjusters do not work, as brake pads wear, the parking brake lever's effective engagement point will increase until the parking brake no longer engages.

If the parking brake does not operate properly, the vehicle, when parked on a slope, may move unexpectedly, increasing the risk of a crash.

Before starting this campaign procedure, CHECK THE WARRANTY SUPERSCREEN to verify if the vehicle is an affected VIN for this campaign and that this campaign procedure has not already been completed. The repair procedure is VIN-specific. If the vehicle has Campaign Operation C1802X or C1803X, follow Workflow A. If the vehicle has Campaign Operation C1802Z or C1803R, follow Workflow B.

Letters will be sent to all owners of affected vehicles requesting them to bring their vehicle to a local Authorized Mitsubishi dealer to have their vehicle remedied. Copies of the customer notification letters appear at the end of this bulletin.

Brake fluid (approximately 16 fl oz per caliper)

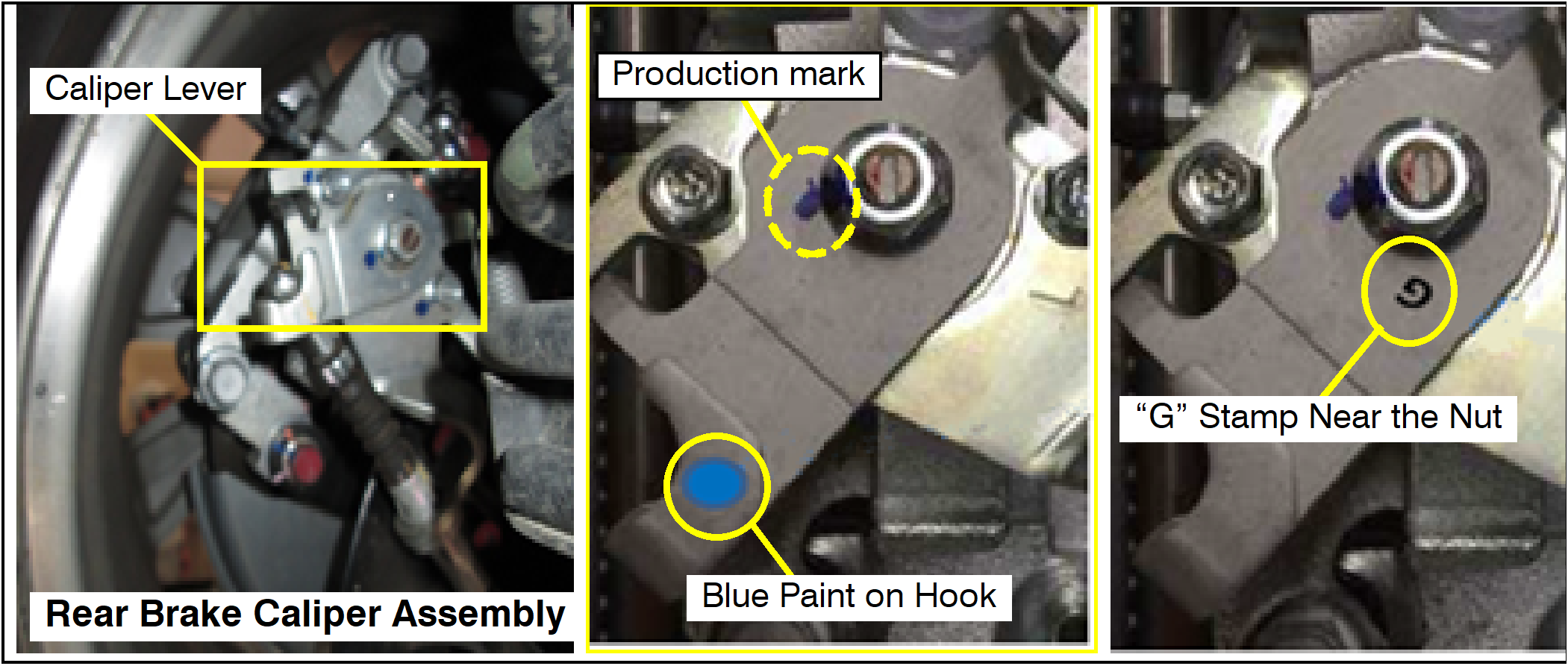

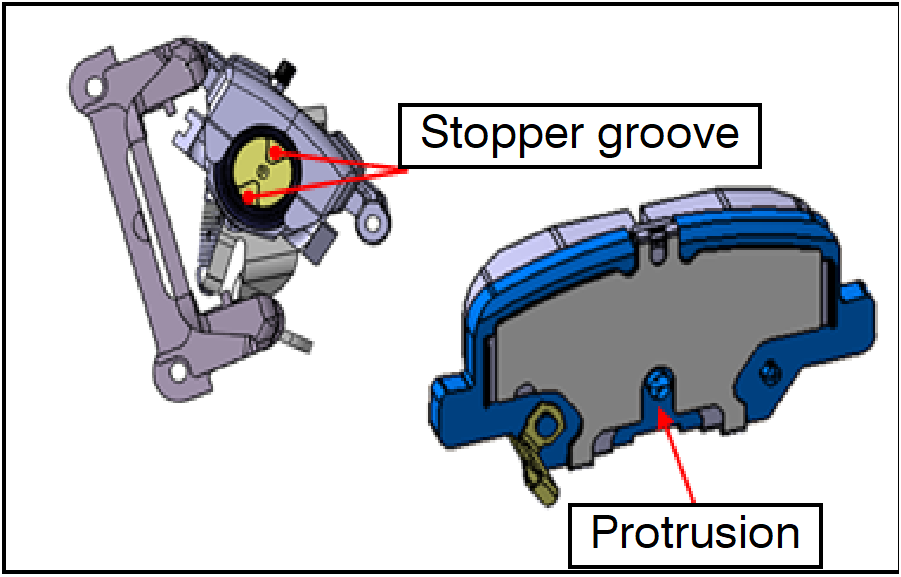

Brake fluid (approximately 16 fl oz per caliper)The affected parts may have already been replaced with improved parts even if the vehicle is listed as a campaign-affected vehicle. Check for identification marks on the caliper lever of the rear brake caliper assembly to determine whether the repair/replacement procedures are required.

If blue paint mark is found on the hook of the caliper lever or if “G” is stamped near the nut, the caliper is already a countermeasure unit. No further inspection or replacement work is required.

Check both left and right rear brake caliper assemblies.

NOTE: Blue or green marks located on areas other than the lever hook are production marks and do not mean they are improved parts.

|

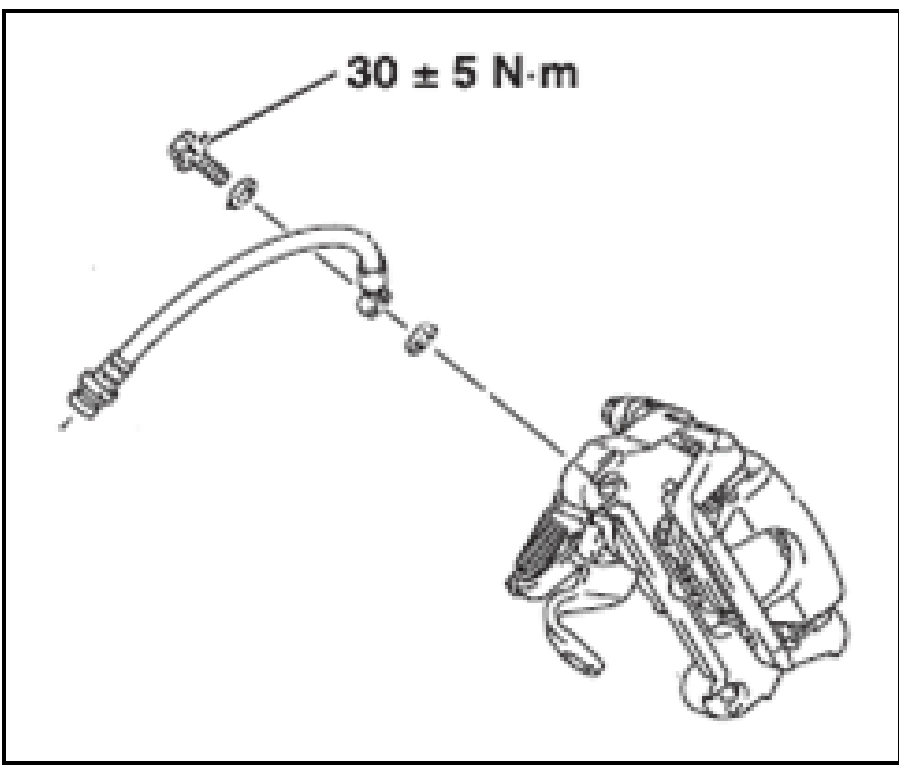

Do NOT spill any brake fluid on vehicle or vehicle components.

Do NOT spill any brake fluid on vehicle or vehicle components.

Do NOT pinch or bend the brake hose.

Do NOT pinch or bend the brake hose.

|

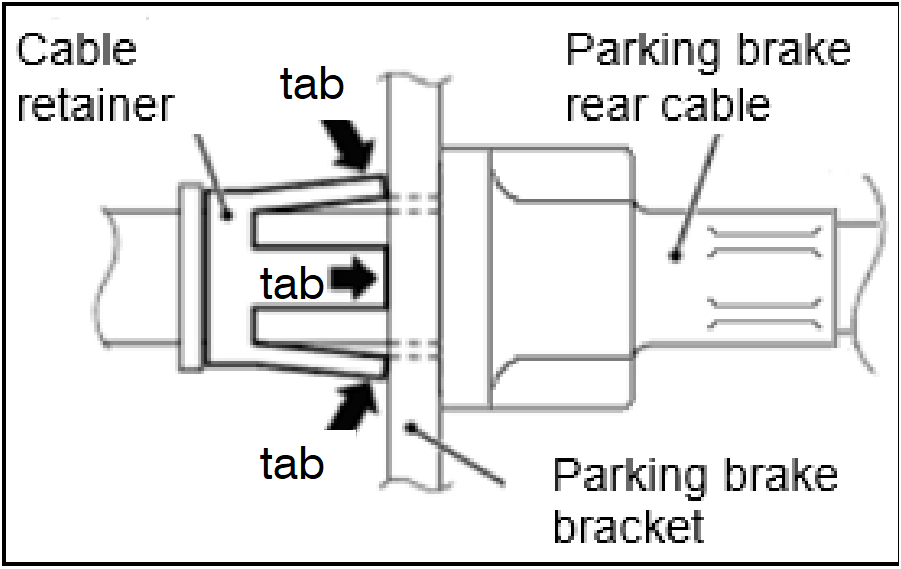

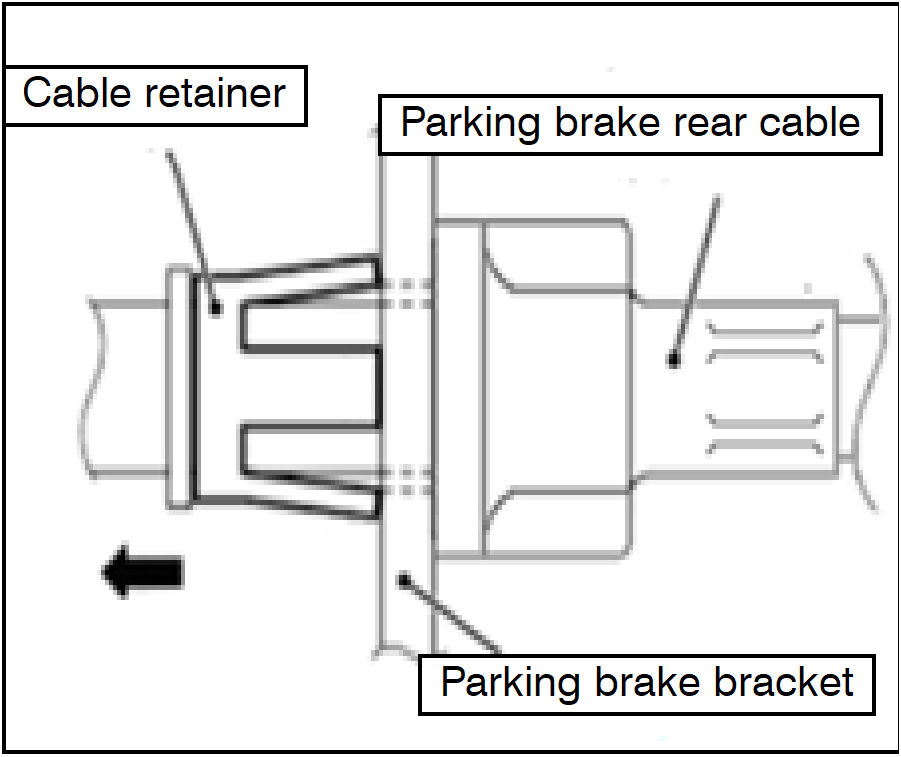

When disconnecting the parking brake rear cable, be careful not to damage the tabs located on the retainer of the parking brake rear cable. Fit a 12.8 mm (0.5 in) hose clamp (MB248923) on the retainer of the parking brake rear cable will prevent damage to tabs during tabs compression.

When disconnecting the parking brake rear cable, be careful not to damage the tabs located on the retainer of the parking brake rear cable. Fit a 12.8 mm (0.5 in) hose clamp (MB248923) on the retainer of the parking brake rear cable will prevent damage to tabs during tabs compression.

|

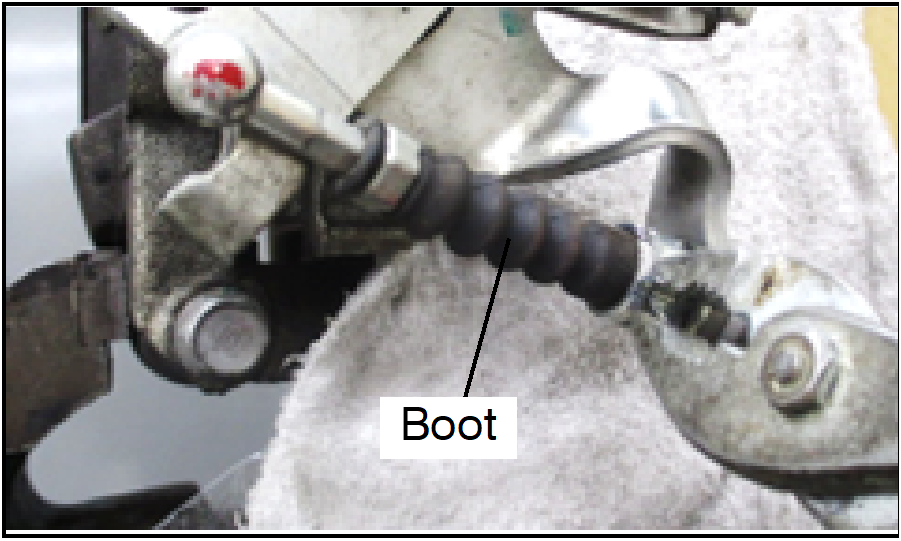

Be careful to not damage the boot while pulling the parking brake rear cable off of the parking brake bracket.

Be careful to not damage the boot while pulling the parking brake rear cable off of the parking brake bracket.

|

|

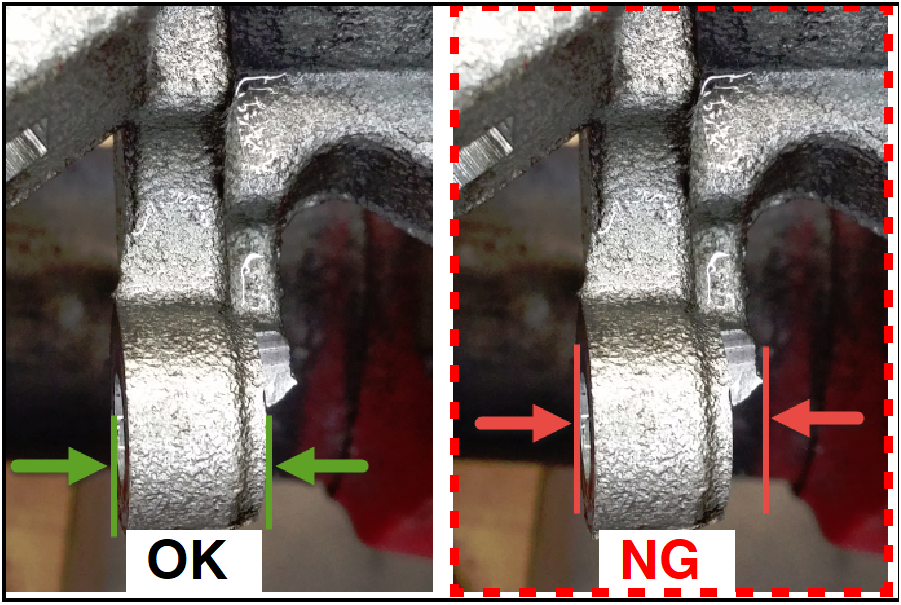

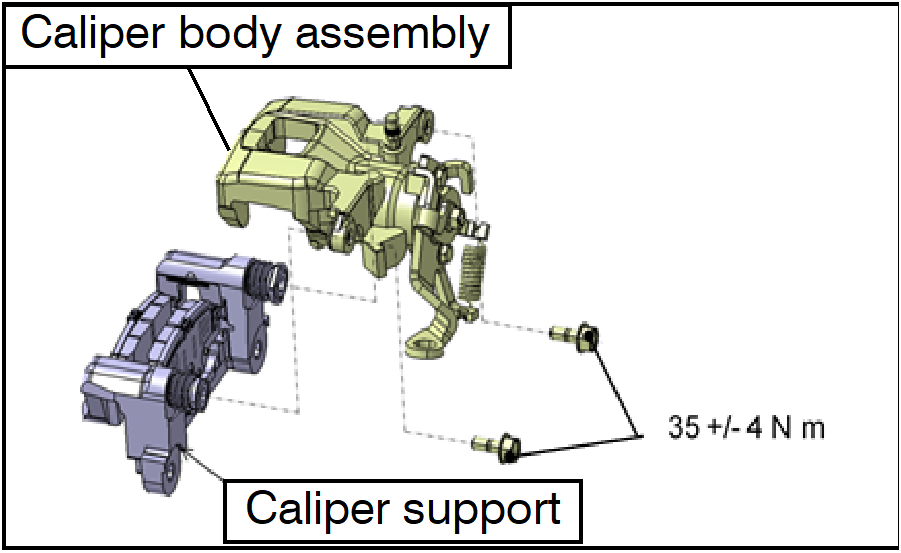

CAUTION: DO NOT fix the caliper body assembly at the stepped section (NG). |

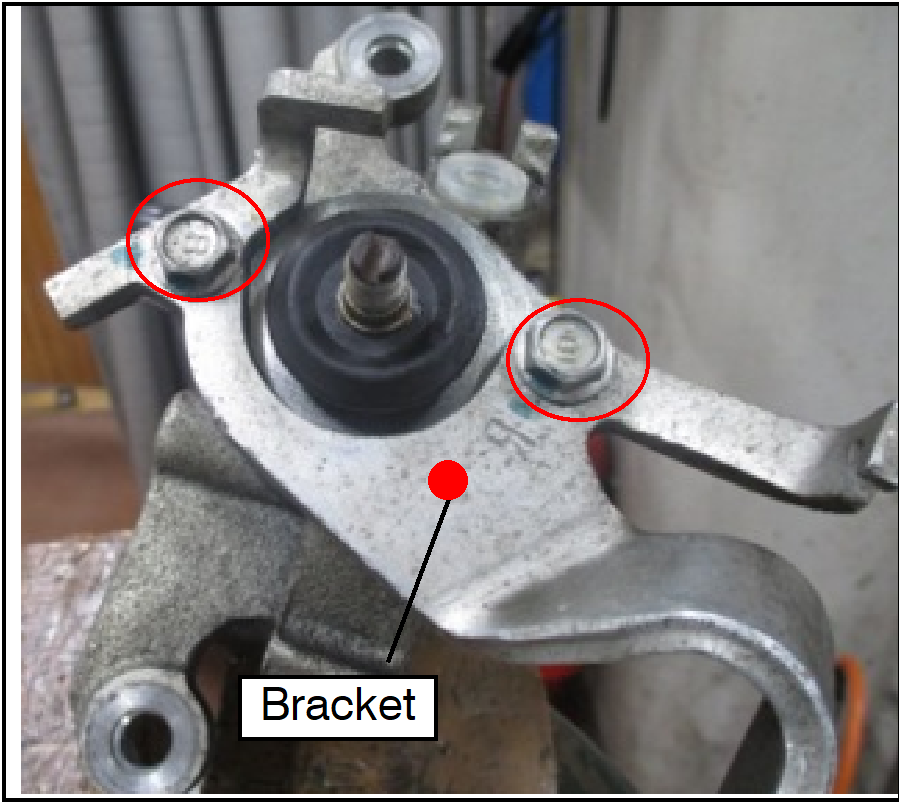

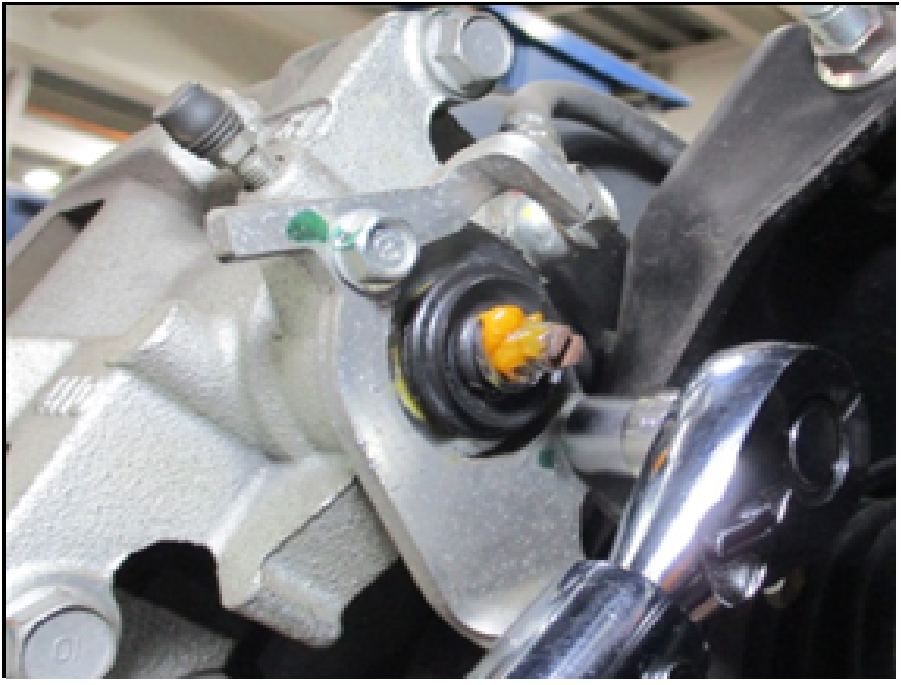

Risk of Injury. Force is required to remove the caliper lever as it is press-fitted. Ensure that the circled nut is loosened and not completely removed in the next step.

Risk of Injury. Force is required to remove the caliper lever as it is press-fitted. Ensure that the circled nut is loosened and not completely removed in the next step.

|

|

|

(After bracket removal.) |

|

|

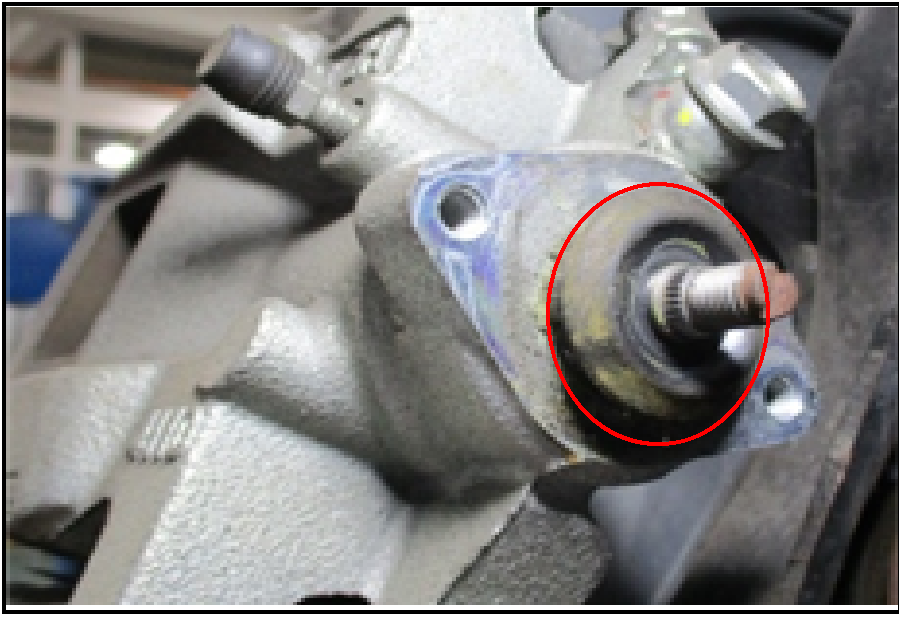

NOTE: The condition must be evaluated as NG if any scarring is found on the operating shaft (1) or near the caliper body groove. |

Identify the parts required for the following procedure.

|

|

|

|

|

|

|

|

|

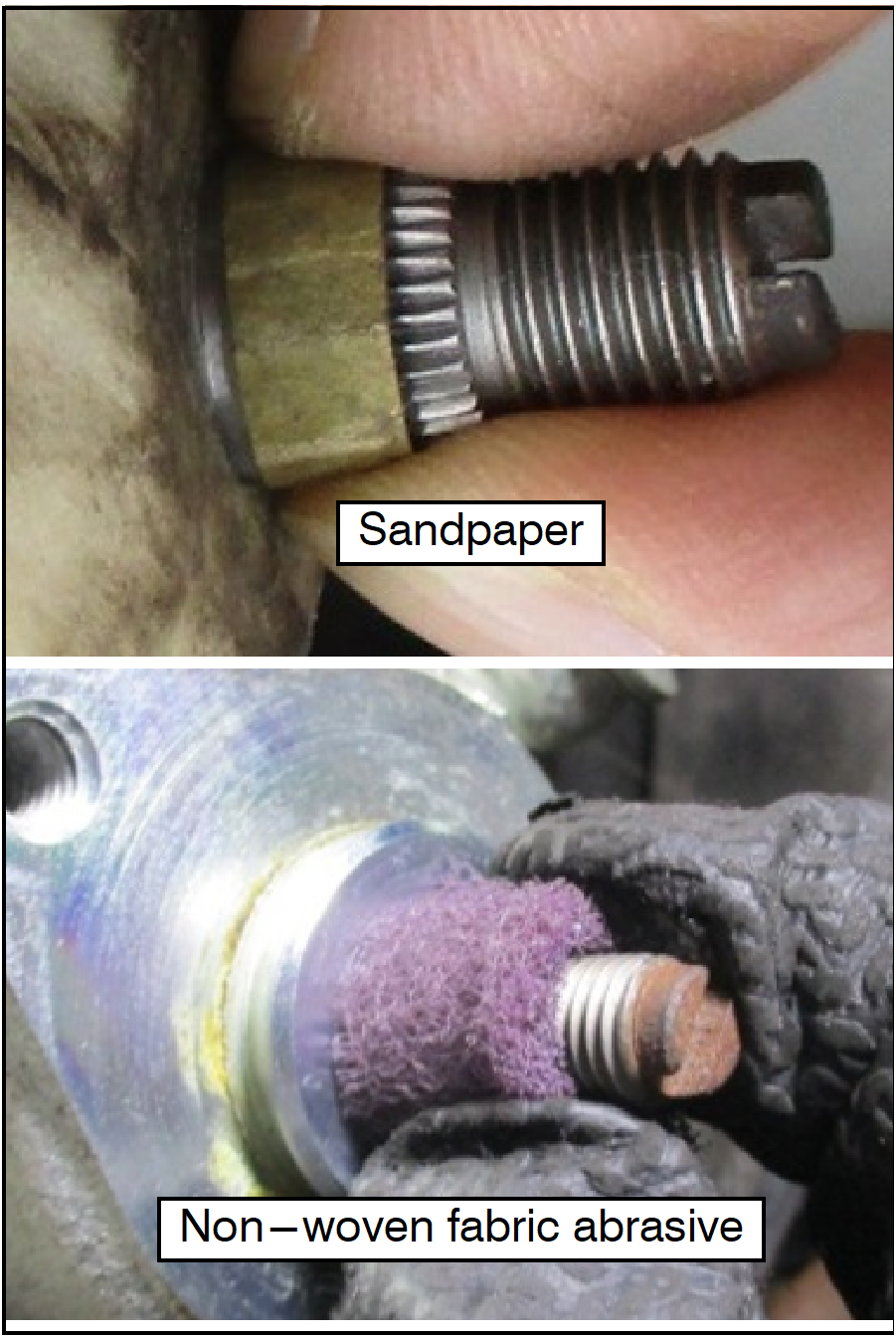

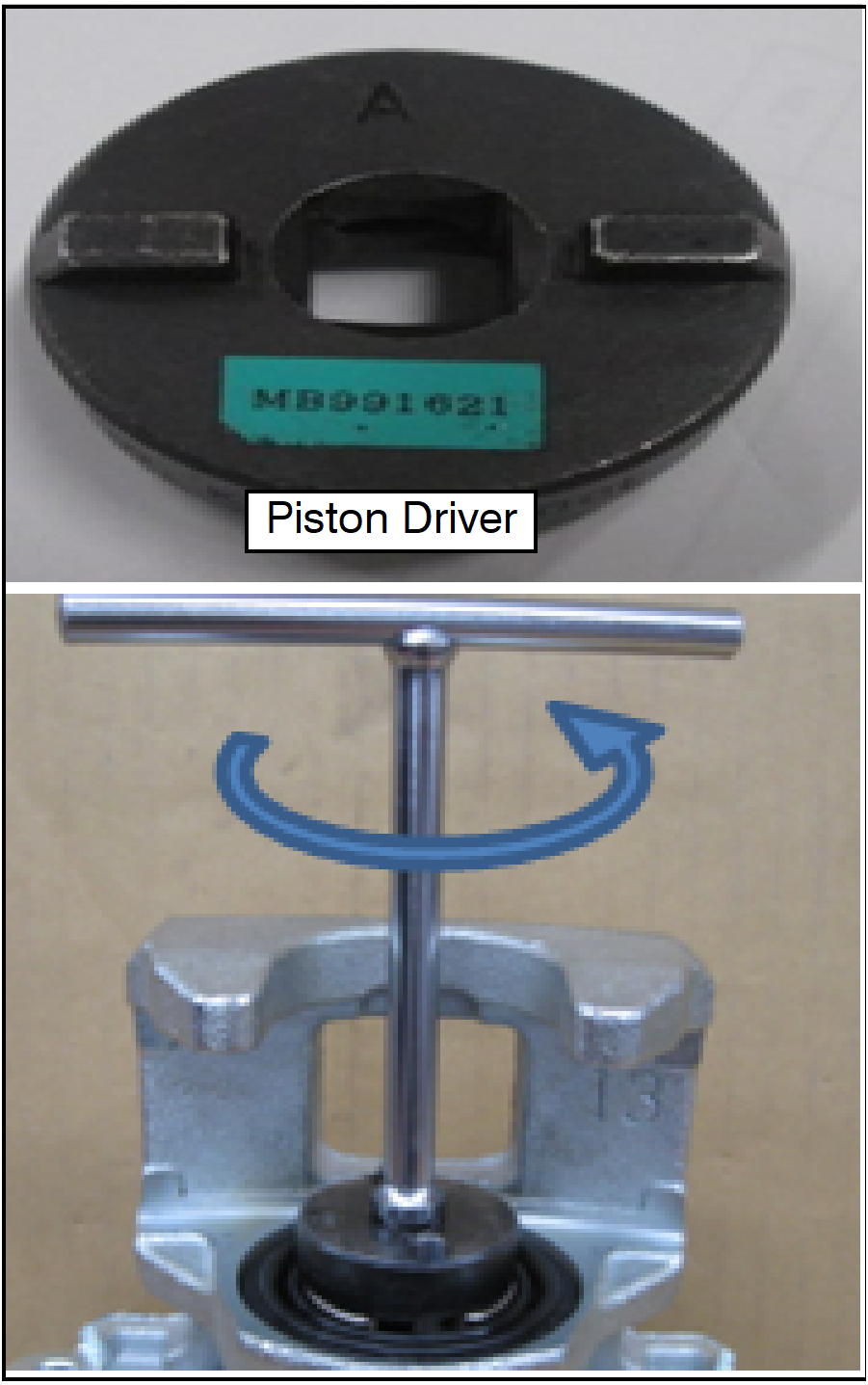

REPLACE PISTON ASSEMBLY AND PISTON BOOTS - (ONLY ON AFFECTED VEHICLES [C1802Z AND C1803R] AND WHERE THE CALIPER BODY IS NOT BEING REPLACED)

Identify the parts required for the following procedure.

|

CAUTION: When clamping the caliper body assembly with a vise, sandwich the caliper body with wood or rags, to prevent damage to the caliper body. |

|

|

|

|

|

|

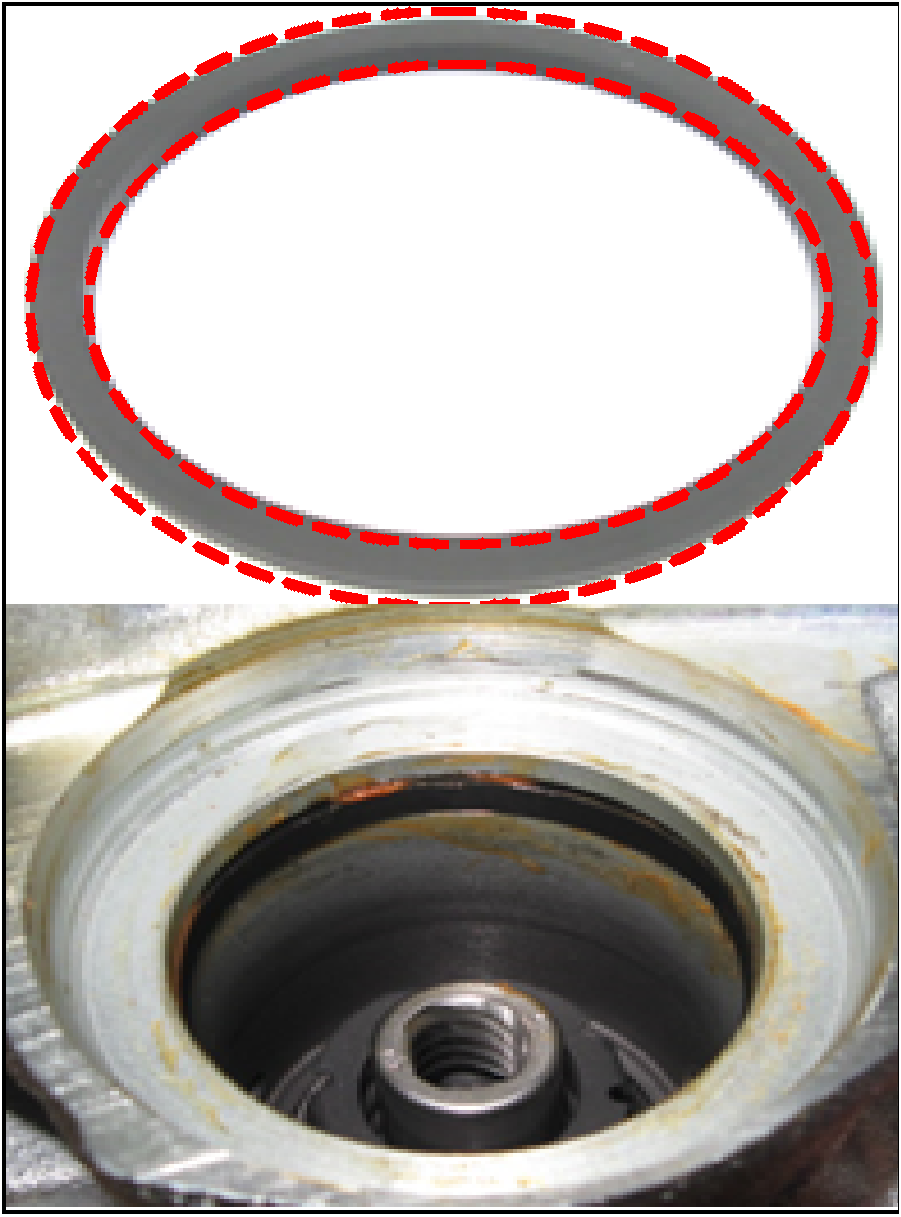

CAUTION: Do NOT allow any foreign materials to enter the caliper cylinder. |

|

|

|

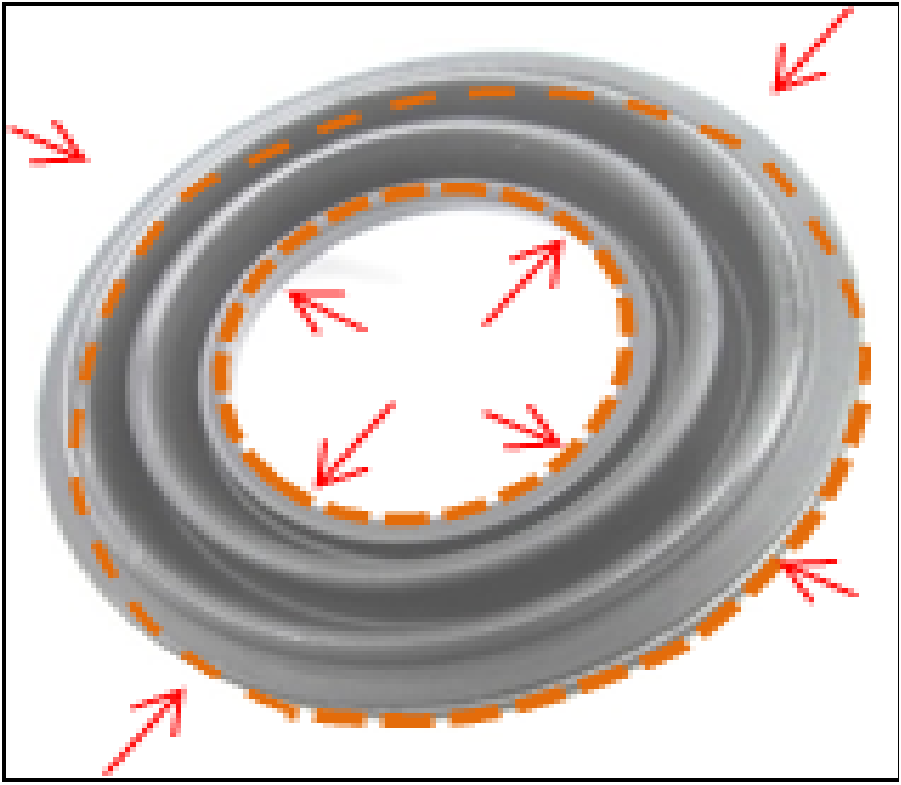

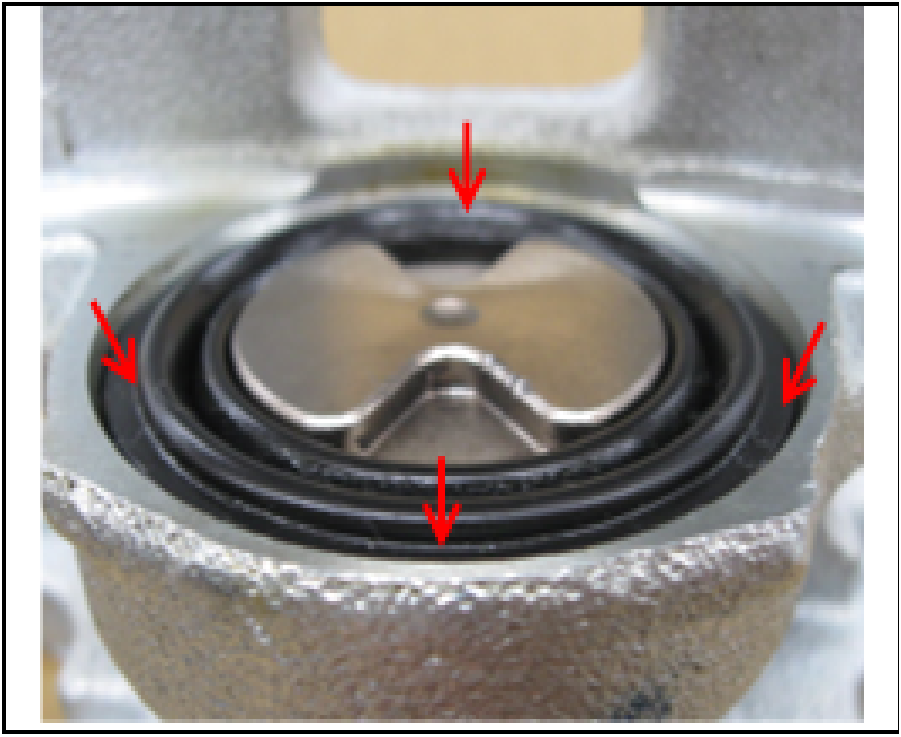

CAUTION: Confirm that the seal is fully seated. |

|

|

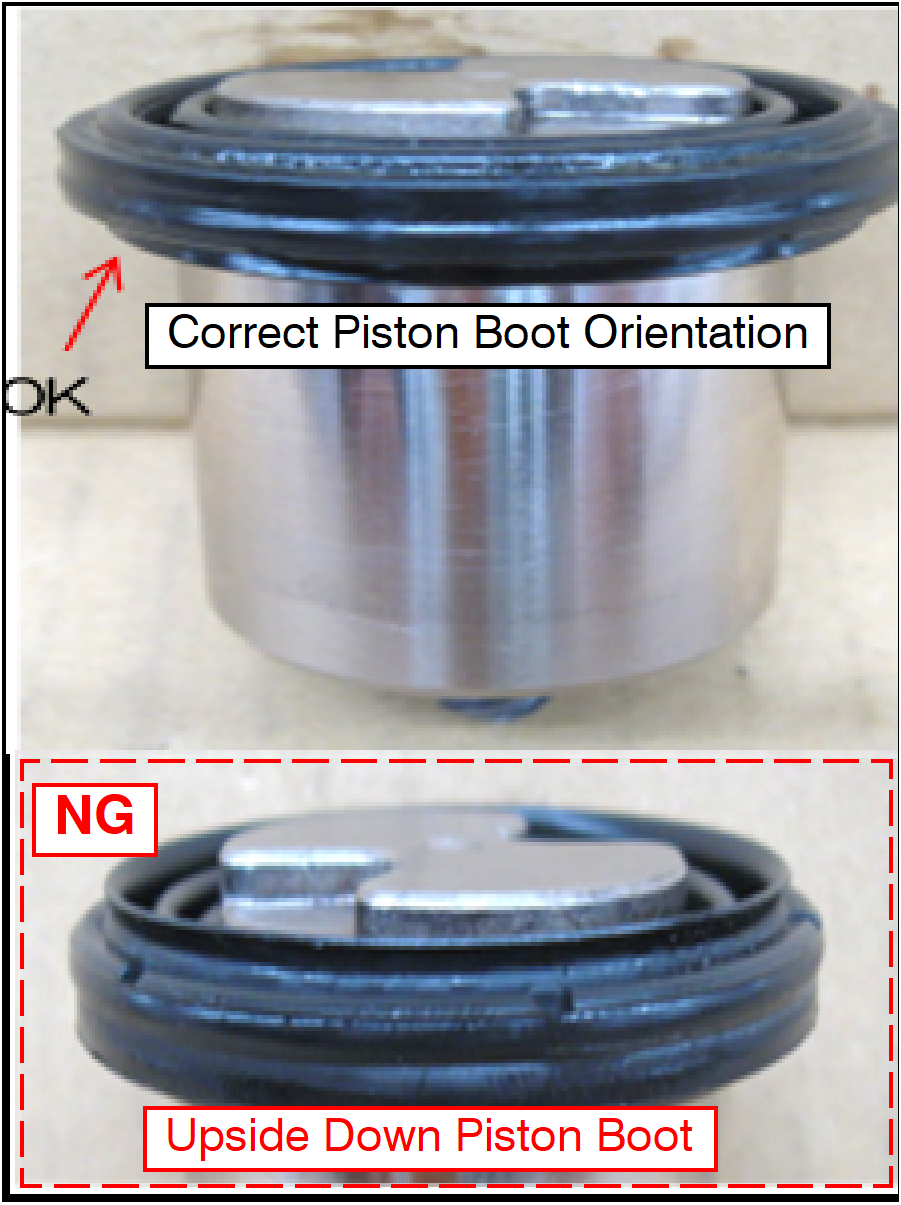

CAUTION: Do NOT install the piston boot upside down (NG). |

|

|

|

|

|

|

|

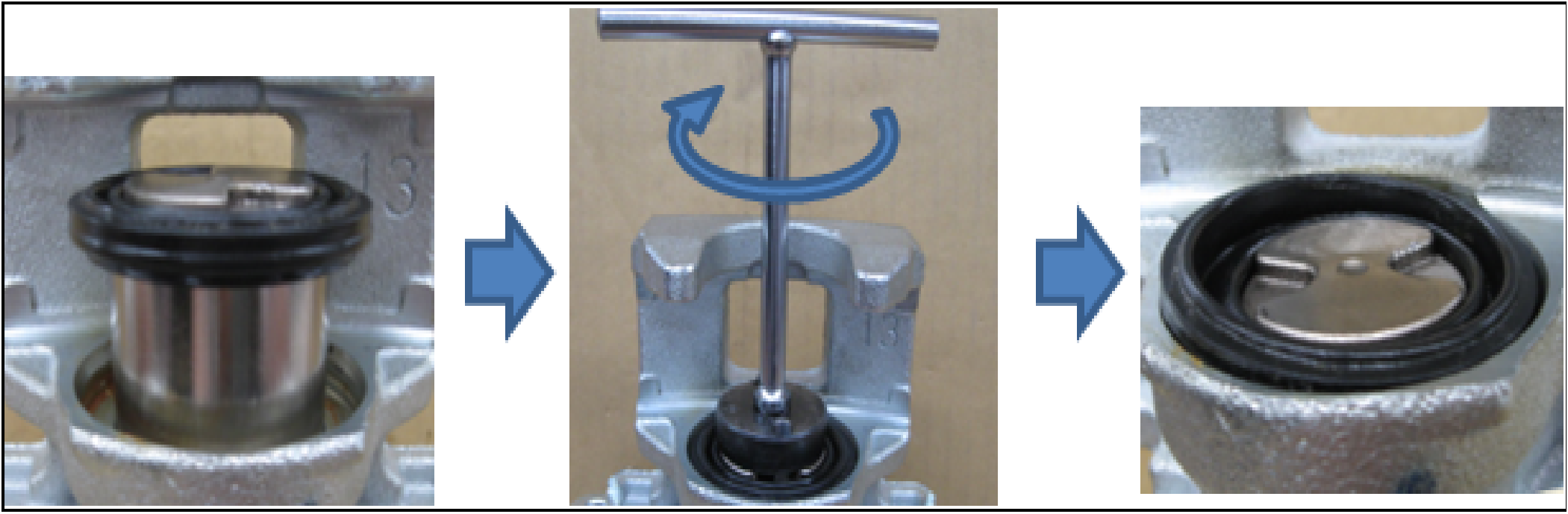

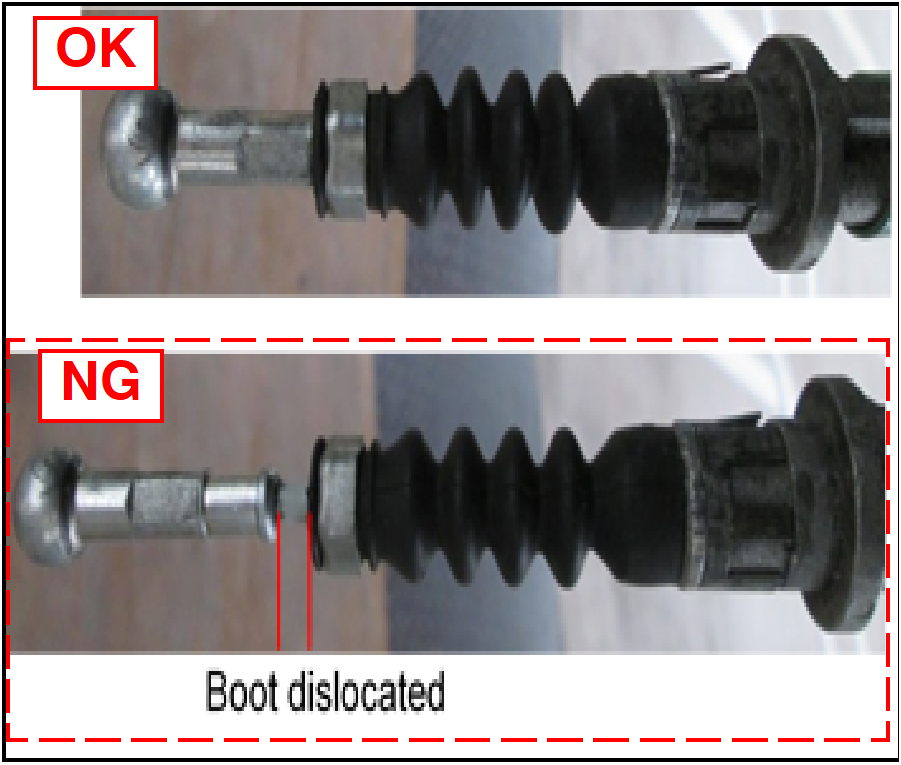

NOTE: Ensure that the boot is not dislocated. |

|

|

|

|

Use DOT4 brake fluid.

Do NOT mix different types of brake fluid.

Do NOT mix different types of brake fluid.

For Manual Transmission vehicles, ensure the fluid level is maintained above the clutch inlet line at all times.

|

|

NOTE: By depressing the brake pedal, the clearance between the brake pads and rear brake disc is adjusted to its optimum level.

The brake pedal should not sink to the floor while the engine is running. Perform troubleshooting to identify and repair any issues.

|

Model |

Outlander, Outlander Sport, RVR |

|

Lever operating force |

200 N (45 pounds) |

|

Lever travel |

6 to 7 notches |

Do NOT set the parking brake lever travel to a value lower than the standard value as it will cause dragging of the rear brakes.

Use only the Genuine Mitsubishi Parts listed below:

|

Part Number |

Description |

Qty |

Note |

|

4605B841 |

Caliper body assy (LH) |

1 |

|

|

4605B842 |

Caliper body assy (RH) |

1 |

|

|

4605B849 |

Caliper lever & Boots Kit (LH) |

1 |

|

|

4605B850 |

Caliper lever & Boots Kit (RH) |

1 |

|

|

4605B846 |

Washer Kit |

1 |

(1) washer kit required per piston assembly. |

|

4605C046 |

Piston assy |

1 |

Only C1802Z and C1803R campaigns |

|

4650B827QA |

Gasket |

2 |

(2) gaskets required for each caliper body installation |

|

MZ341022RCL* |

DOT4 Brake Fluid (to be used only for claims processing on this recall) |

1 |

(1) per side when caliper or piston is replaced |

*Order part number MZ320900 if additional brake fluid is required.

*Order part number MZ320900 if additional brake fluid is required.

Recall Campaign Claim Information

Enter all claims as claim type ‘C’ – Recall/Campaign Claims

Please follow the campaign instructions when entering each claim. See the example below.

Certain 2013-2015 MY Outlander Sport (4A models only), 2014-2016 MY Outlander, 2016 MY Outlander Sport (JA models only).

Recall Claim Header Section

After entering the required customer data and vehicle information, select the applicable campaign number and the one replacement scenario that was actually performed. Then, by hitting the “Save and Continue” button, the system will automatically fill-in several other fields.

Labor and Parts:

Labor: There are many possible repair scenarios for this campaign - follow the charts provided to select the appropriate labor operation and parts used for the repair performed.

If there is a need to provide the owner with a rental car, claim the applicable charges in this section

NOTE: Rental cars applicable in the US and Puerto Rico only.

Copyright 2018, Mitsubishi Motors North America, Inc.