A clicking noise (along with whining/humming), directly related to vehicle speed, is heard in the passenger compartment. As vehicle

speed increases, the clicking speed increases (engine speed has no effect on the noise). Due to engine

and road noises, the sound typically cannot be heard at vehicle speeds above 40 MPH.

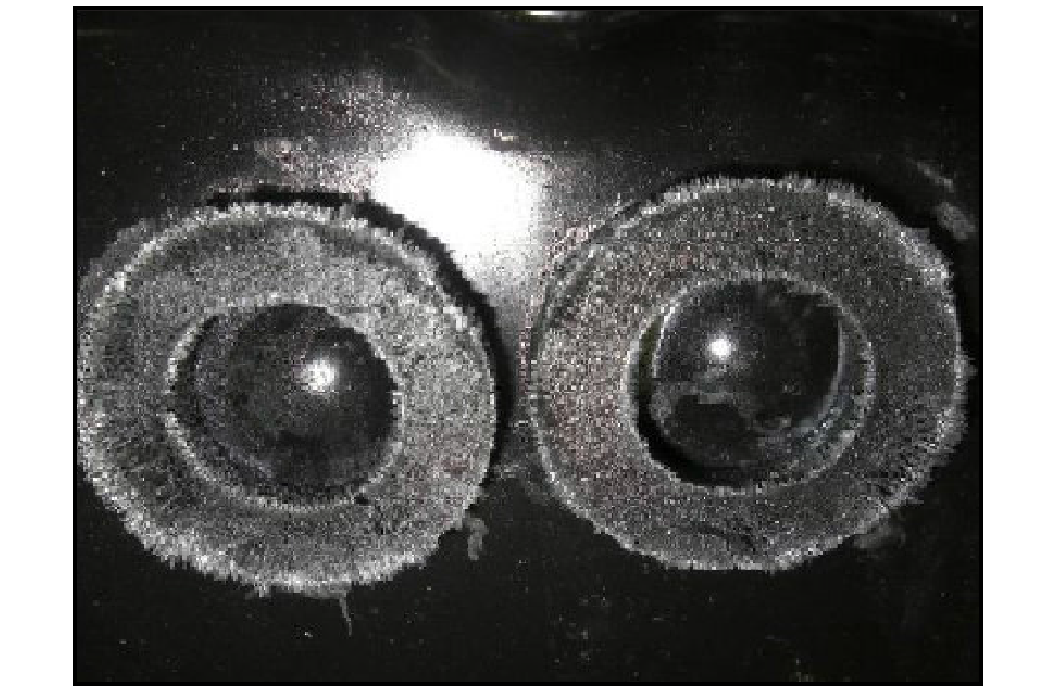

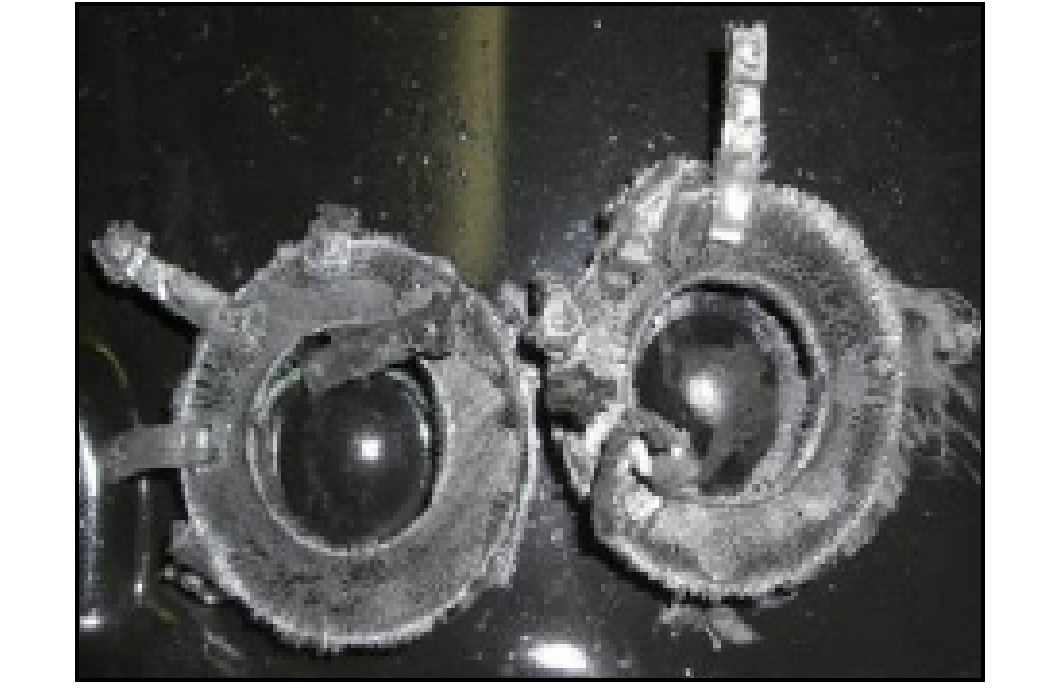

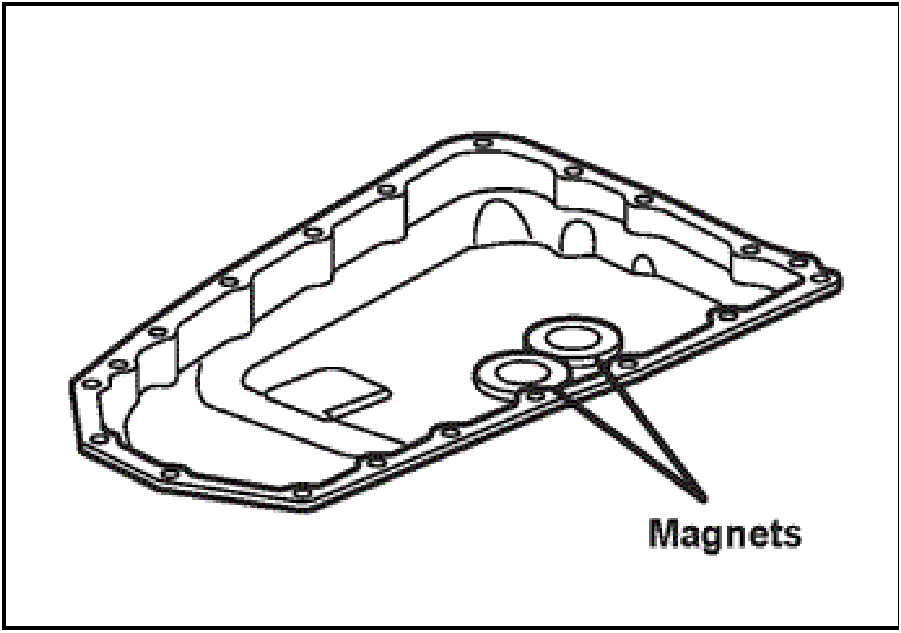

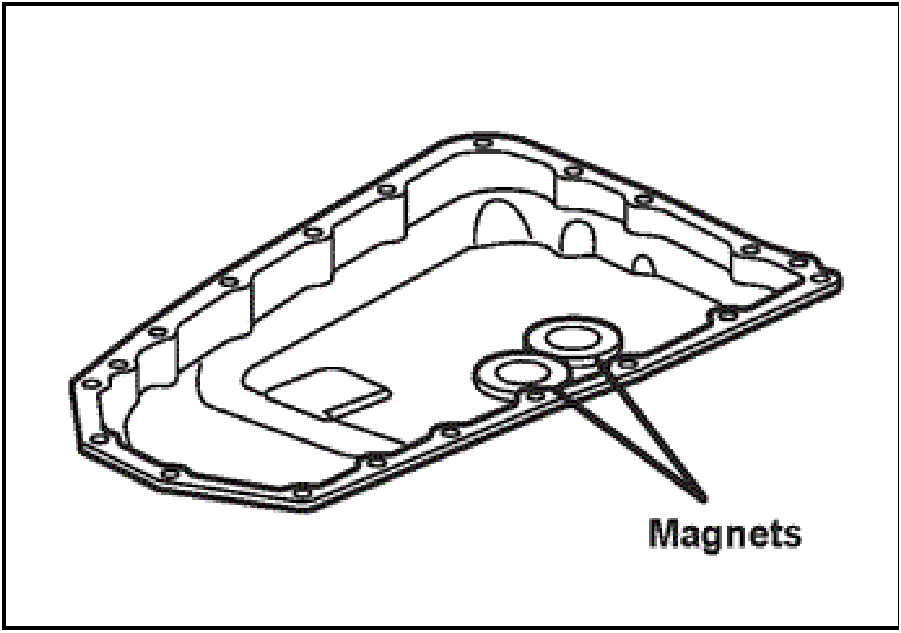

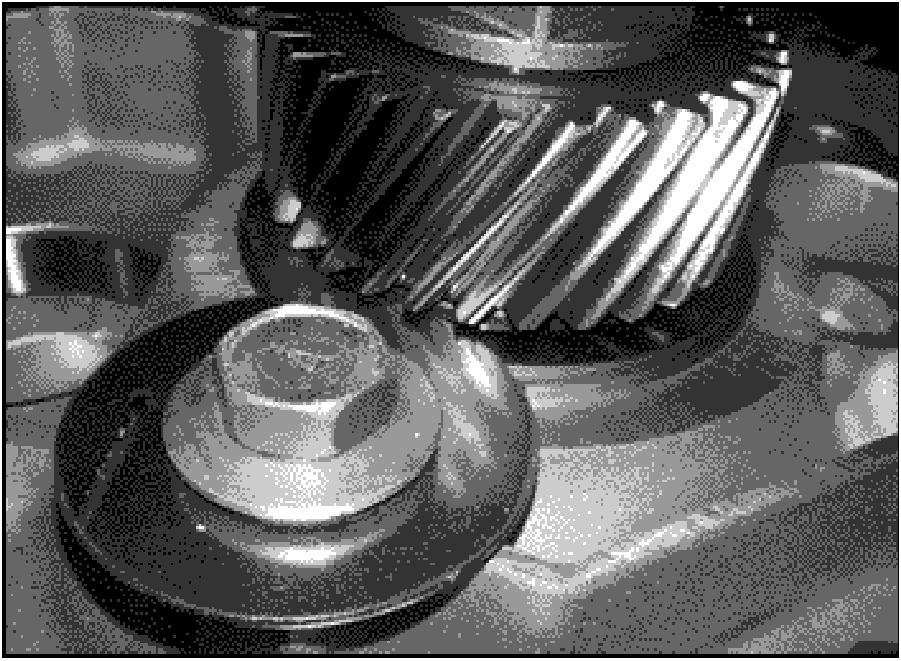

Prior to removal, drain the transaxle and remove the oil pan. Inspect the two magnets in the pan for debris

and foreign material. Compare the magnets to the photos below.

Following is a brief outline of the repair steps contained in this TSB. Specific procedures to be followed

after the transaxle has been removed begin on page 3.

In addition to the CVT special tools specified in the service manual Group 23B, the following tools are

required to complete this repair.

|

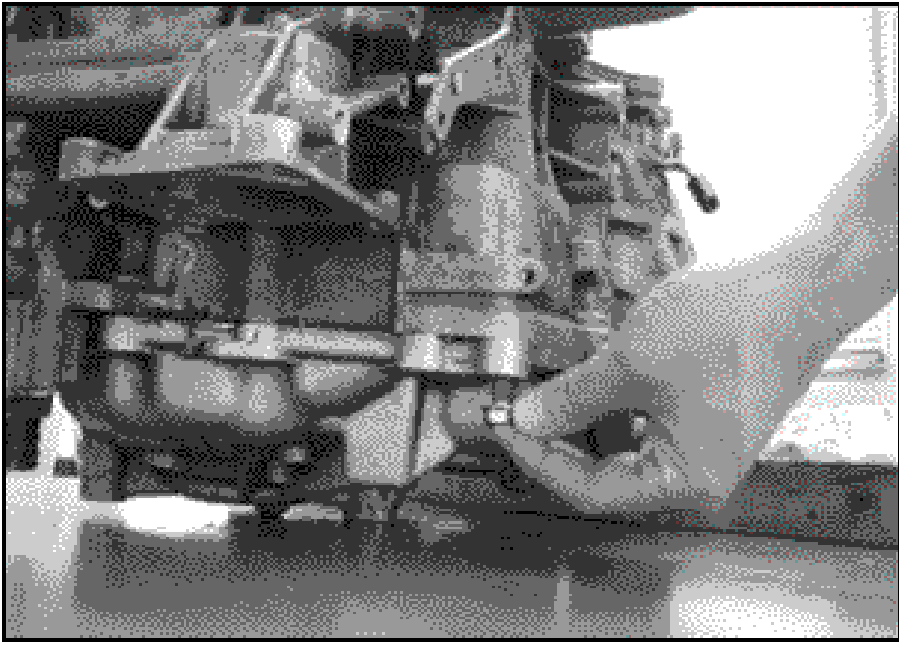

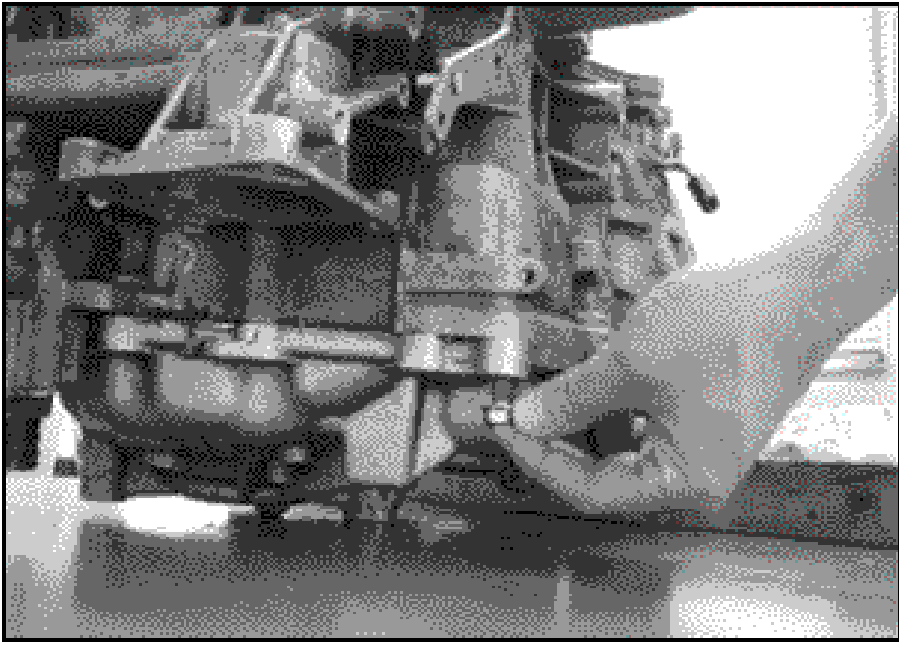

TRANSAXLE REMOVAL

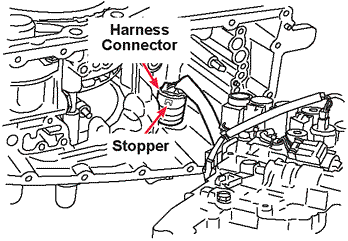

With the transaxle still in the vehicle, unfasten the

control harness cable bracket from the dipstick.

Remove the dipstick and transaxle mount. Remove the

transaxle from the vehicle.

Before transaxle disassembly, always clean any debris

from the outside of the transaxle case.

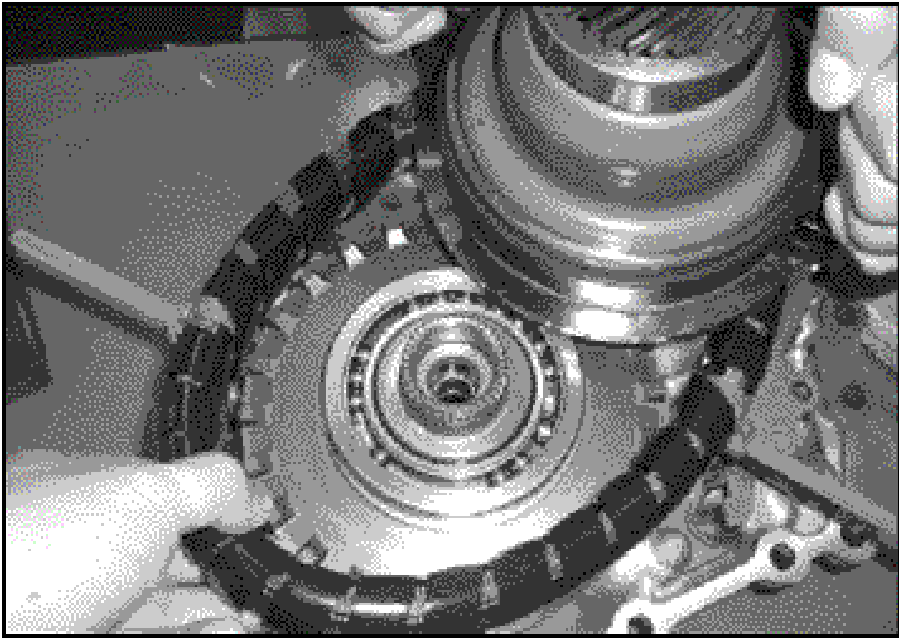

- Remove the torque converter from the transaxle and

drain.

|

|

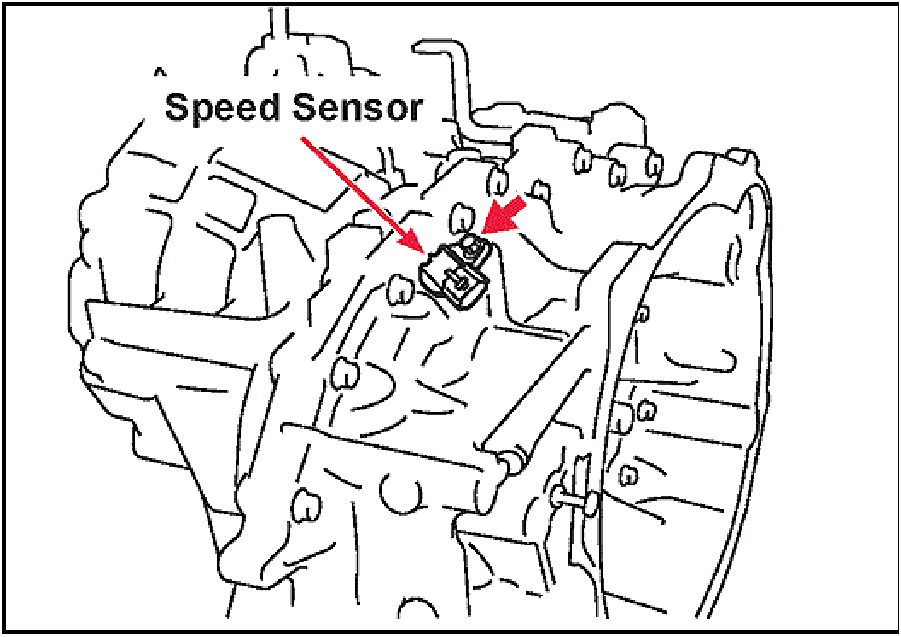

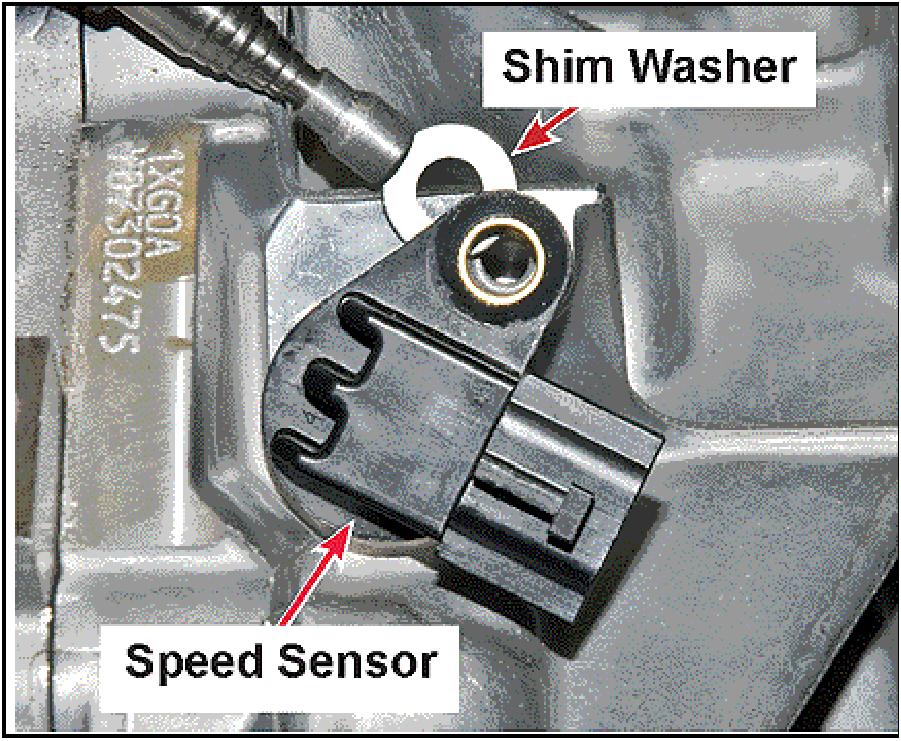

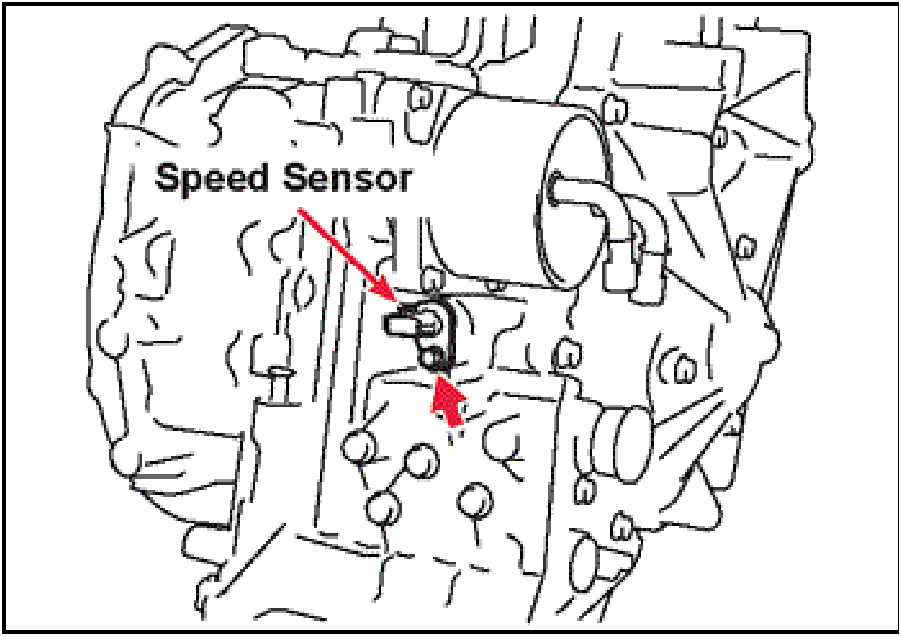

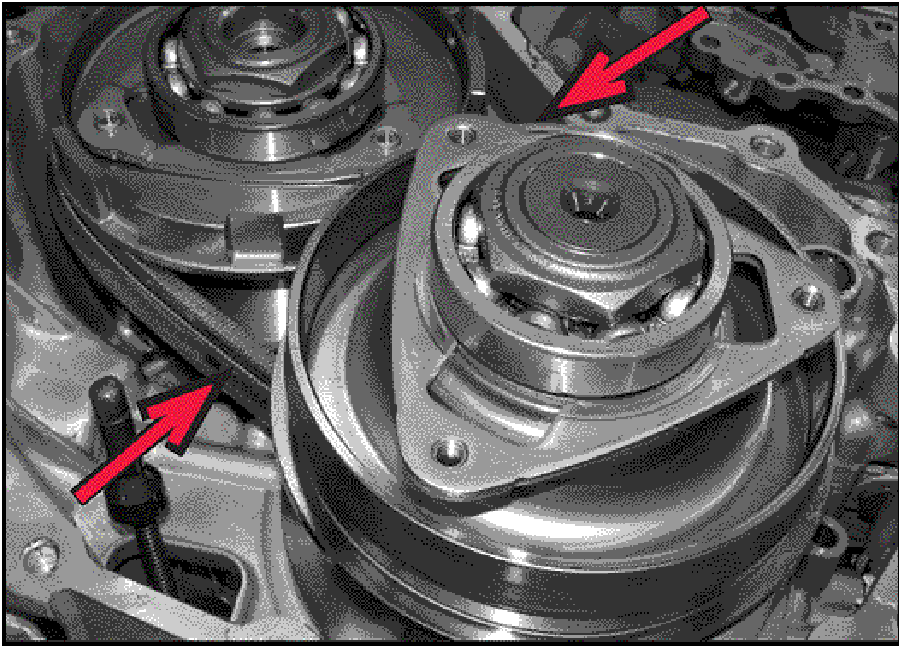

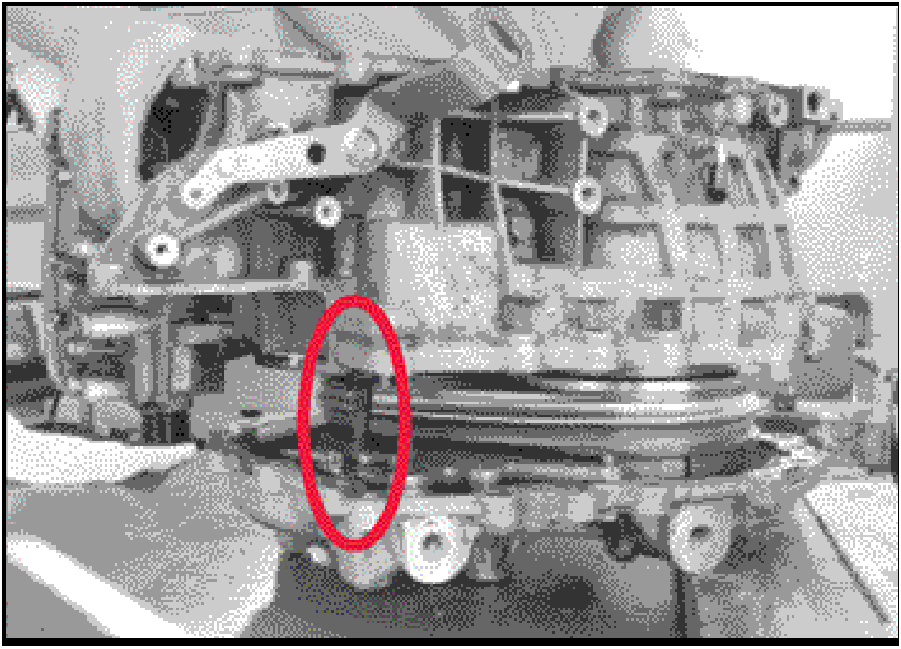

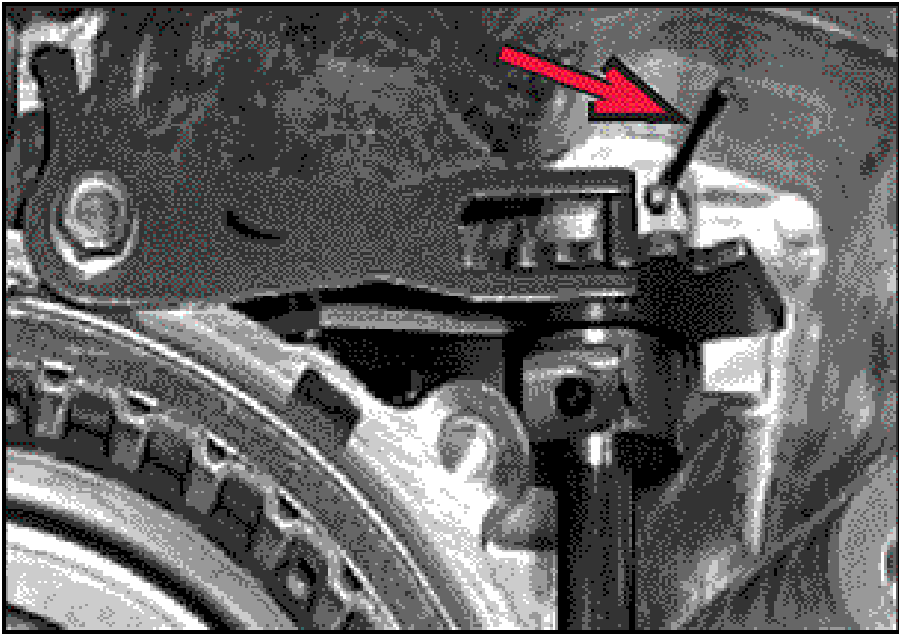

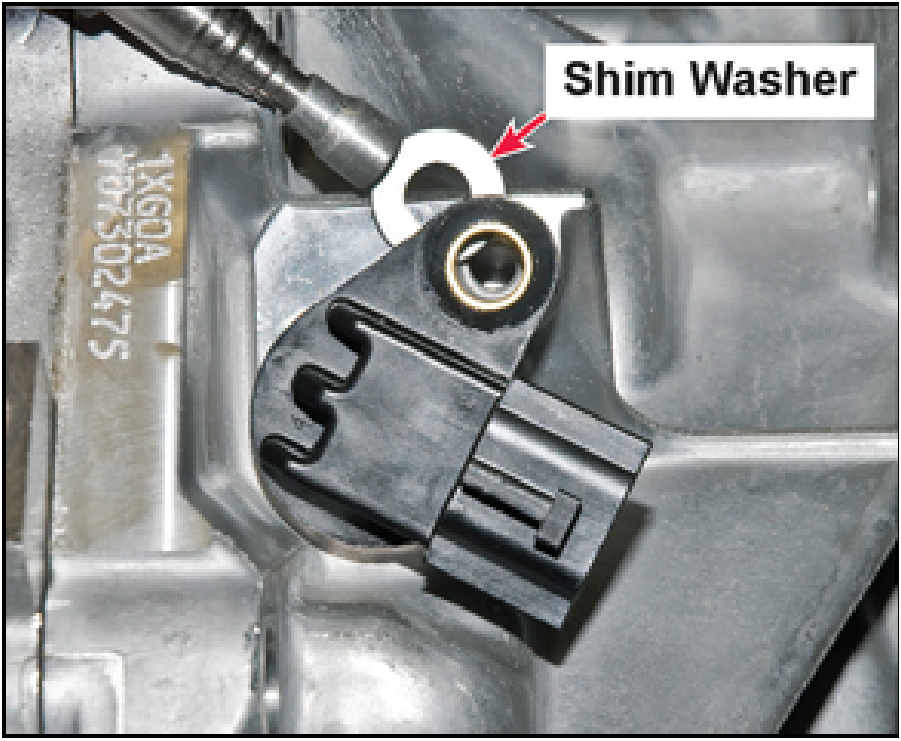

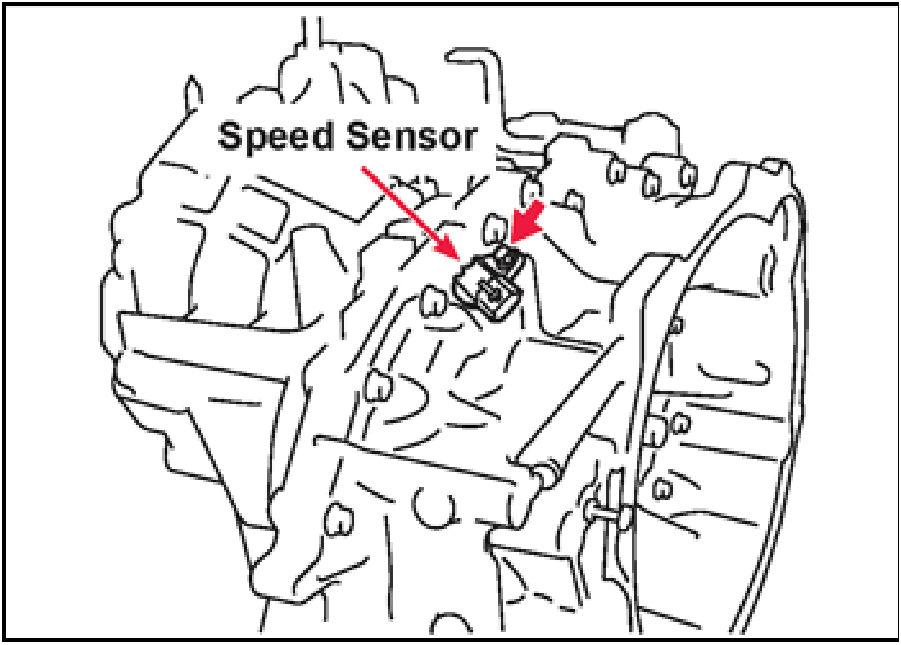

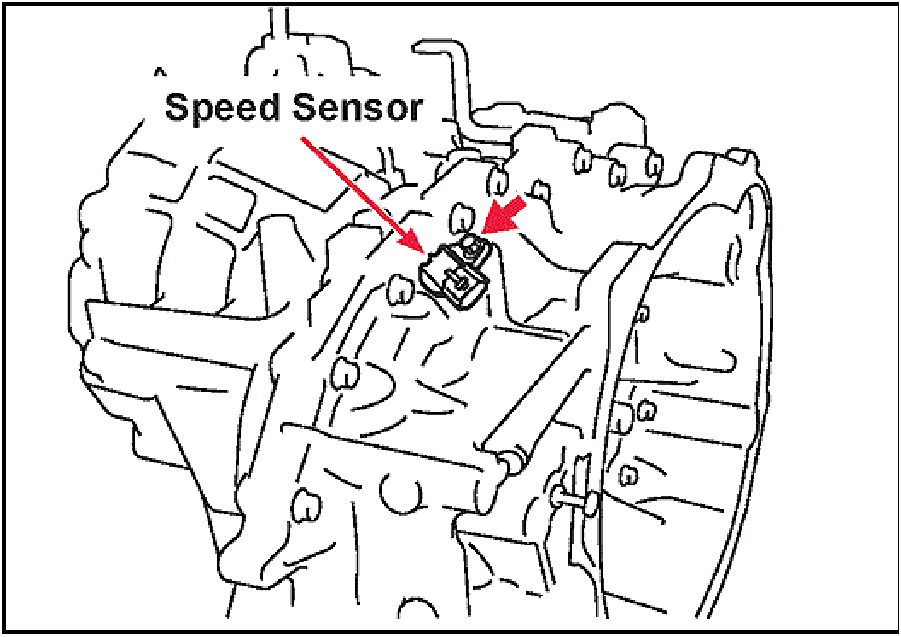

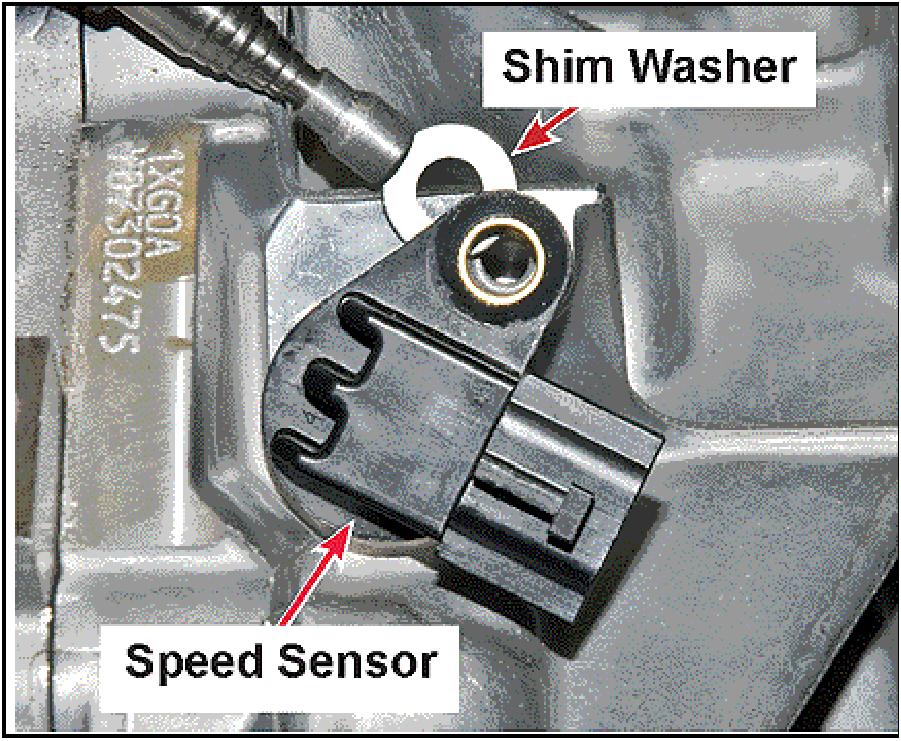

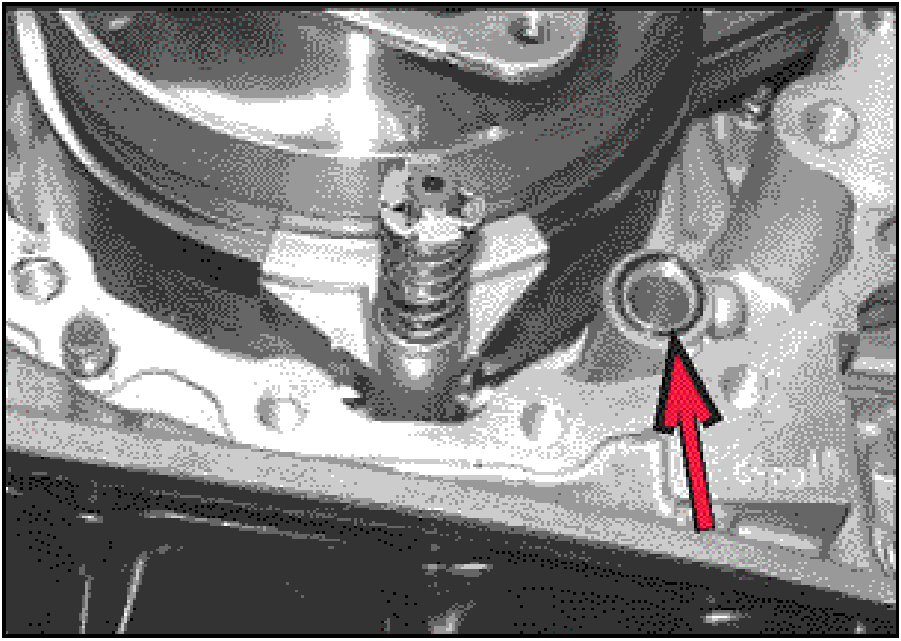

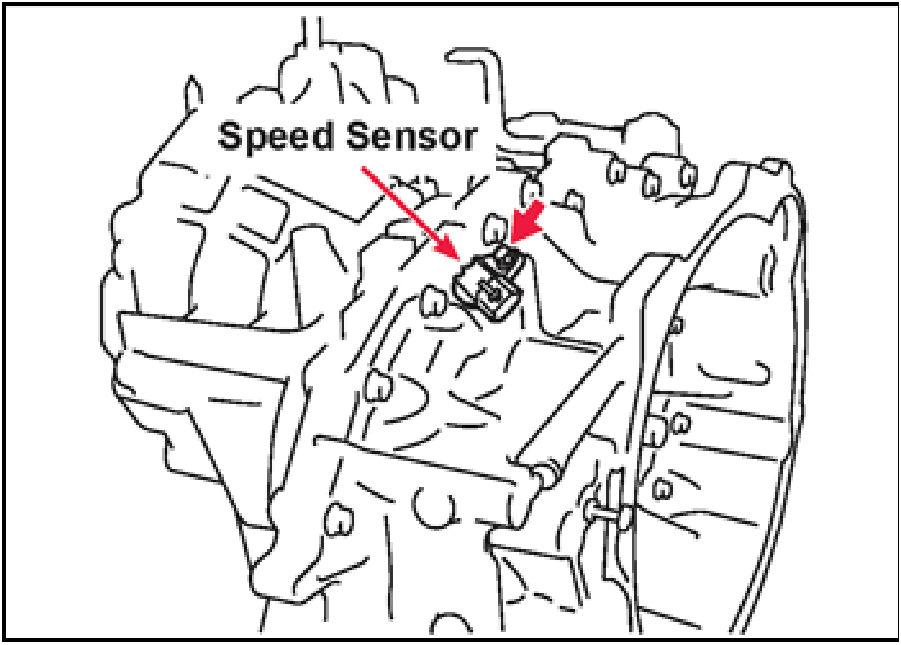

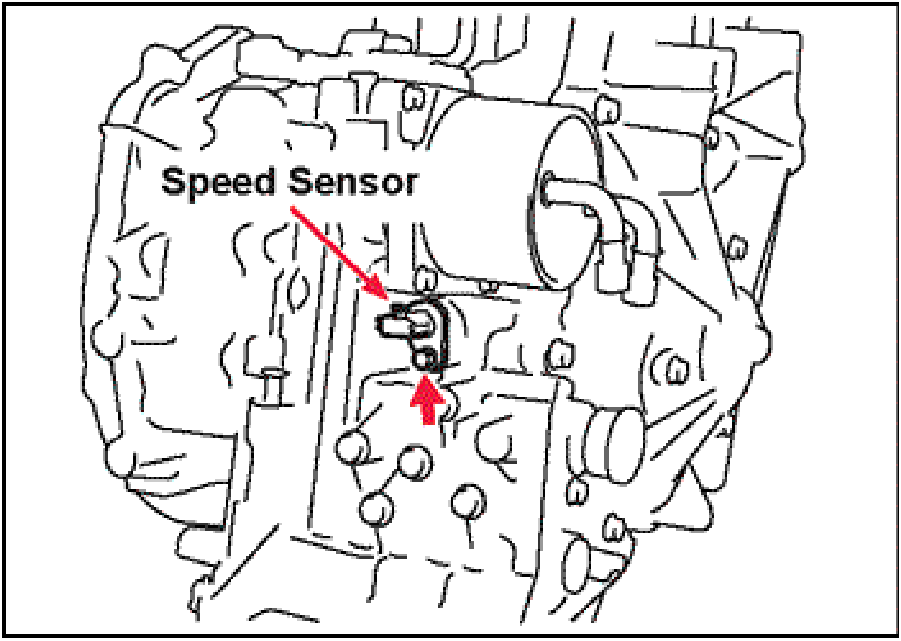

- Remove the secondary pulley speed sensor mounting

bolt

|

|

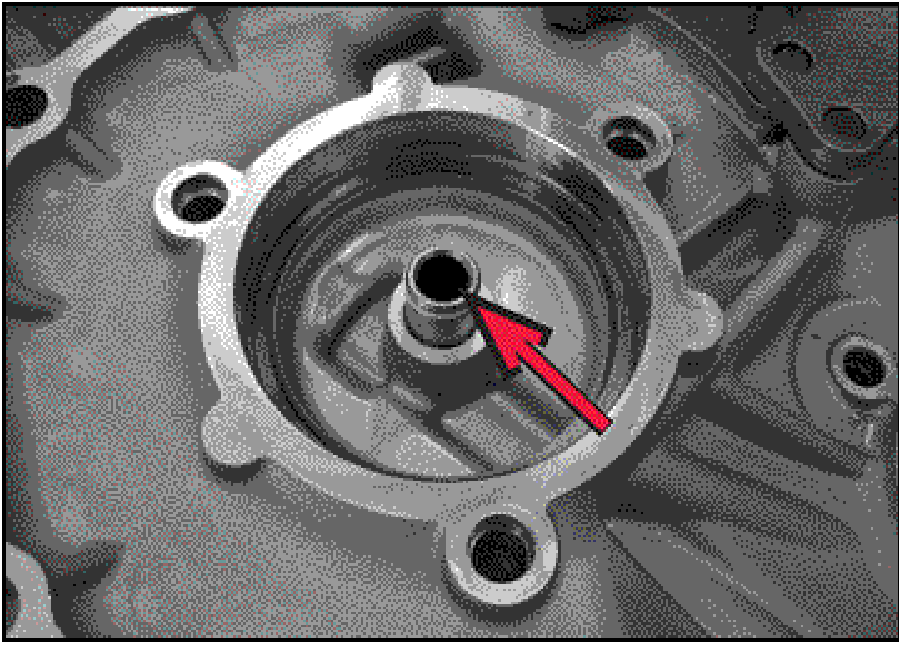

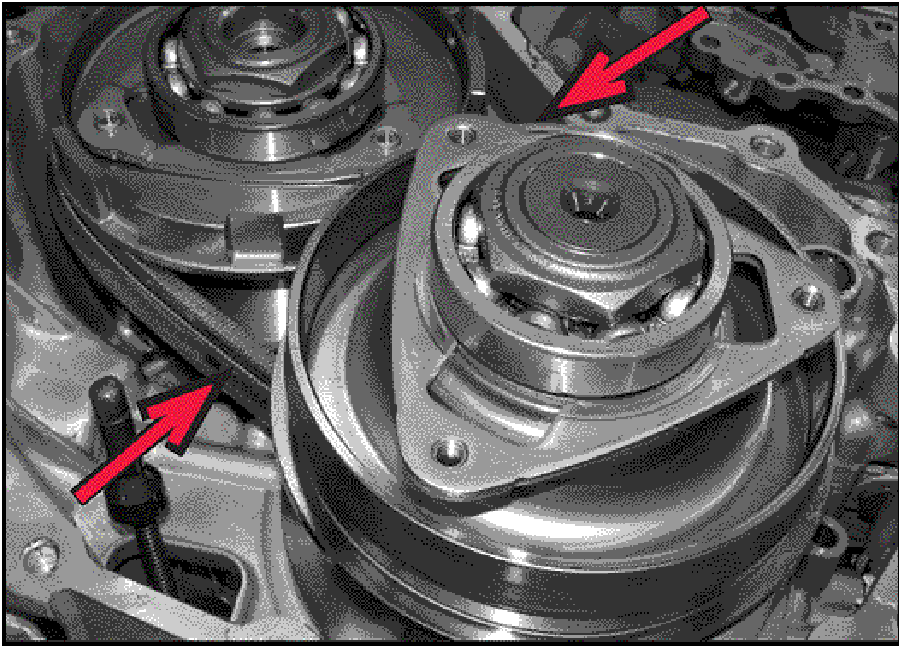

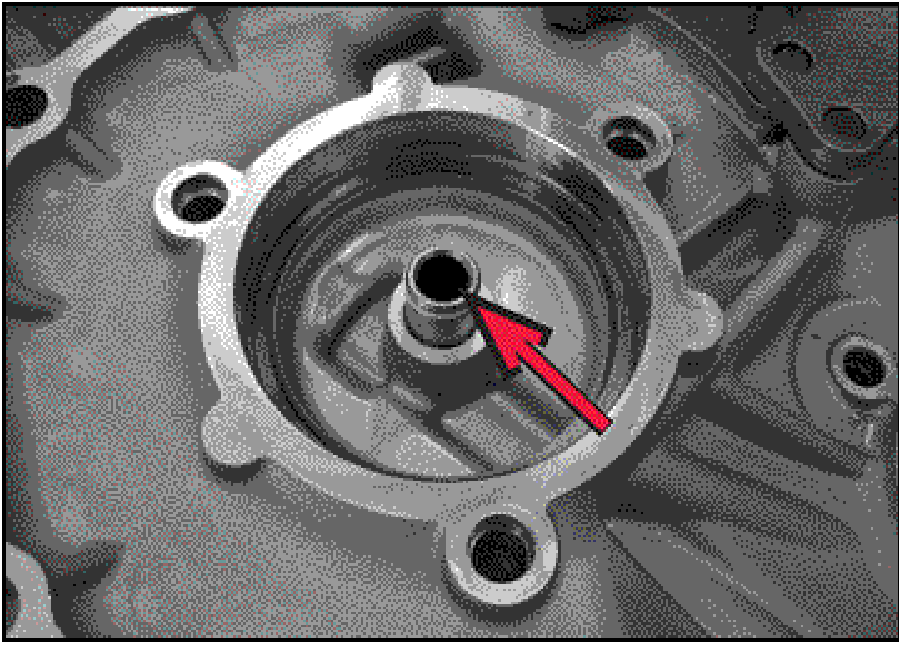

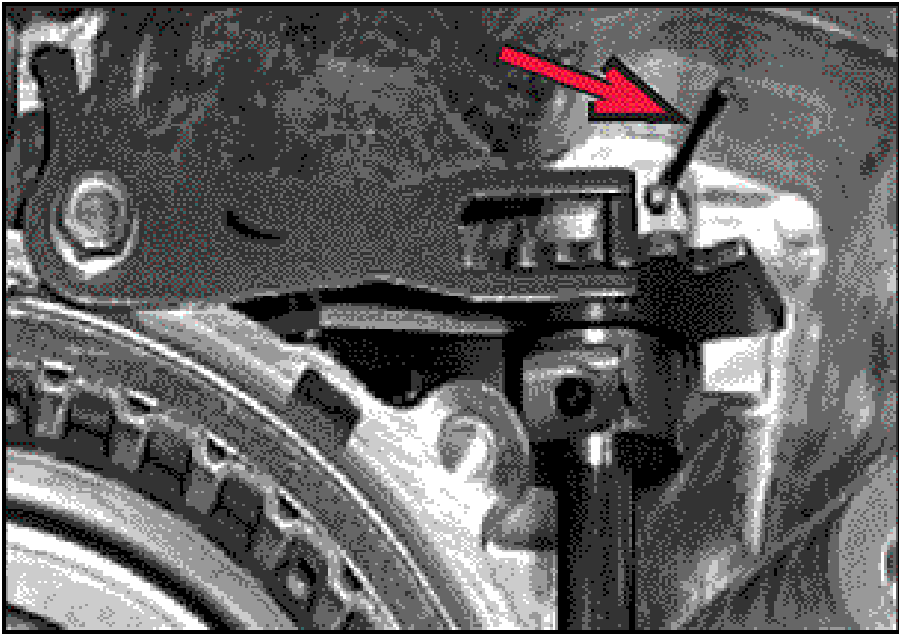

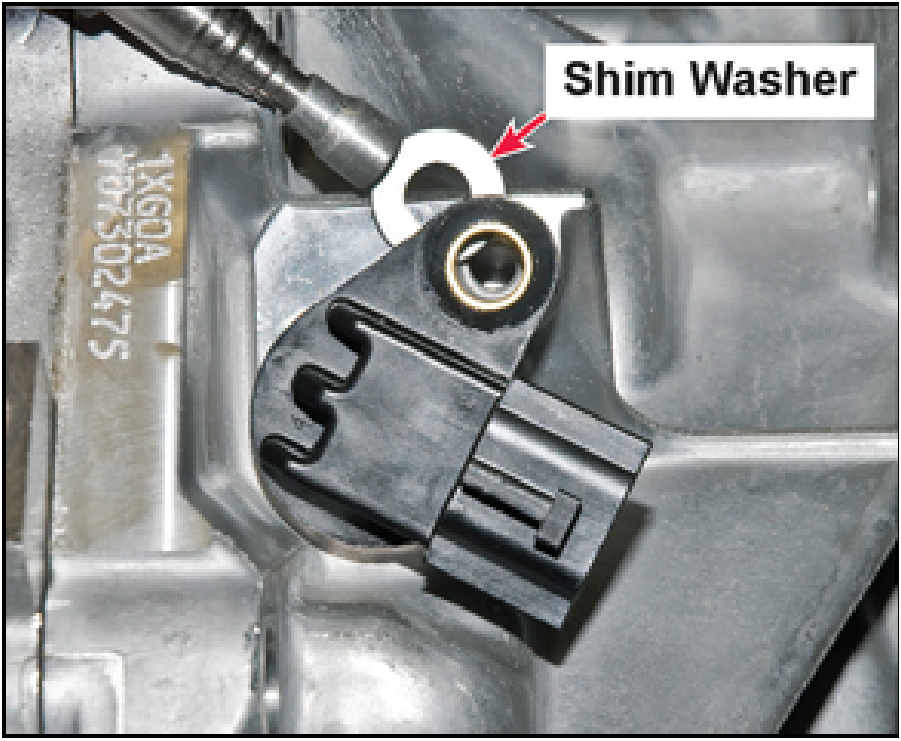

- At the same time the secondary pulley speed sensor

is being removed from the transaxle case, using a stick

magnet to remove the secondary pulley speed sensor

shim washer.

NOTE: If the shim washer is omitted, the speed

sensor will rub against the Secondary Pulley and

damage the tip of the sensor.

|

|

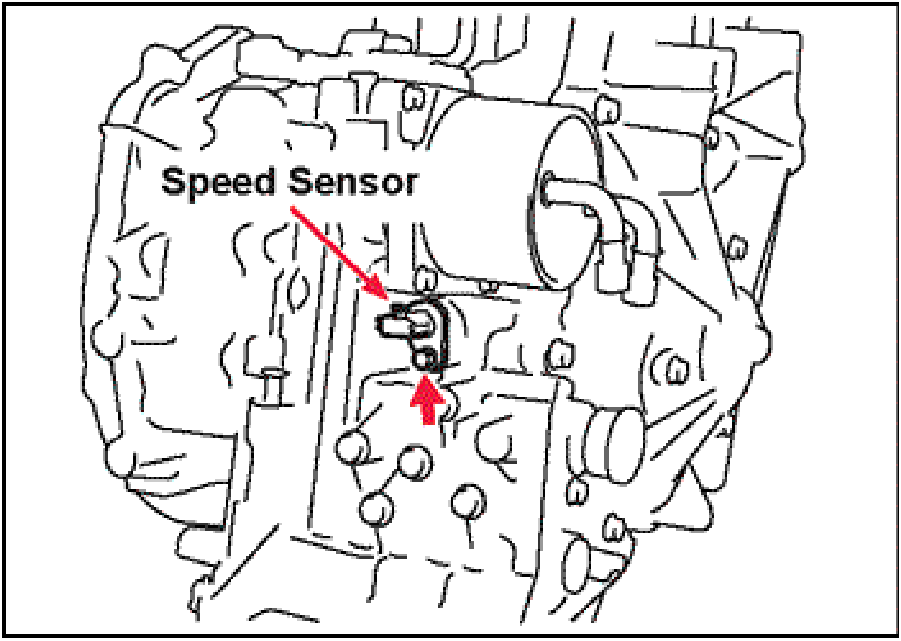

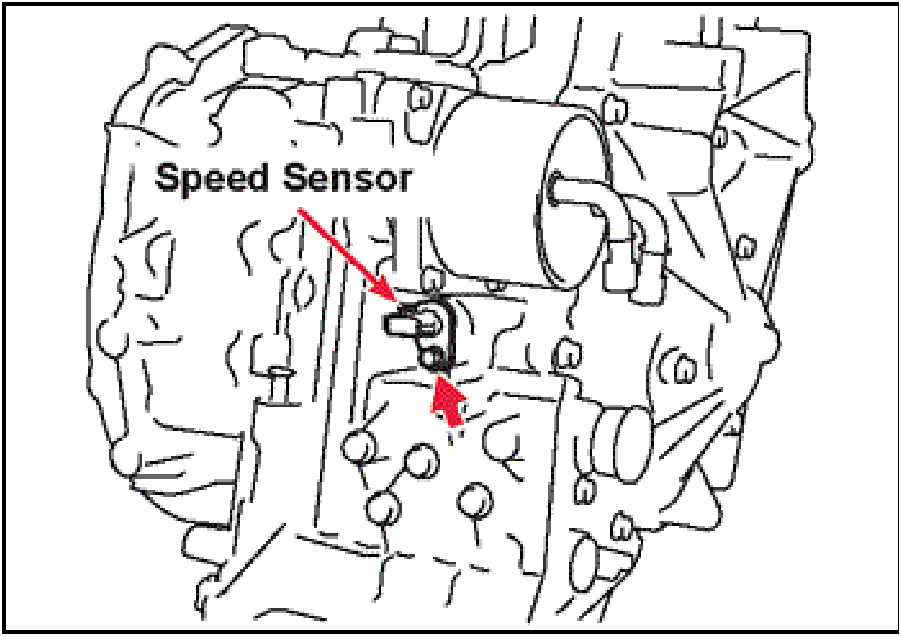

- Remove the primary pulley speed sensor.

|

|

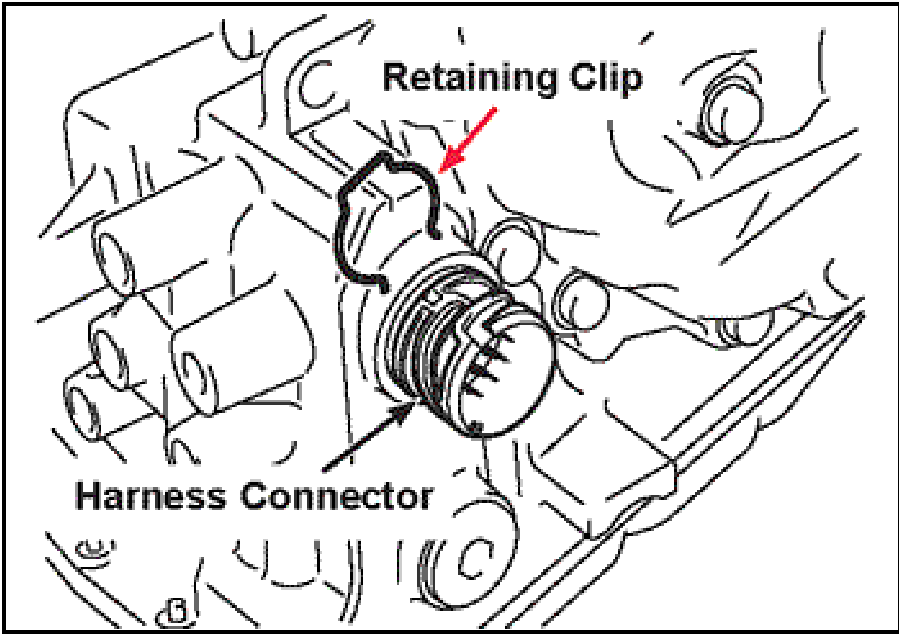

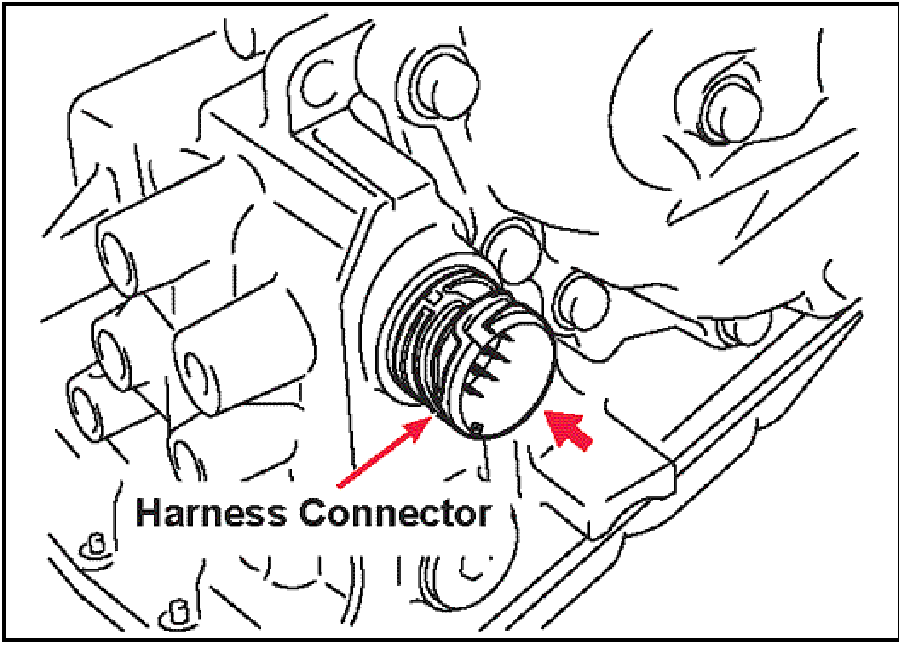

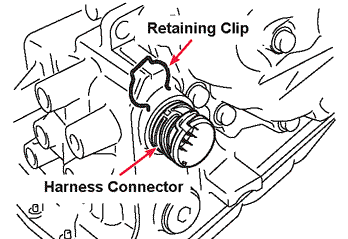

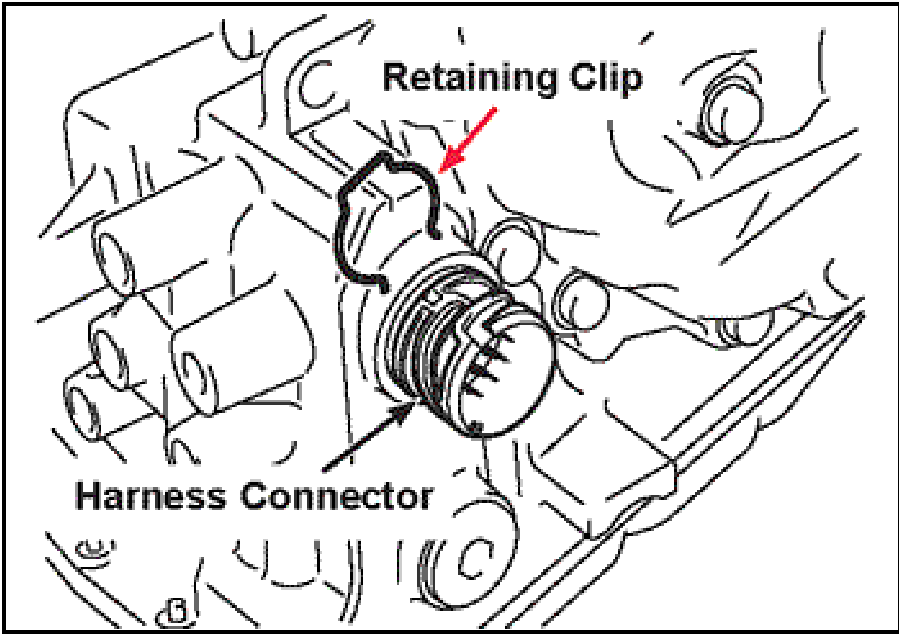

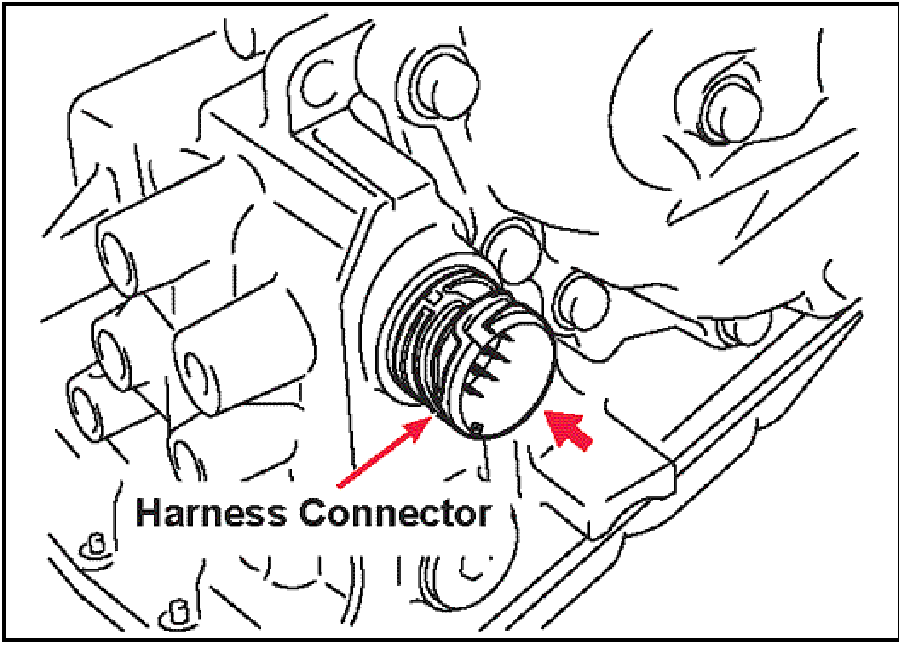

- Remove the retaining clip from the harness connector.

|

|

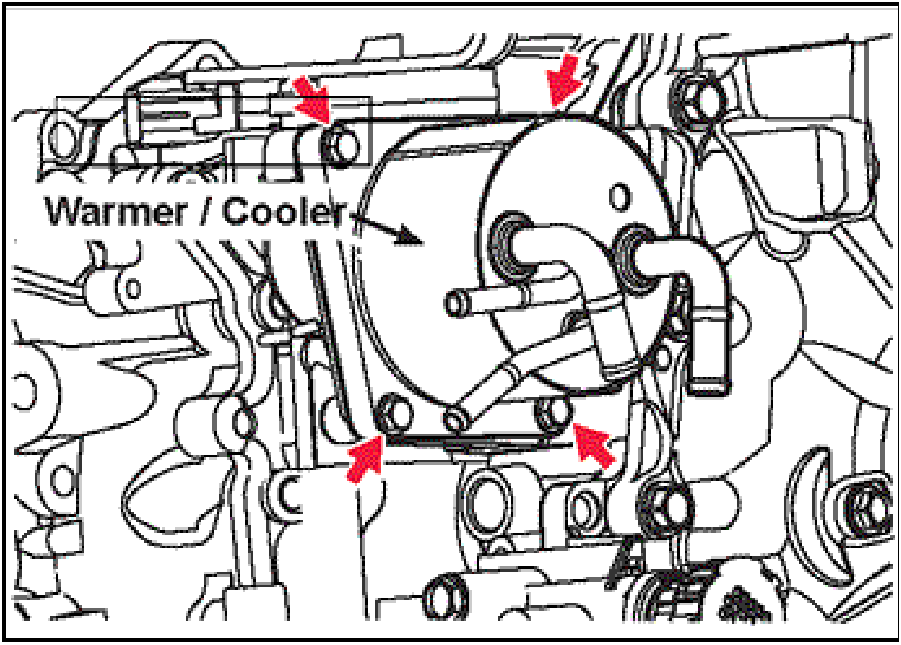

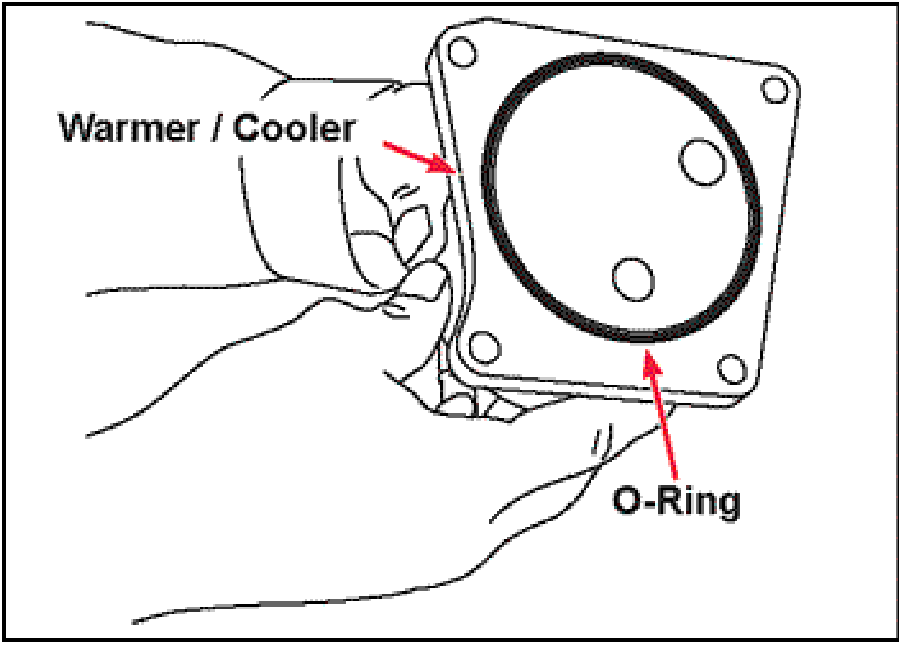

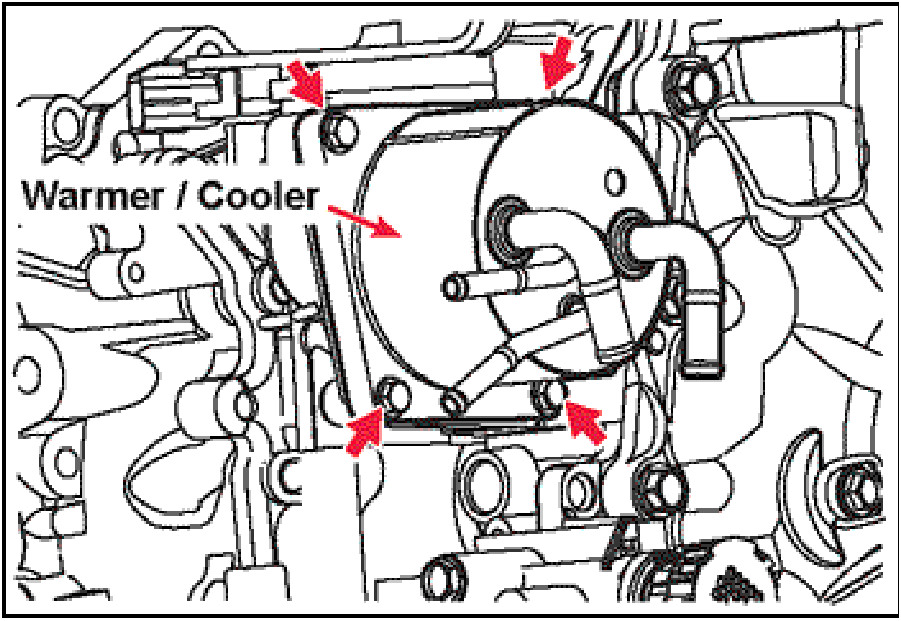

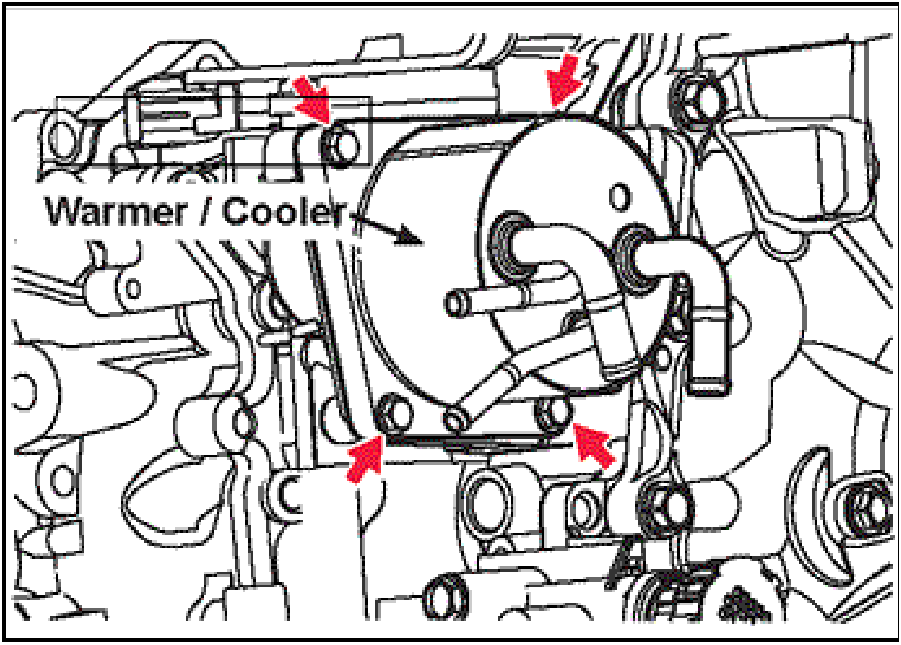

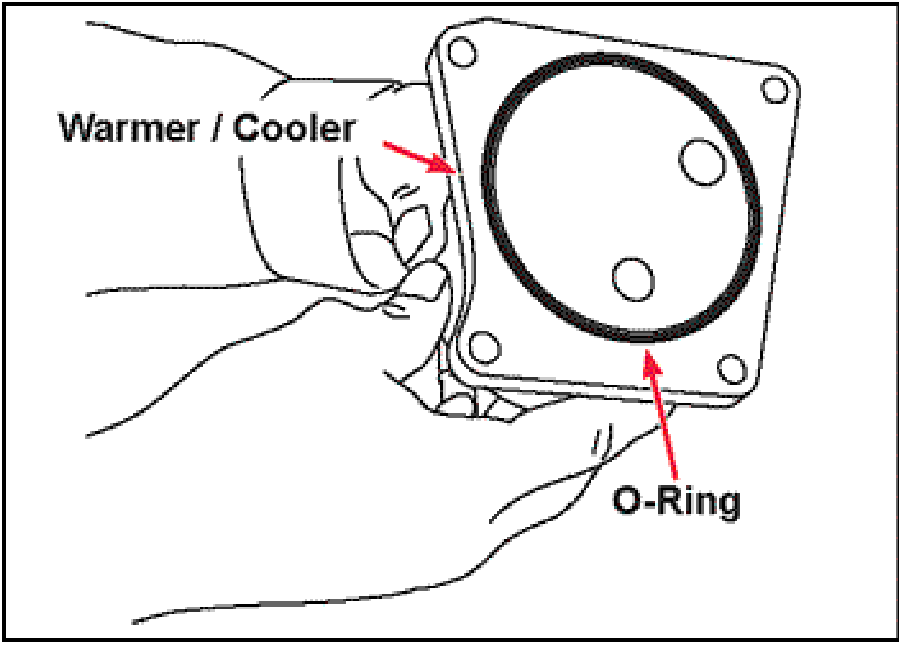

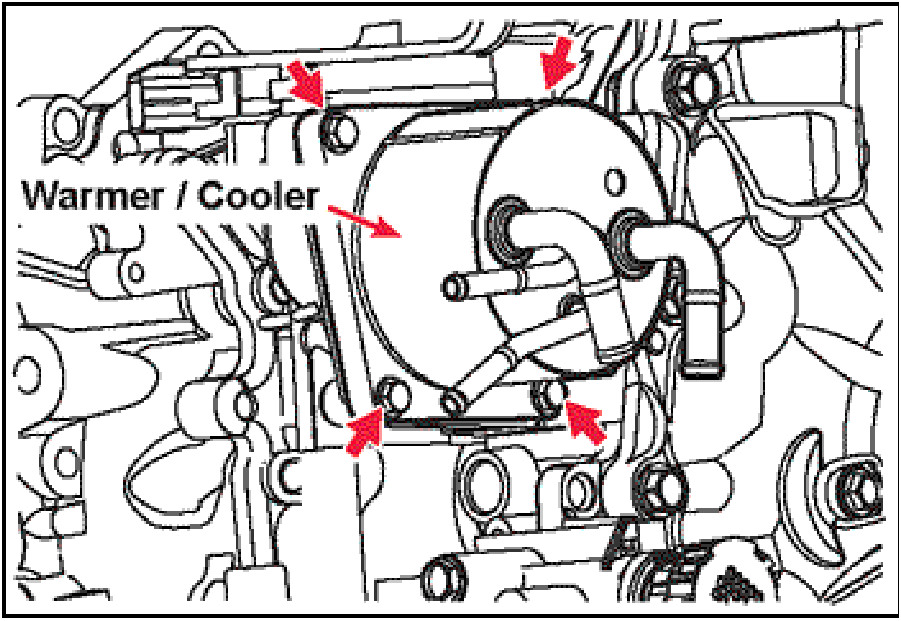

- Remove the warmer/cooler and large o-ring.

Discard the o-ring.

The aluminum tubes on the warmer/cooler are very

soft. Take care as not to bend, kink or crush them

in any way.

|

|

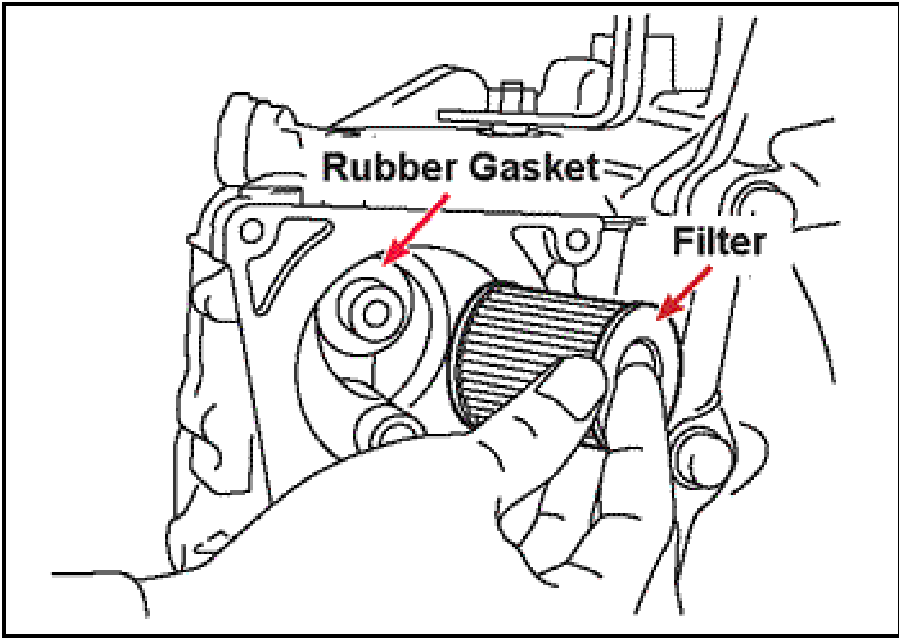

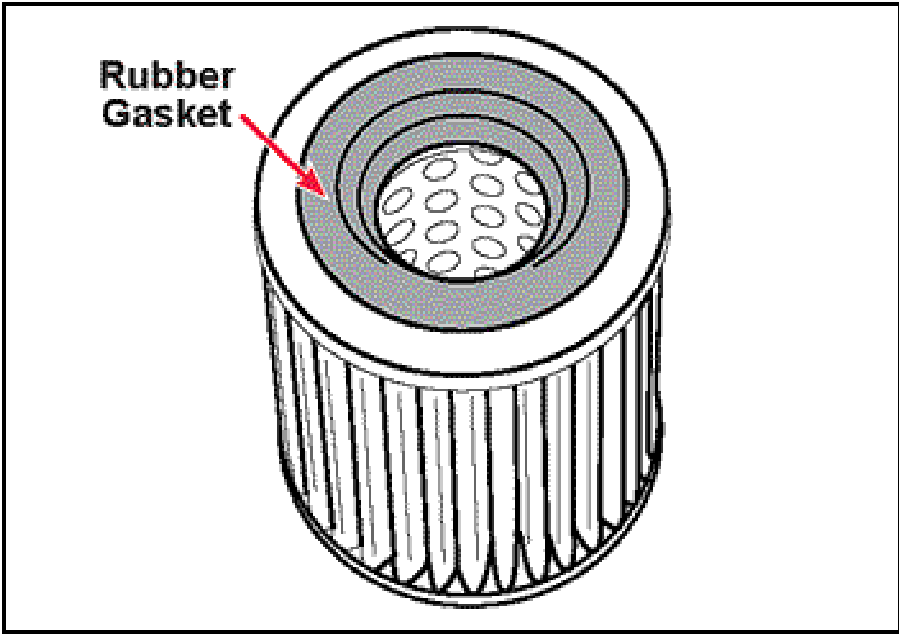

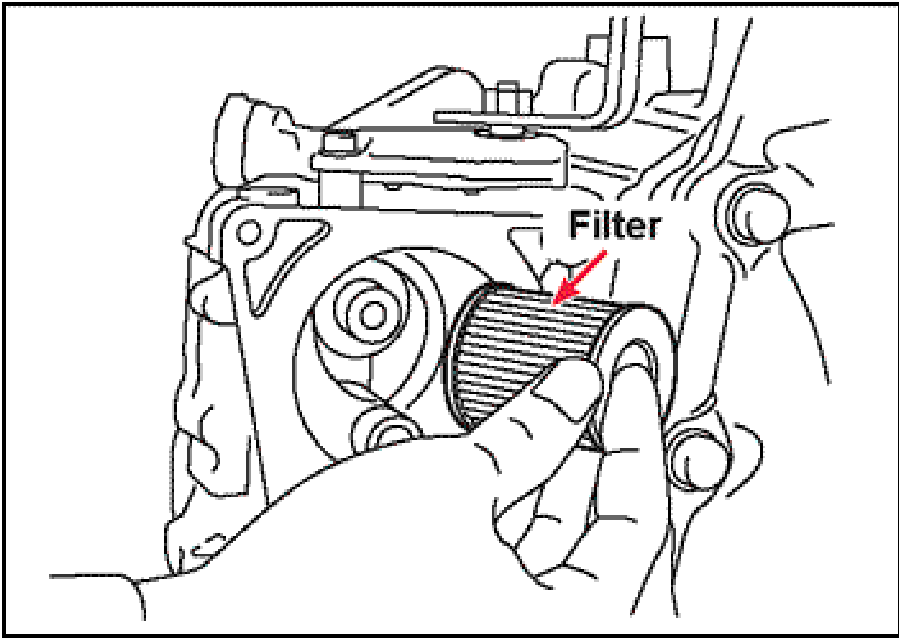

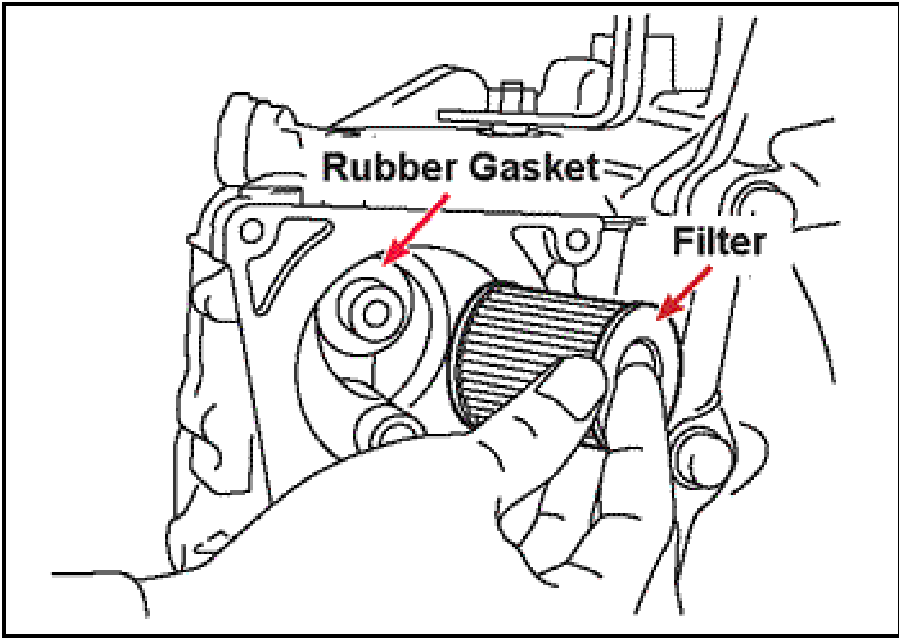

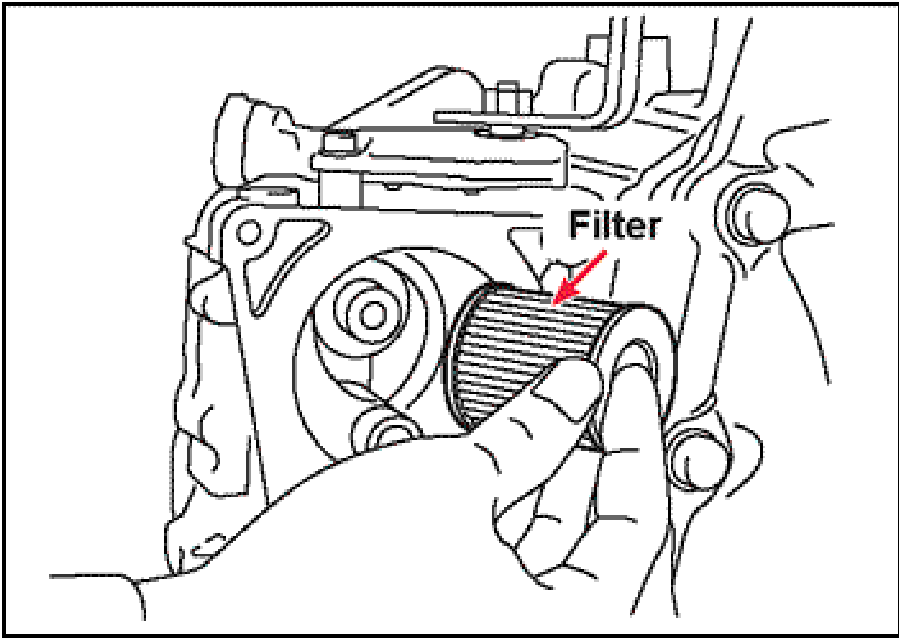

- Remove the ATF warmer/cooler filter and rubber seal

from the case and discard both.

NOTE: Verify the rubber filter seal comes out with

the filter.

|

|

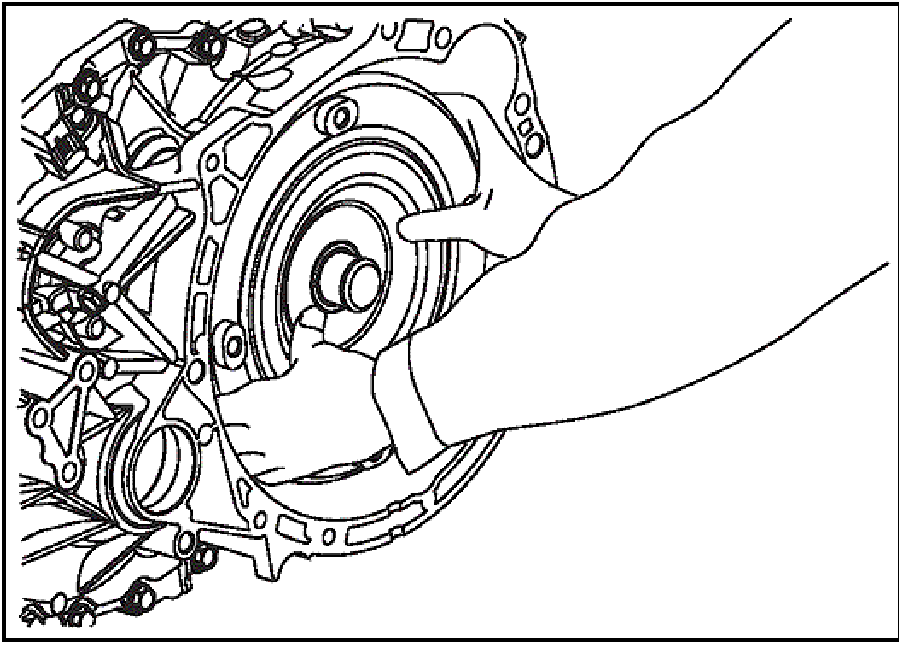

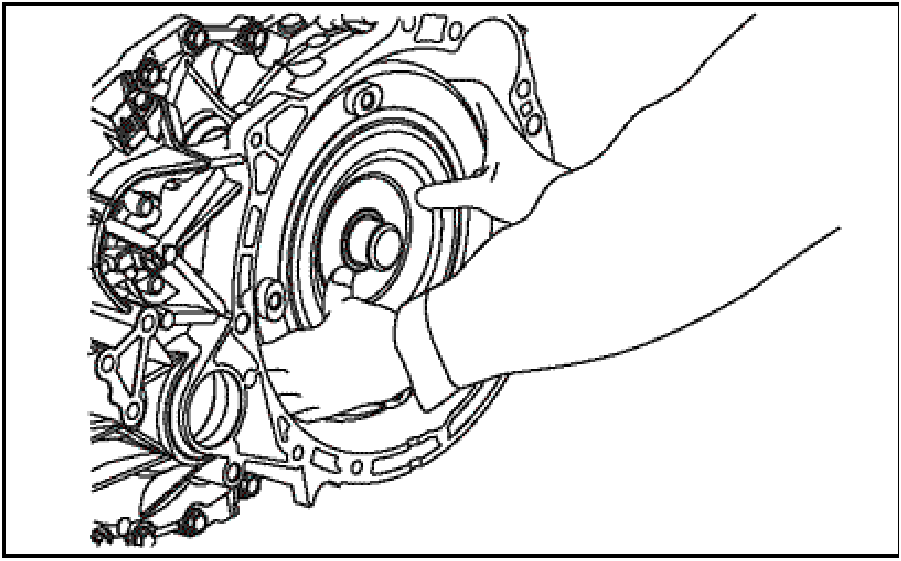

- Rotate the transaxle on the bench so the converter

housing faces up.

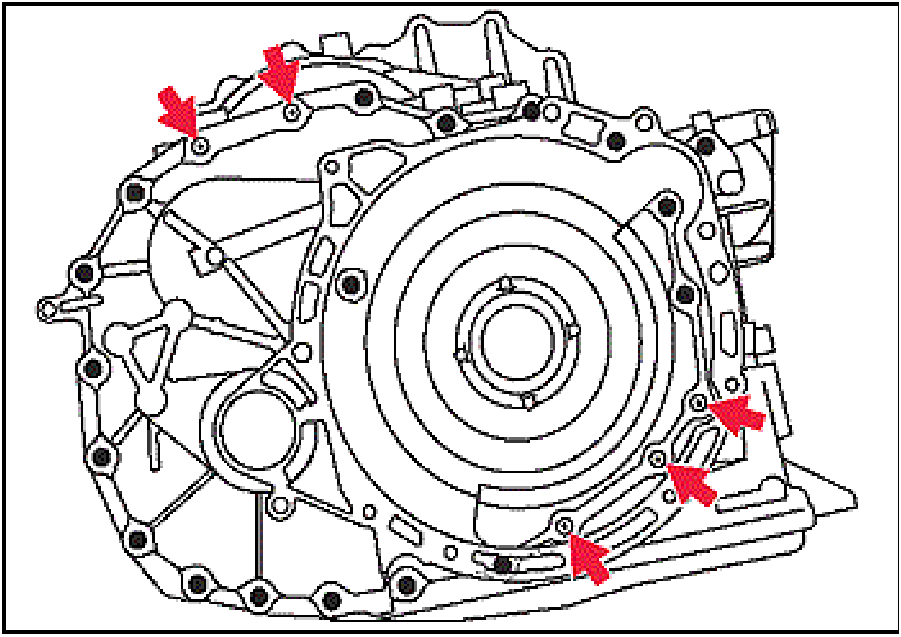

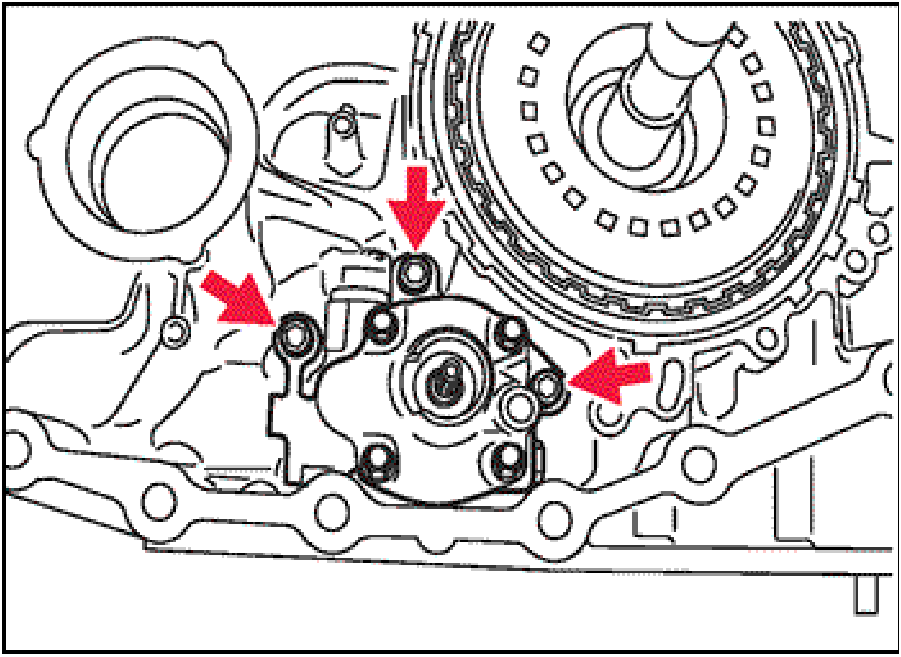

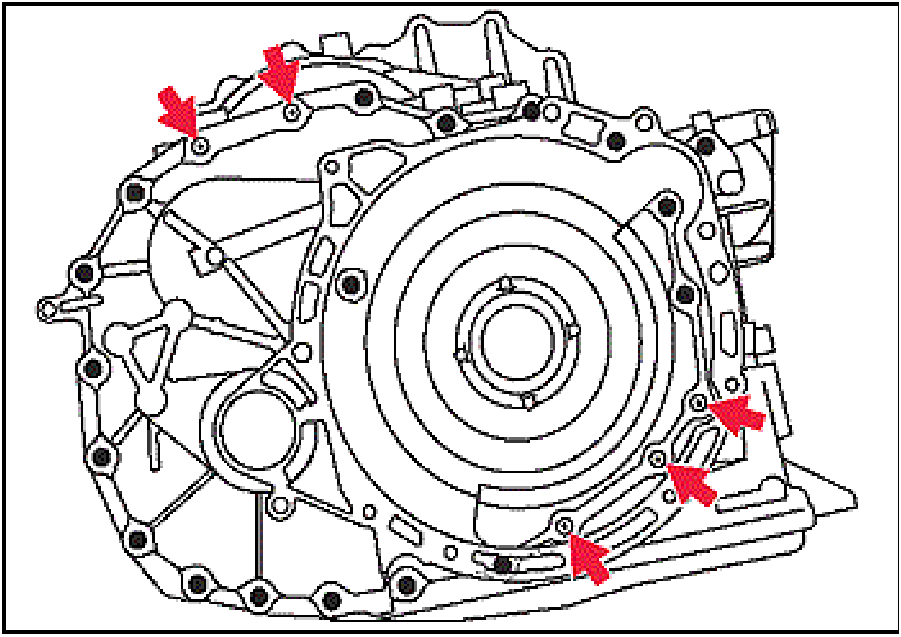

- Remove the five LONG converter housing mounting

bolts identified by the dimple located in the center of

the hex head. as indicated by the arrows.

|

|

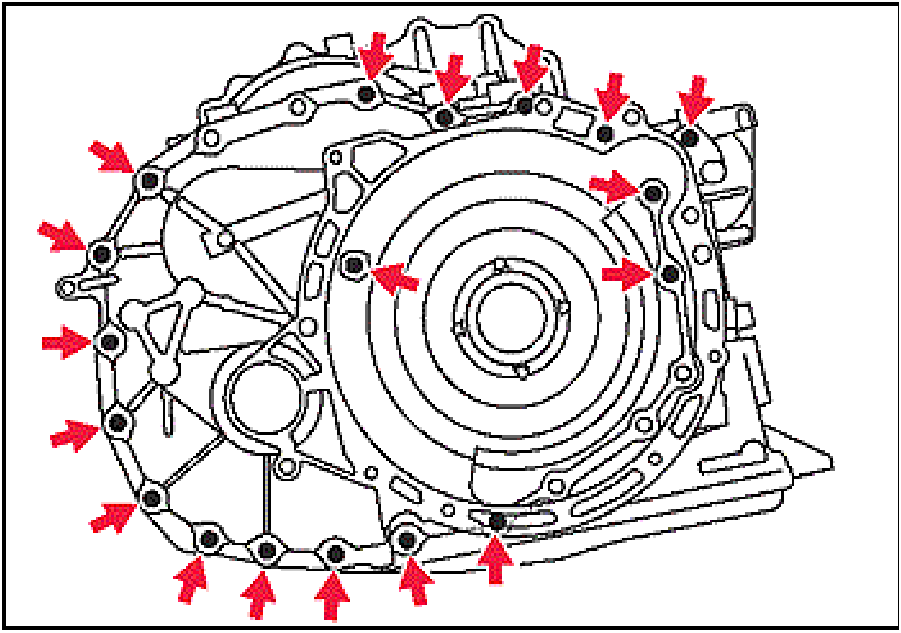

- Remove the eighteen SHORT converter housing

mounting bolts.

Use a deadblow mallet to carefully remove the

converter housing from the transaxle case.

|

|

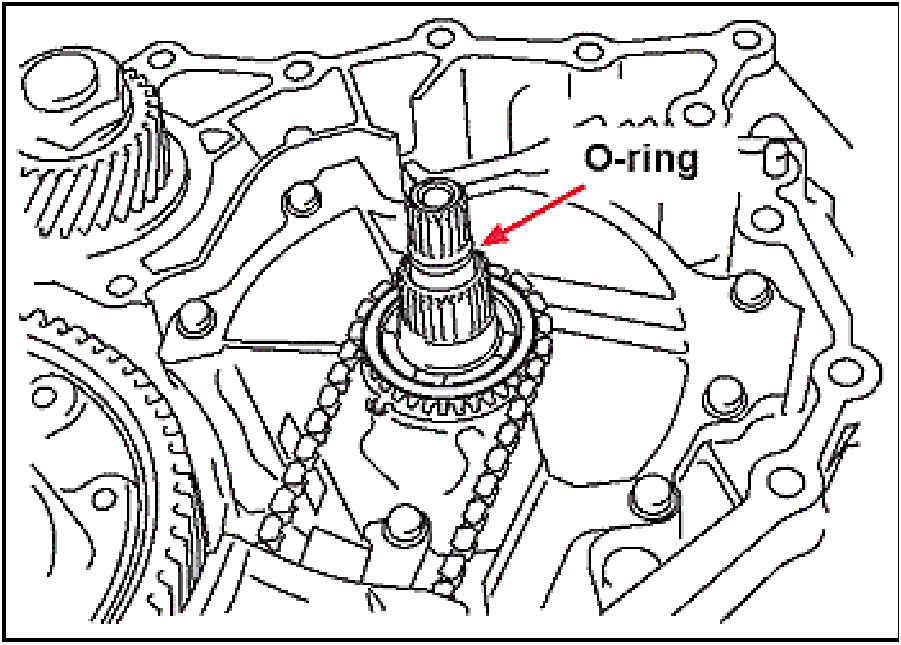

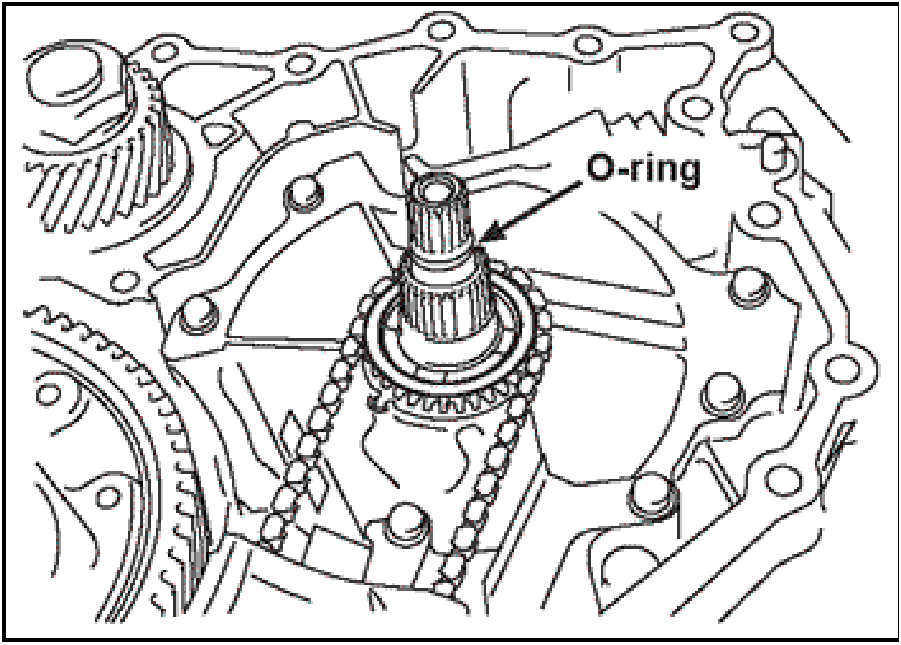

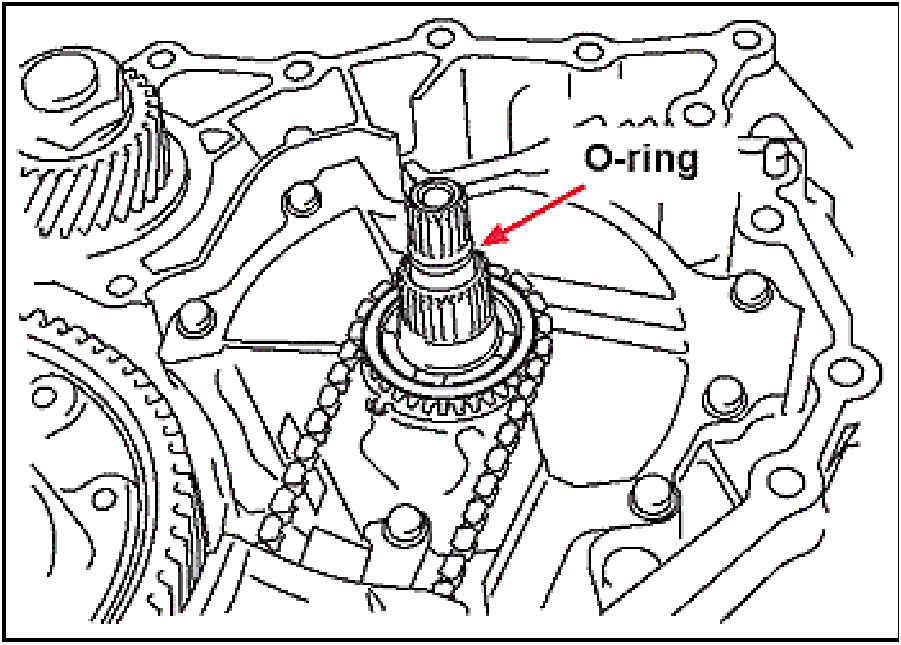

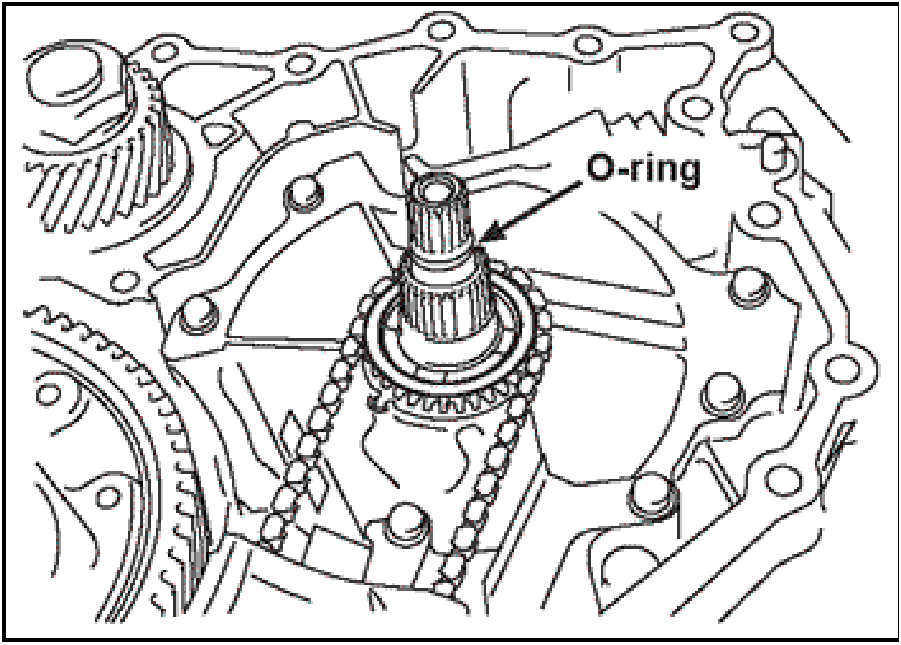

- Remove and discard the input shaft o-ring.

|

|

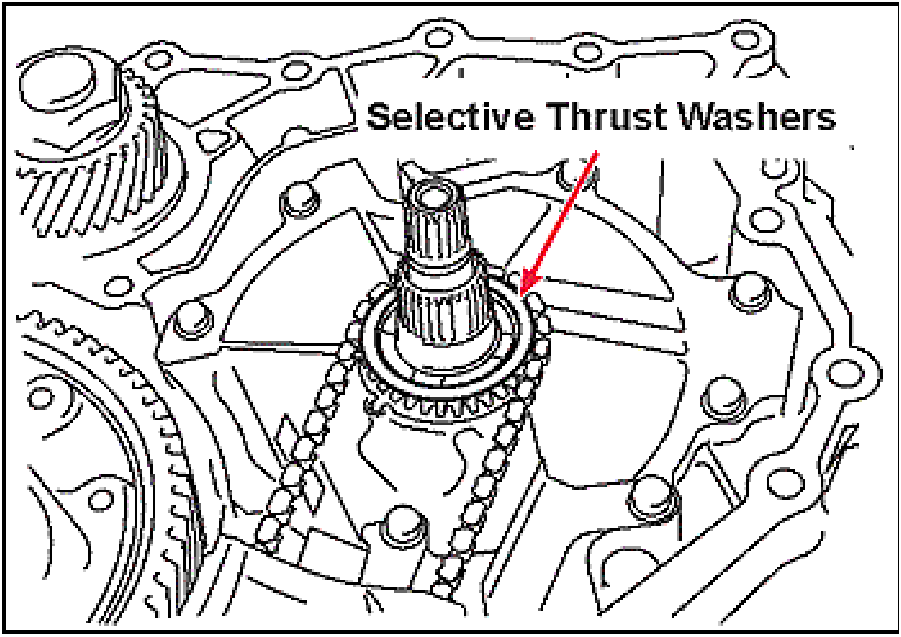

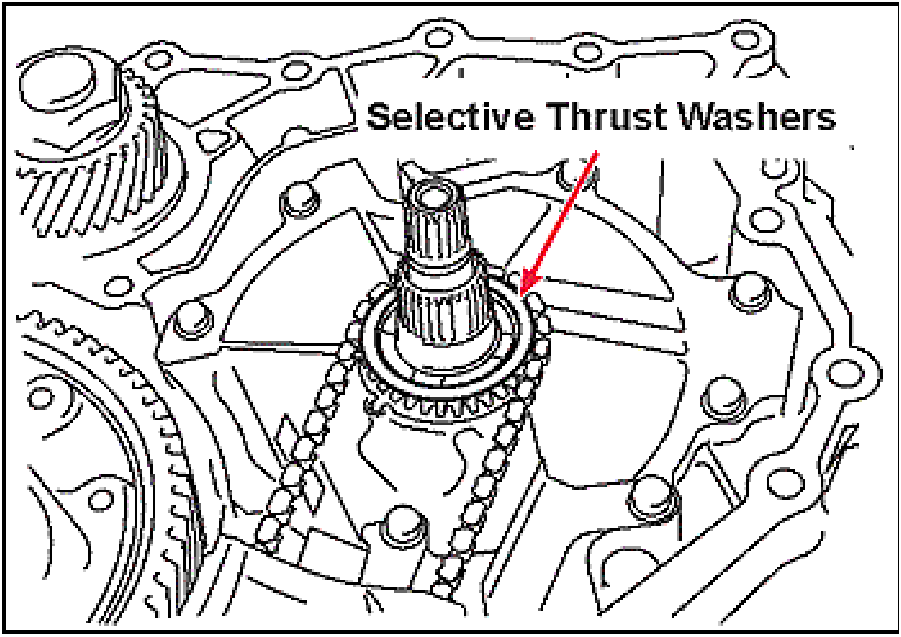

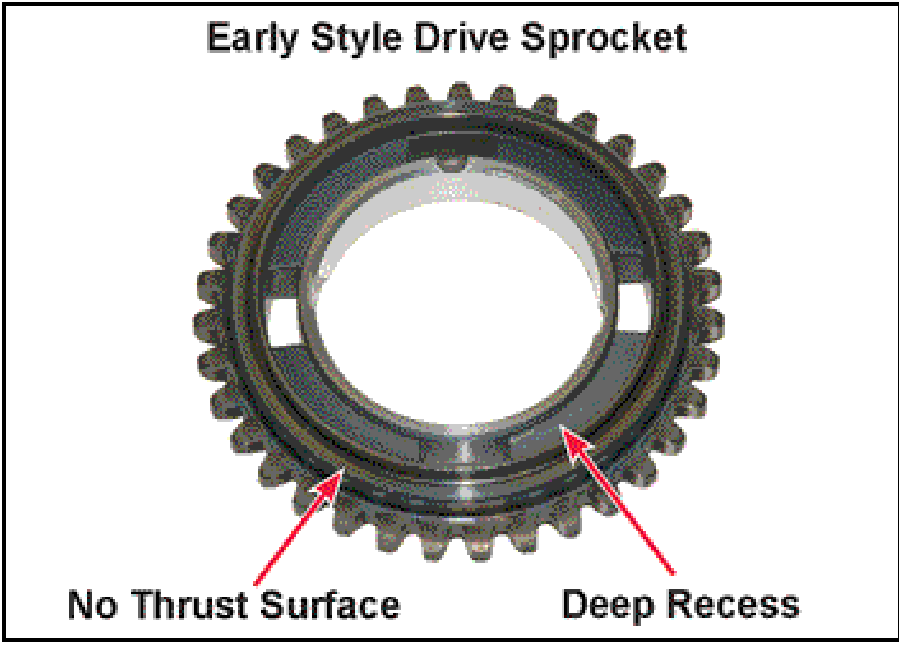

- Remove the two selective thrust washers from the oil

pump drive sprocket.

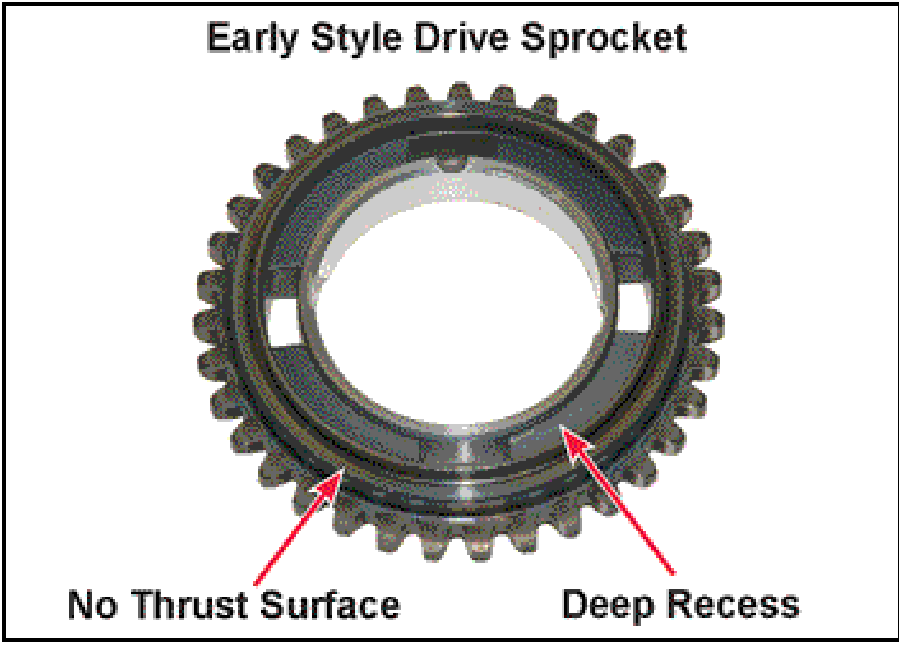

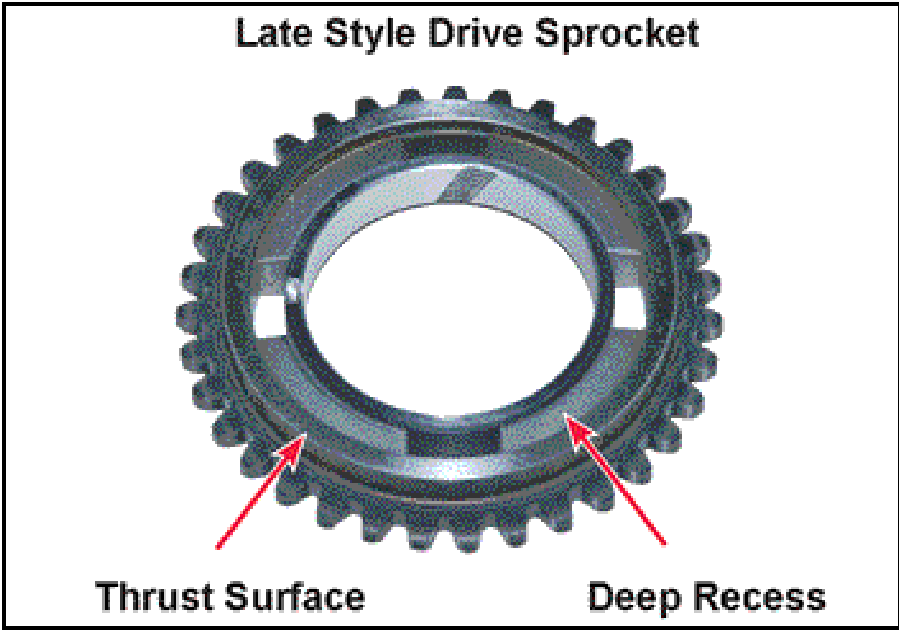

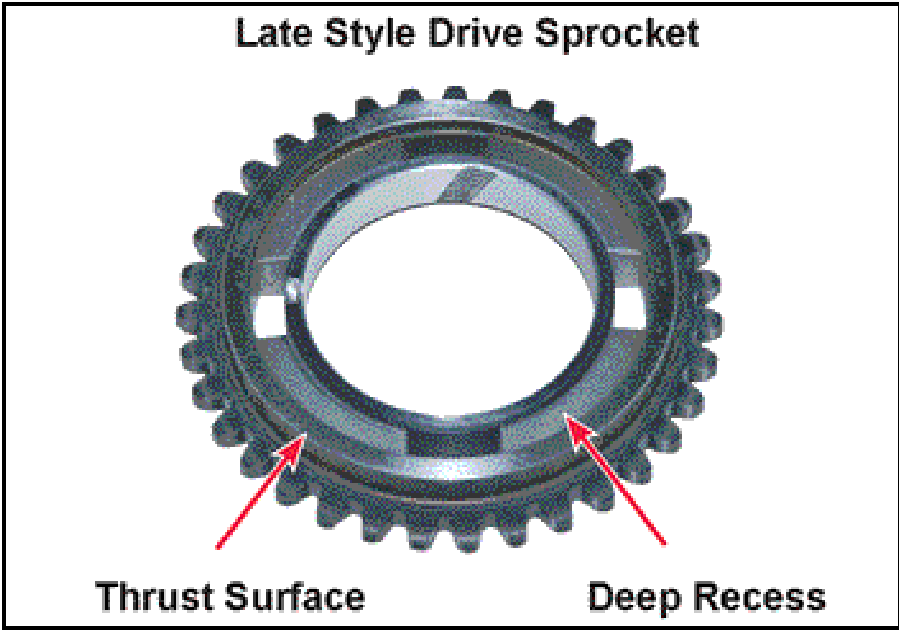

NOTE: The drive sprocket used with transaxles

starting with serial # Y08808317 was redesigned

which eliminated the need for selective shims.

|

|

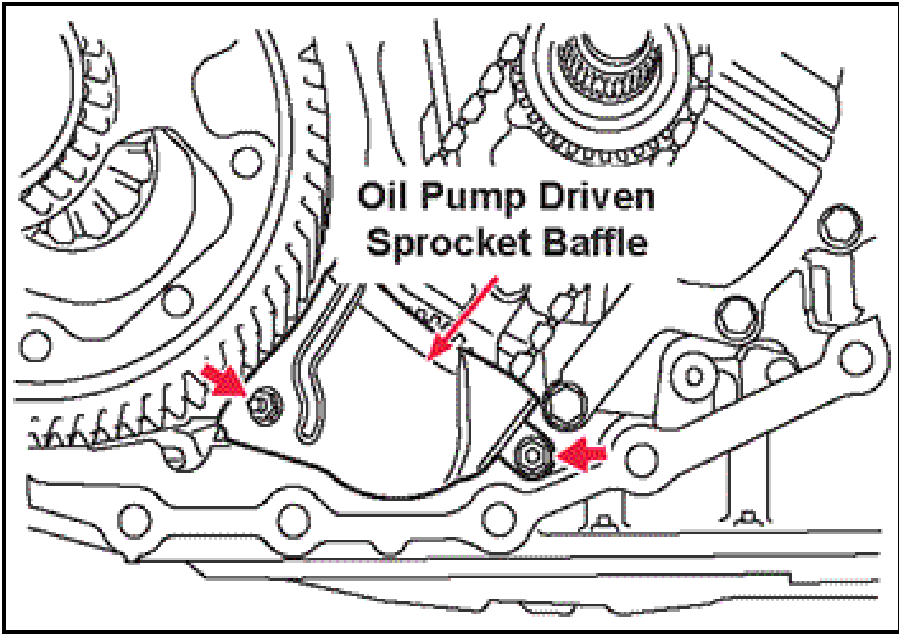

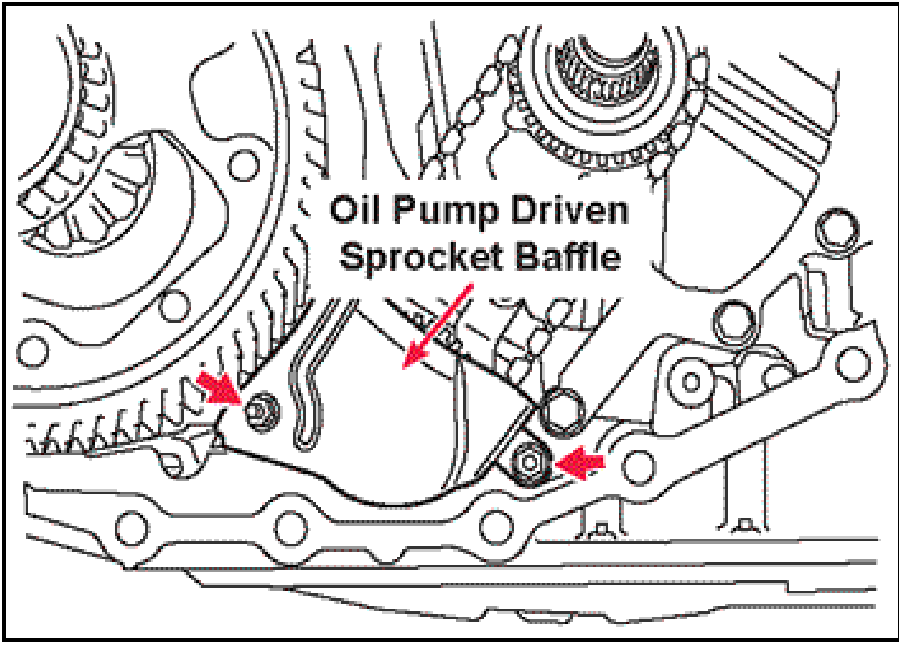

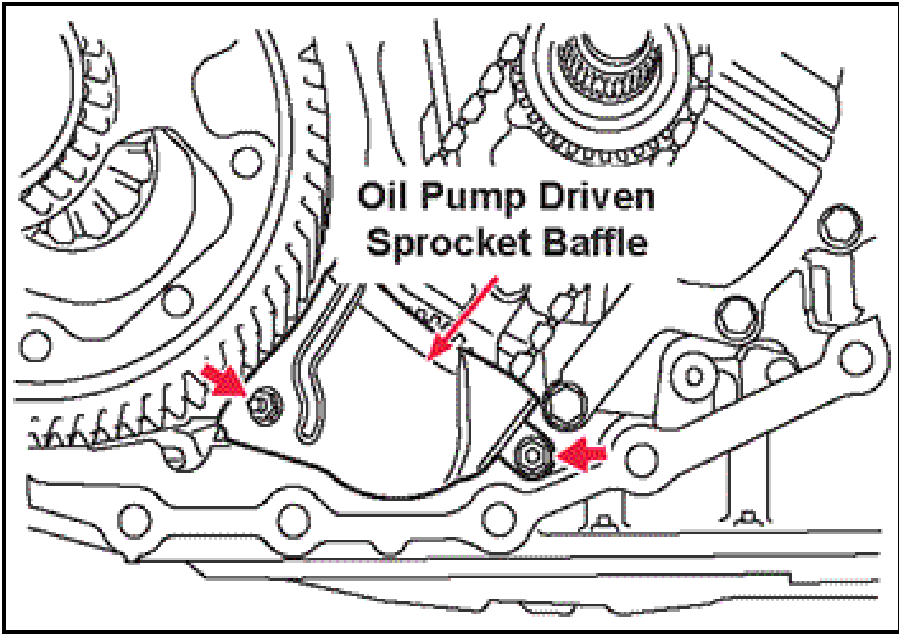

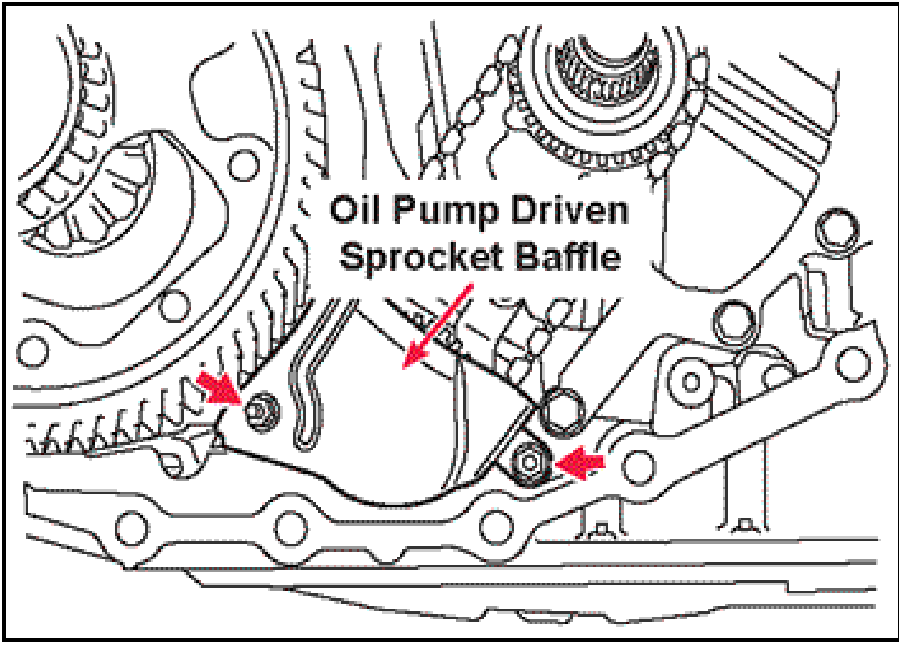

- Remove the two oil pump driven sprocket baffle

mounting nuts, then remove the baffle.

|

|

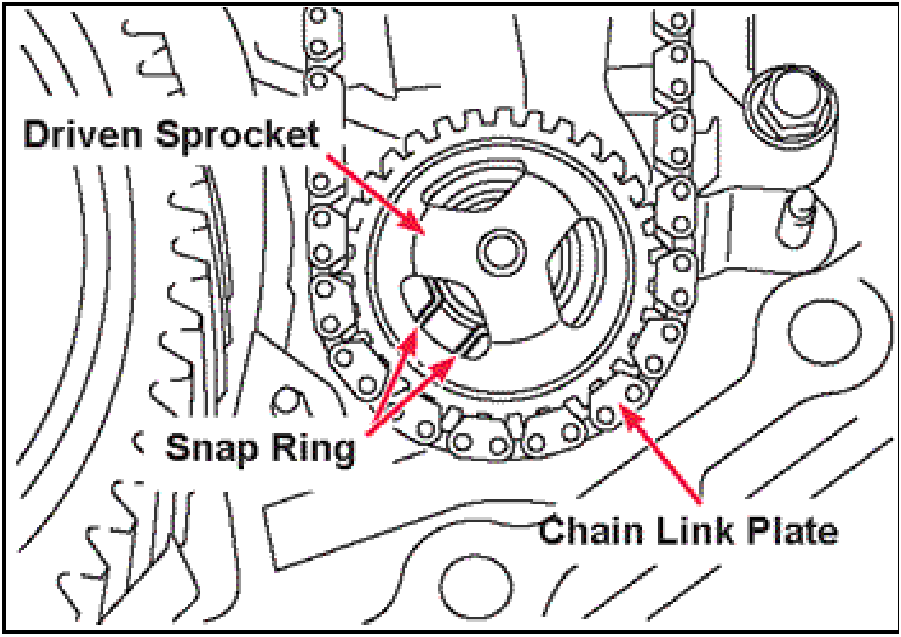

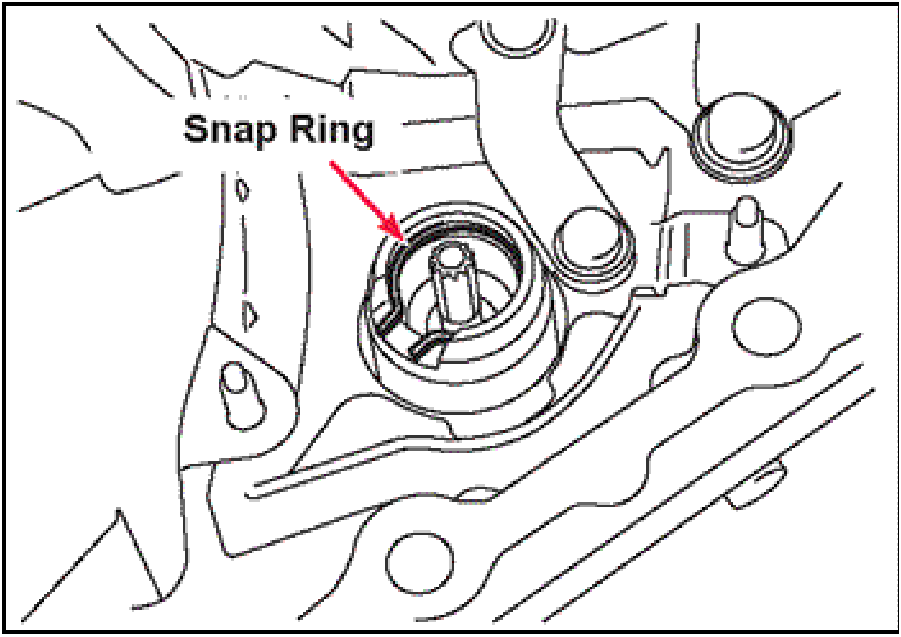

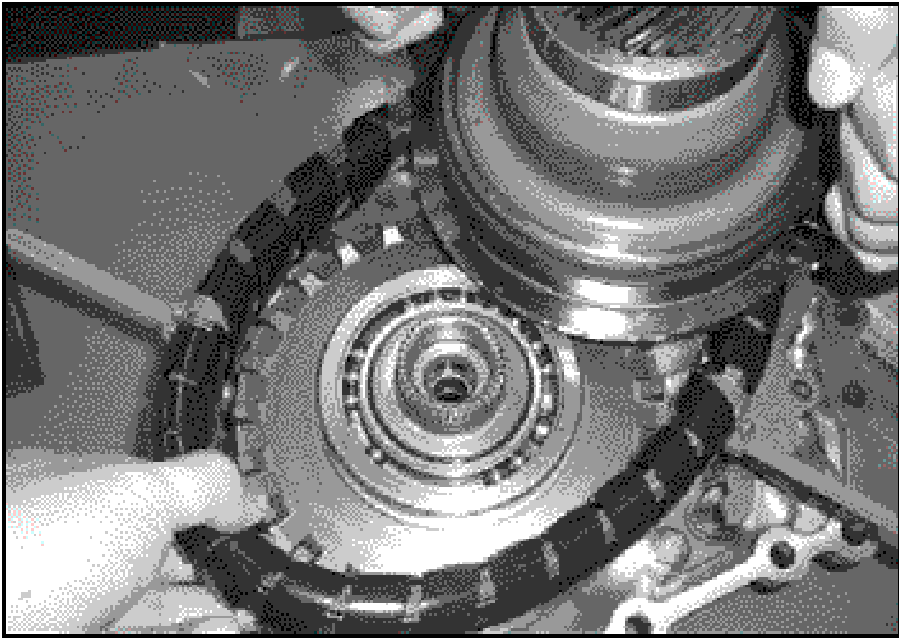

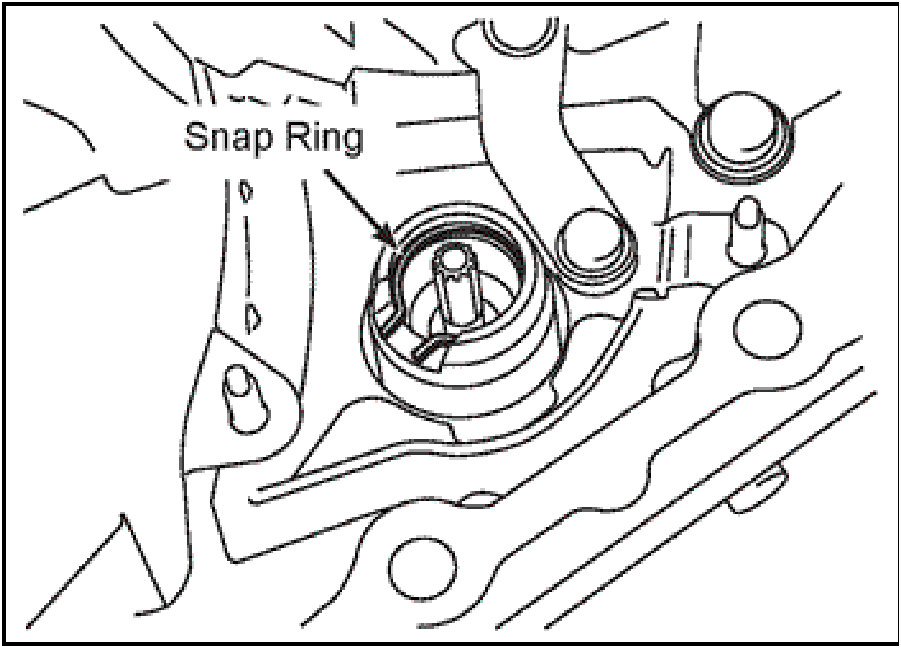

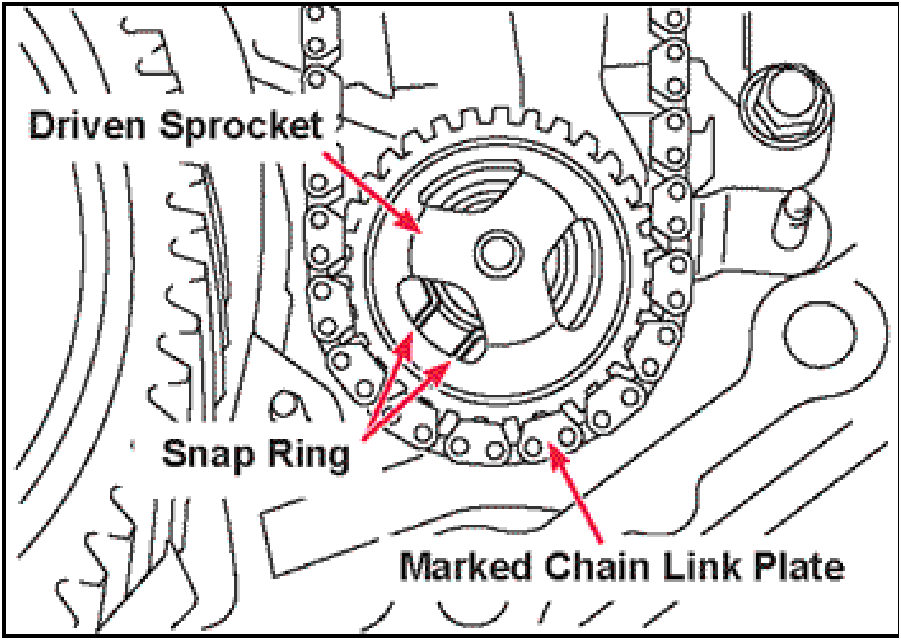

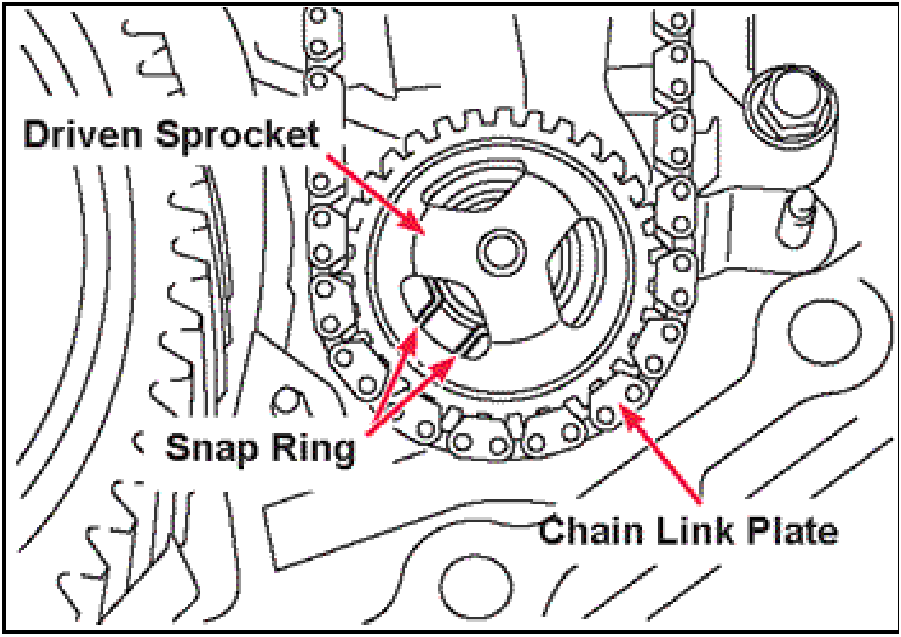

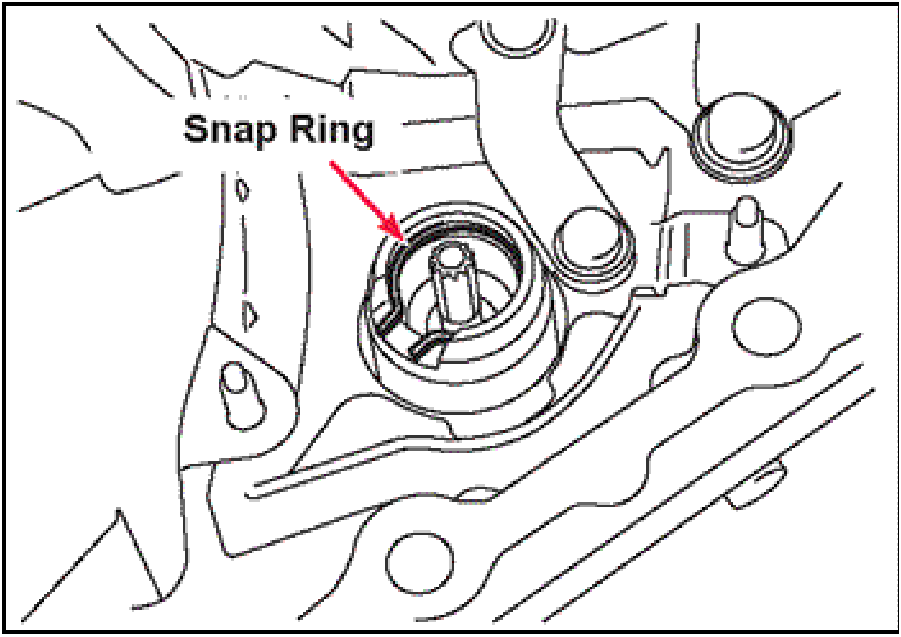

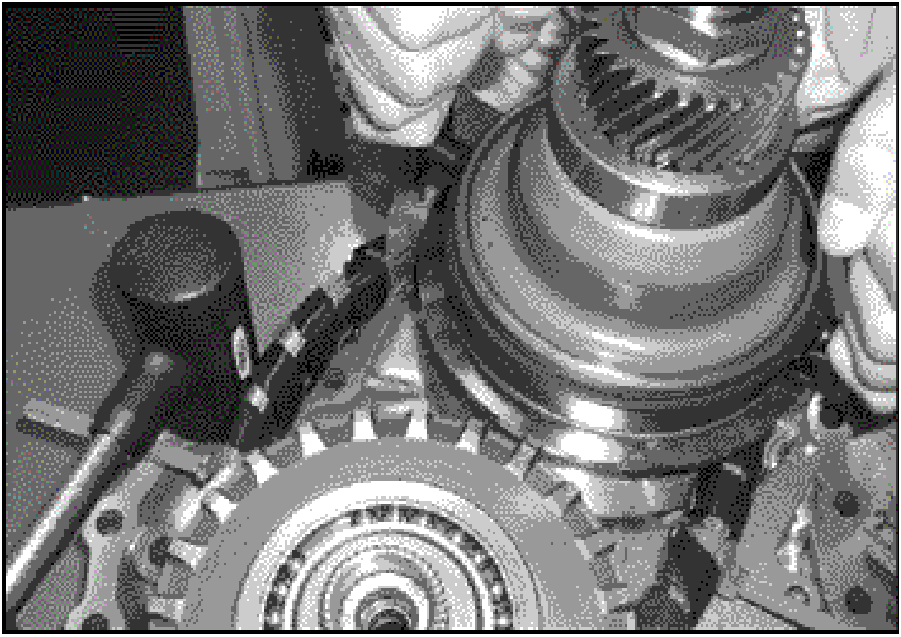

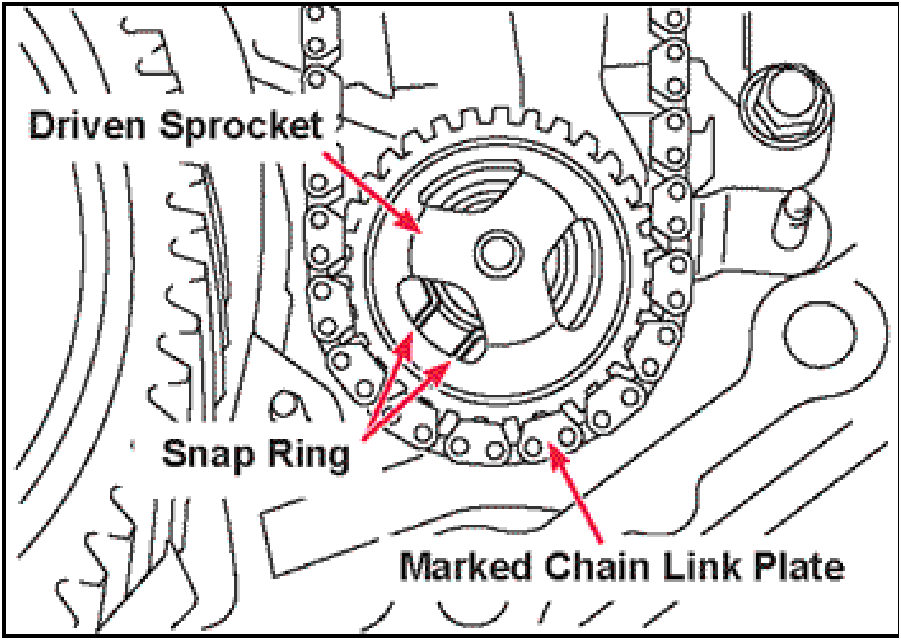

- Rotate the oil pump driven sprocket until one of the

three cutouts in the driven sprocket lines up with the

opening in the snap ring.

|

|

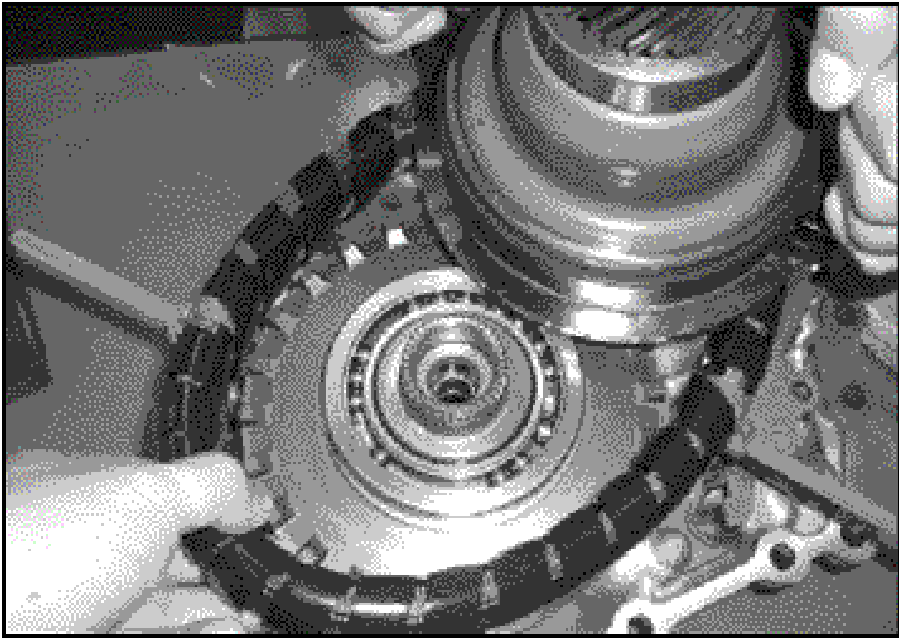

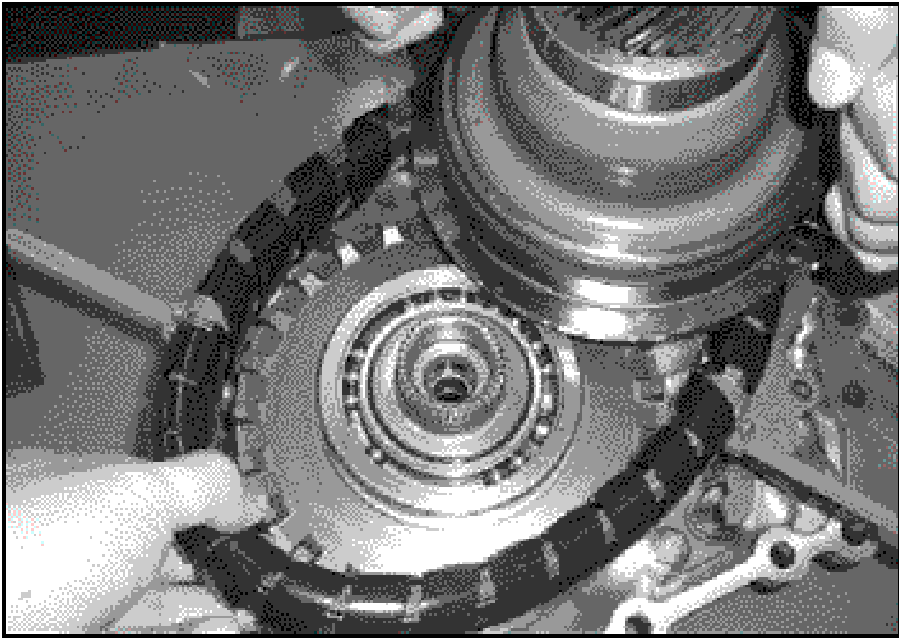

- Using a pair of external snap ring pliers, expand the

snap ring and slide both sprockets and the chain

upward to remove them from the transaxle.

Discard the chain

|

|

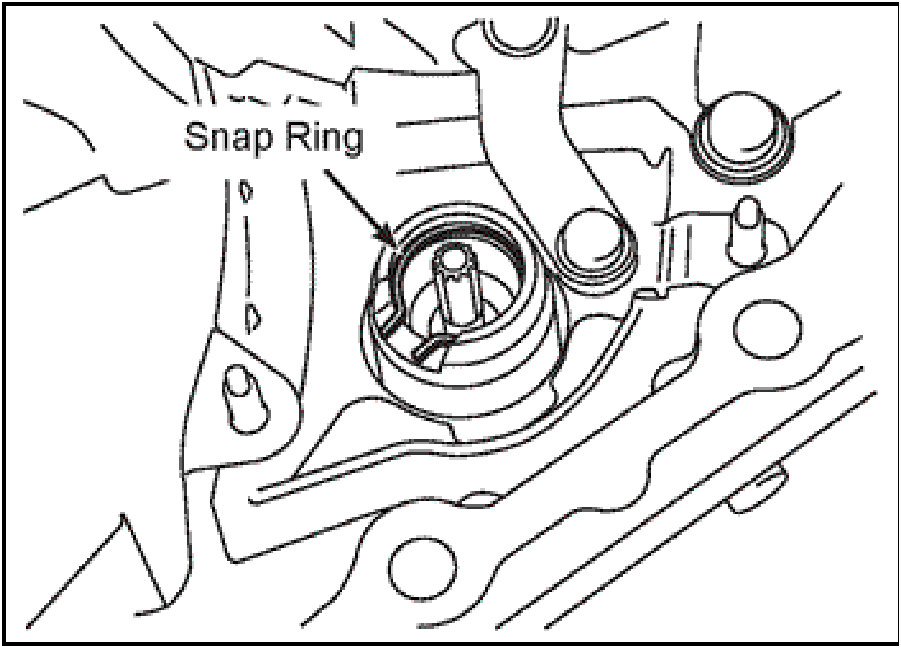

- Remove the snap ring from the oil pump housing

bearing bore.

Discard the snap ring.

|

|

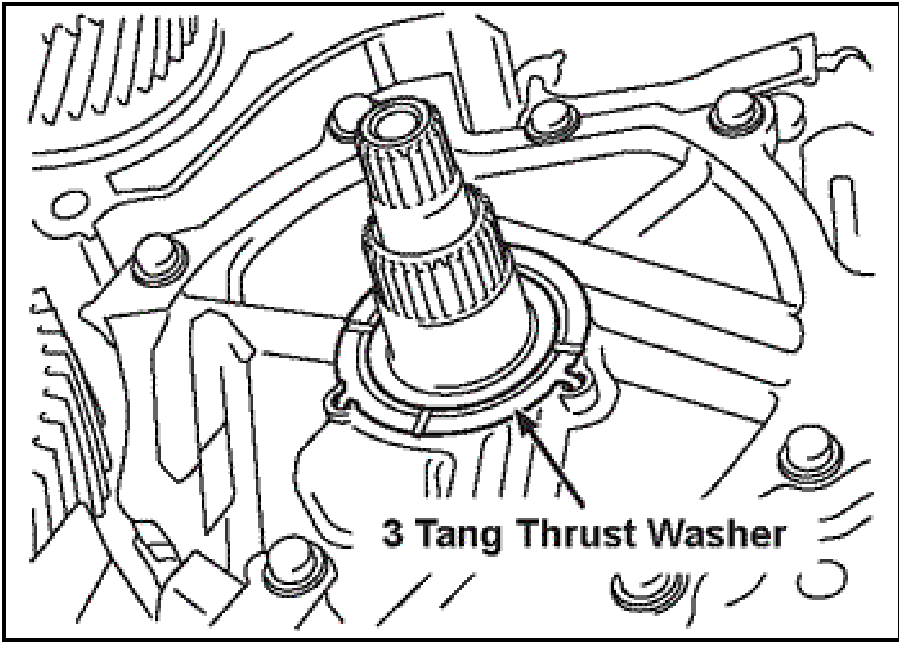

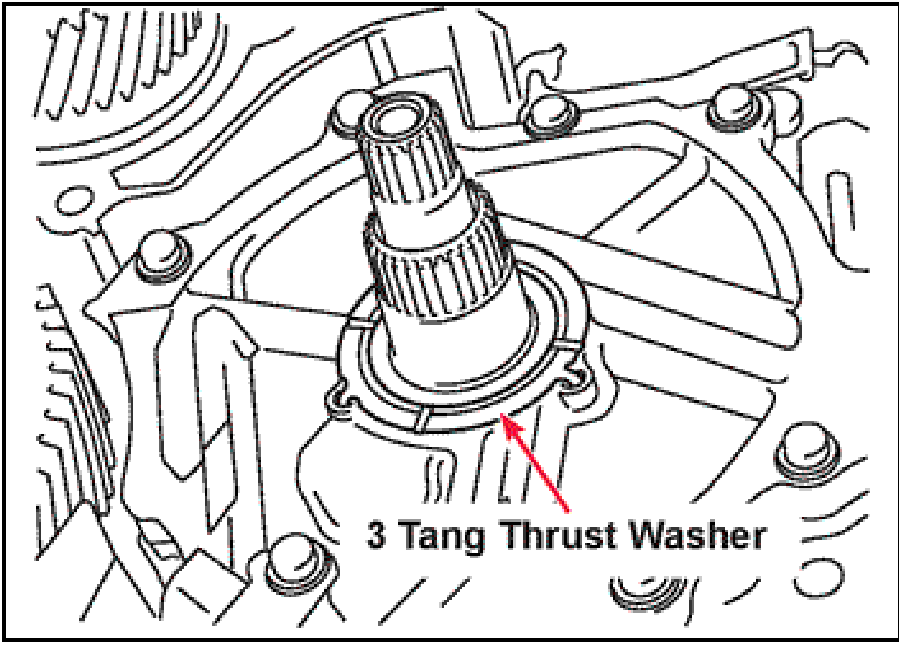

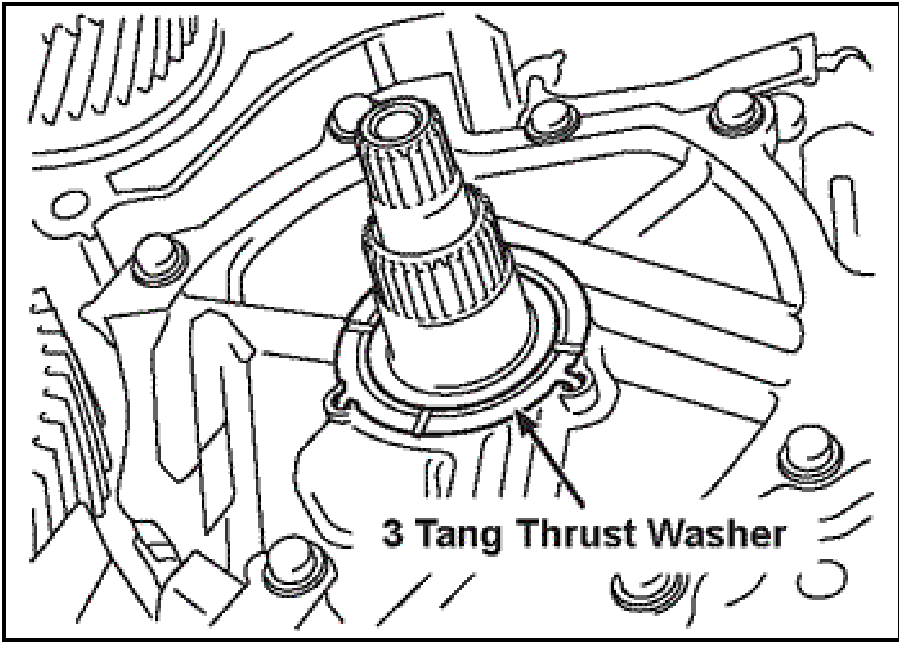

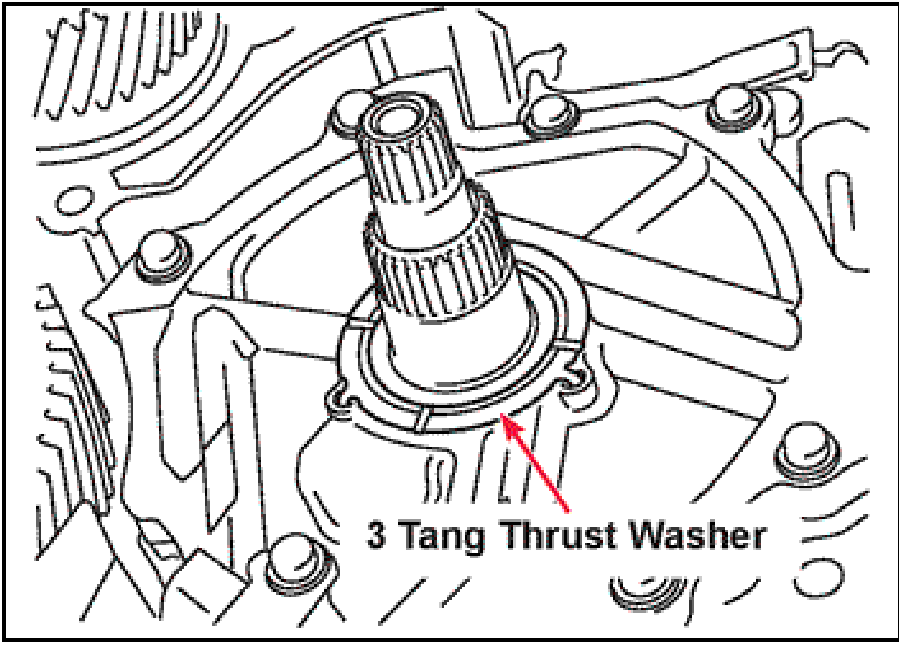

- Remove the three tang thrust washer from the pump

cover (stator support).

|

|

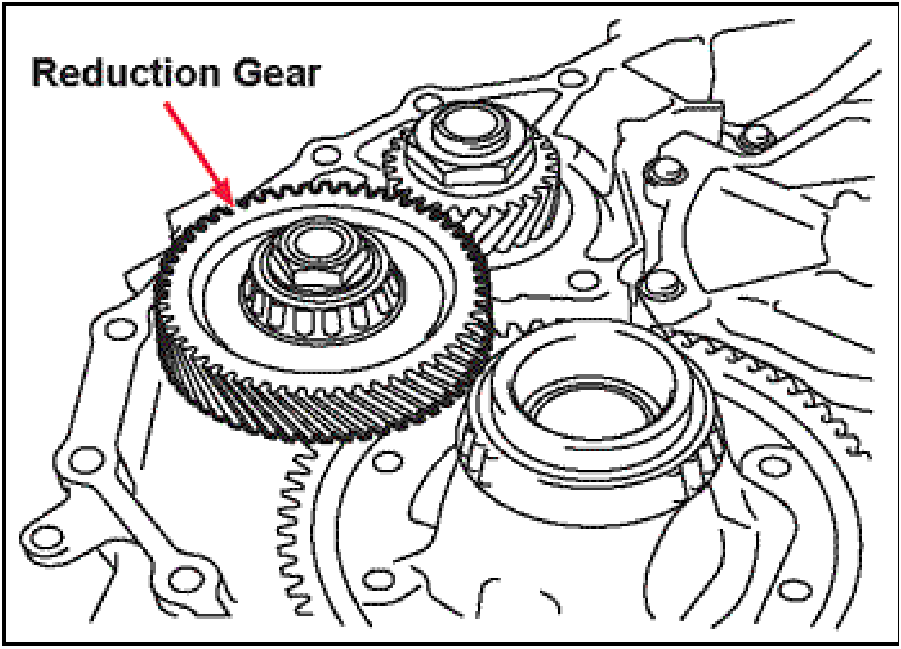

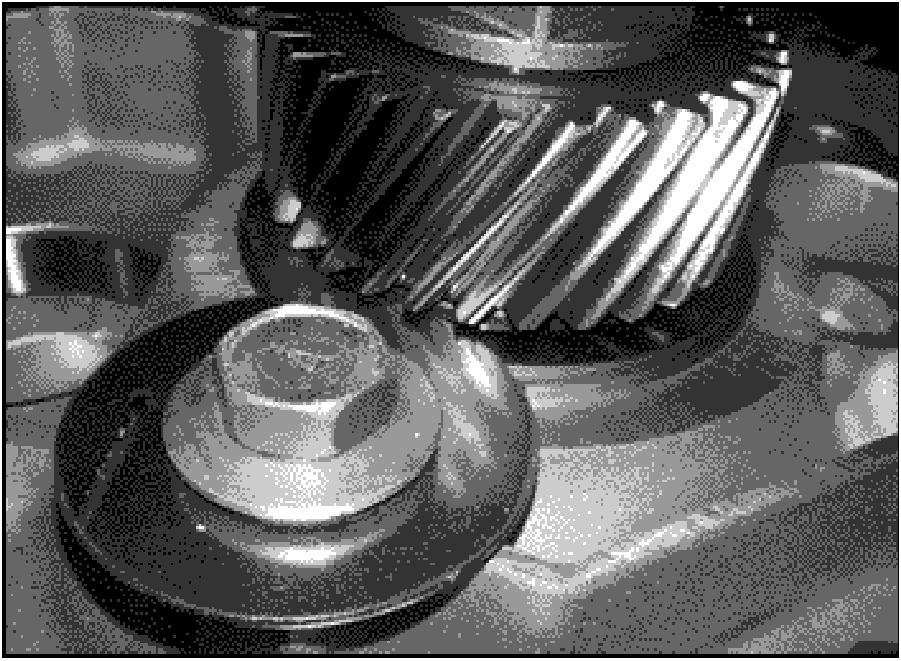

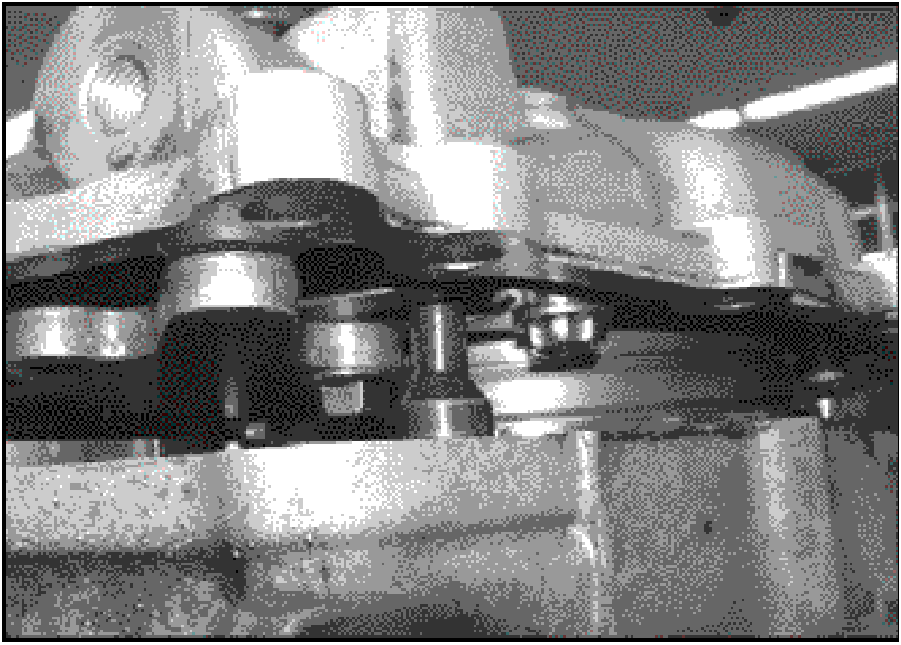

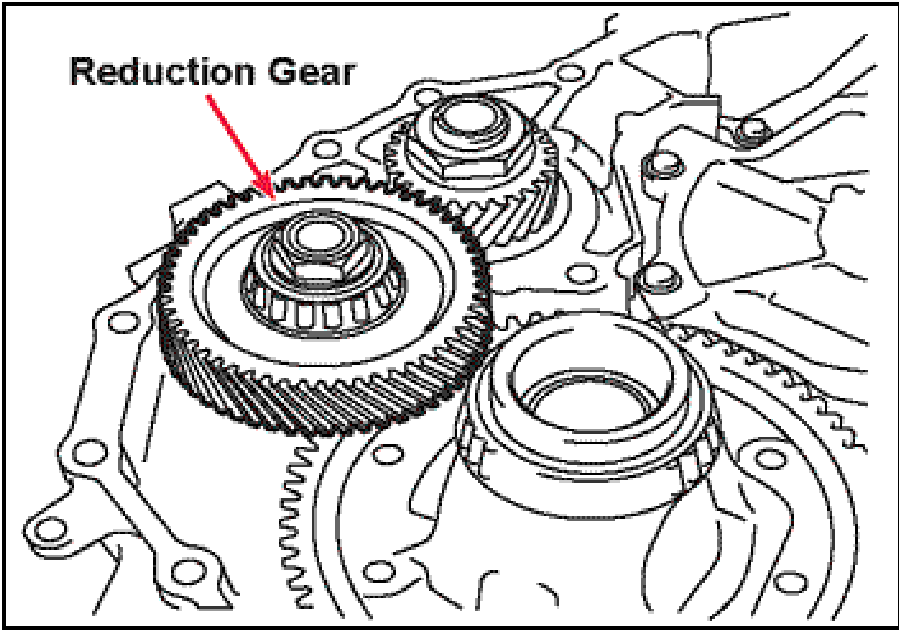

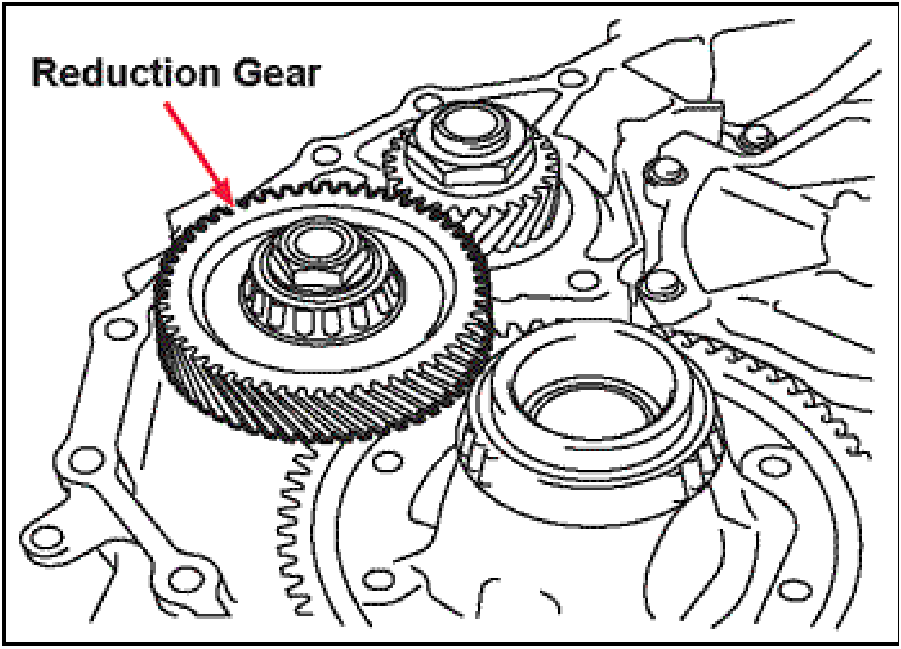

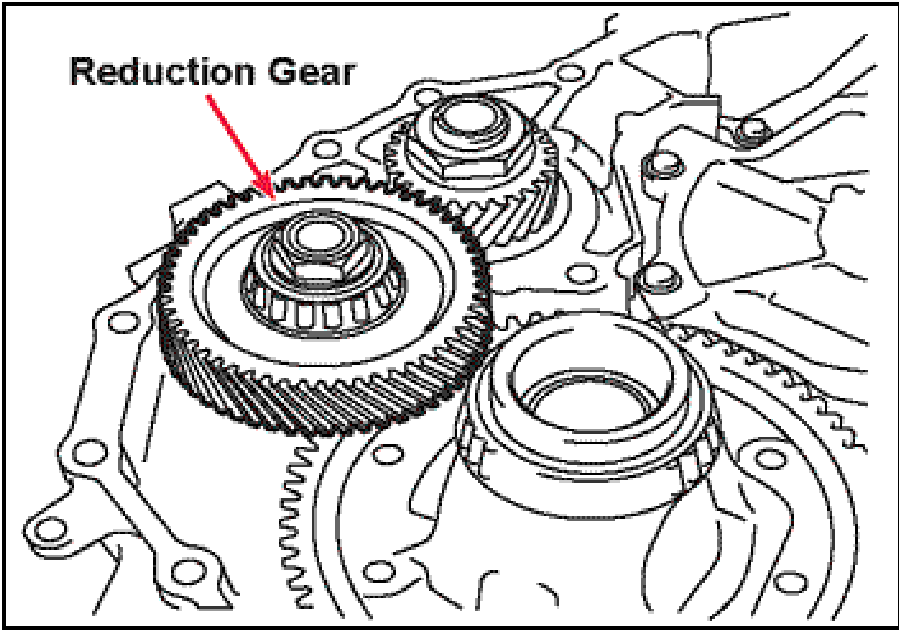

- Remove the reduction gear assembly.

Carefully inspect the bearings for roughness or

damage. Replace as necessary.

|

|

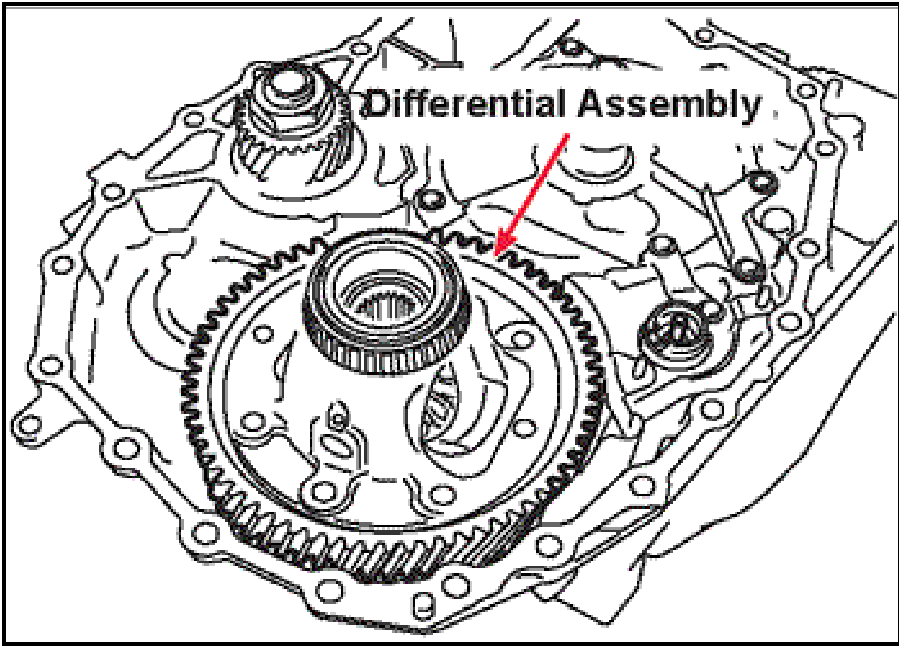

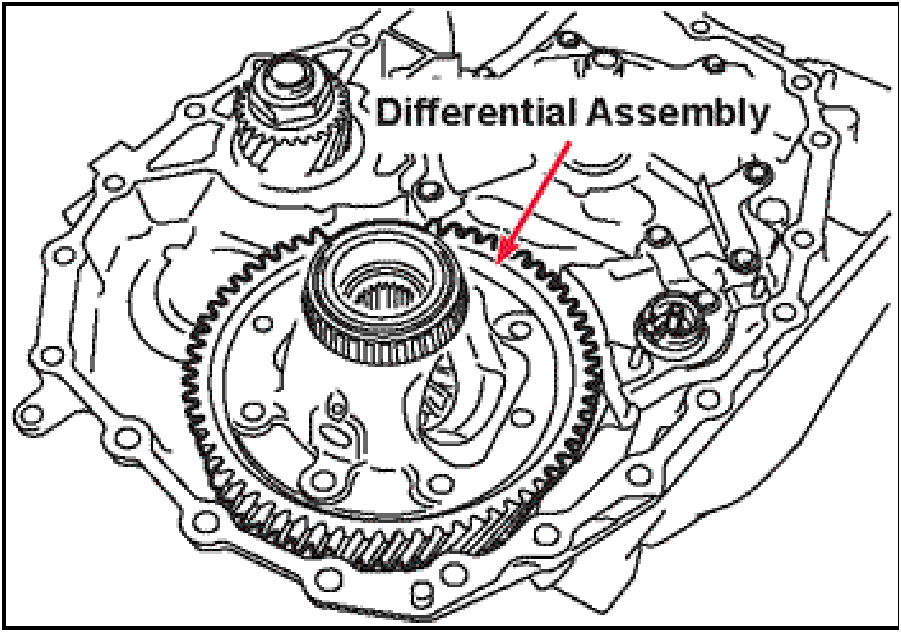

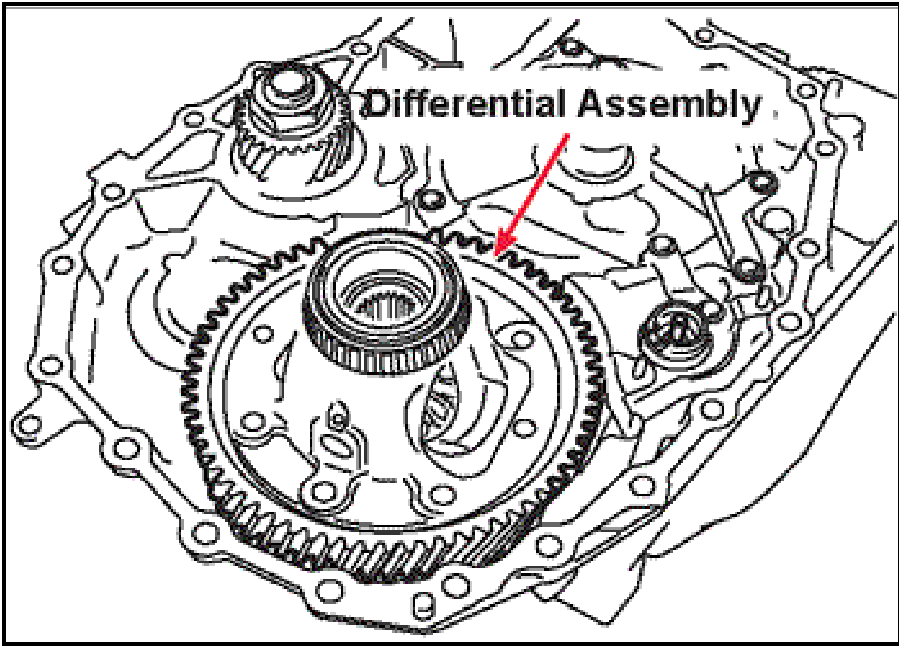

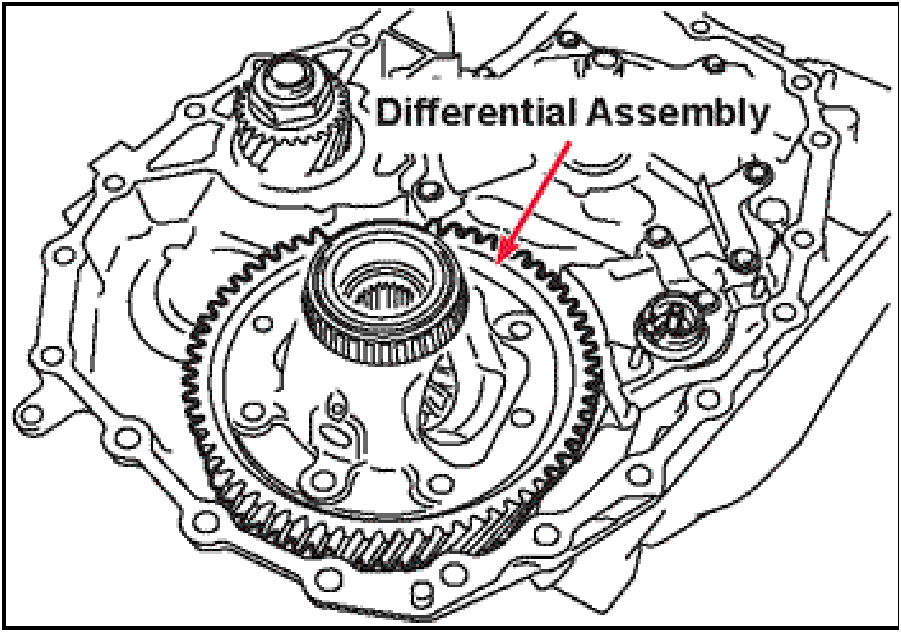

- Remove the differential assembly.

Carefully inspect the bearings for roughness or

damage. Replace as necessary.

|

|

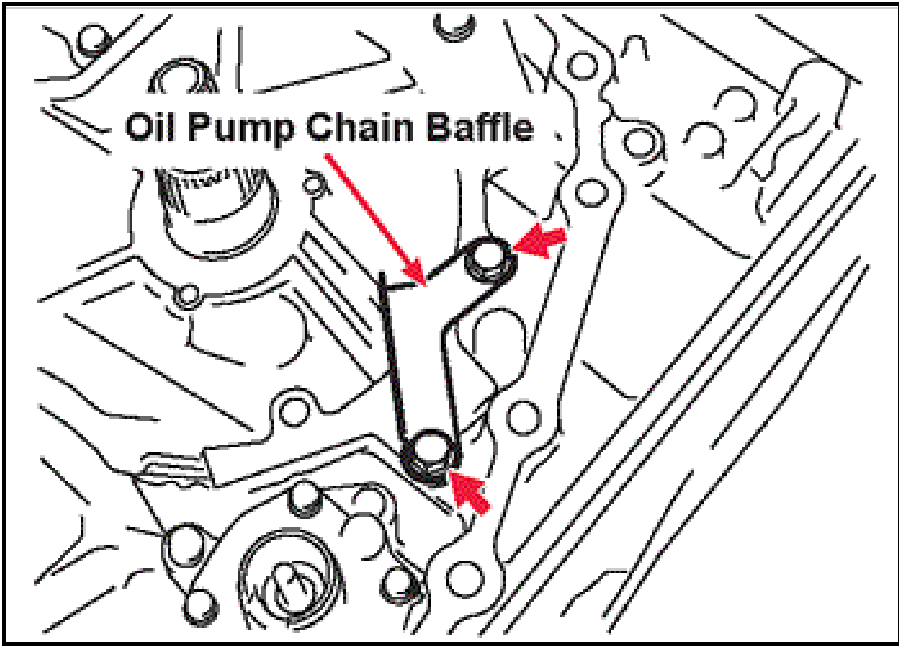

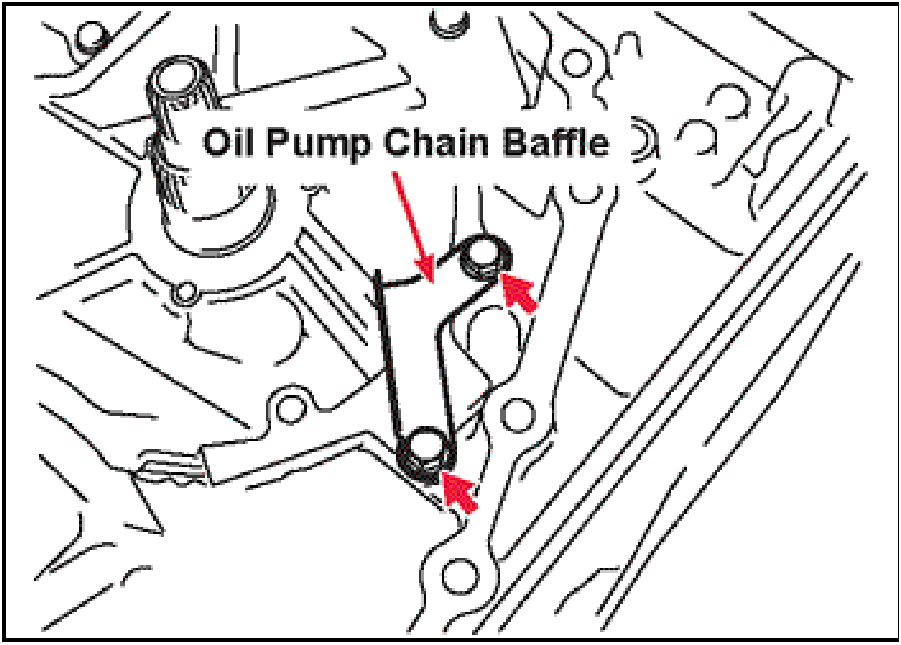

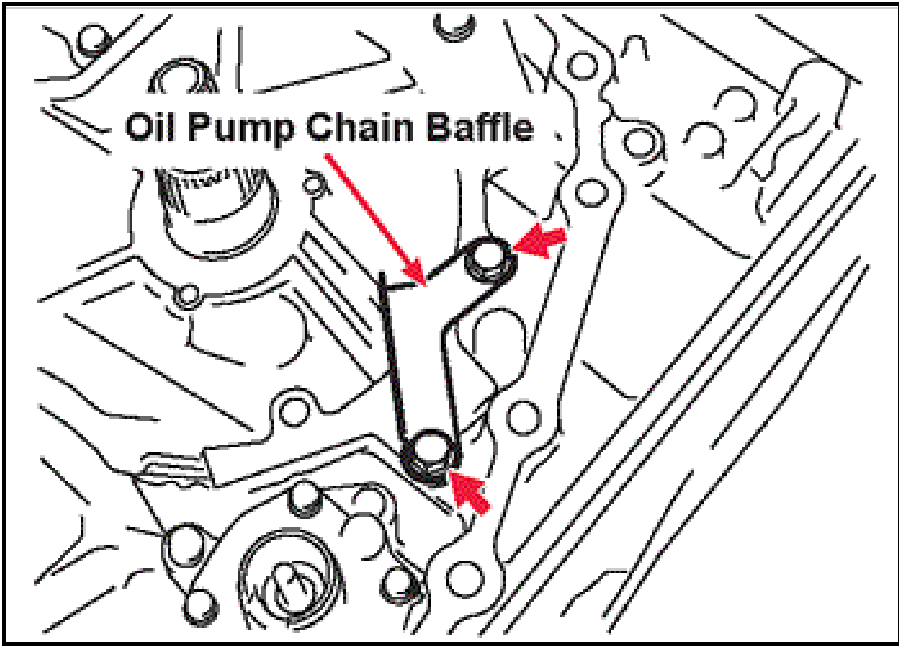

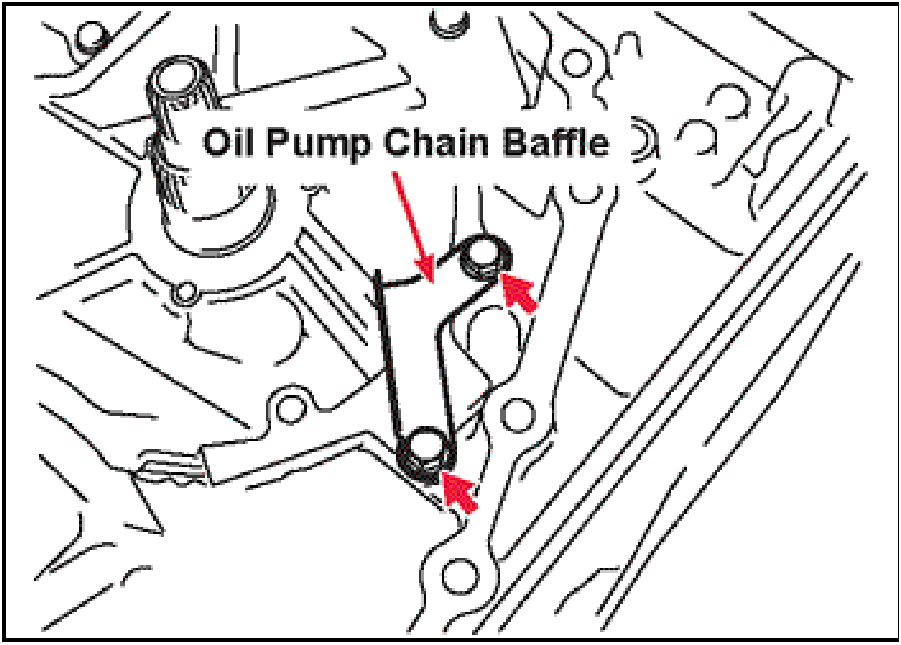

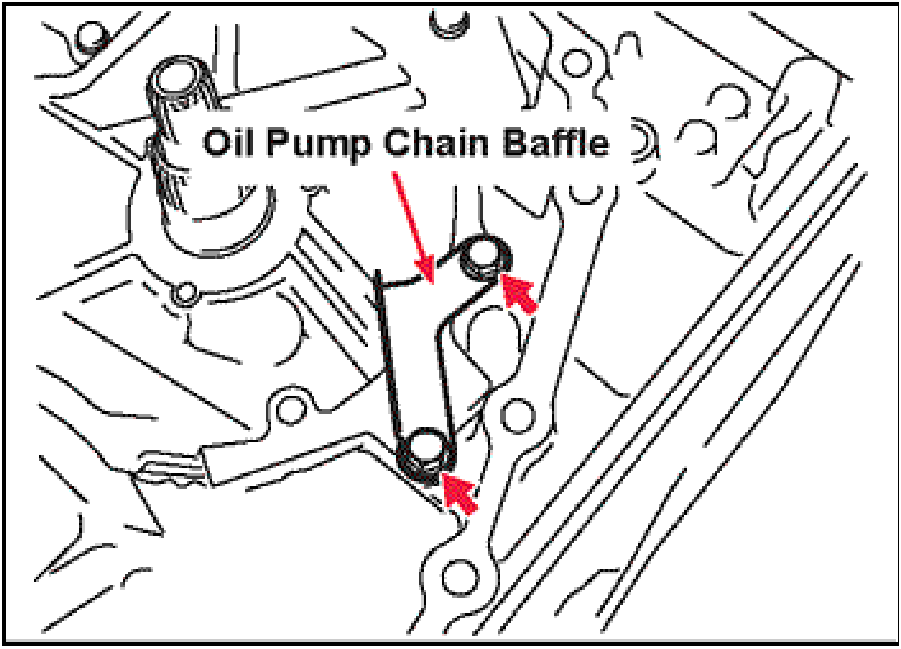

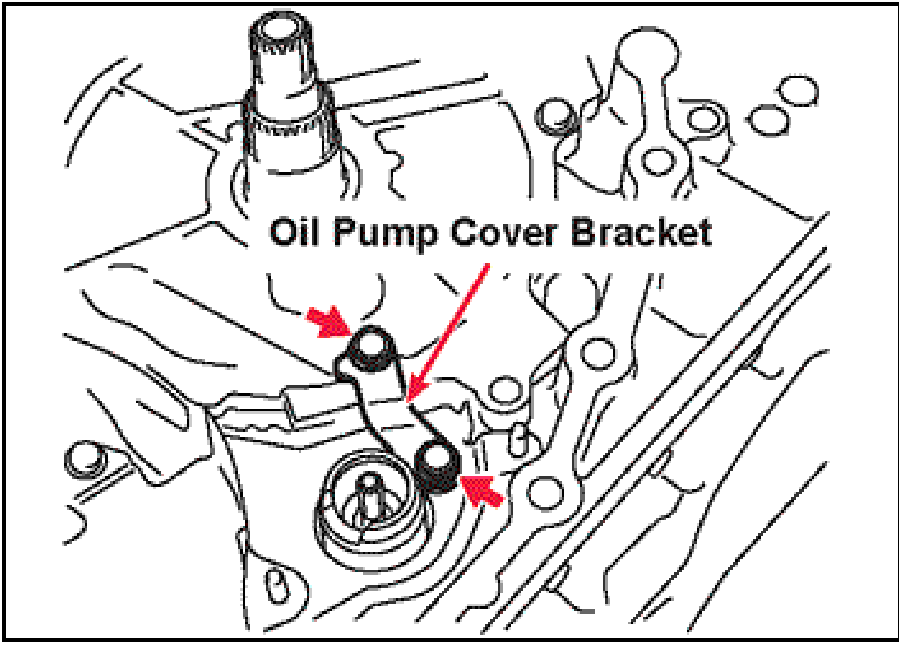

- Remove the two oil pump chain baffle mounting bolts,

then remove the oil pump chain baffle.

|

|

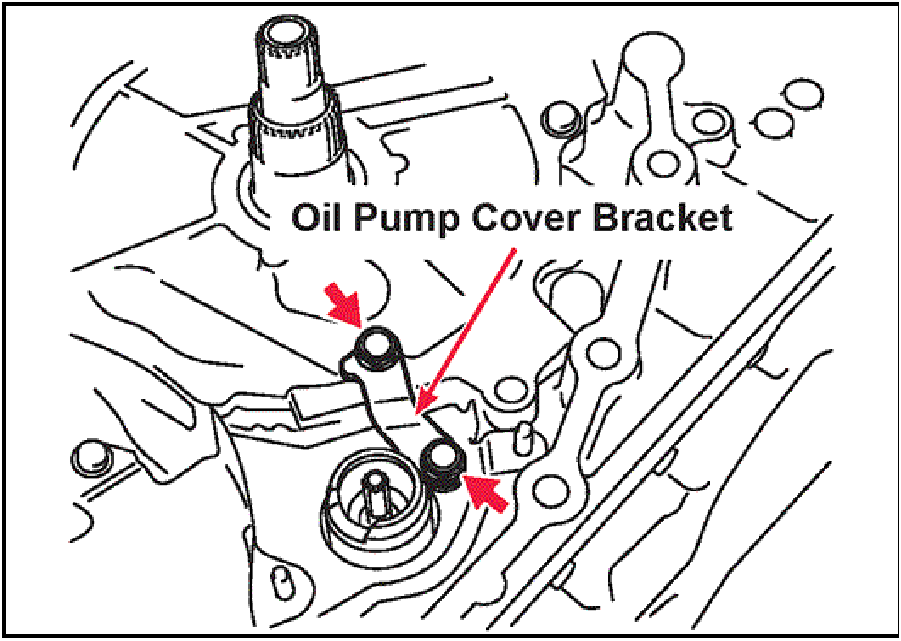

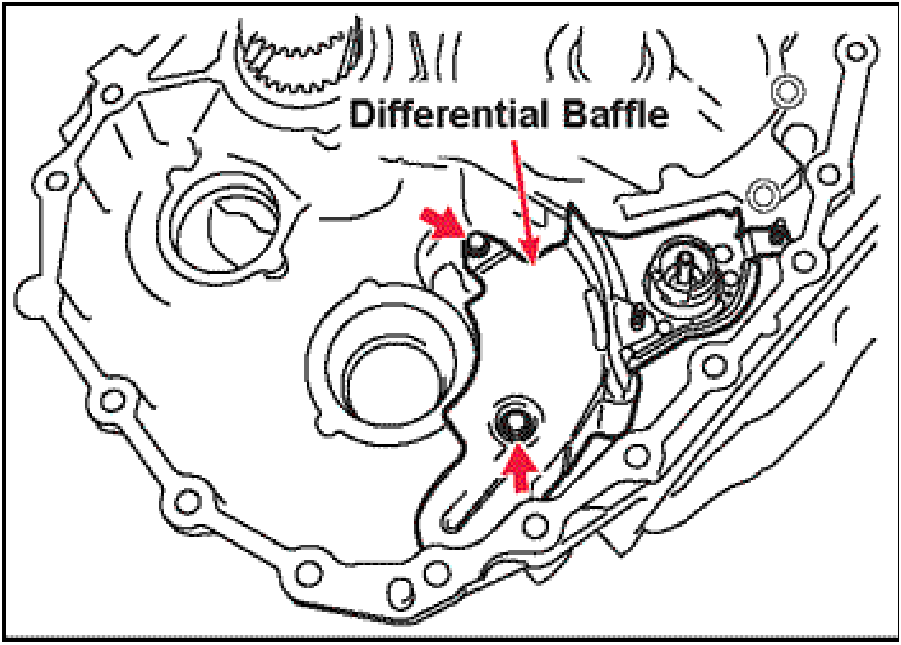

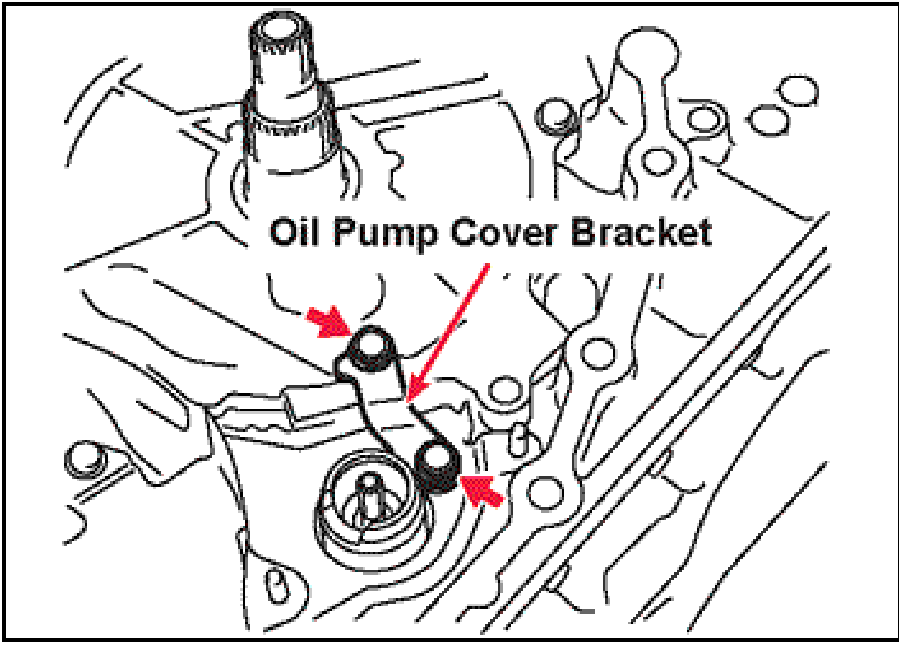

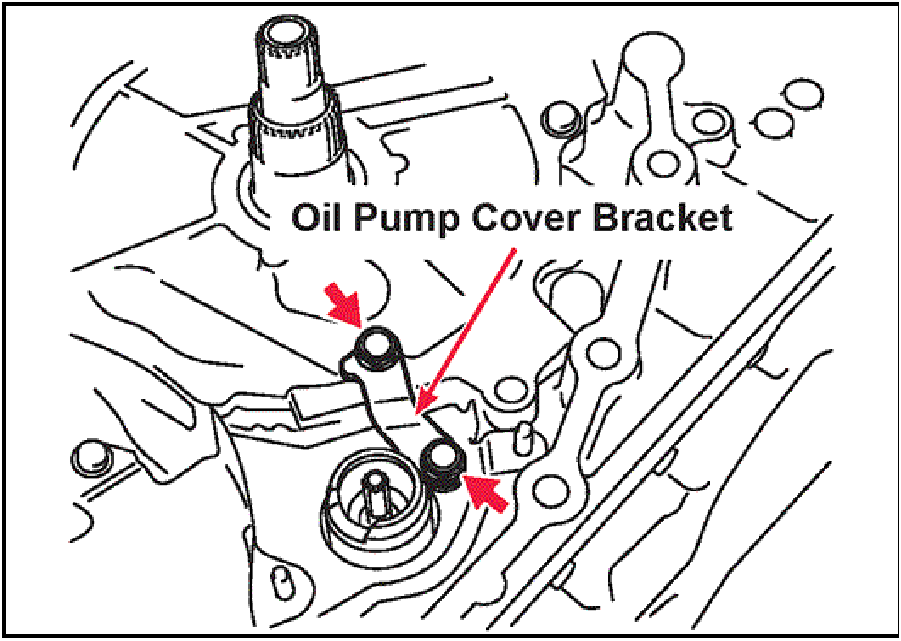

- Remove the two oil pump to pump cover (stator

support) bracket mounting bolts, then remove the

bracket.

|

|

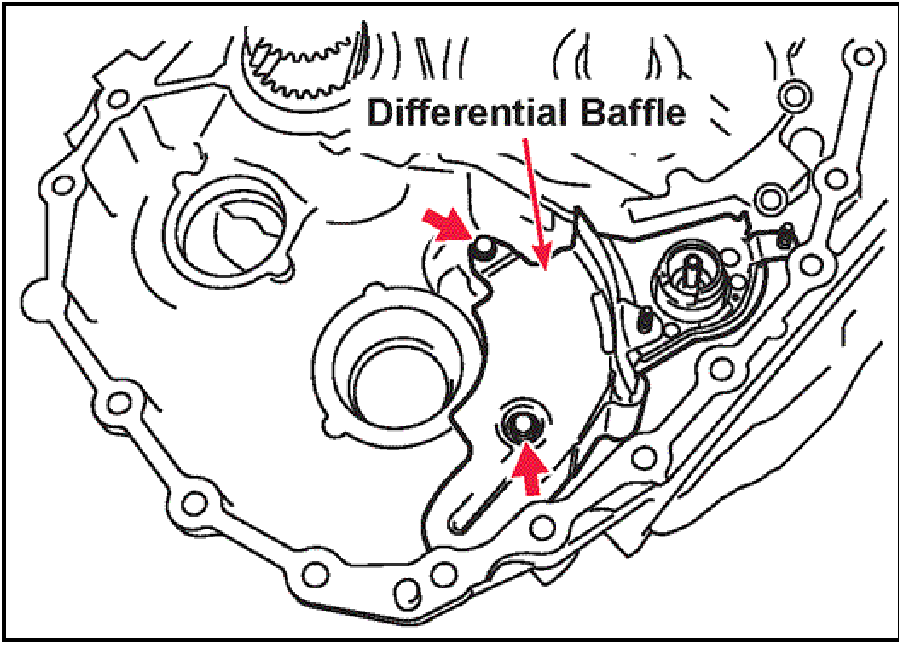

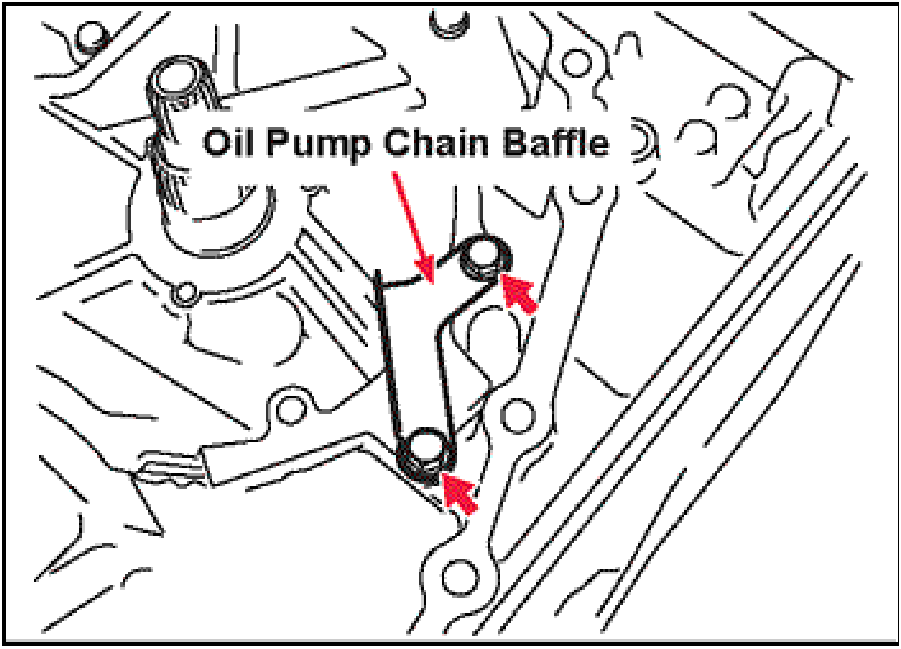

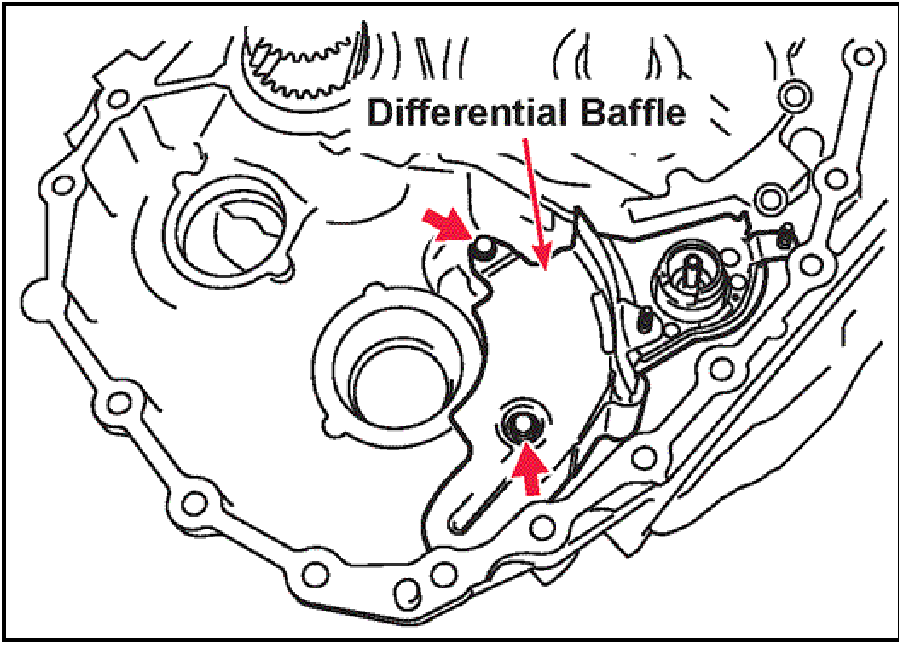

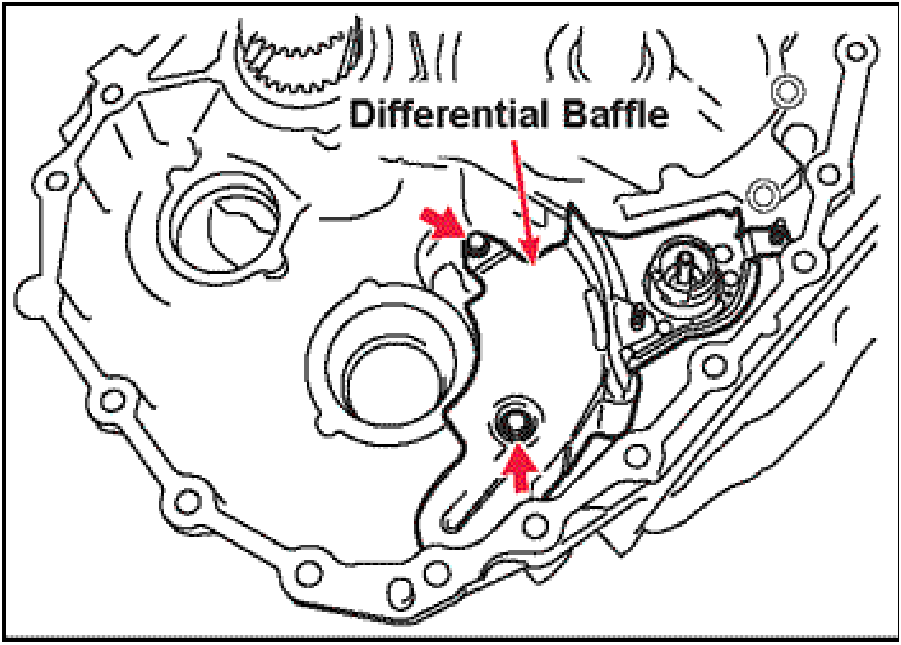

- Remove the two differential baffle mounting bolts, then

remove the baffle.

|

|

- Remove the remaining five oil pump cover (stator

support) mounting bolts, then remove the oil pump

cover (Stator support) from the case.

|

|

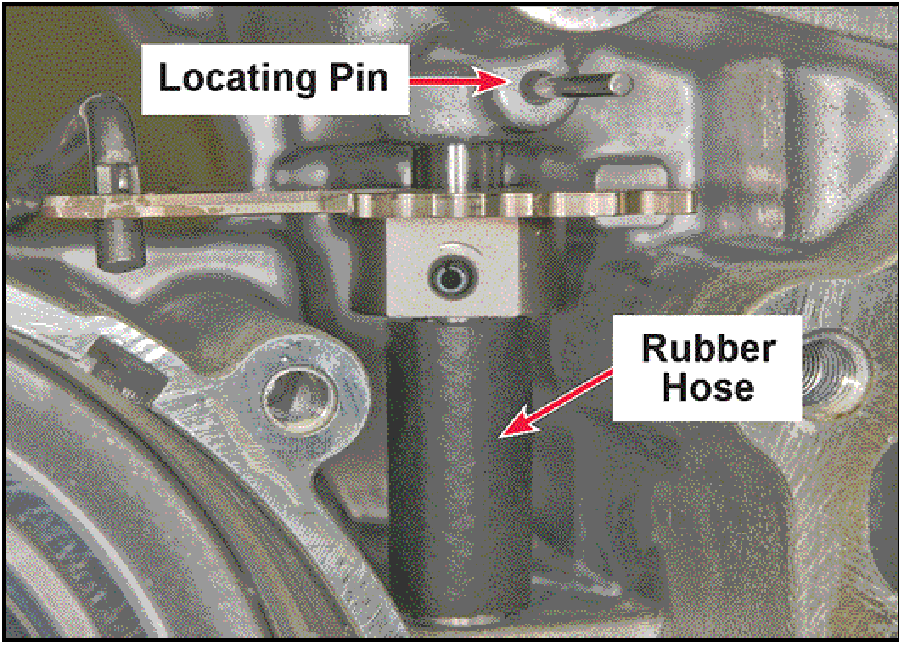

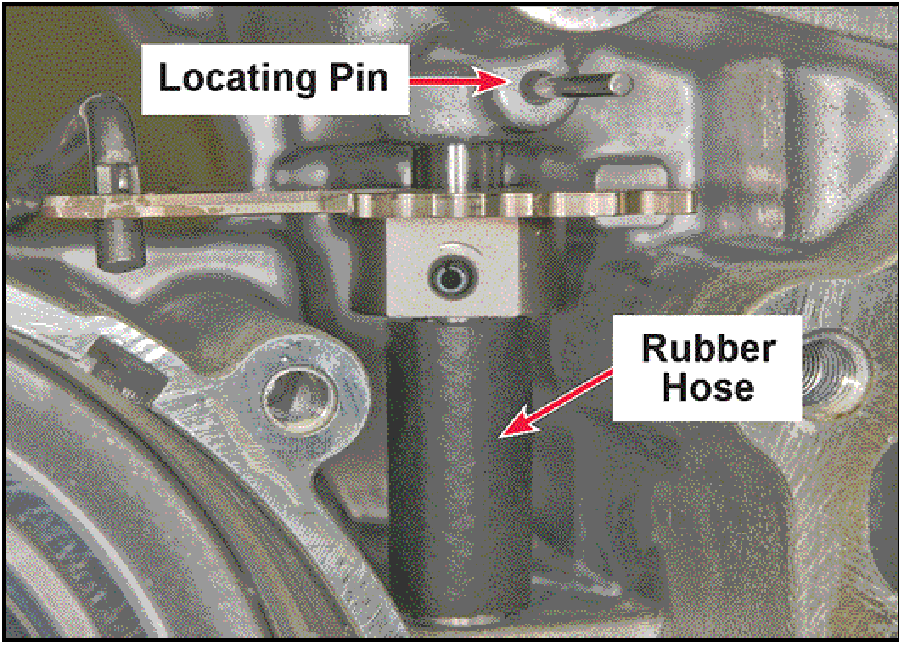

- Cut a small piece of fuel hose and install it onto the

manual control shaft is shown.

Using your fingers or a stick magnet remove the

manual control shaft locating pin from the case.

Failure to install the fuel hose will cause damage to the

non-serviceable manual shaft seal.

|

|

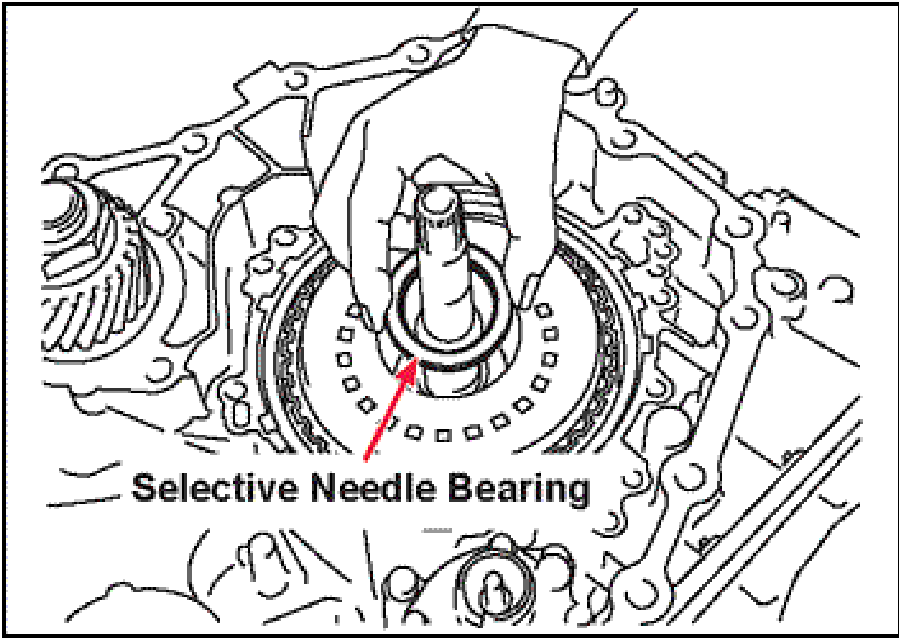

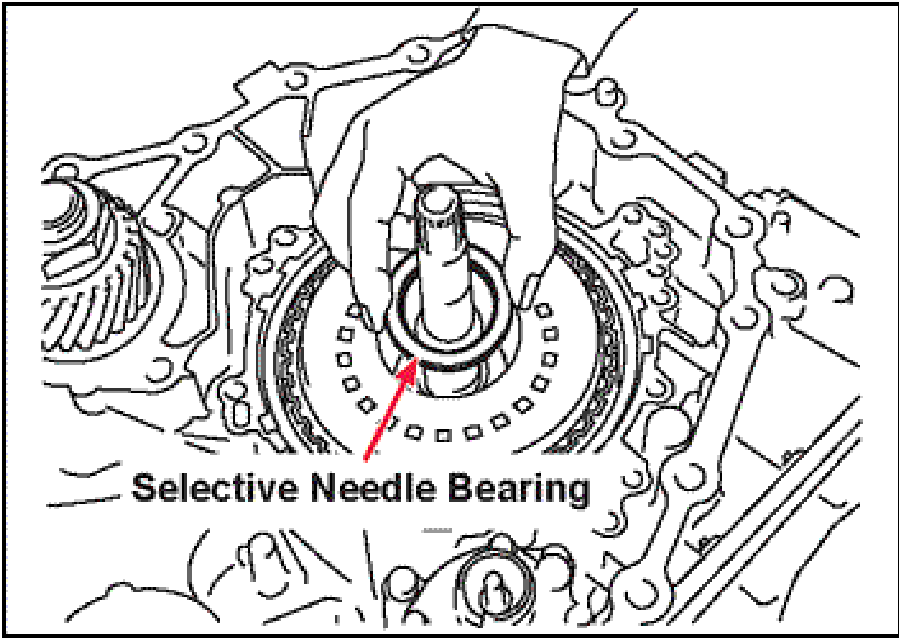

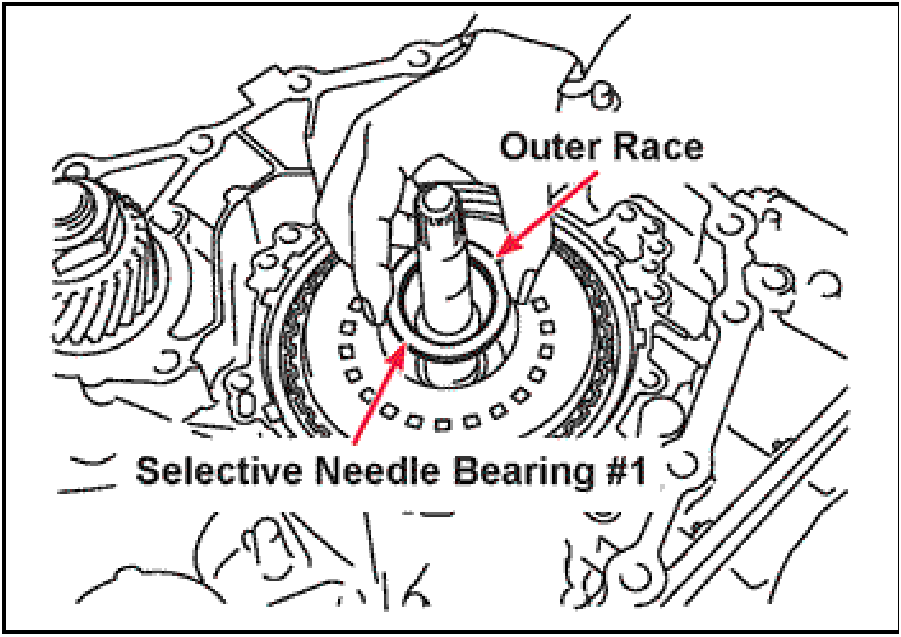

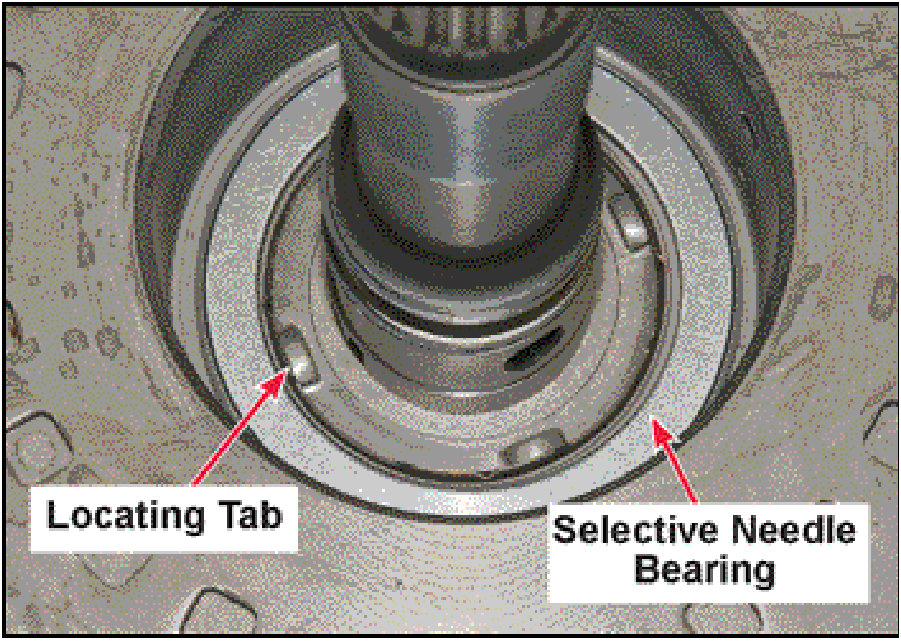

- Remove the selective needle bearing assembly from

the forward clutch drum.

NOTE: The selective needle bearing assembly may

have come out with the oil pump cover (stator support).

|

|

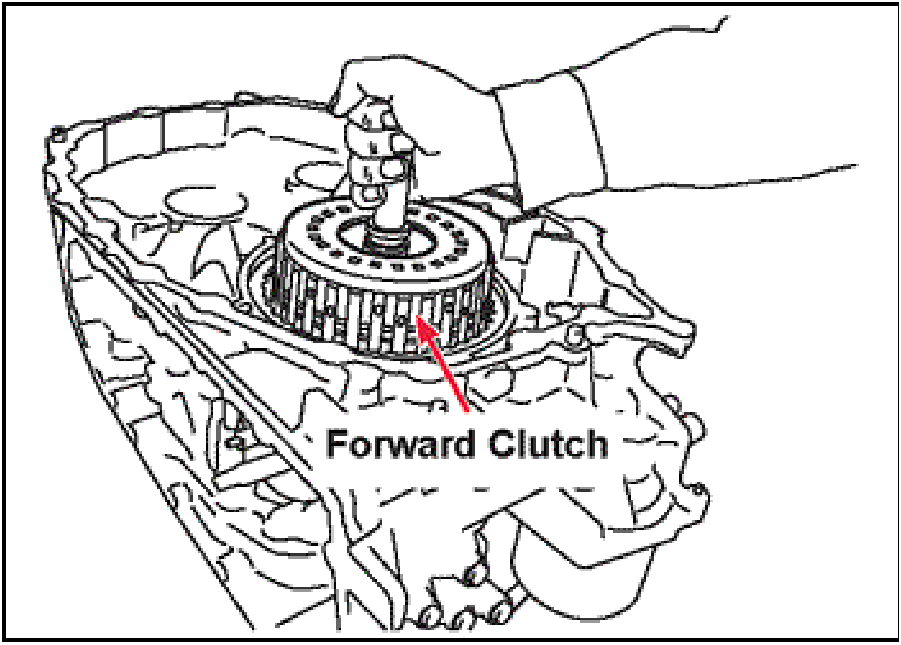

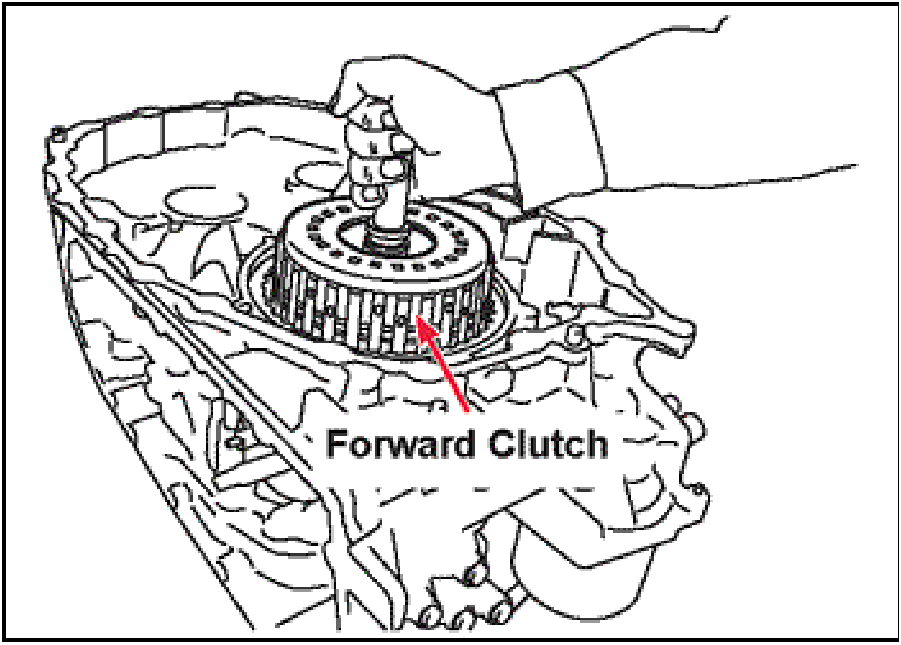

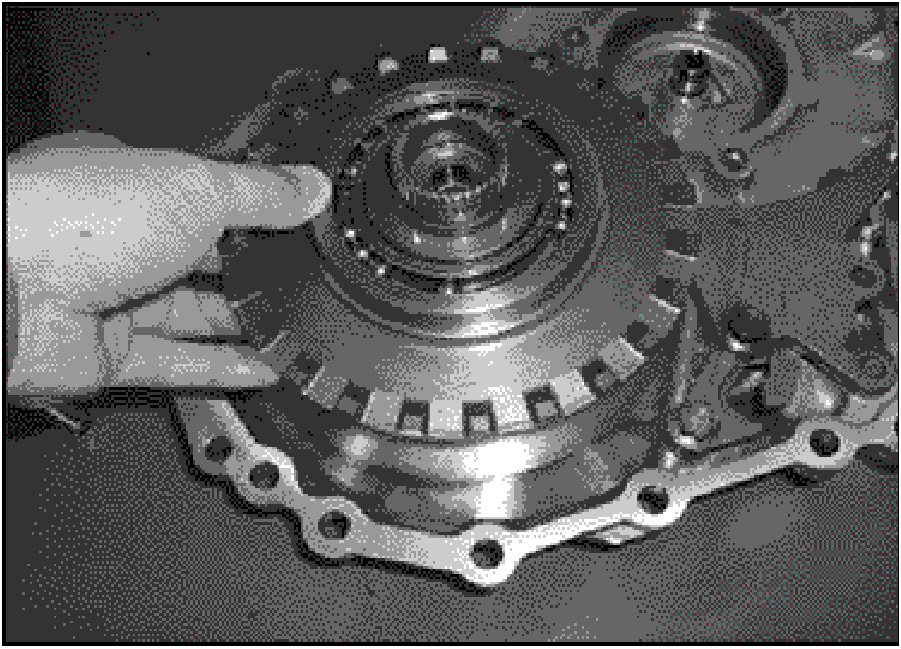

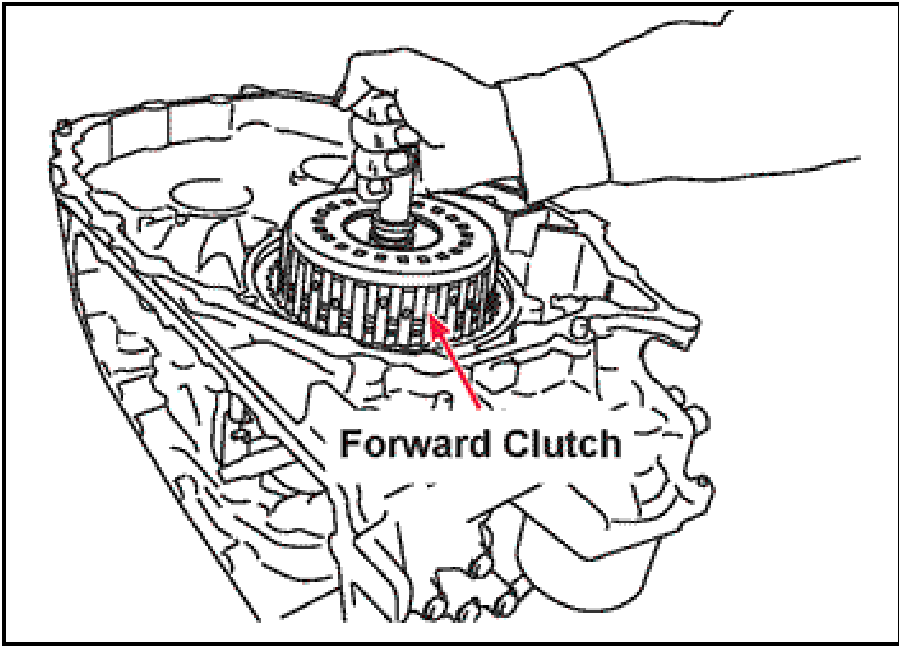

- Remove the forward clutch drum assembly from the

transaxle case

|

|

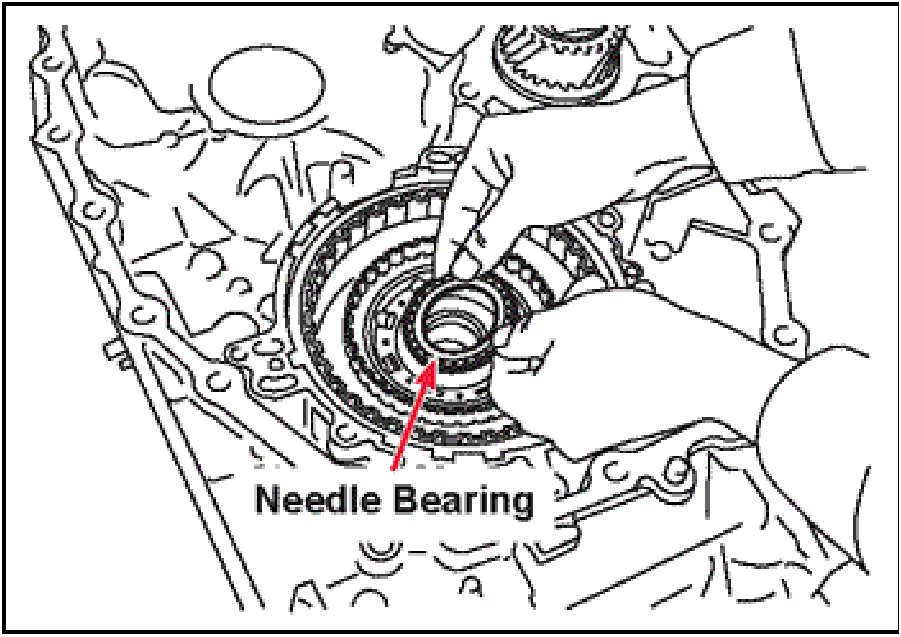

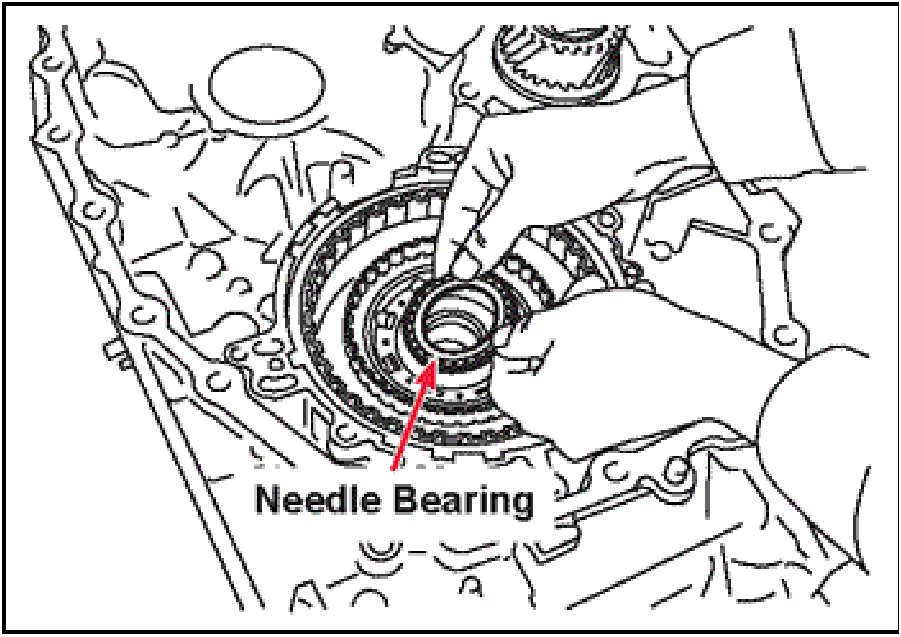

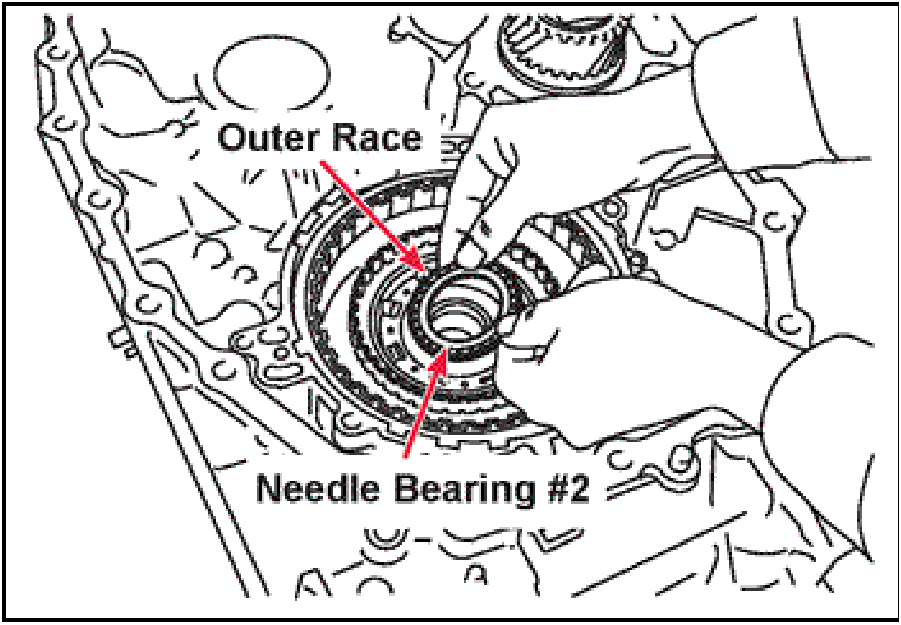

- Remove the needle bearing assembly from the sun

gear.

NOTE: The needle bearing may have come out with

the forward clutch drum.

|

|

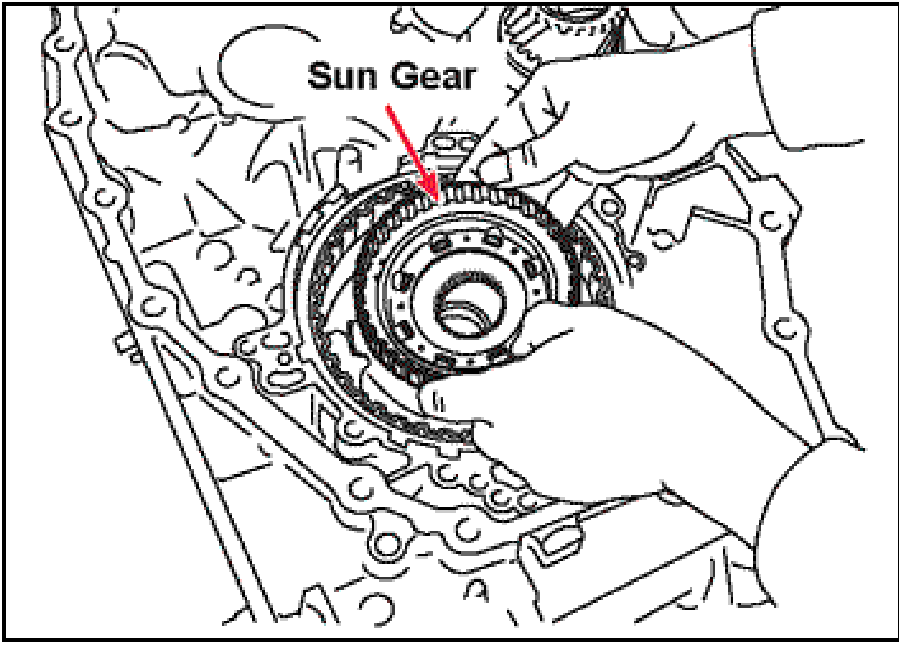

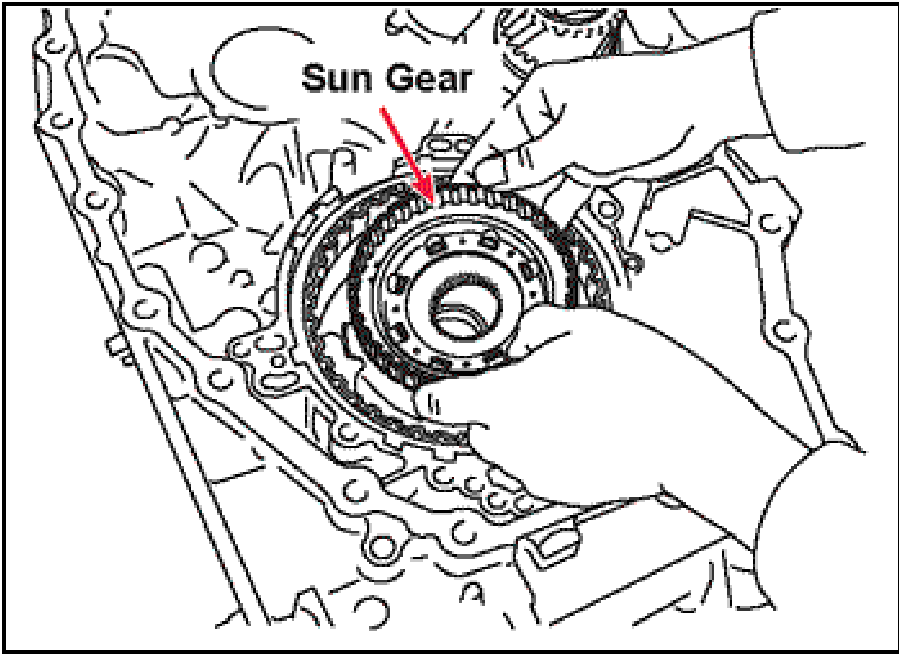

- Remove the sun gear.

|

|

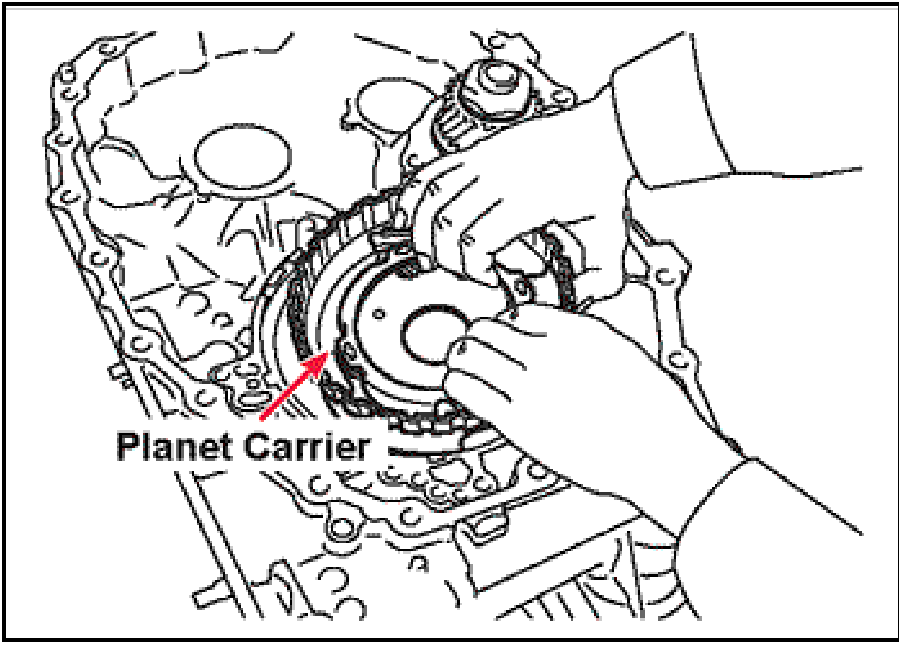

- Remove the planet carrier (reverse brake clutch hub)

assembly from the transaxle case.

|

|

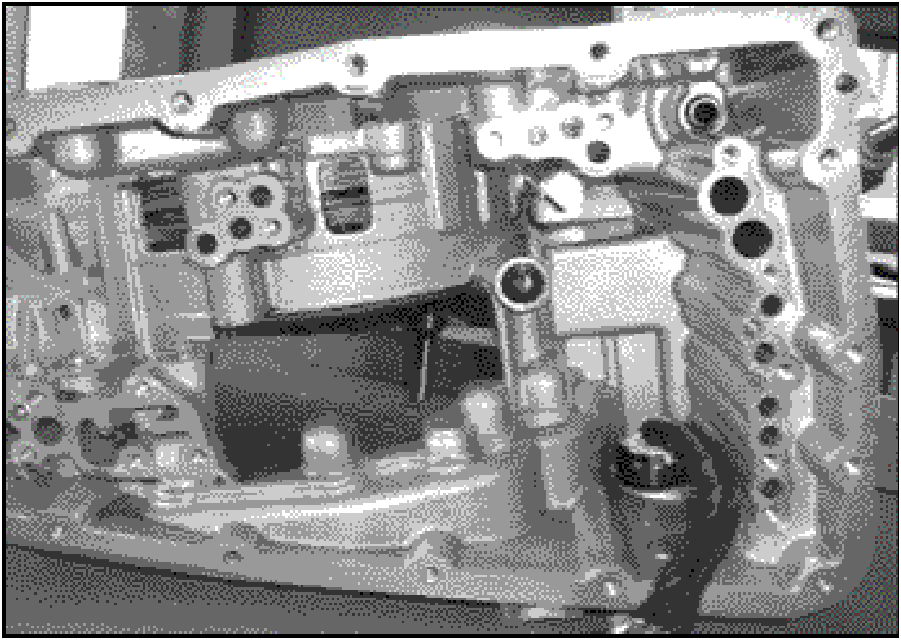

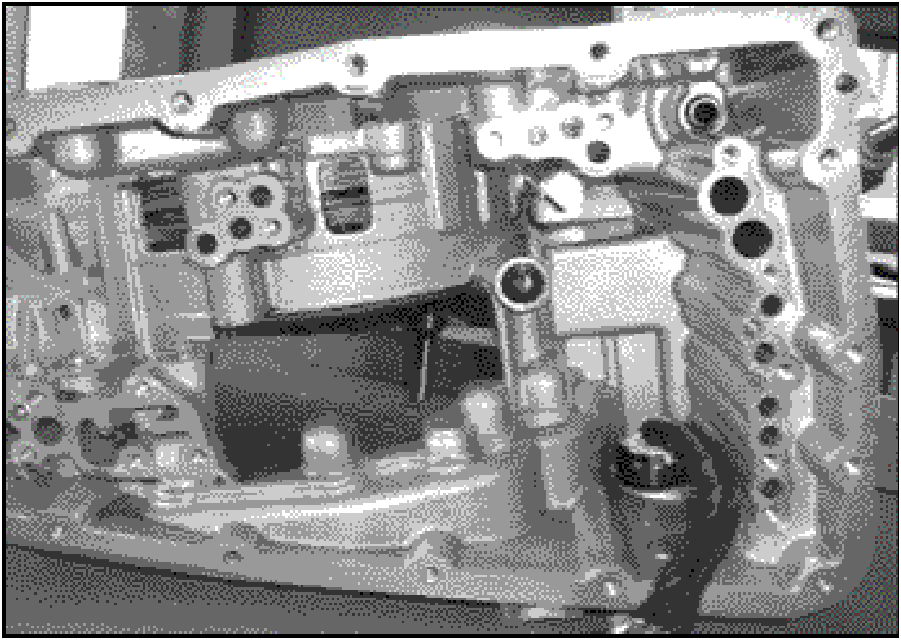

- Remove the pan

Discard the pan gasket

|

|

- Remove the strainer and 0-ring.

Discard both the strainer and 0-ring.

|

|

- Remove the one oil pump mounting bolt from the rear

of the transaxle case

Remove and discard the o-ring.

|

|

- Remove the three allen head oil pump mounting bolts.

Remove the oil pump from the transaxle.

DO NOT remove the four hex head bolts from the

oil pump assembly, this will cause damage to the

oil pump.

|

|

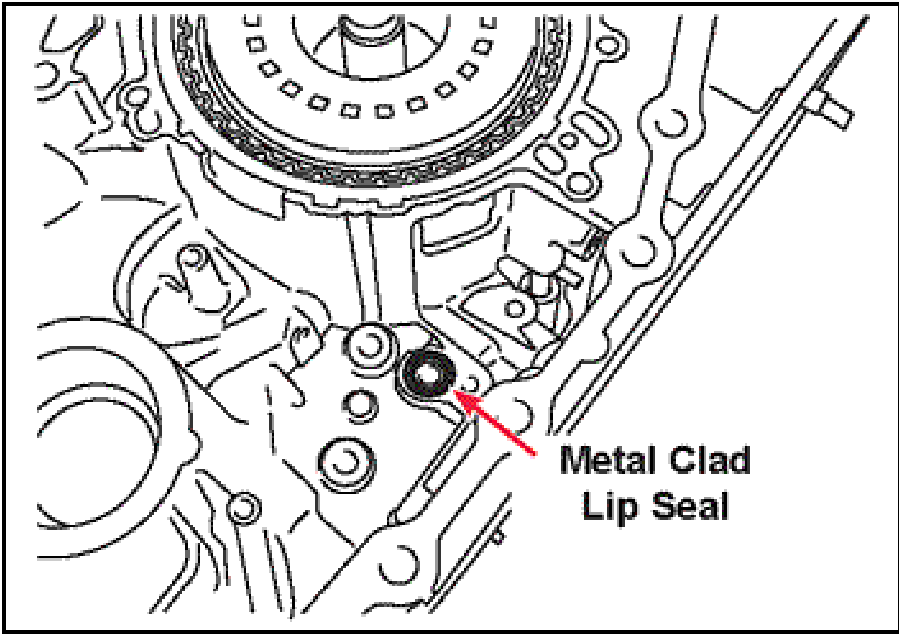

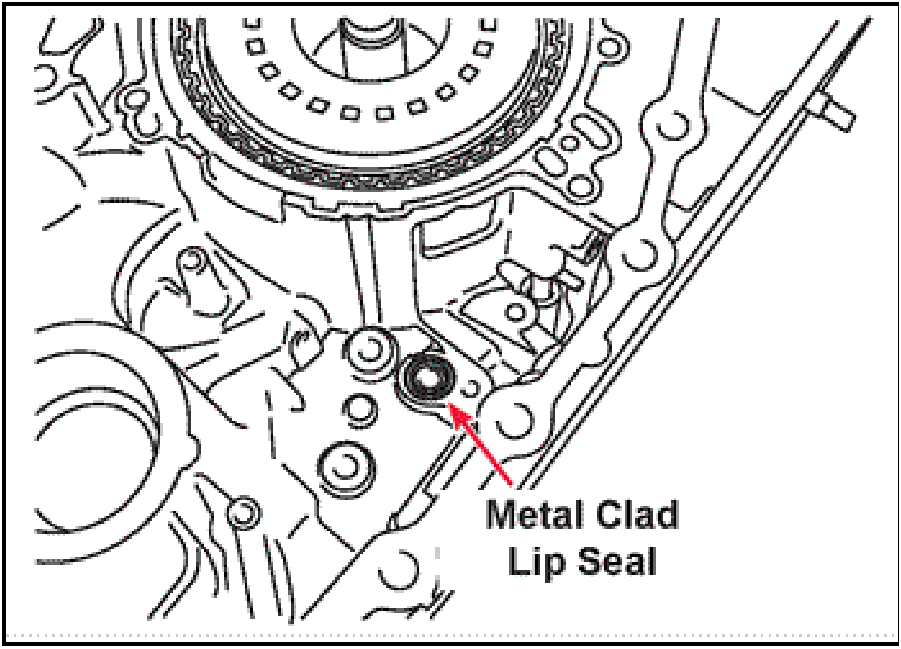

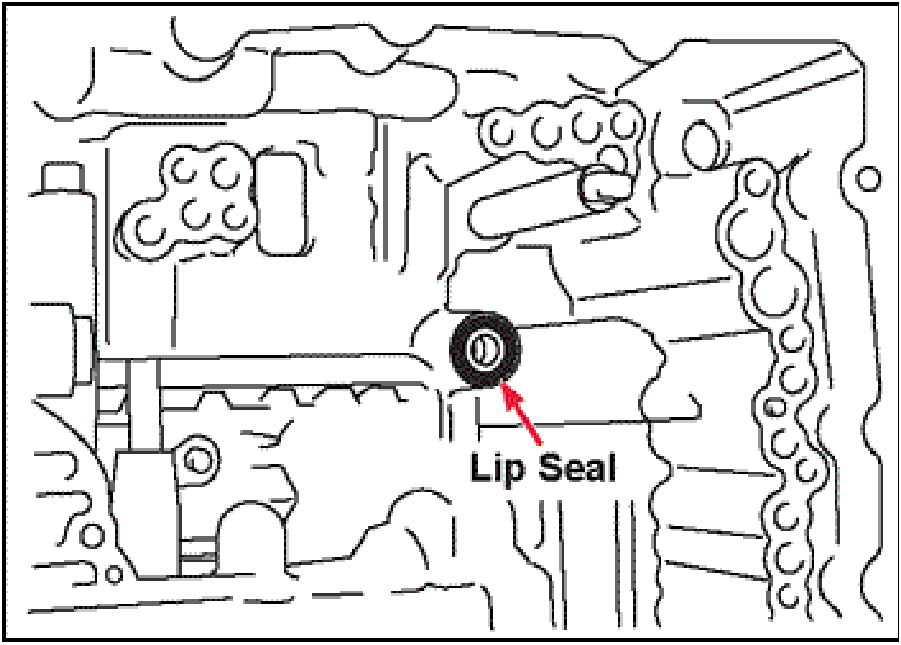

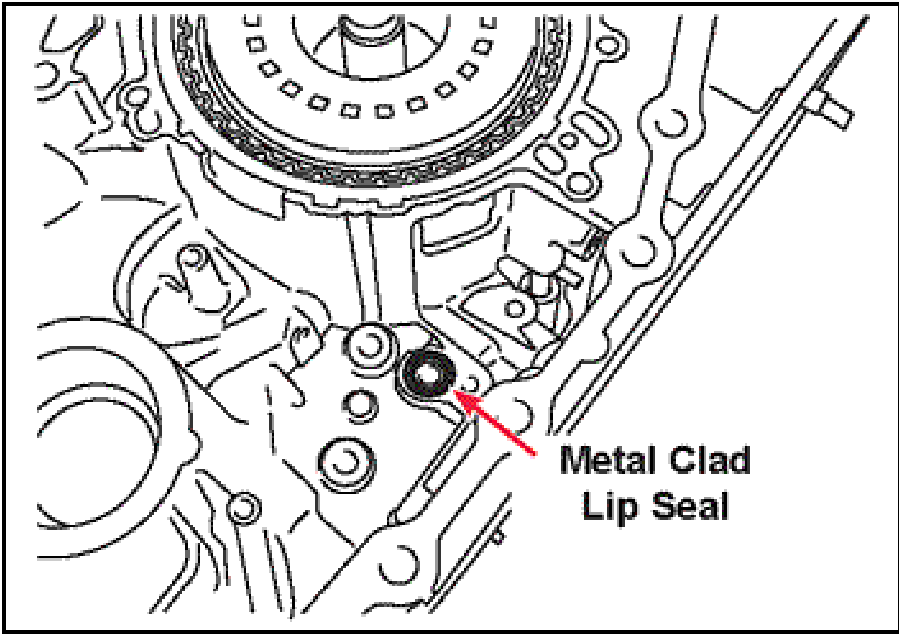

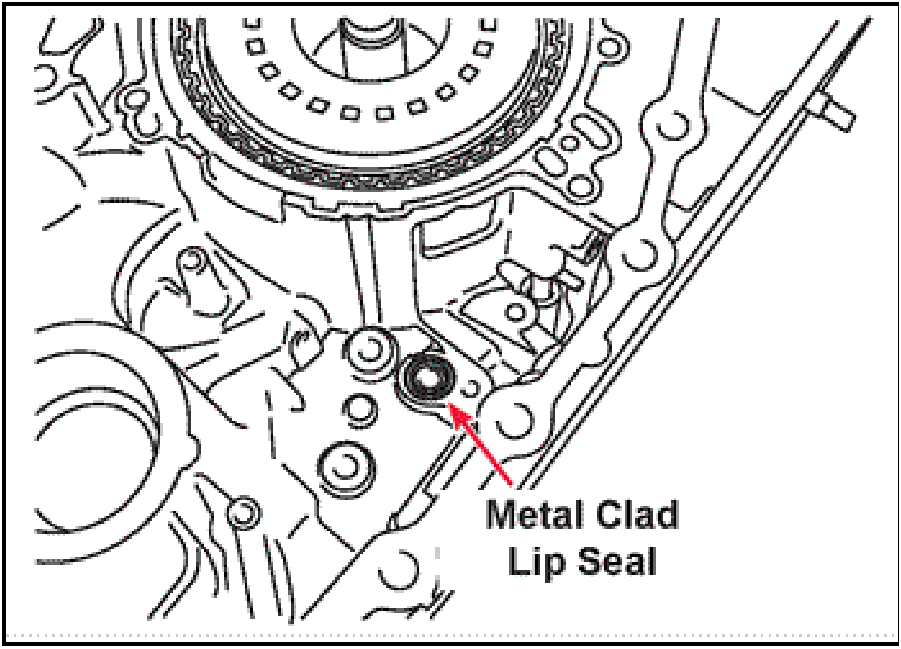

- Remove and discard the metal clad lip seal from the

transaxle case.

|

|

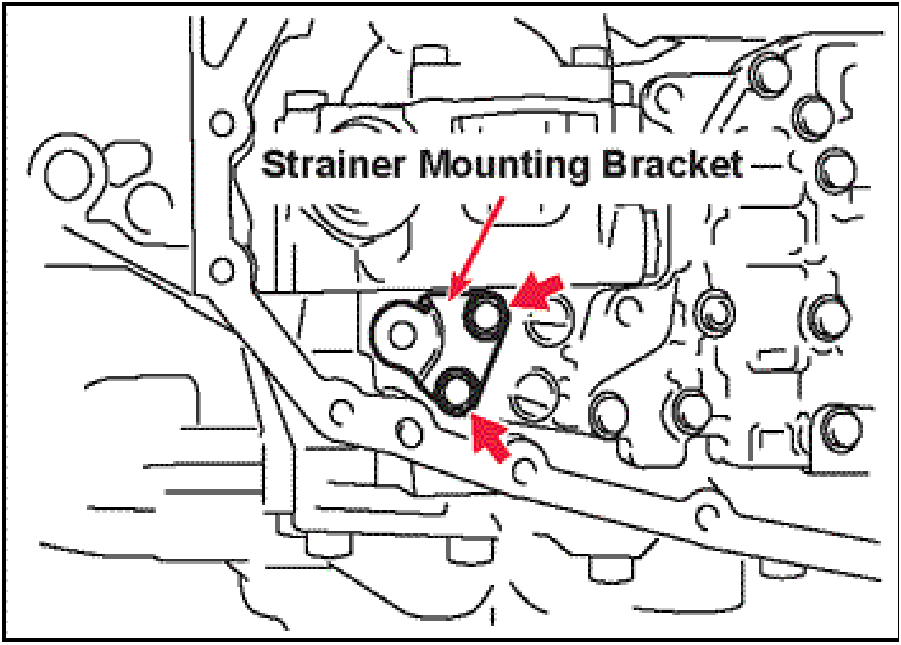

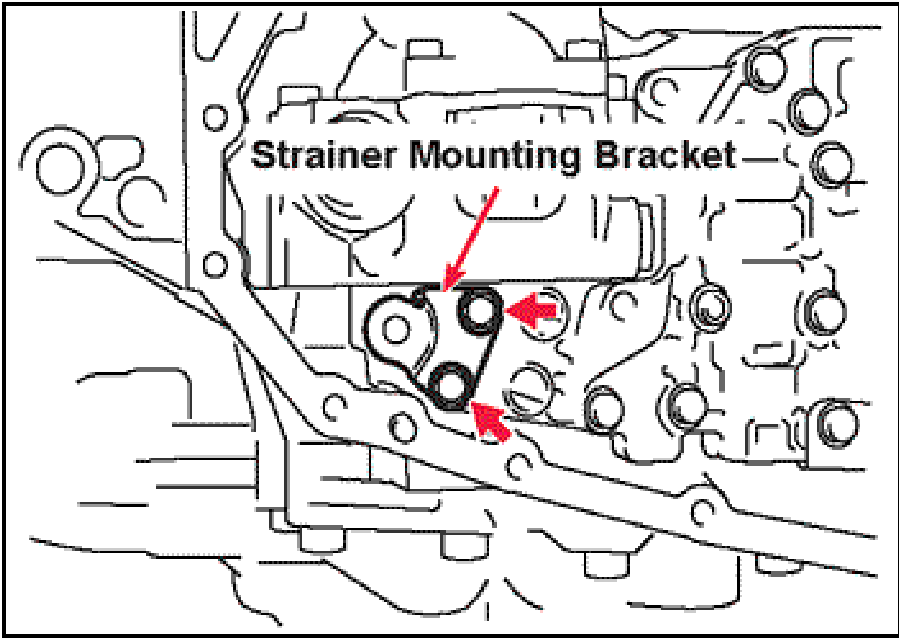

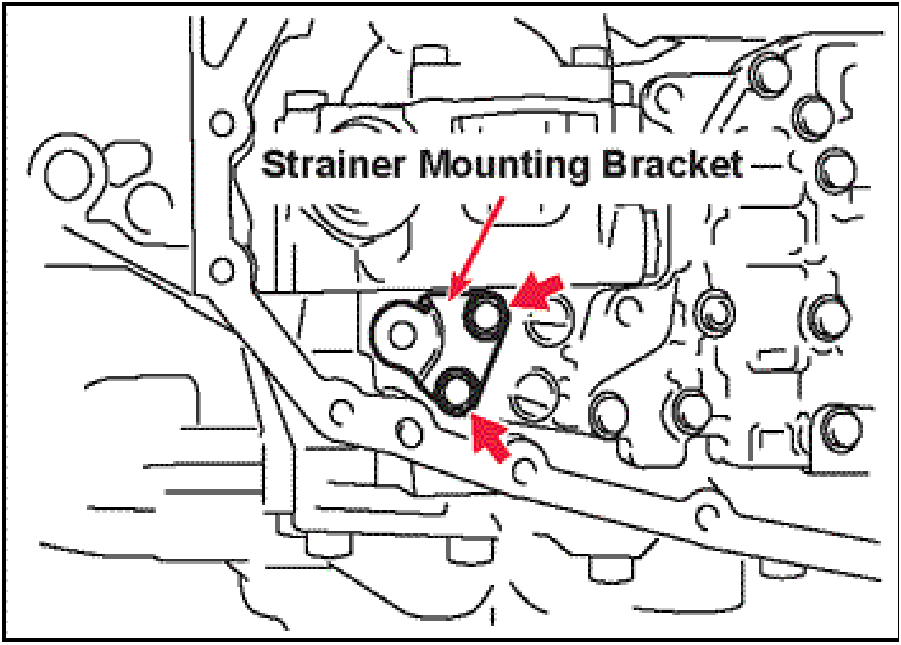

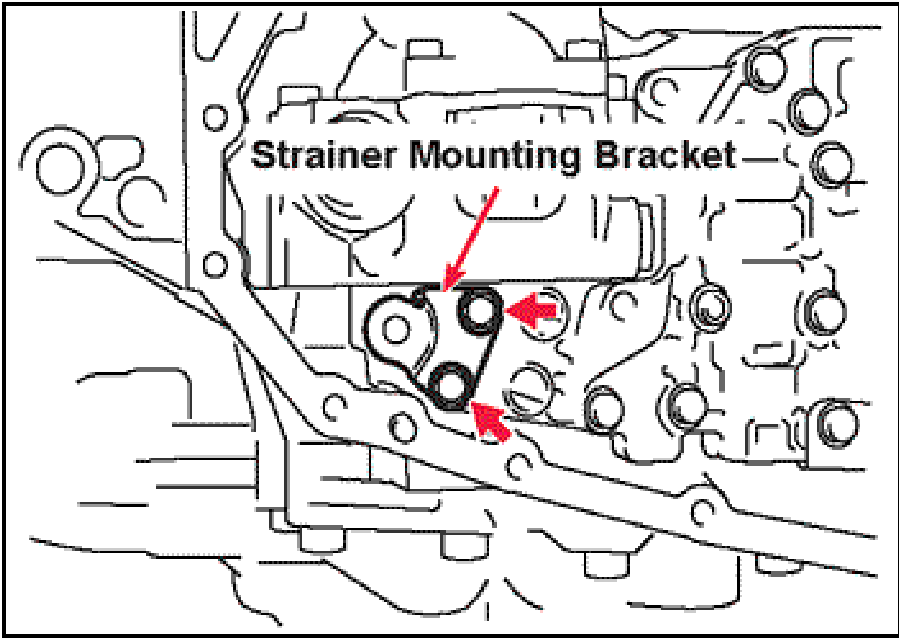

- Remove the oil strainer mounting bracket from the

valve body.

|

|

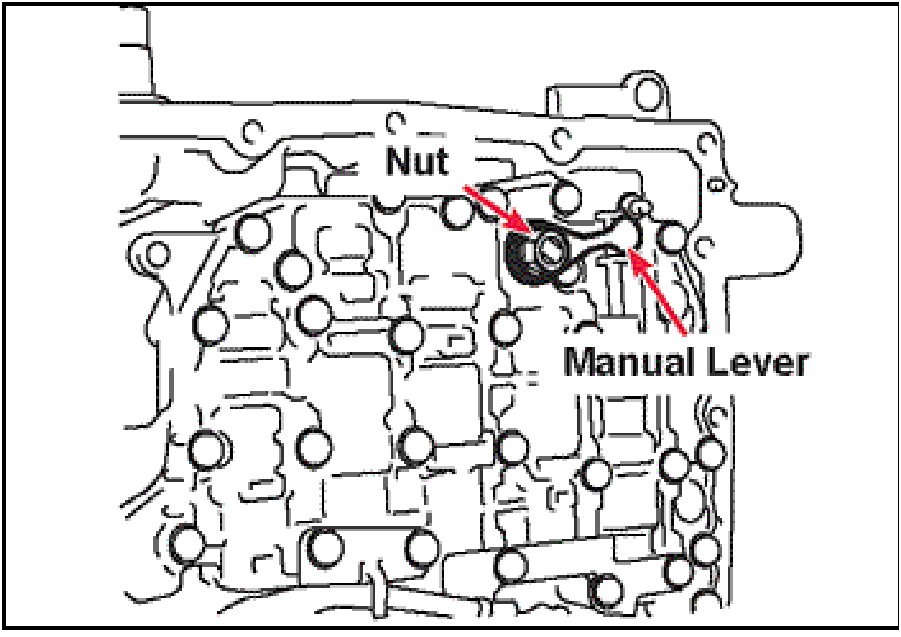

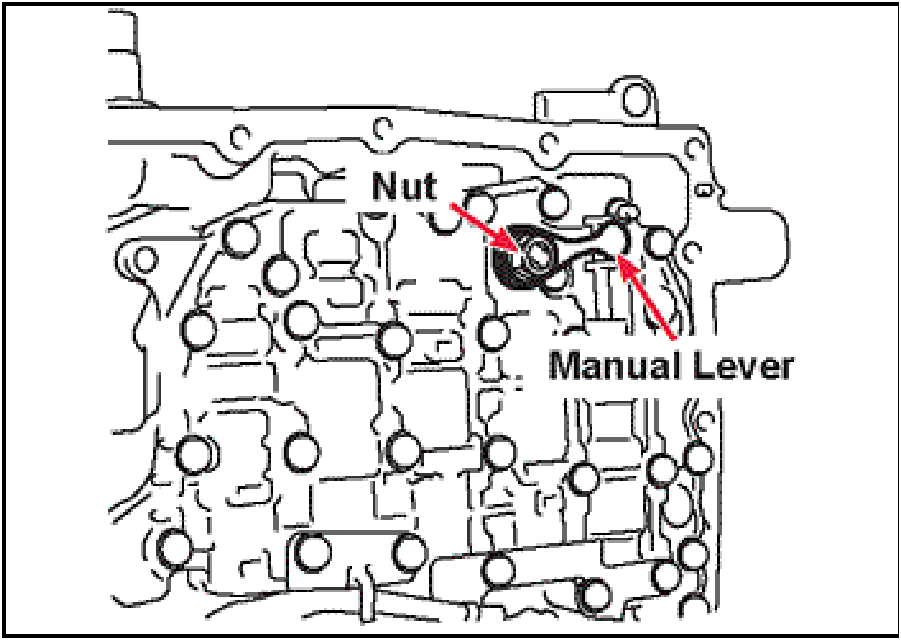

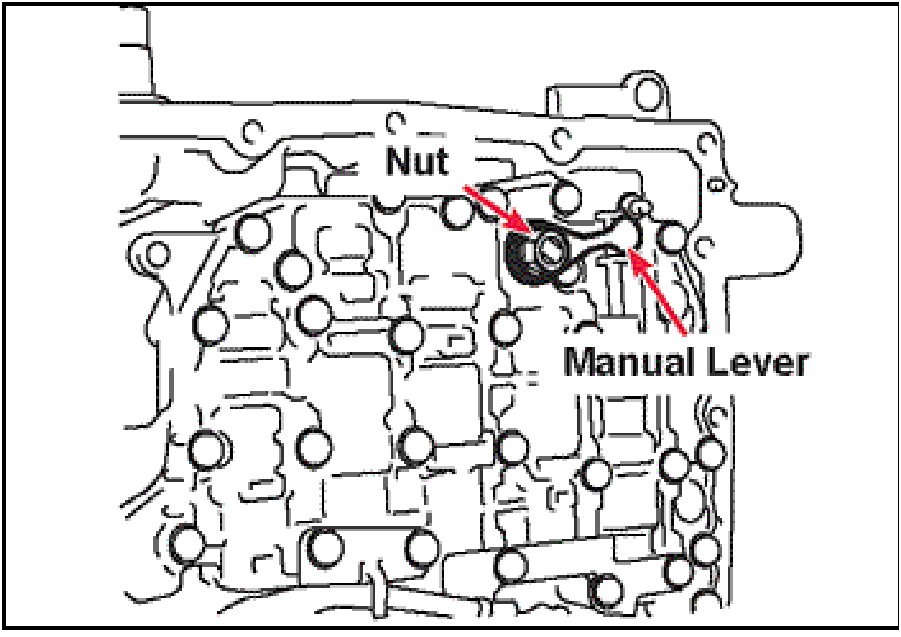

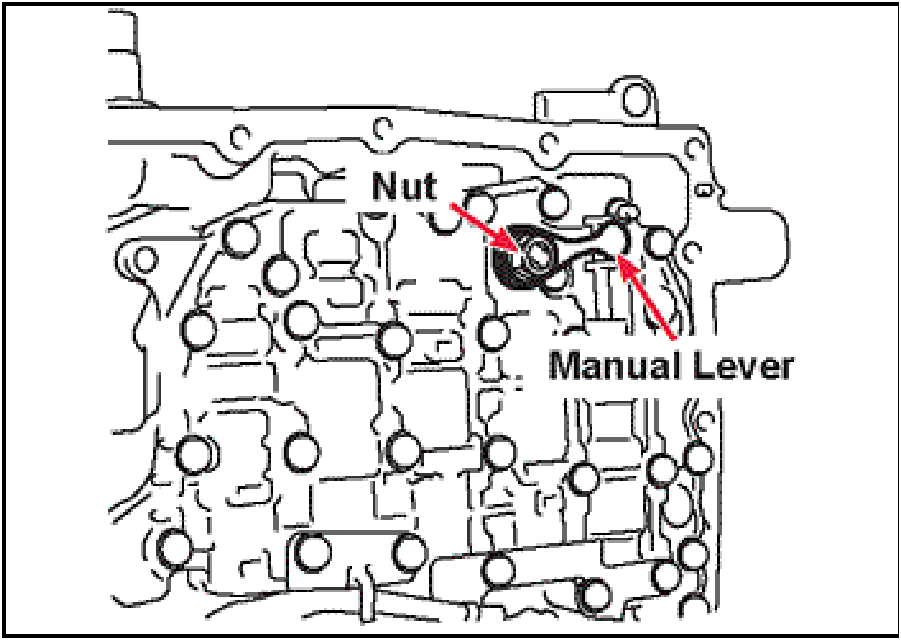

- Remove the nut and lock washer from the manual

control shaft.

Remove the manual valve control lever.

|

|

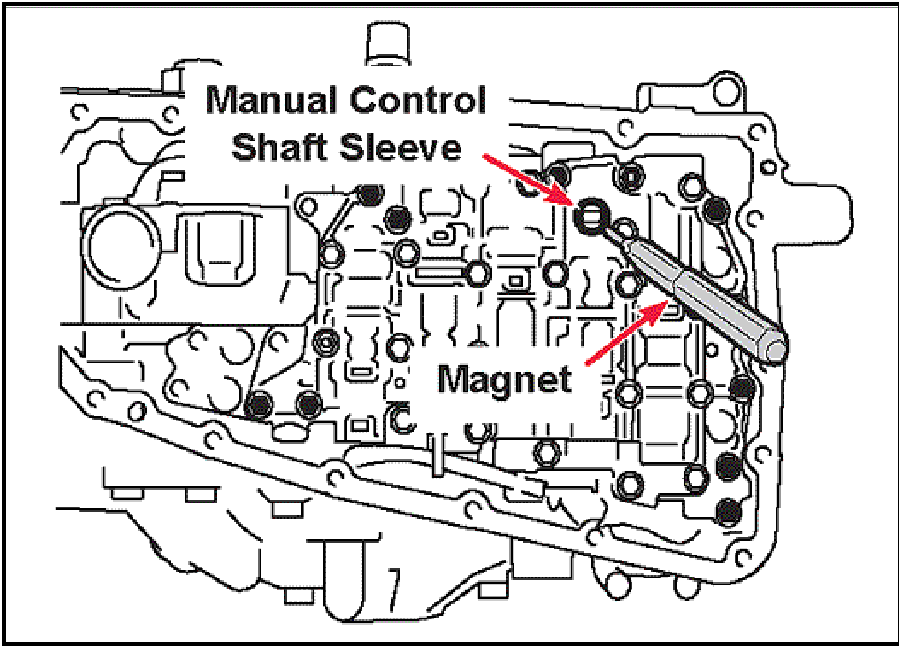

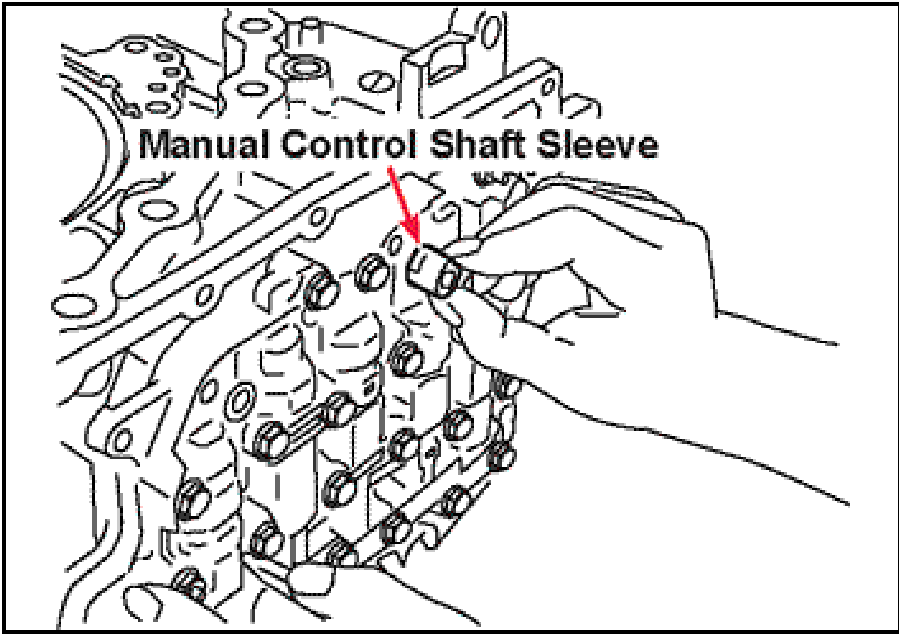

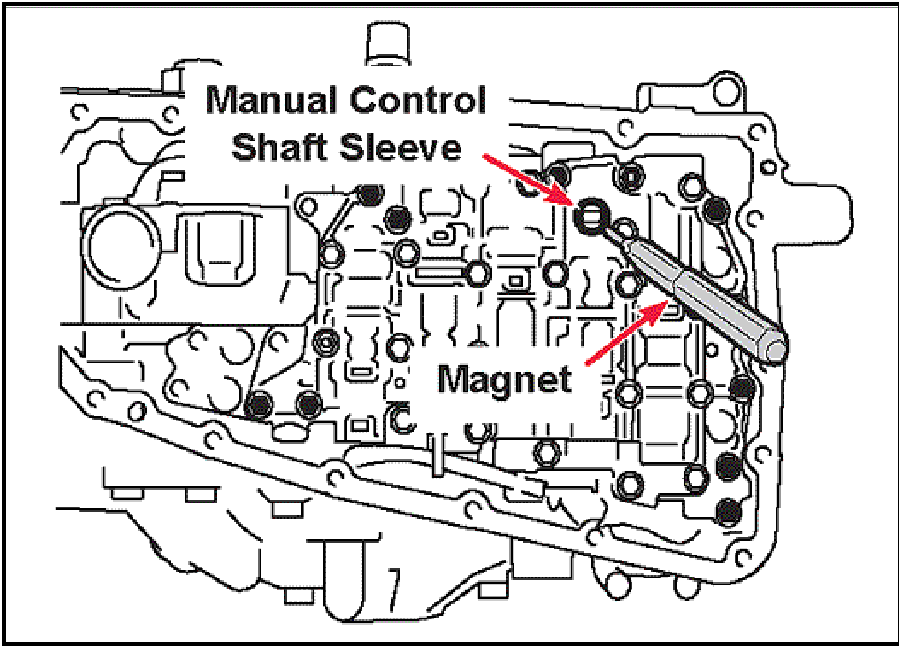

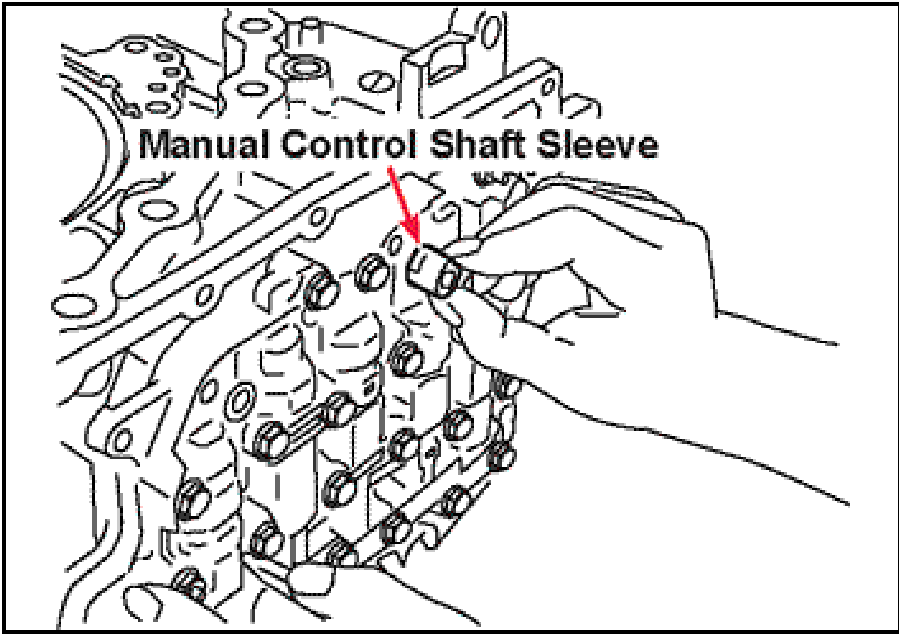

- Using a magnet, remove the manual control shaft

sleeve from the valve body.

|

|

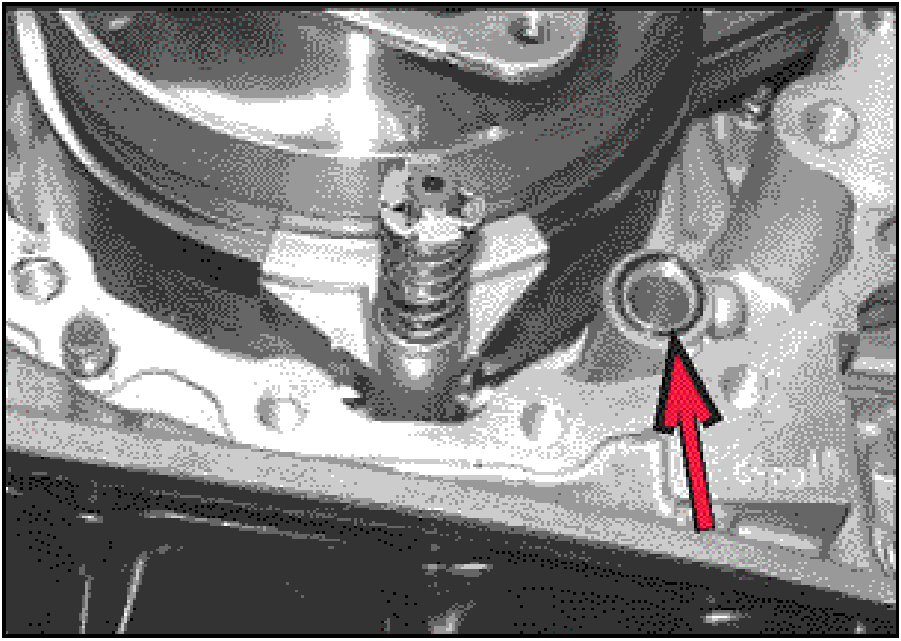

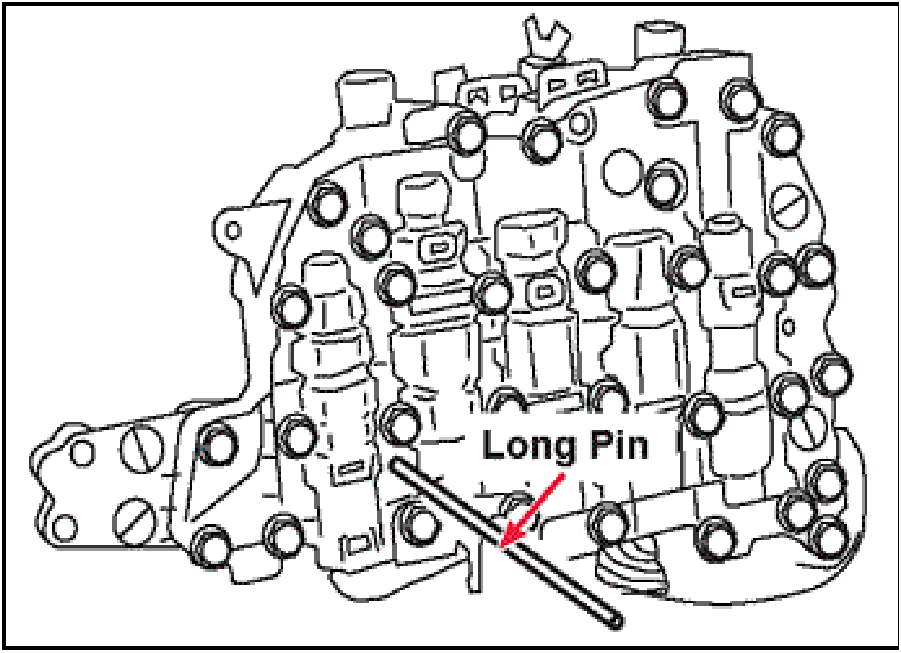

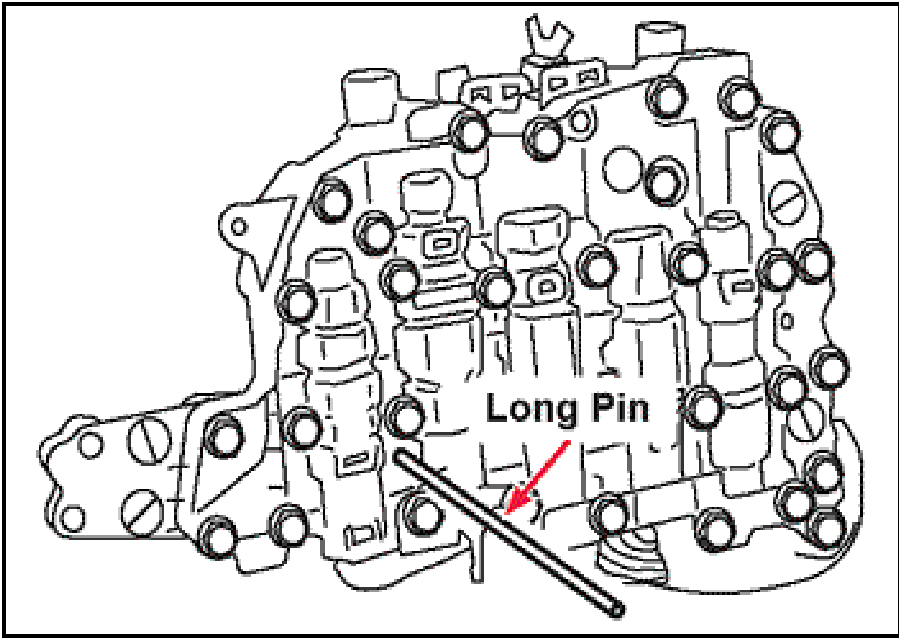

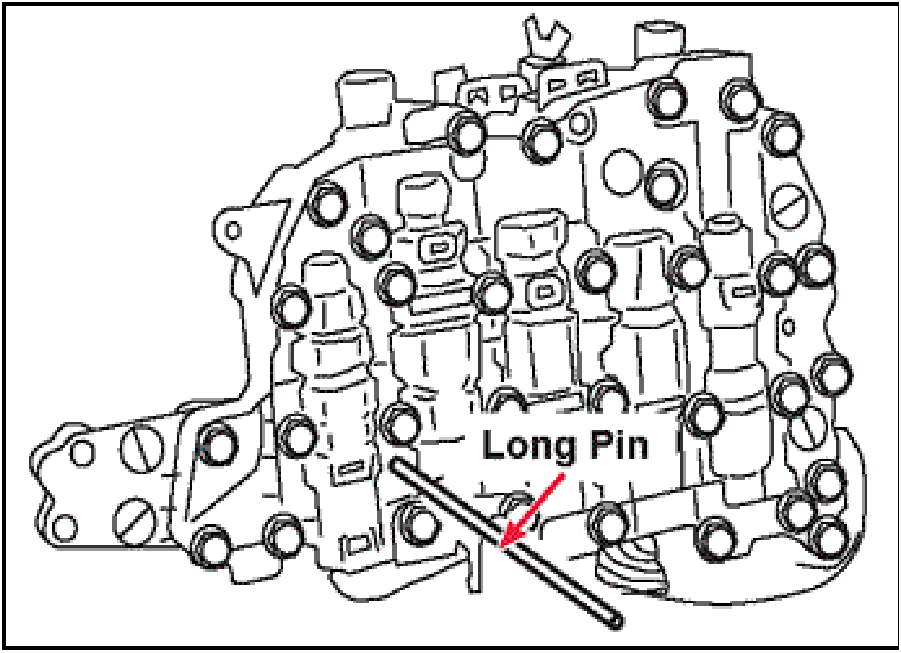

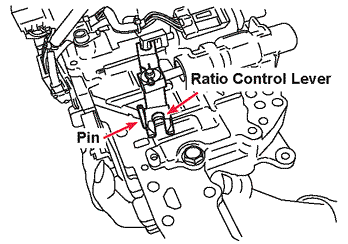

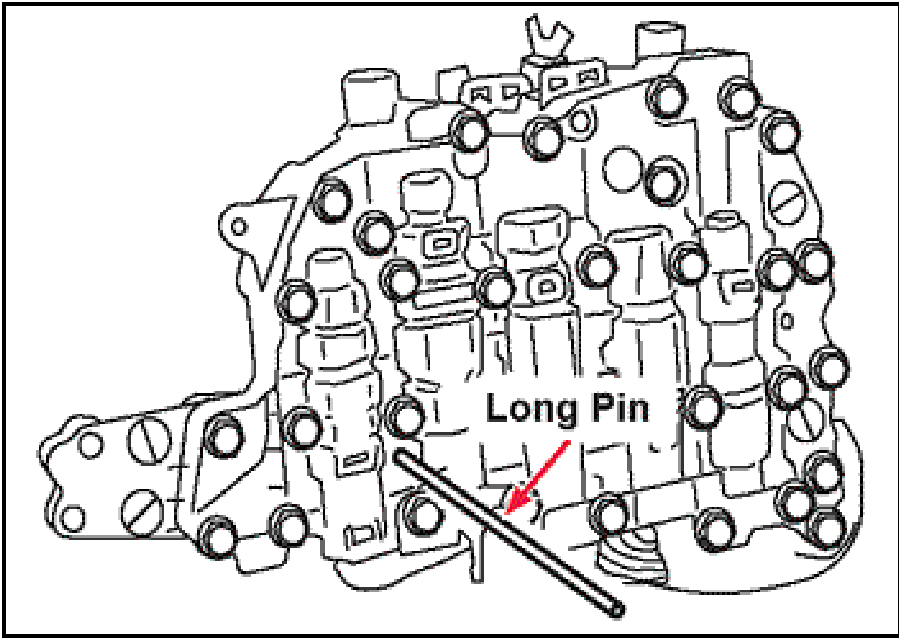

- Insert a 0.120” (3 mm) diameter, 5.0” (126 mm) long pin

into the retaining pin hole in the valve body.

NOTE: Cut a 5.0 in. piece out of an old coat hanger

or use special tool MB995015-01.

|

|

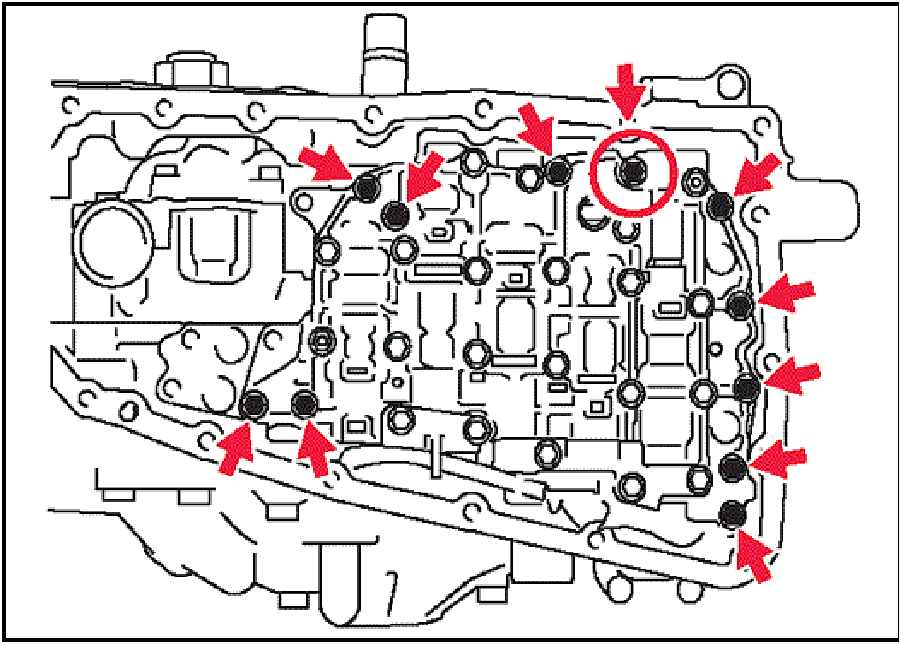

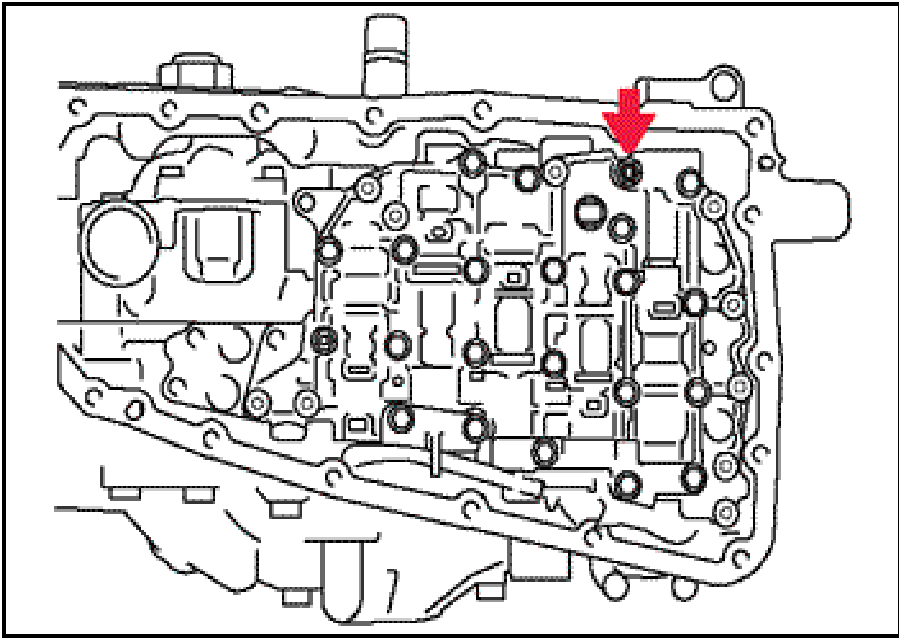

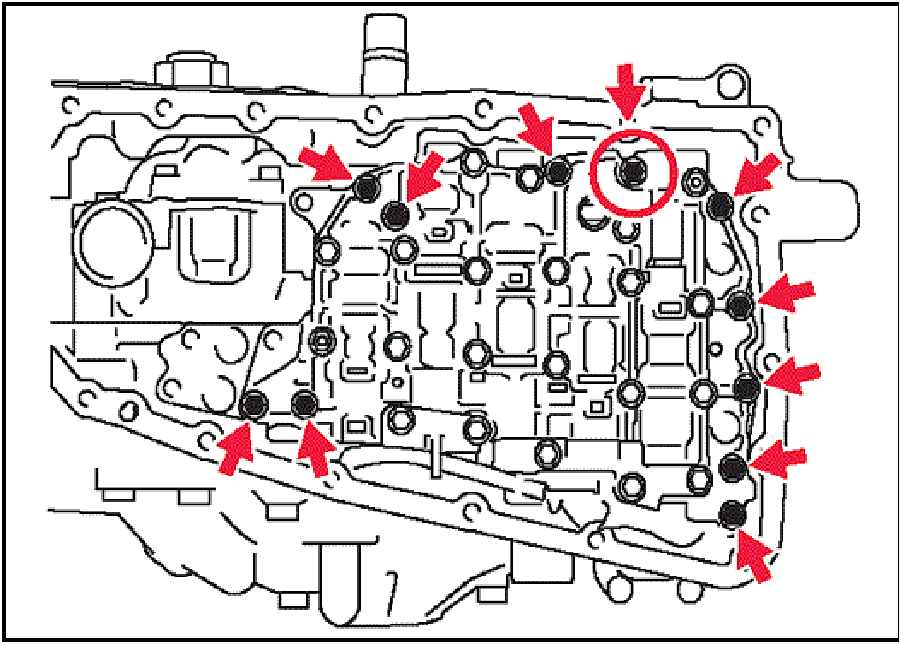

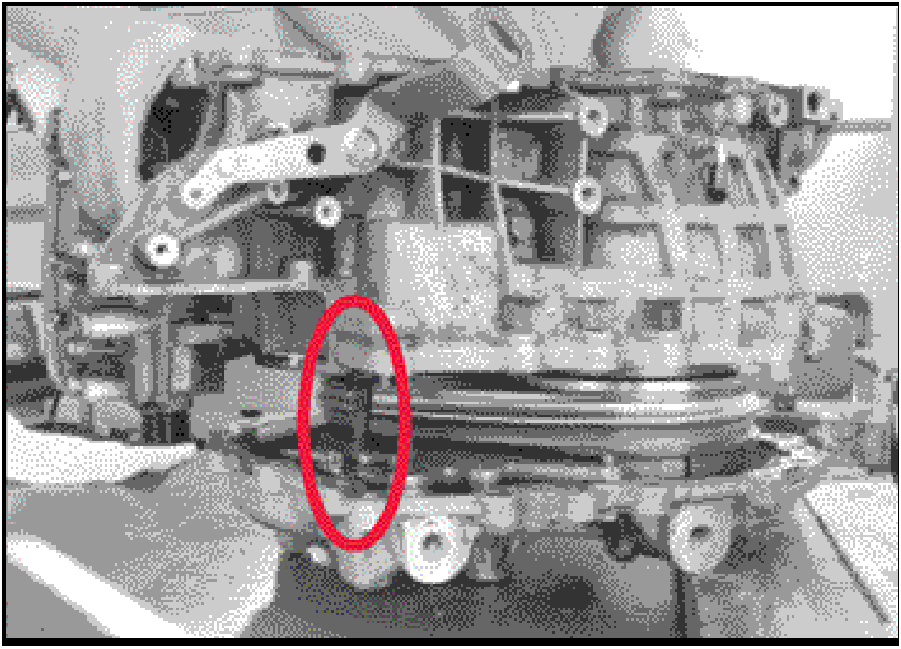

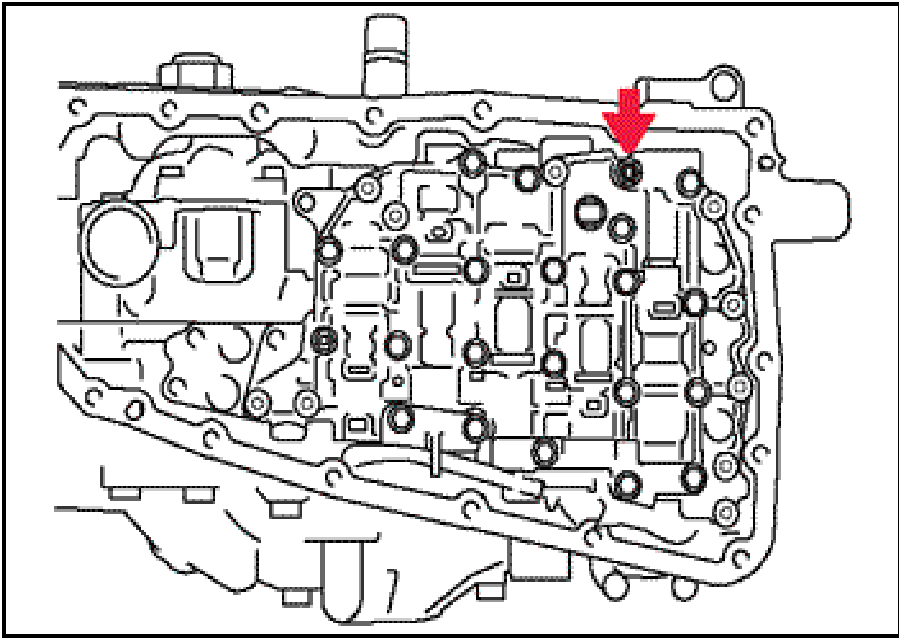

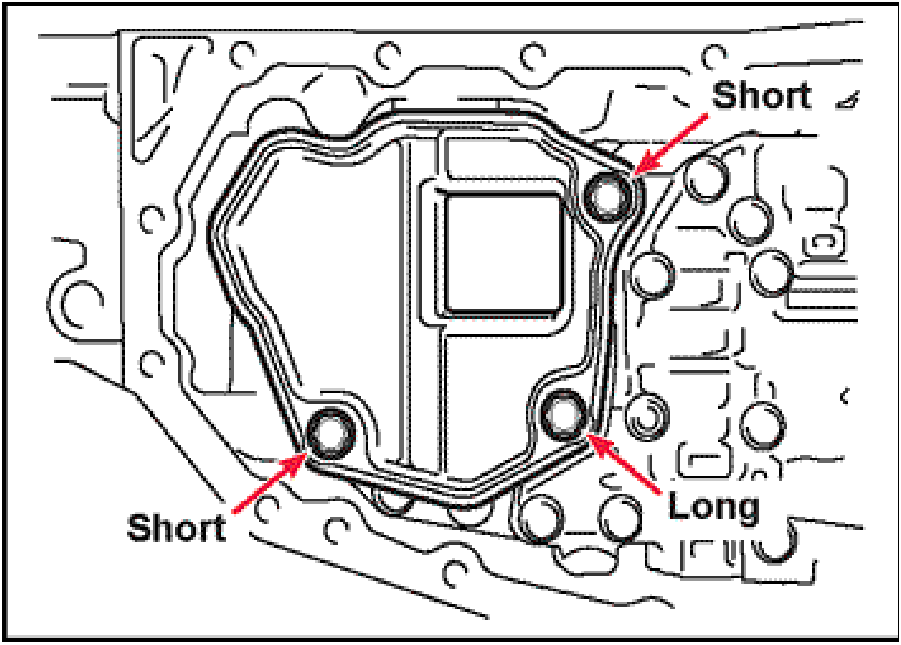

- Remove the one short valve body bolt indicated by the

circle, then remove the remaining ten long valve body

mounting bolts.

|

|

- Remove the valve body by carefully sliding it back off

of the manual control shaft while pushing the harness

connector into the transaxle case.

|

|

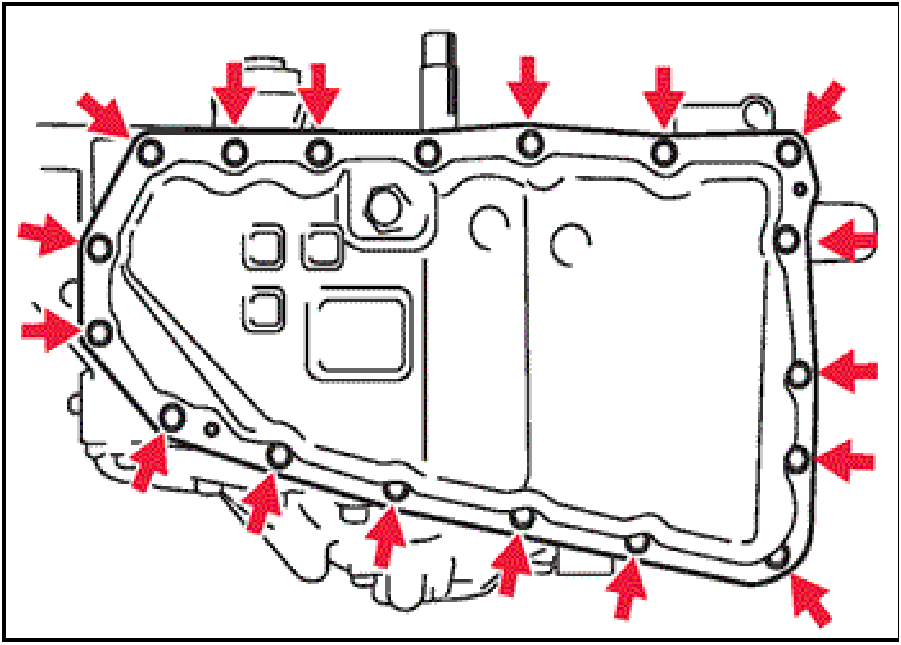

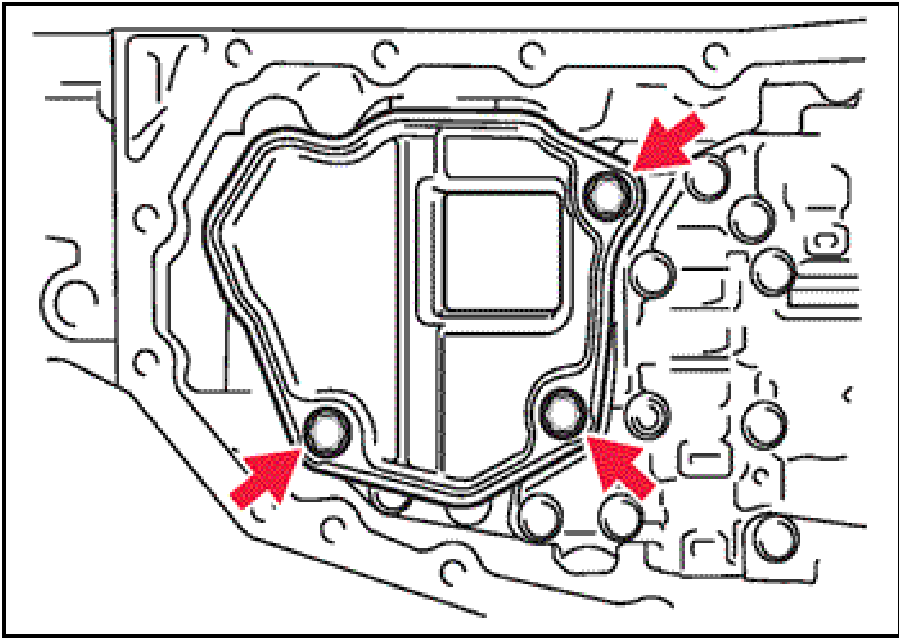

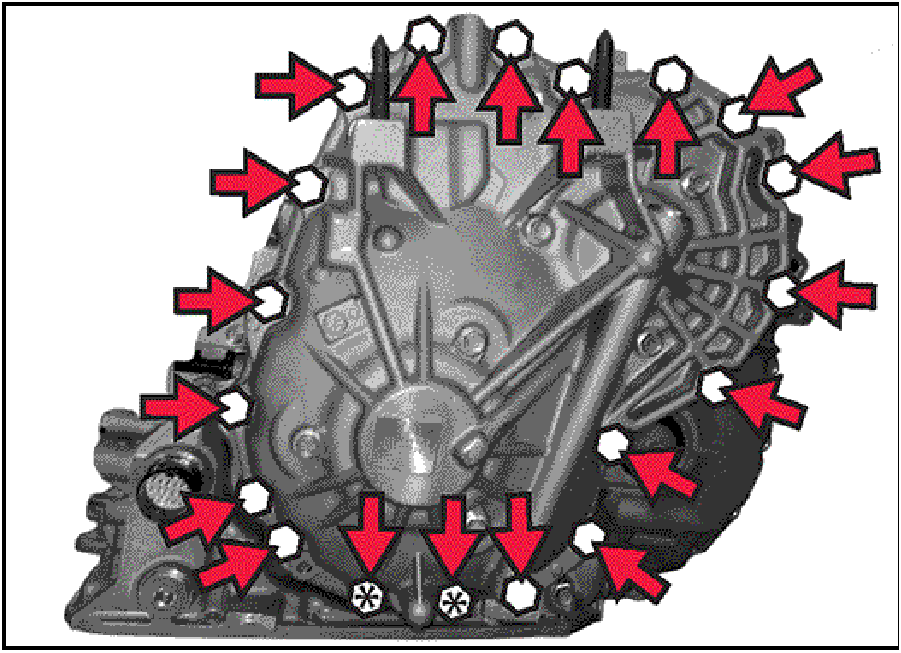

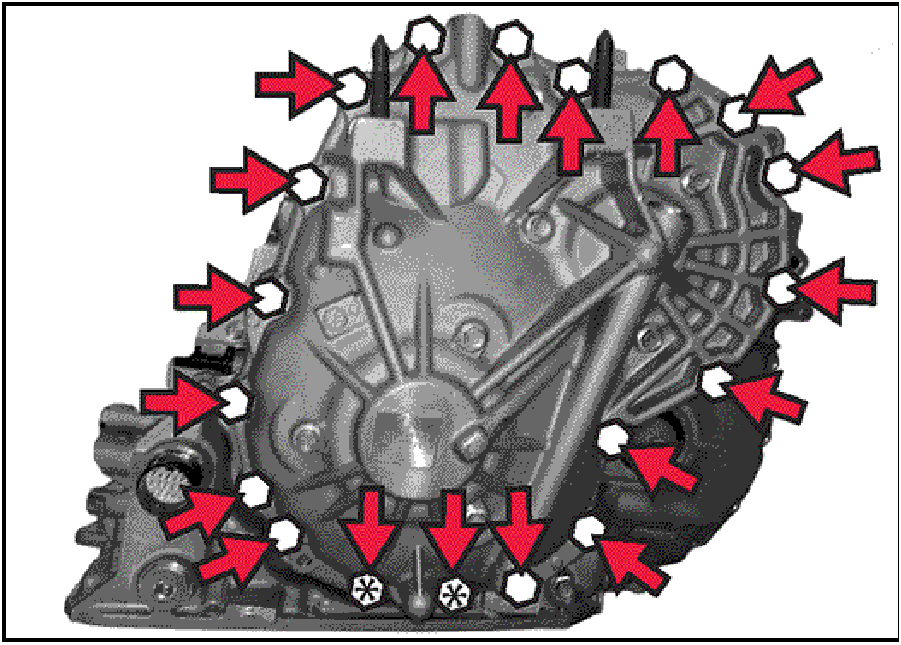

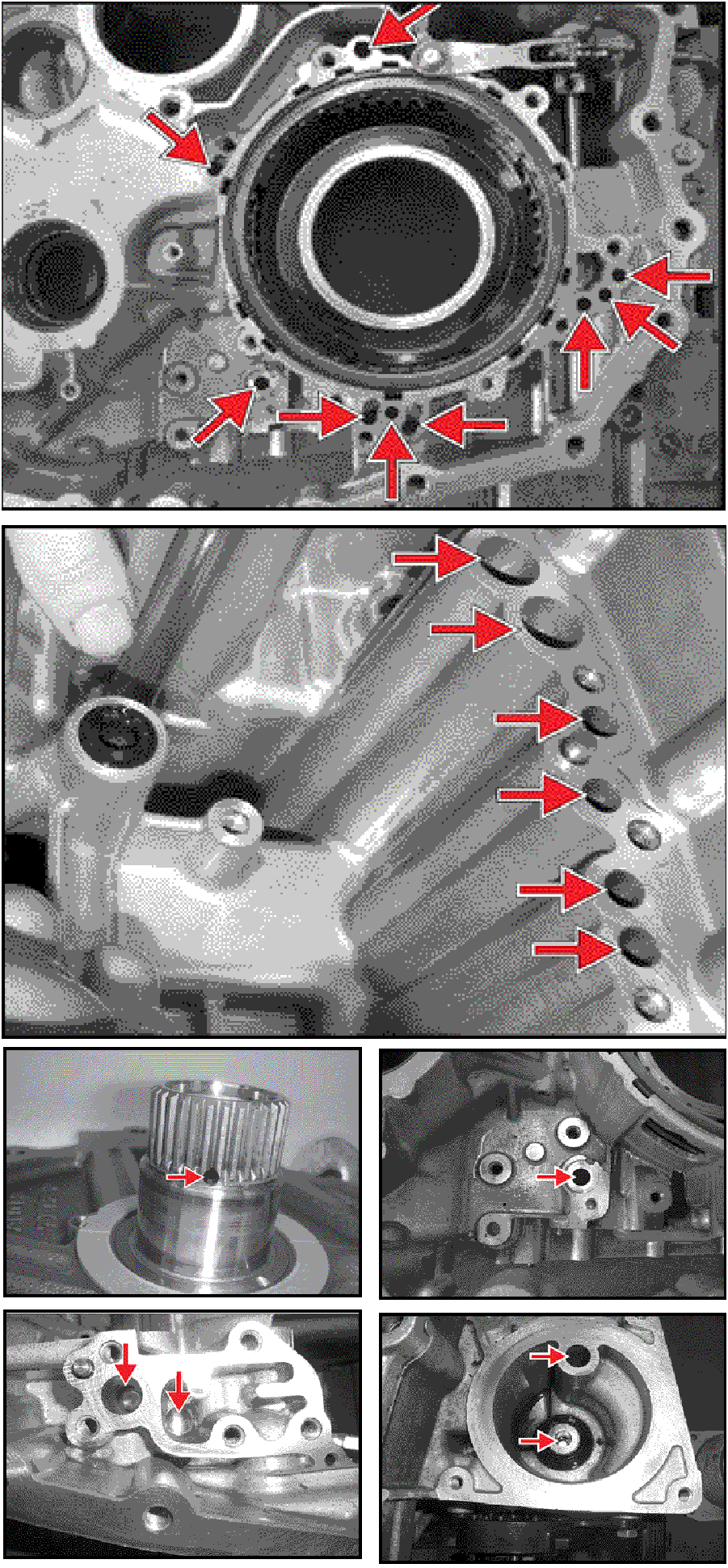

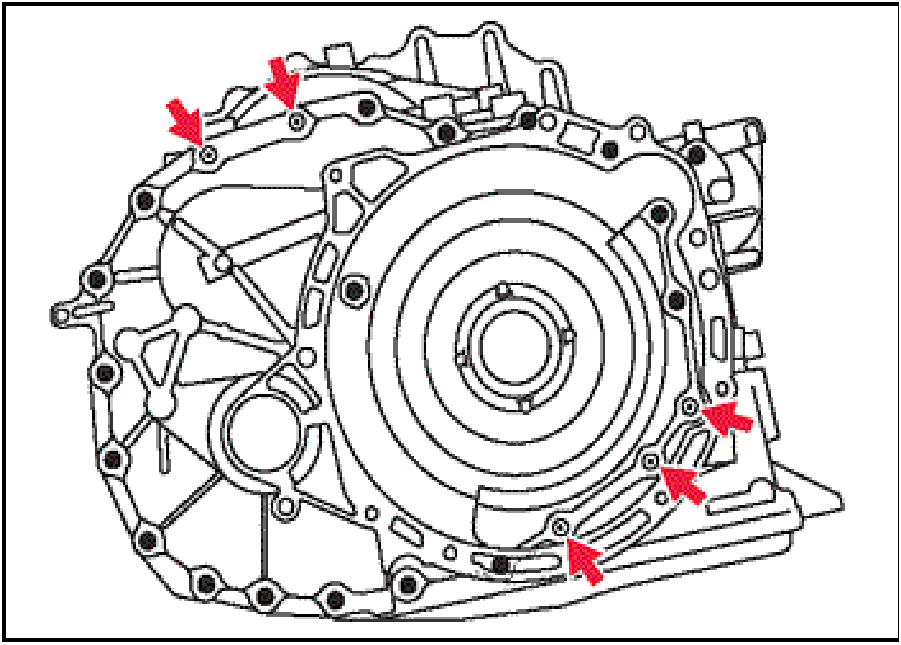

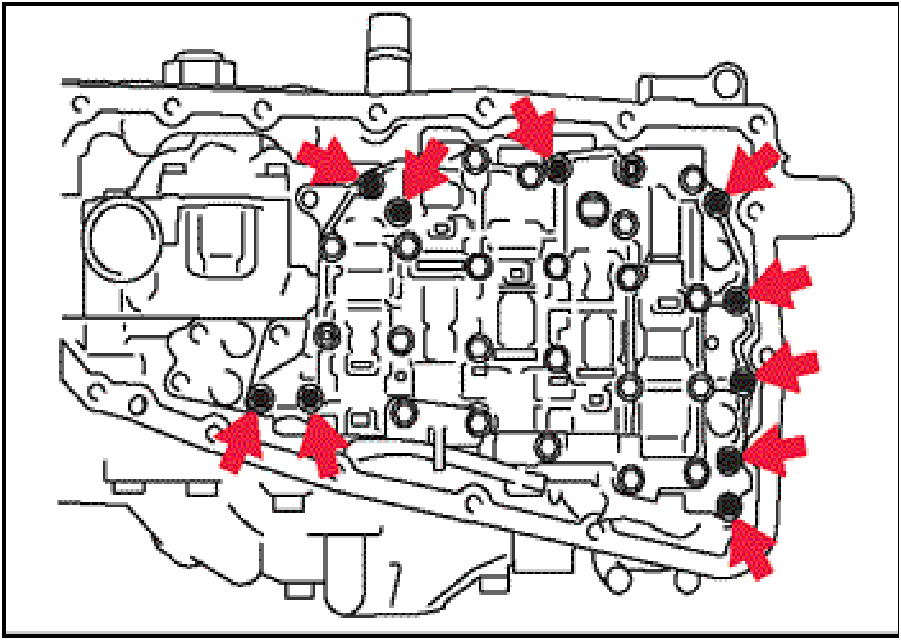

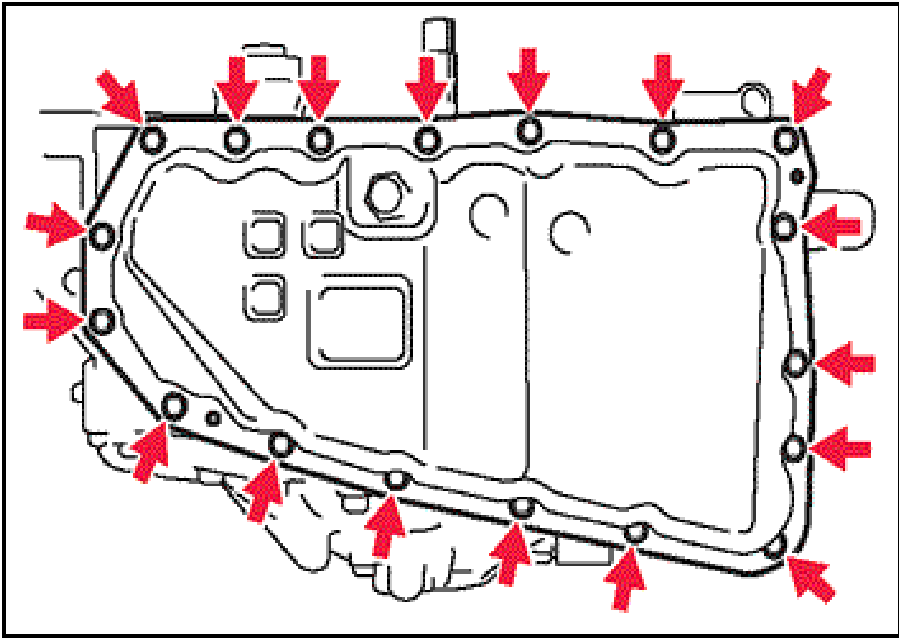

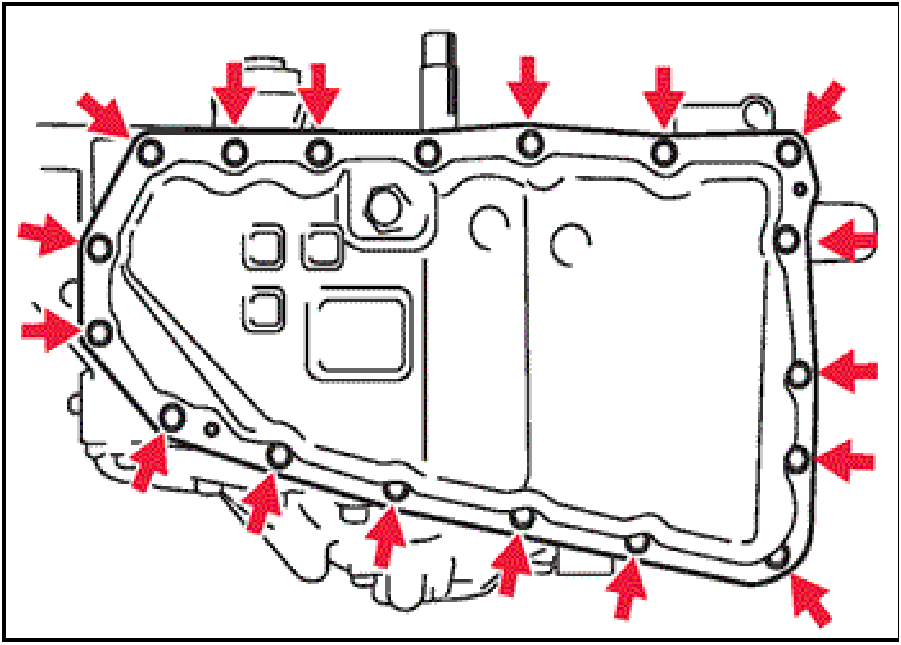

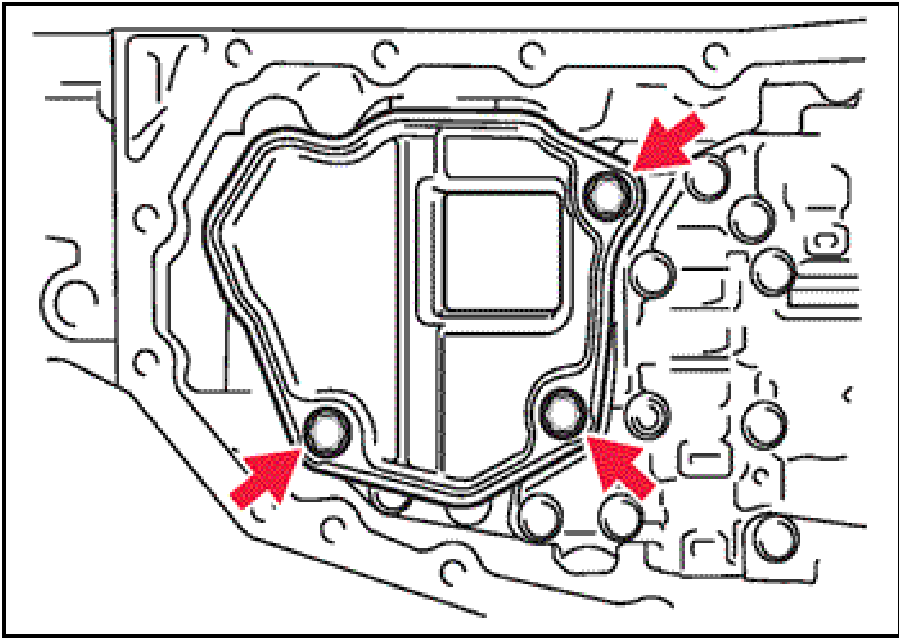

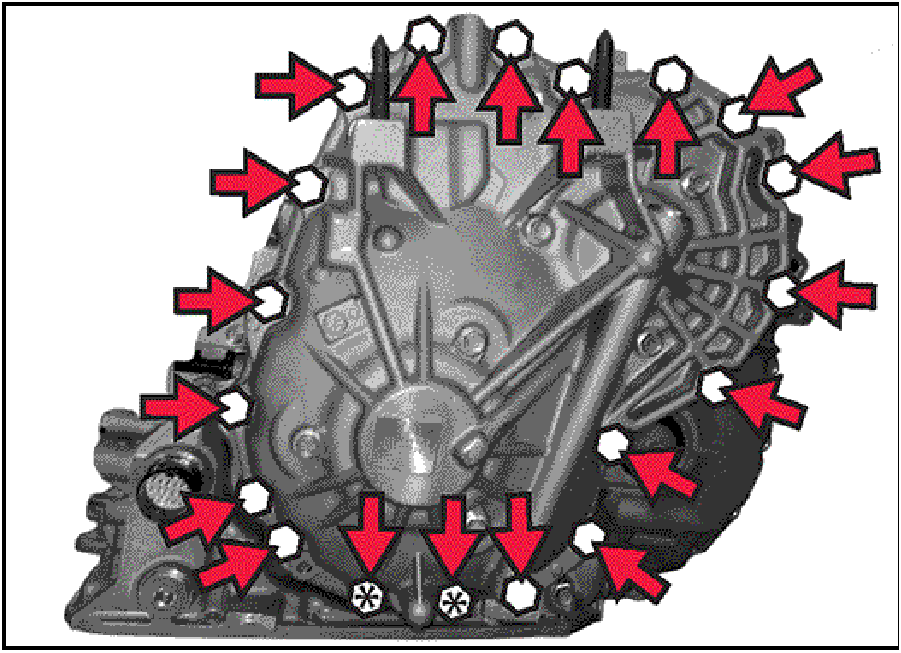

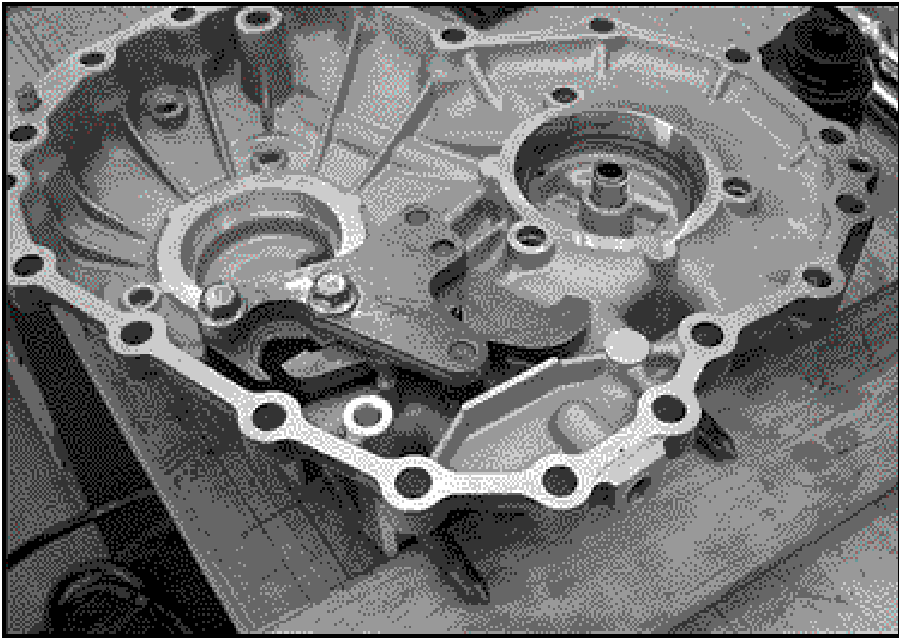

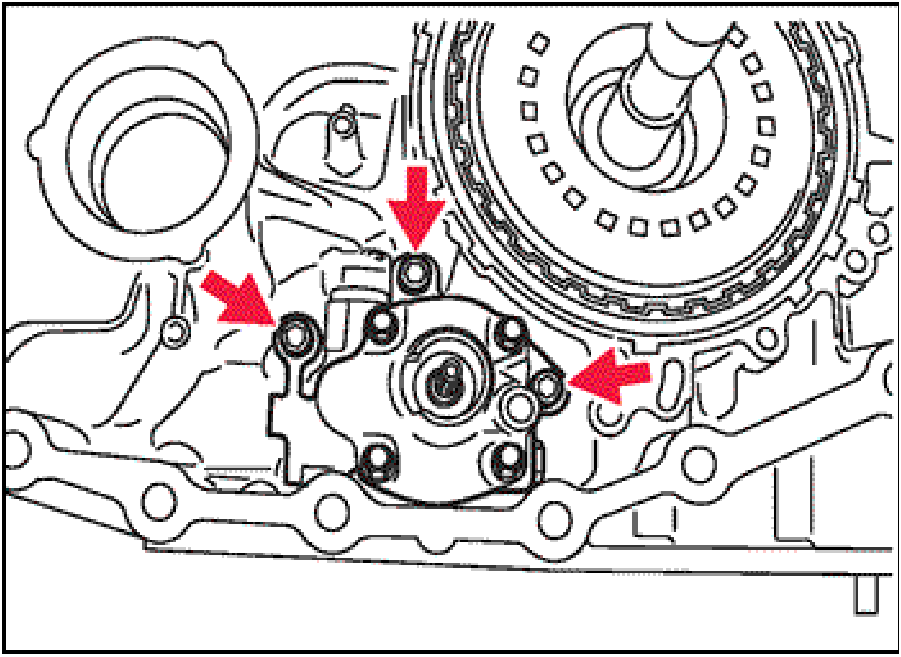

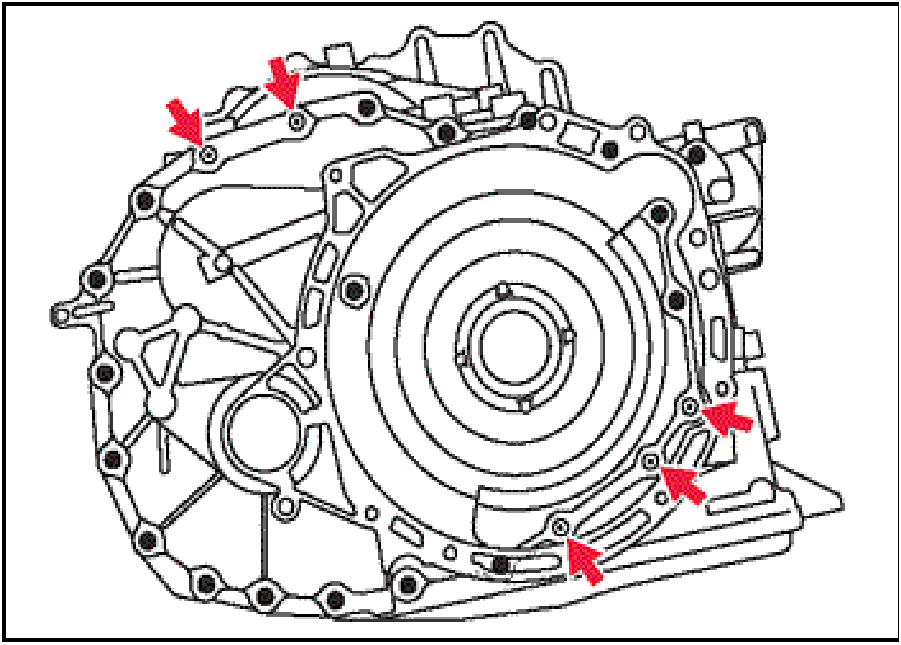

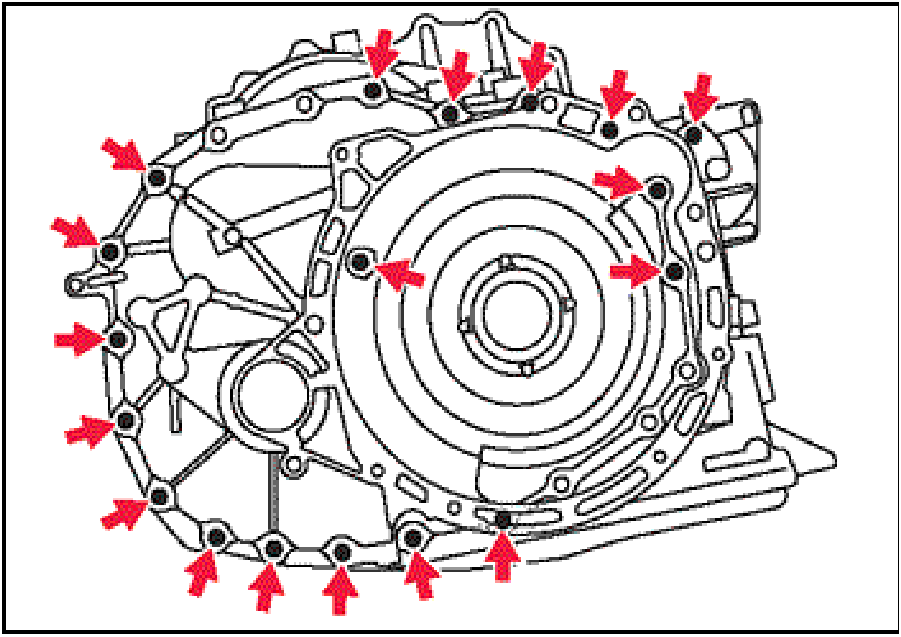

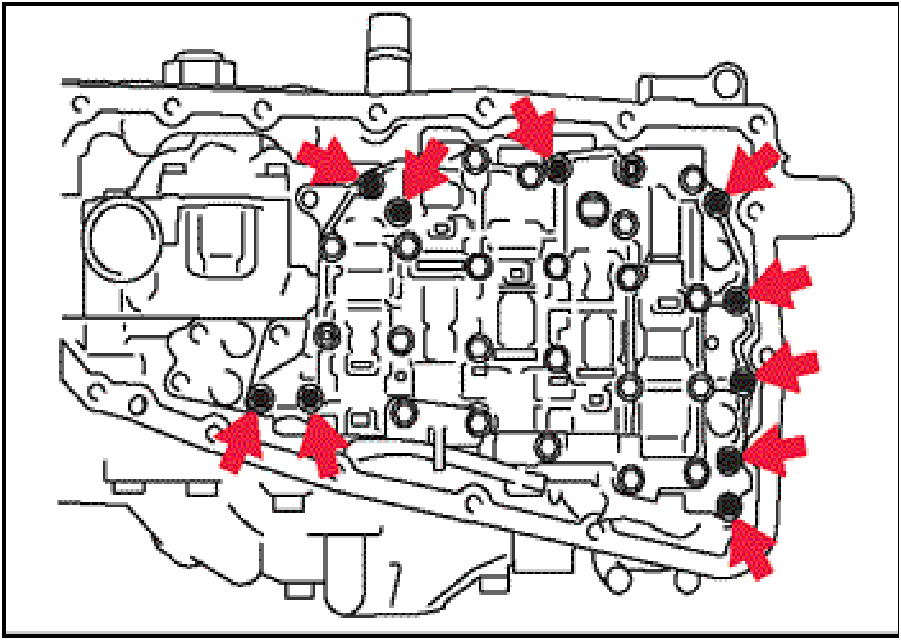

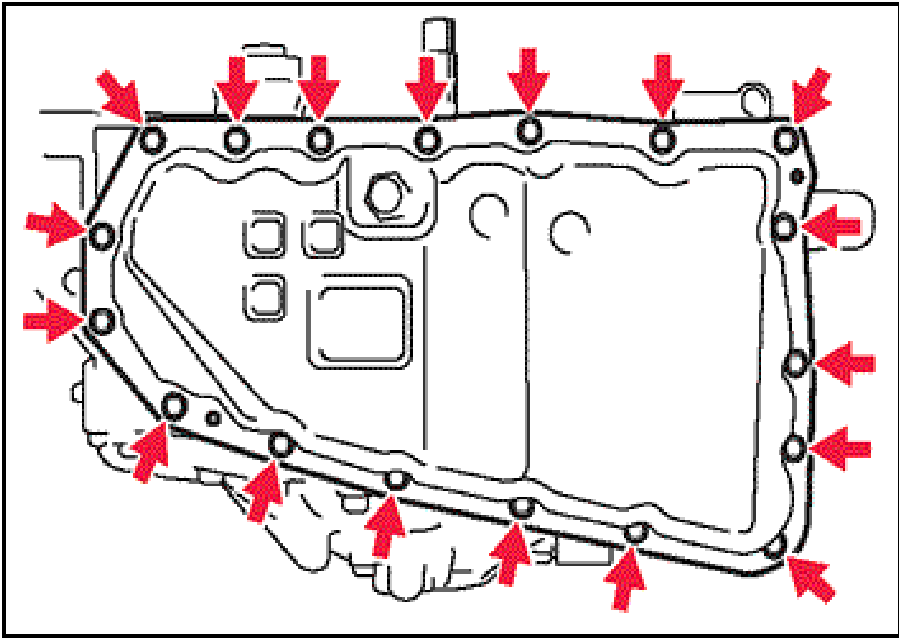

SIDE COVER DISASSEMBLY

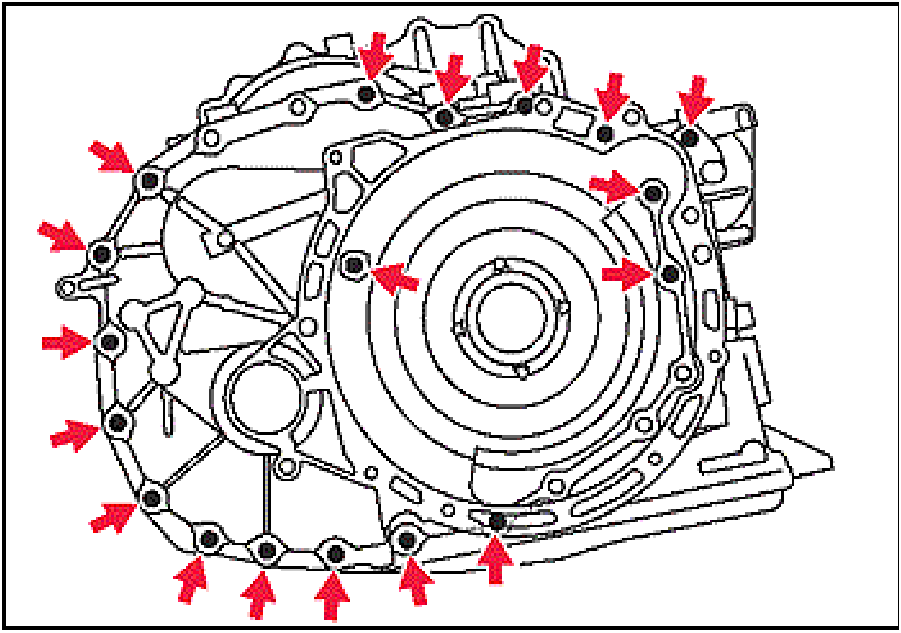

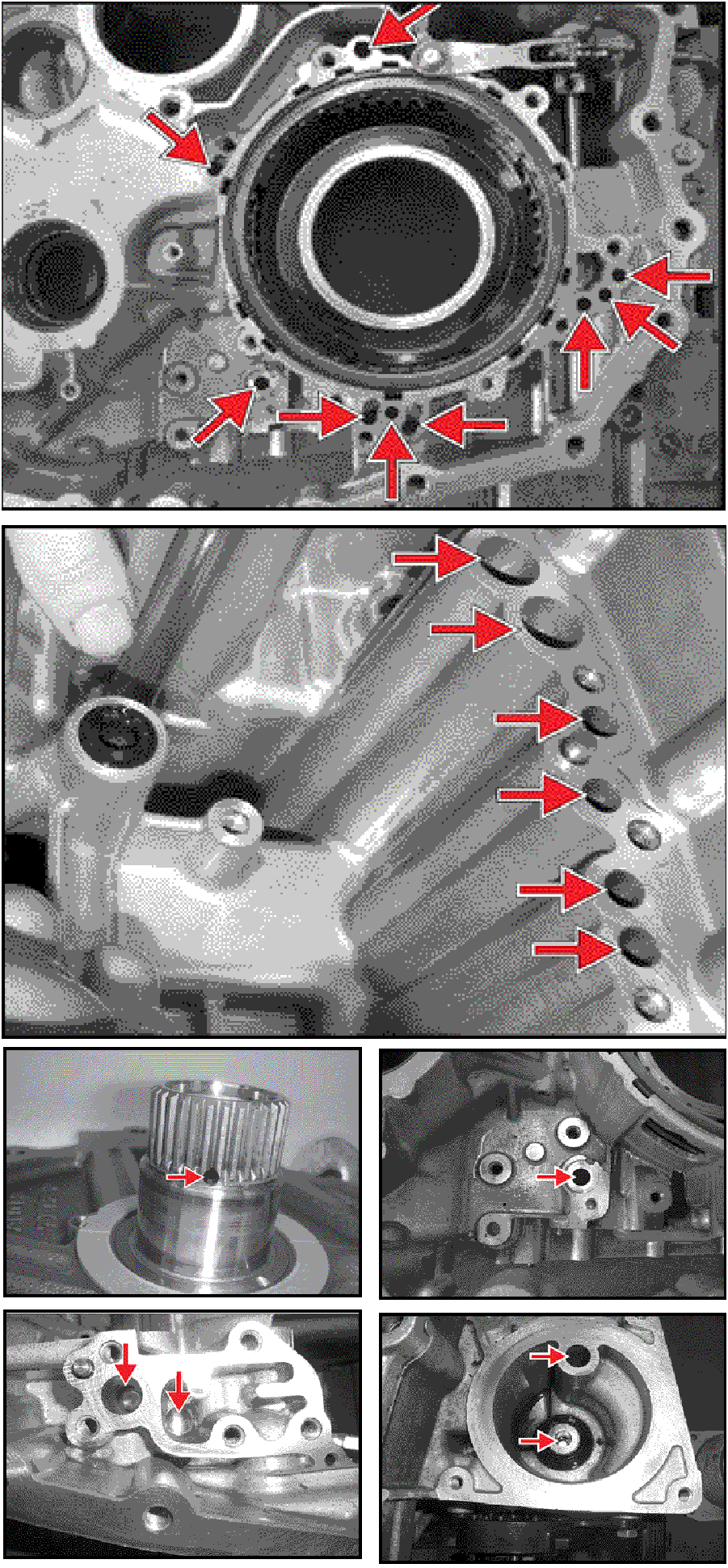

- Remove 19 case bolts as shown by the arrows.

Note the 2 bolts marked with * in the picture are 5mm

longer than the remaining 17 bolts.

17 bolts - 30mm long

2 bolts - 35mm long

|

|

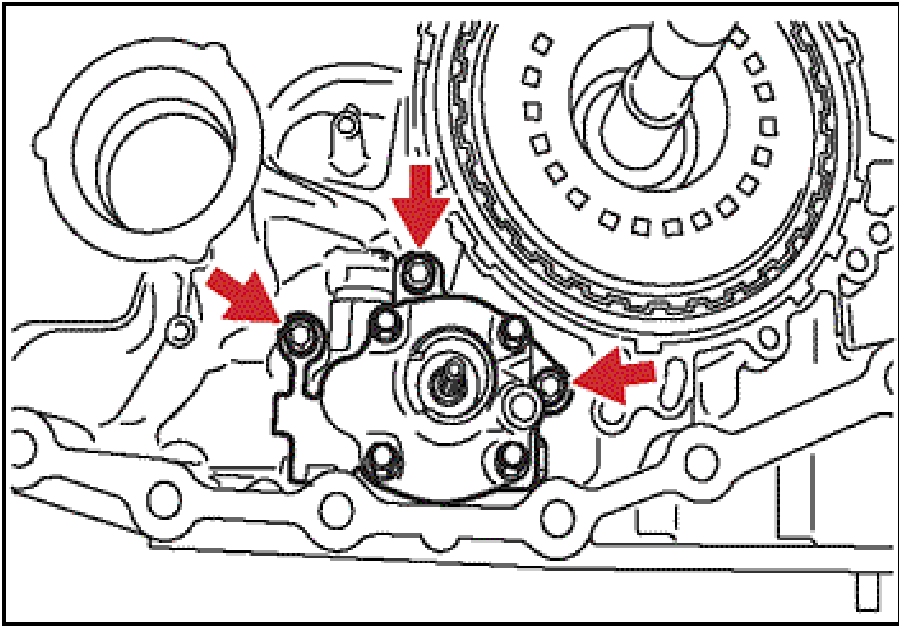

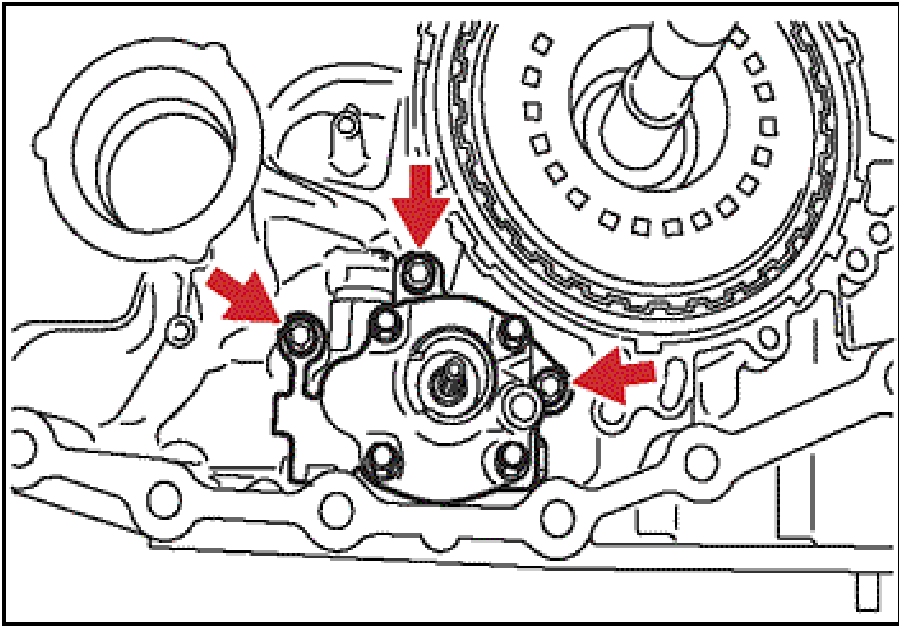

- Remove the 6 bearing retainer bolts from the side

cover as indicated by the arrows.

Rotate the transaxle onto the side cover (converter

housing pointing up) and level the assembly with wood

blocks.

|

|

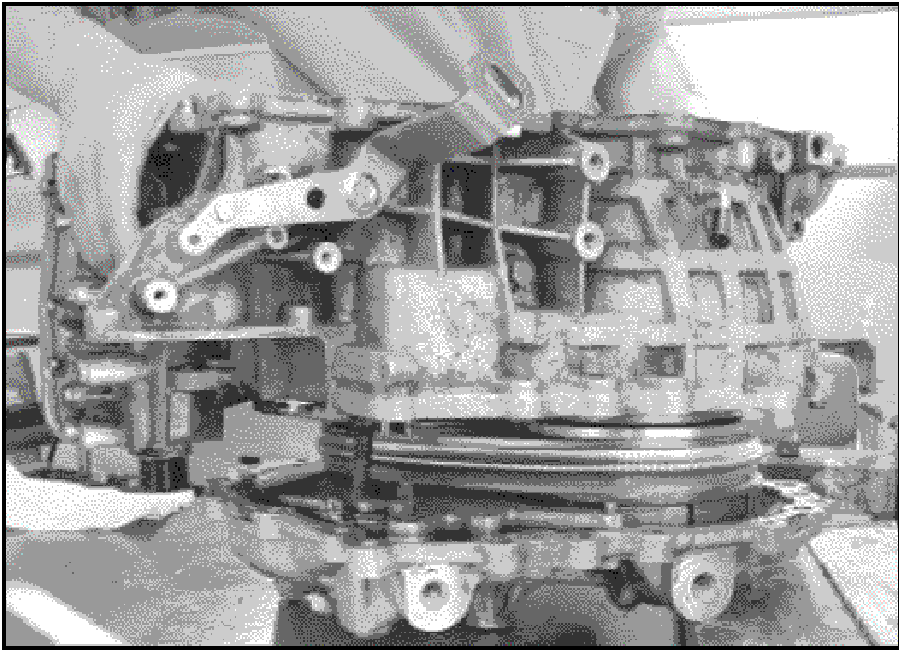

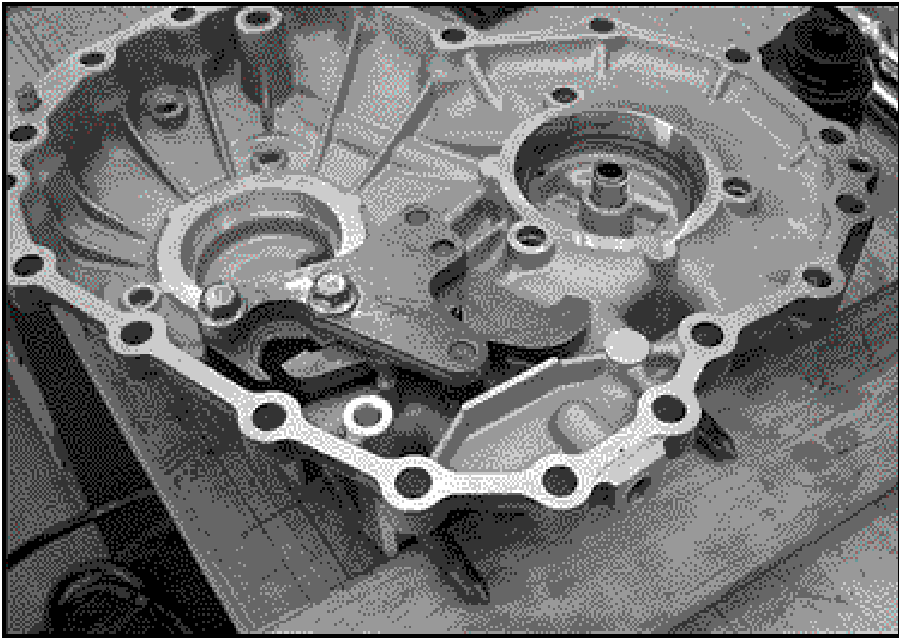

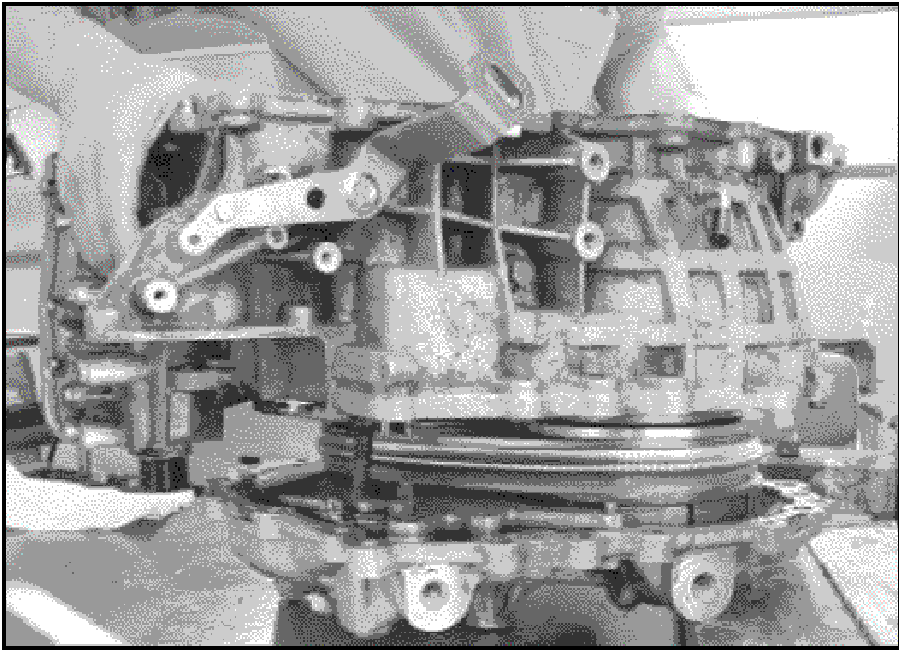

- Separate the transaxle case from the side cover to

expose the pulley assemblies.

|

|

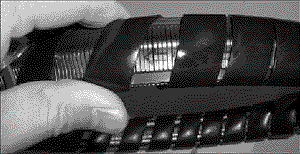

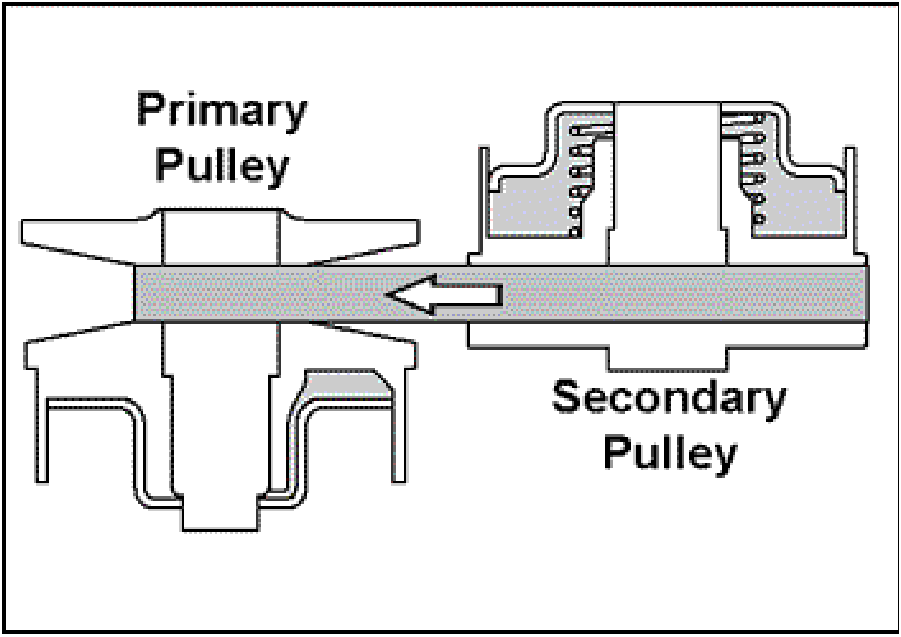

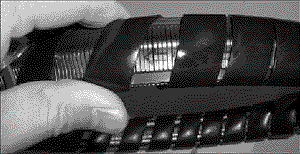

- Keep the drive belt from separating during further

disassembly by securely attaching two tie-wraps

around the belt at the locations shown by the arrows.

|

|

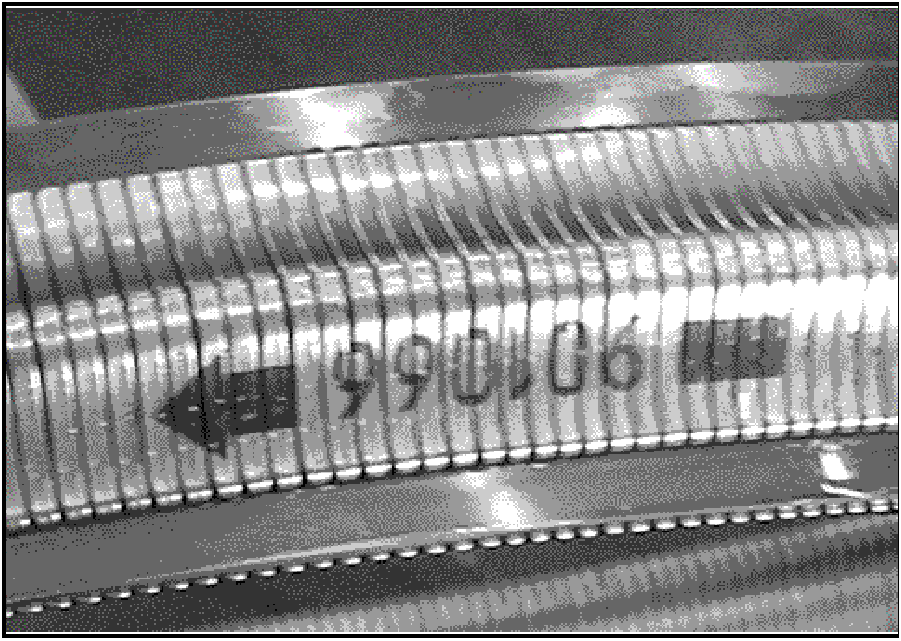

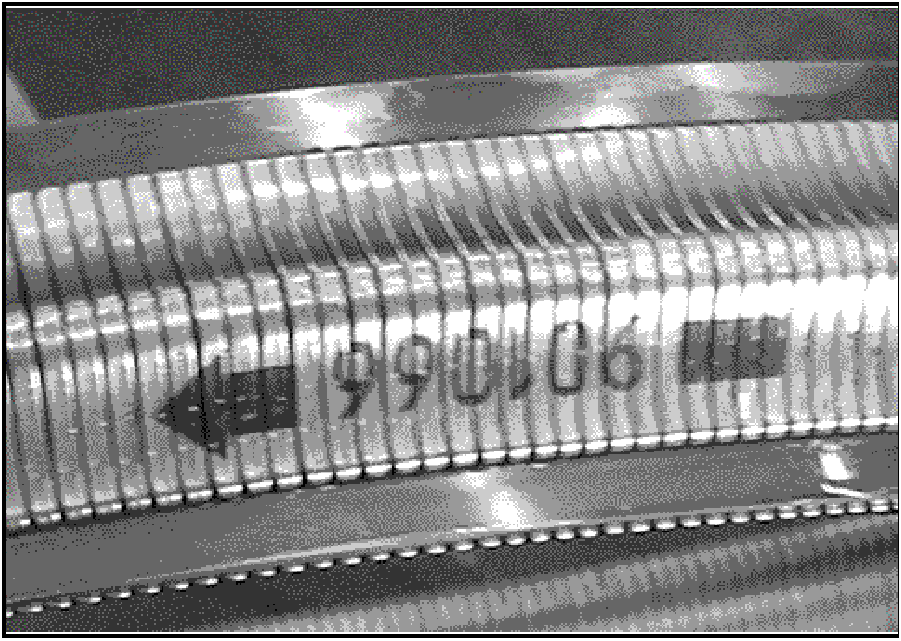

- Note of the direction arrow marked on the belt.

On reassembly, the belt MUST be reinstalled with the

arrow pointing in the same direction as it was removed

|

|

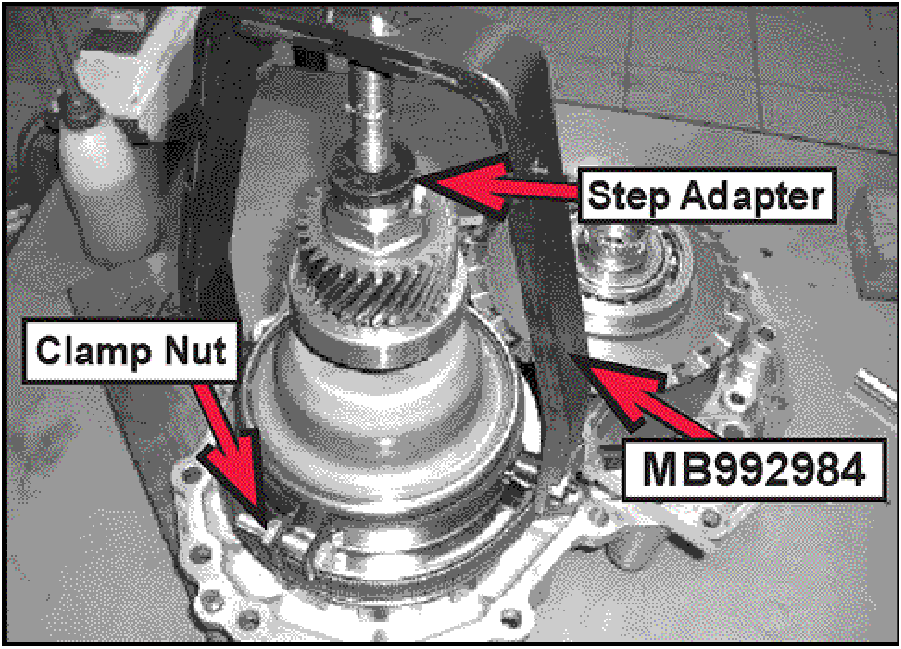

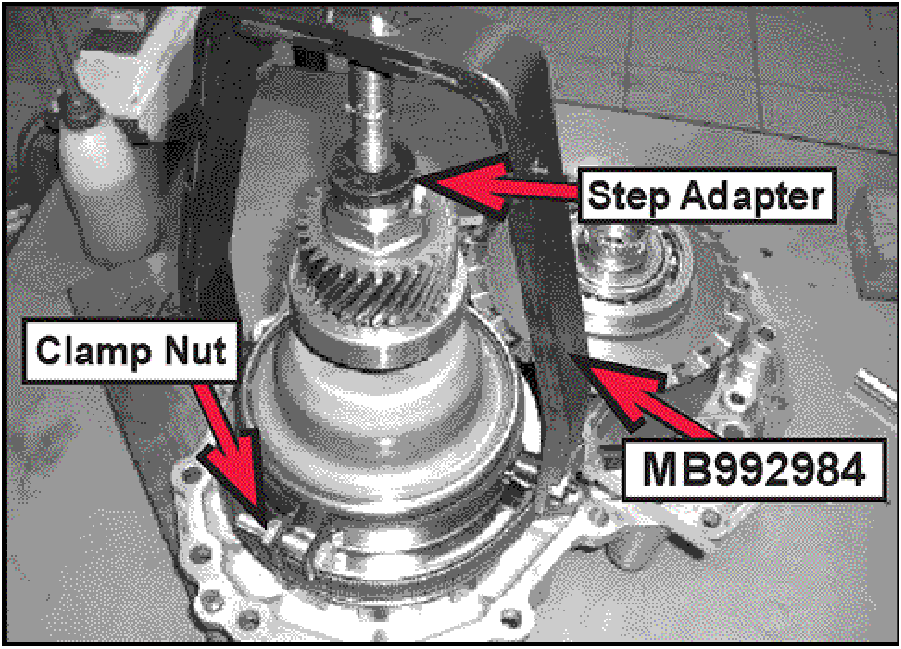

- Place a 1.375” step adapter on the shaft.

NOTE: This tool compresses the pulley's internal

spring, expanding the pulley width allowing belt to

be removed.

|

|

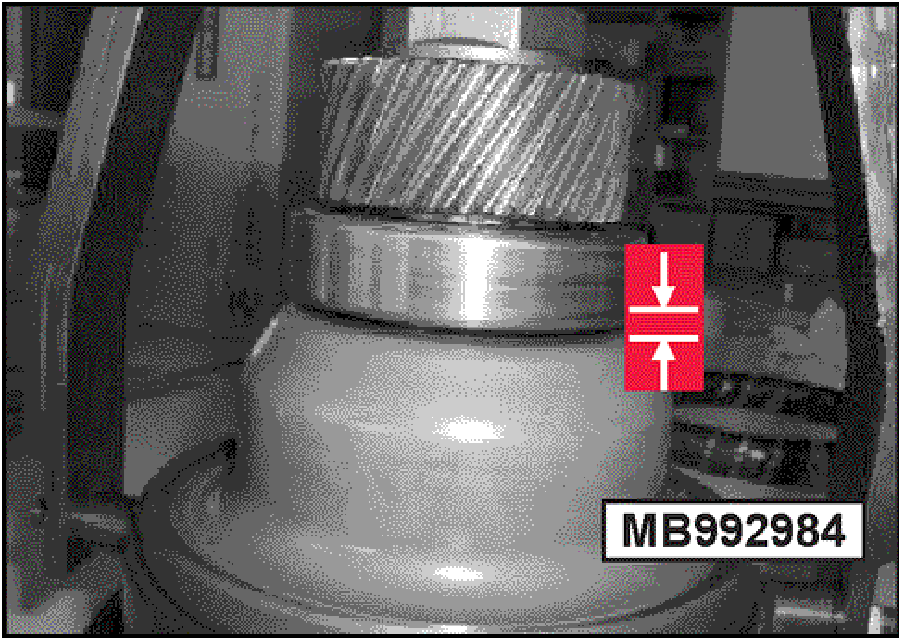

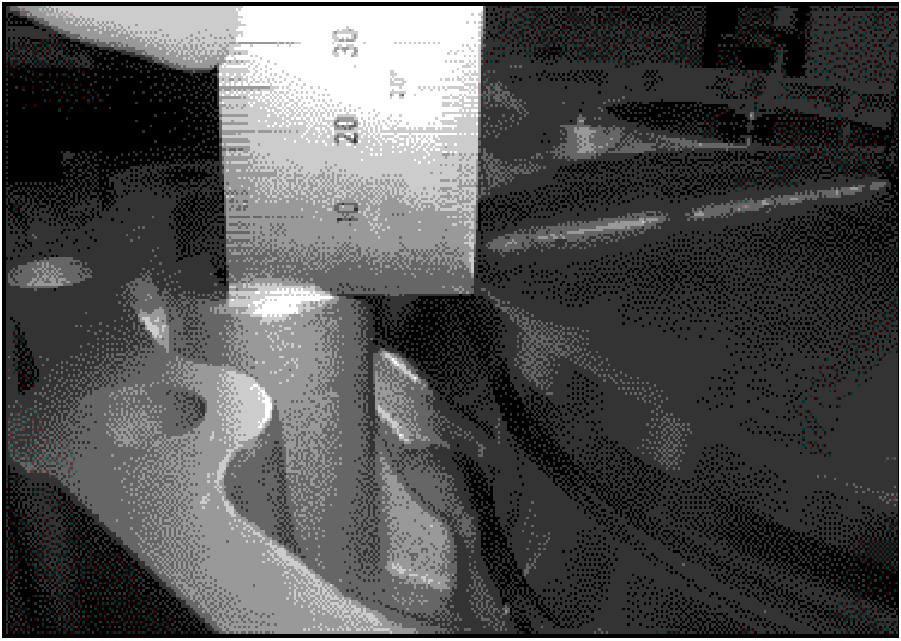

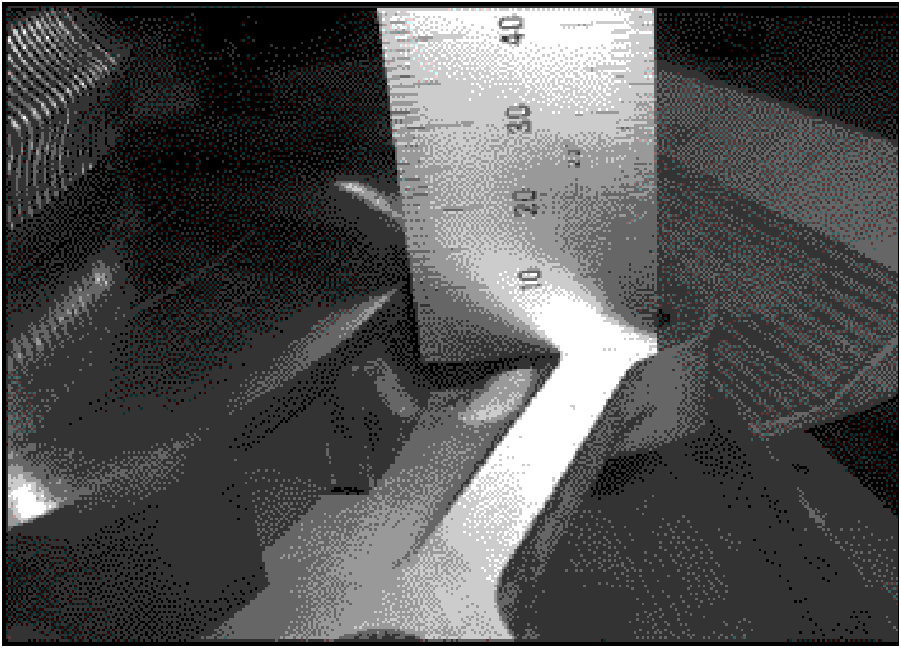

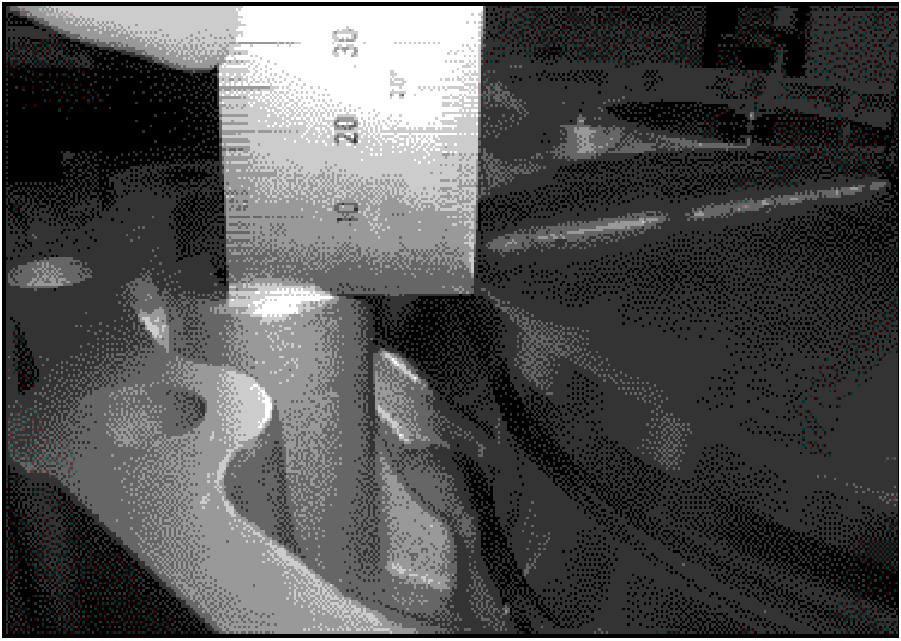

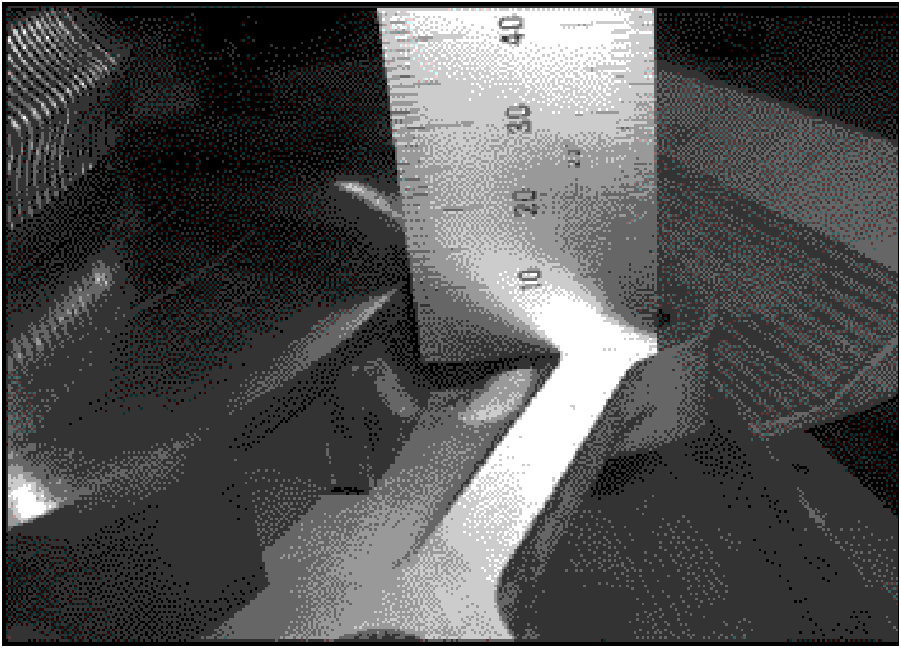

- Turn the forcing screw clockwise. STOP turning when

3mm is measured at the location shown.

Overtightening the forcing screw will damage the

secondary return spring.

|

|

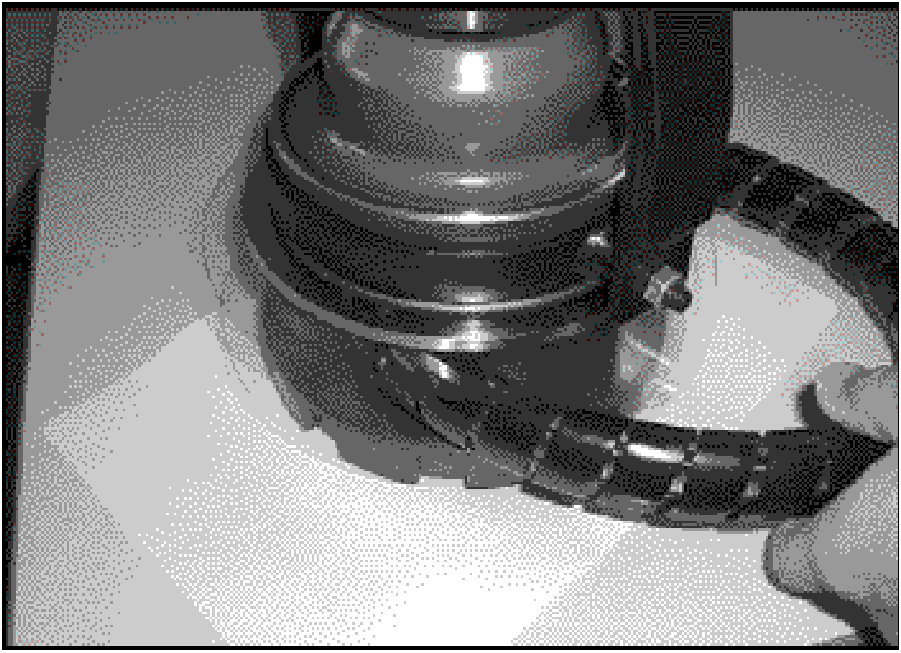

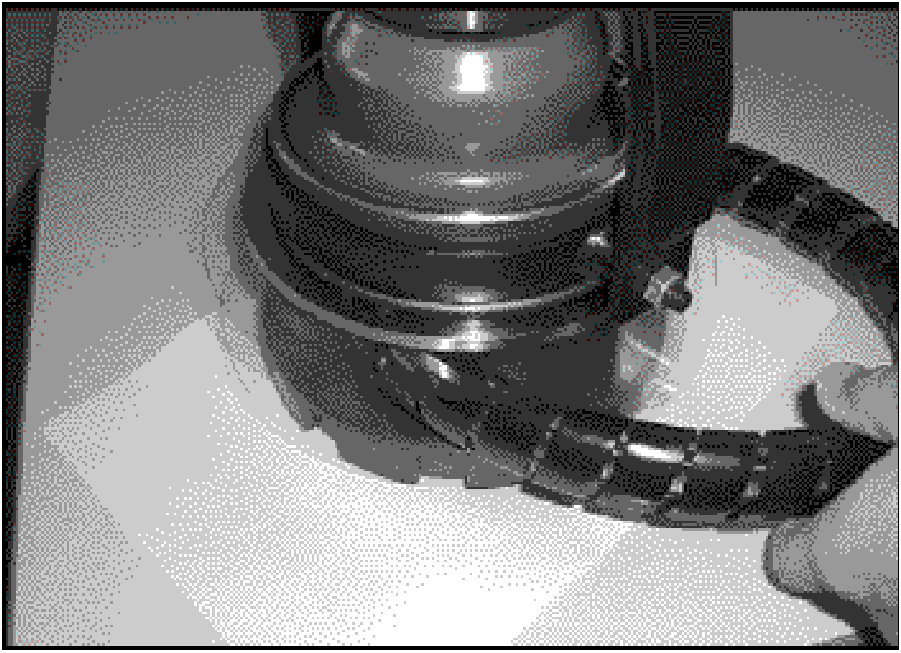

- To prevent damaging the belt during further steps,

wind approximately 28” (711mm) of convolute tubing

around its entire length.

|

|

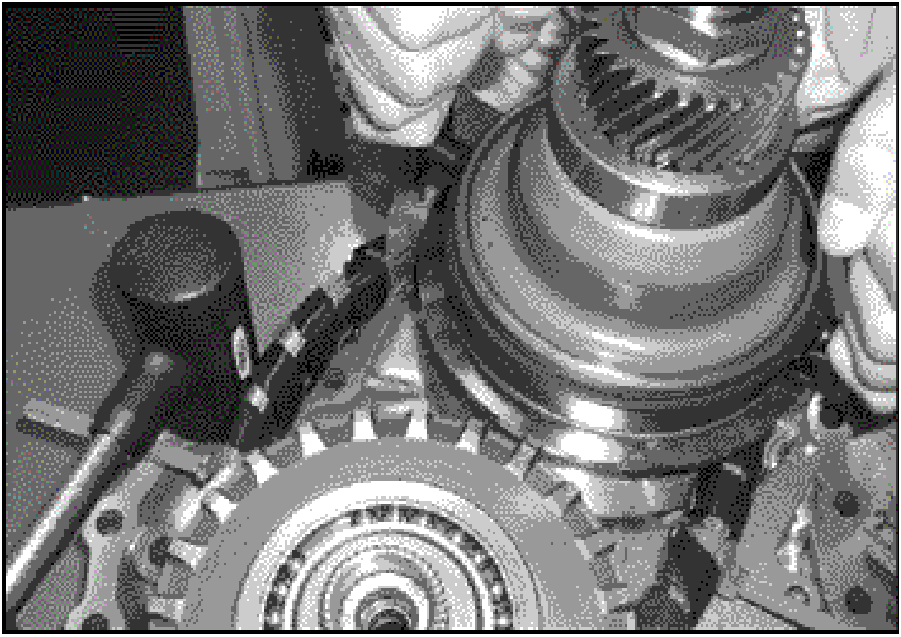

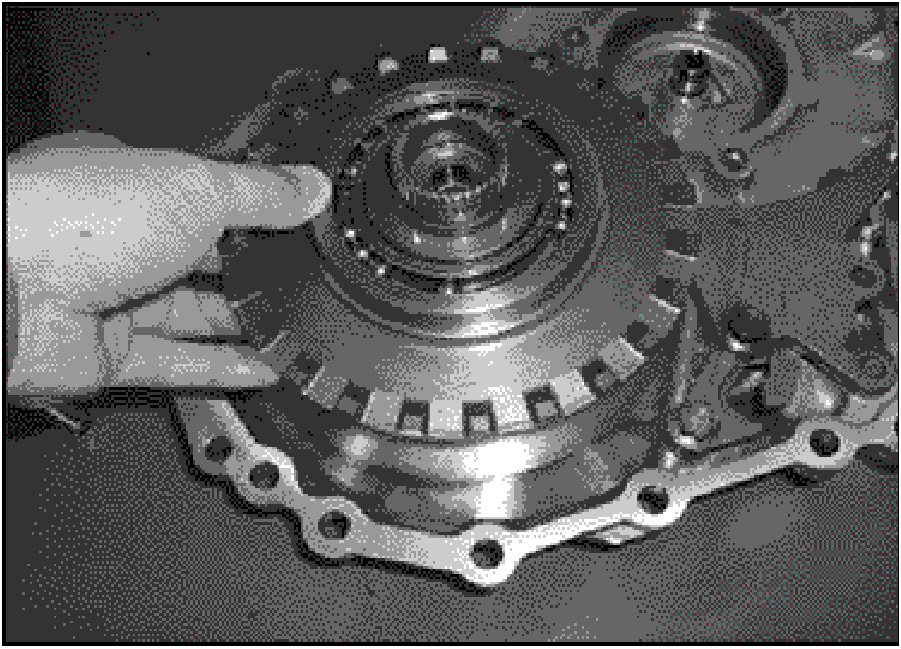

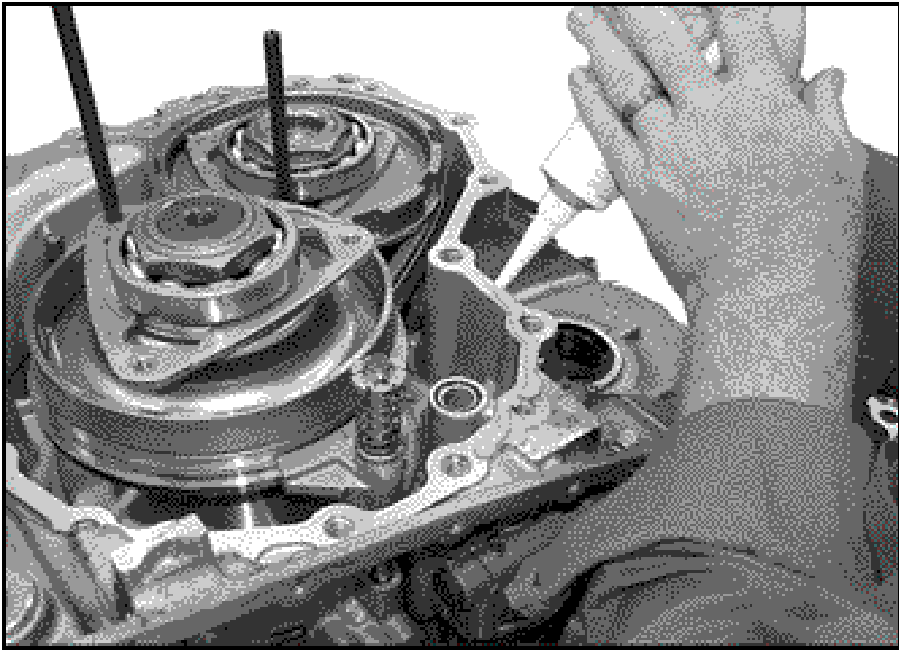

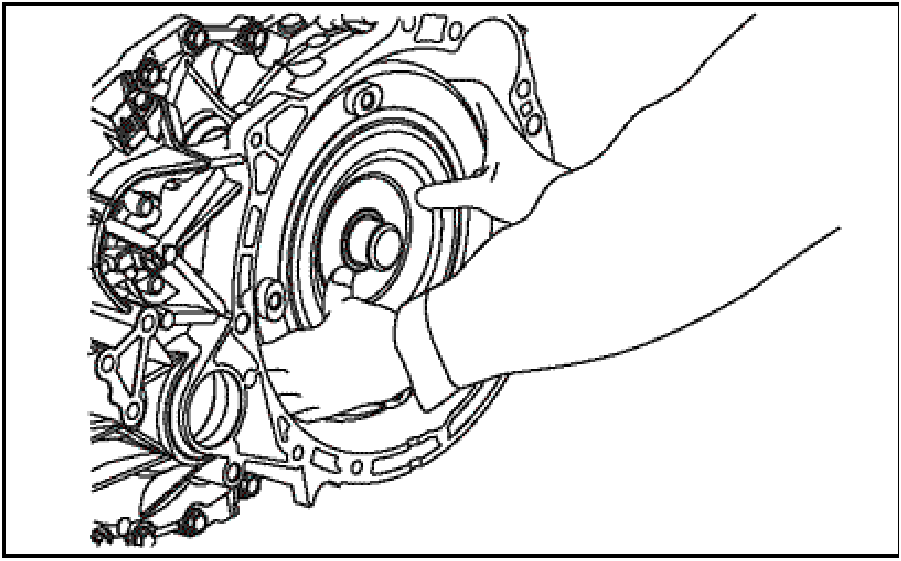

- Firmly grasp the compressor with both hands and lift

the secondary pulley assembly from the side cover.

|

|

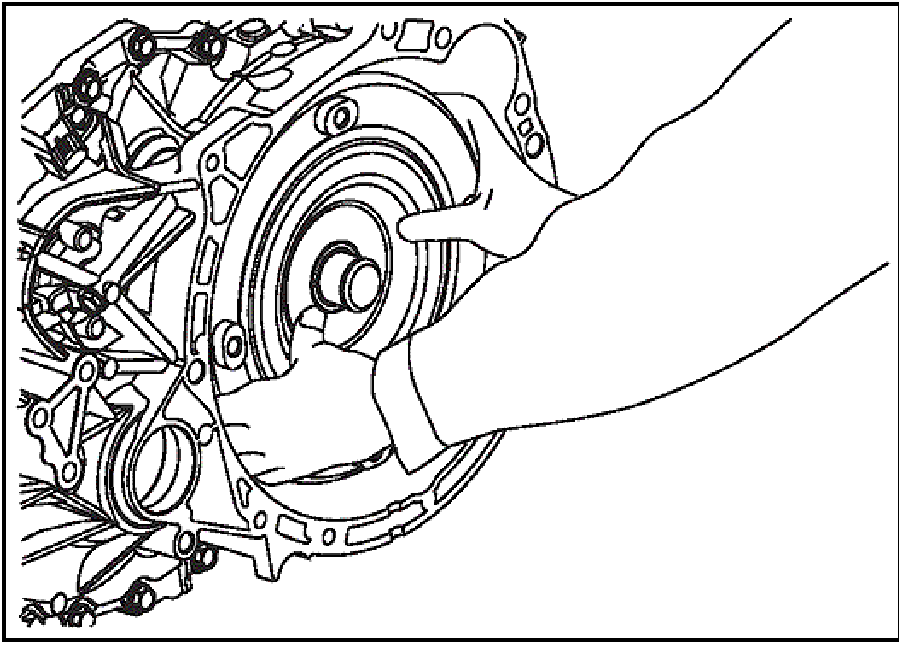

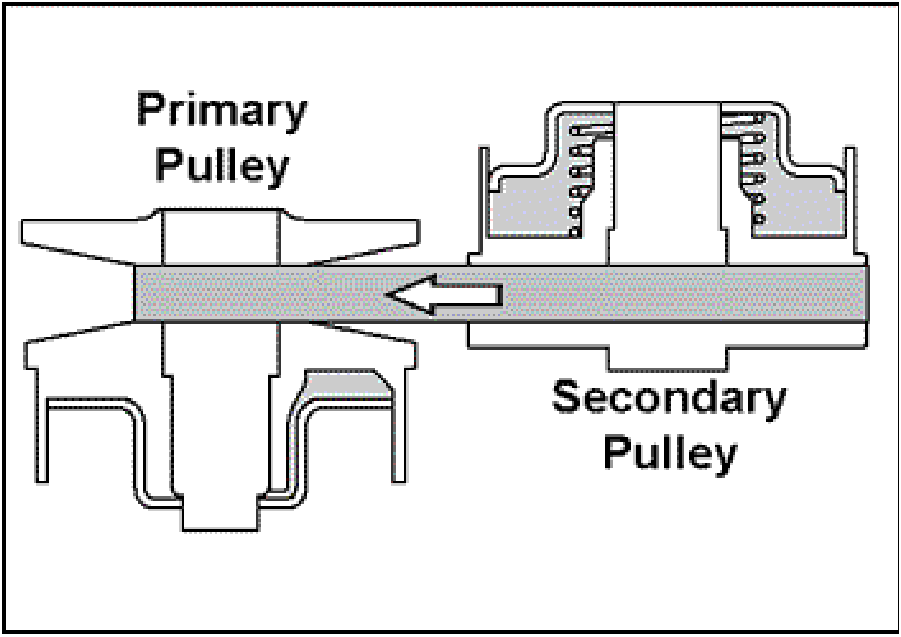

- Once the bearing is free from the side cover, move the

secondary pulley assembly toward the primary pulley.

The added slack in the belt will enable another

technician to slide the belt up and over the primary

pulley as shown here.

- Once the secondary pulley is removed, lift the primary

pulley from the side cover.

|

|

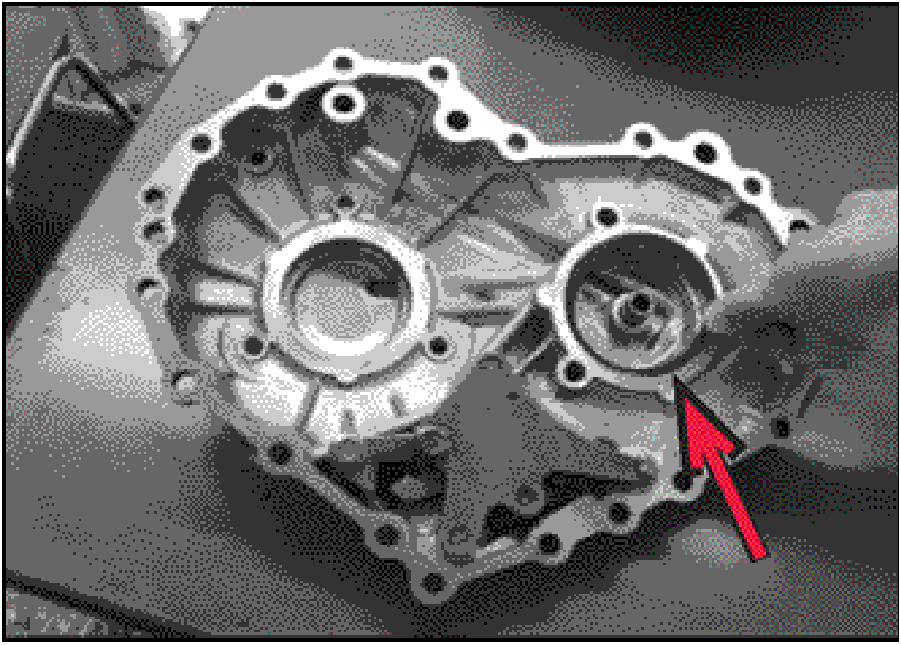

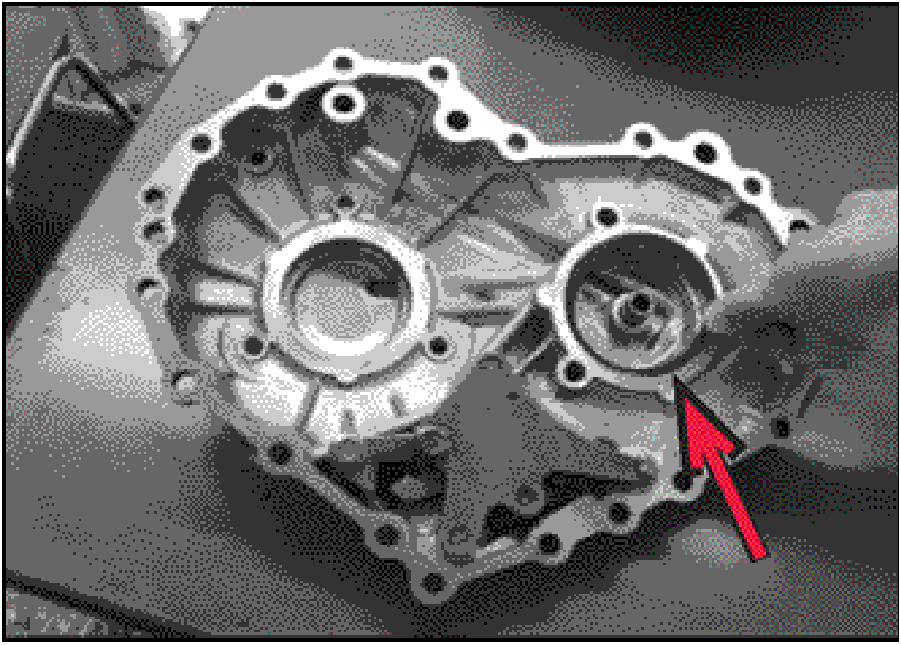

CLEANING

- While wearing eye protection, use a non-chlorinated

aerosol cleaner to flush each fluid passage indicated

by the arrows.

Immediately follow with compressed air to remove any

debris and cleaner residue.

|

|

- Remove all residual liquid gasket sealer from these

mating surfaces:

- Converter Housing to Transaxle Case

- Transaxle Case to Side Cover

|

|

- Thoroughly clean the transaxle pan and magnets.

|

|

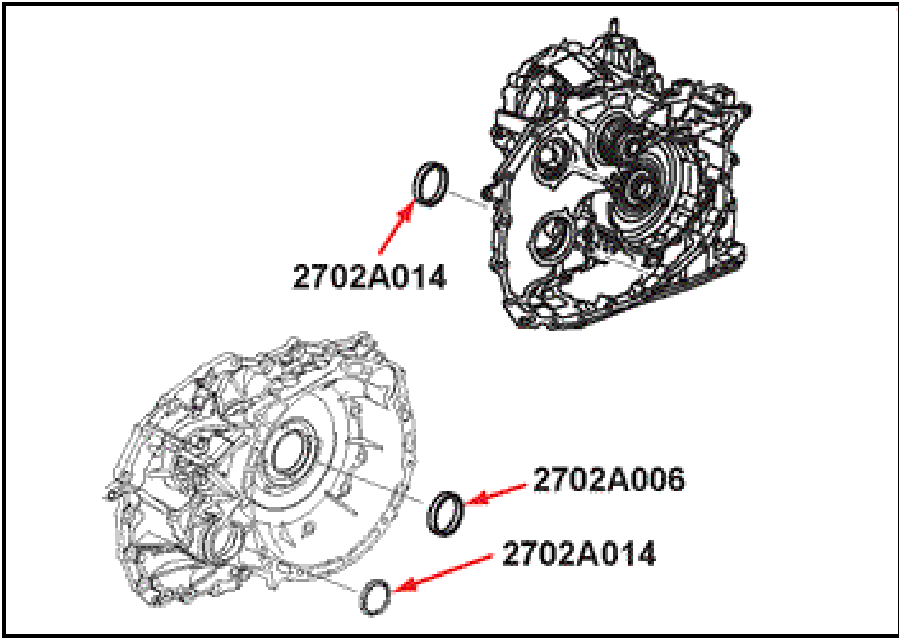

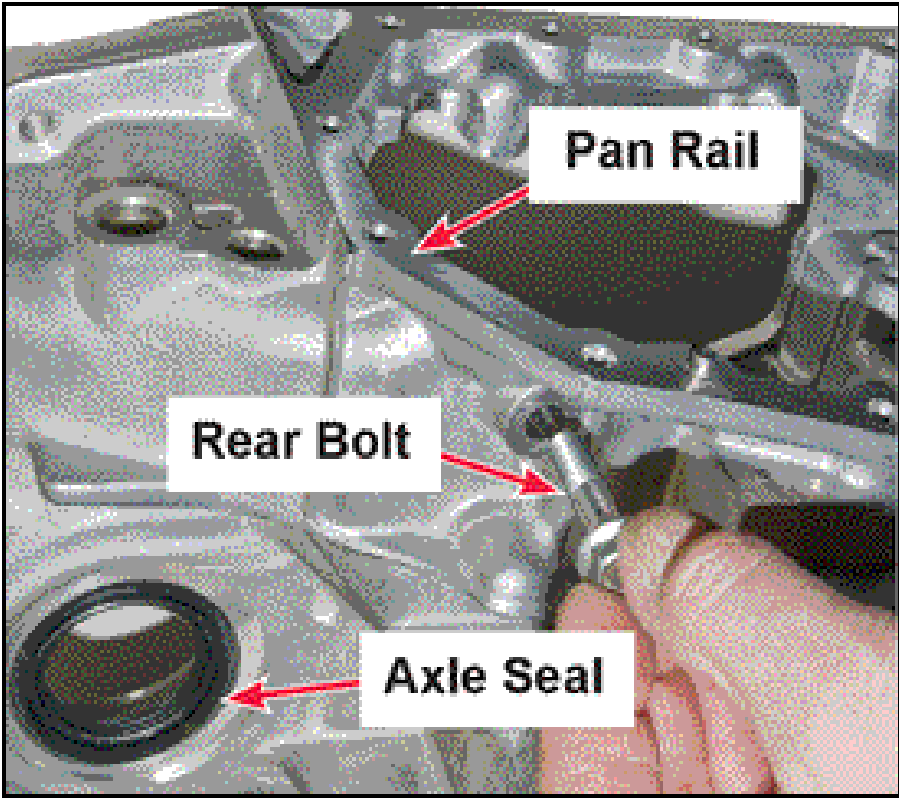

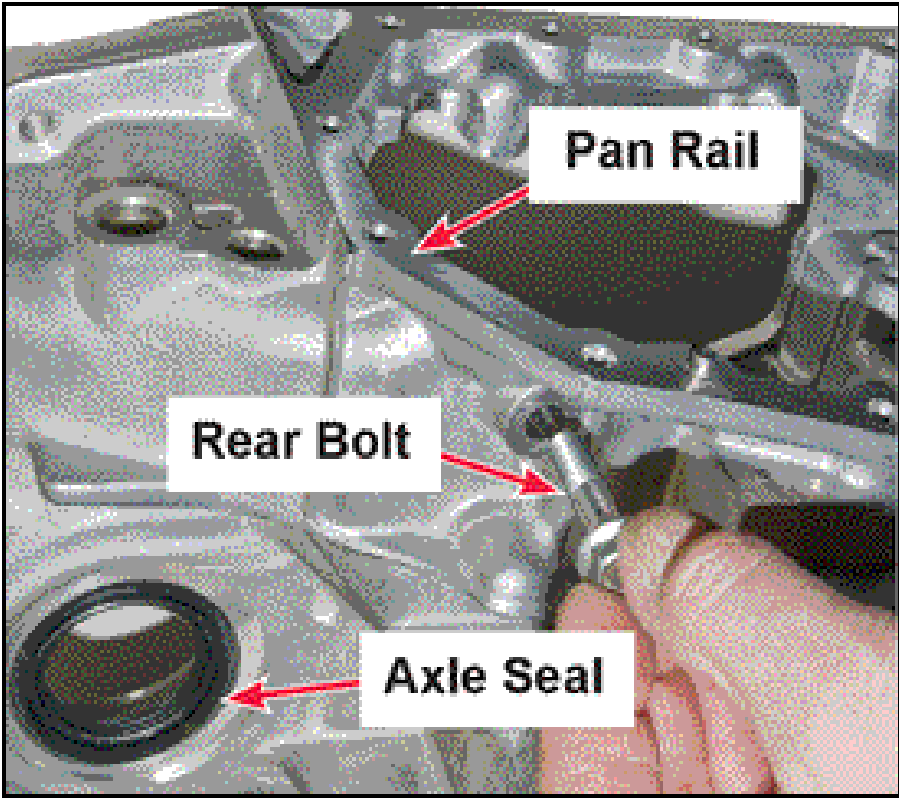

CASE SEALS and O-RINGS

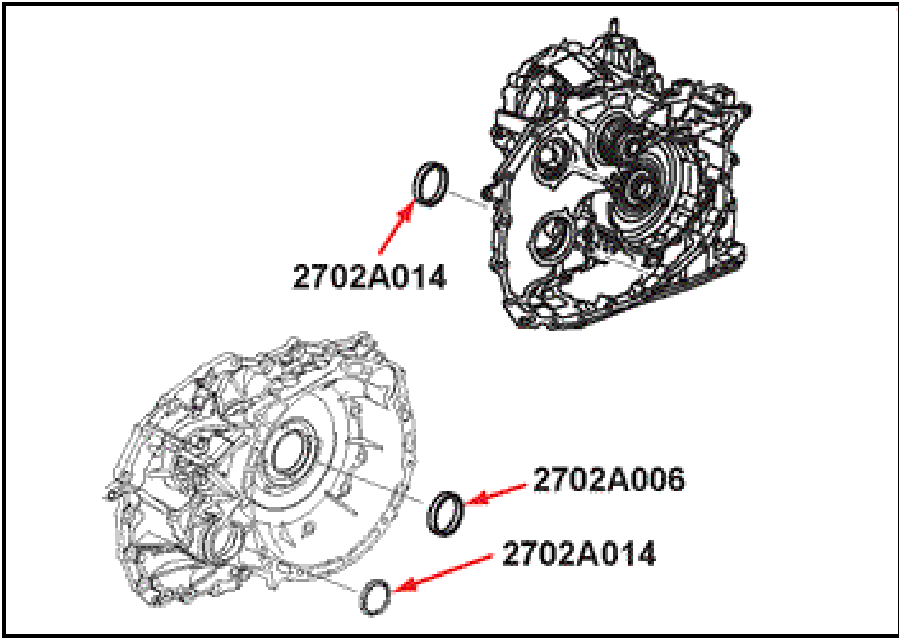

- Before proceeding further, replace the converter

housing seal and axle shaft seals. If necessary,

consult service manual Group 23B for procedures and

special tools.

Converter Housing Seal: 2702A006

Axle Seals: 2702A014

|

|

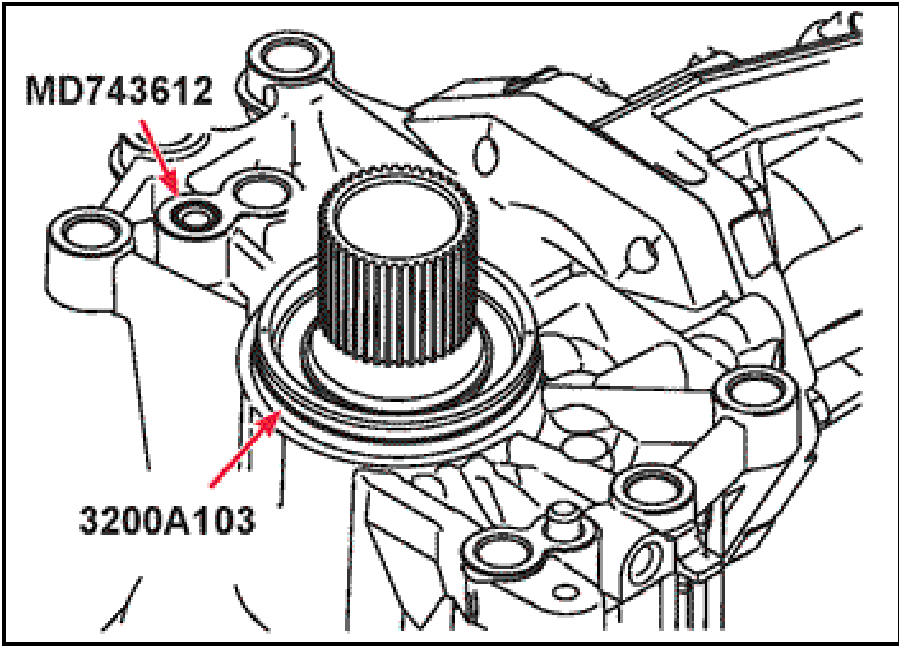

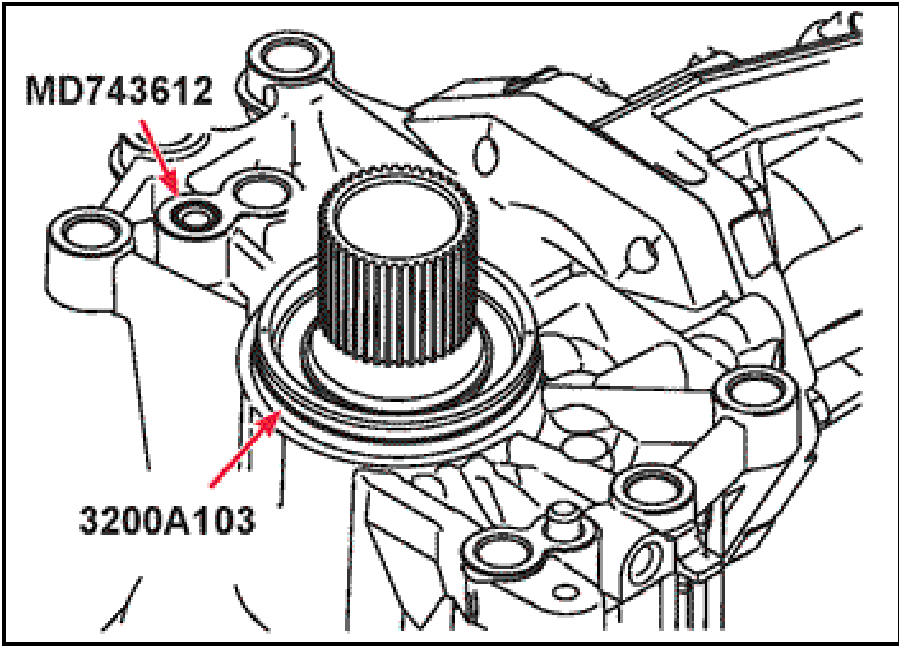

- If the vehicle is equipped with AWD, replace the

transfer case o-rings as shown here

Apply petroleum jelly to the recess in the case where

the small o-ring sits, then install the new o-ring

(MD743612) into the recess.

Install the new large o-ring (3200A103) into the

groove in the transfer case, then apply petroleum jelly

to the o-ring.

|

|

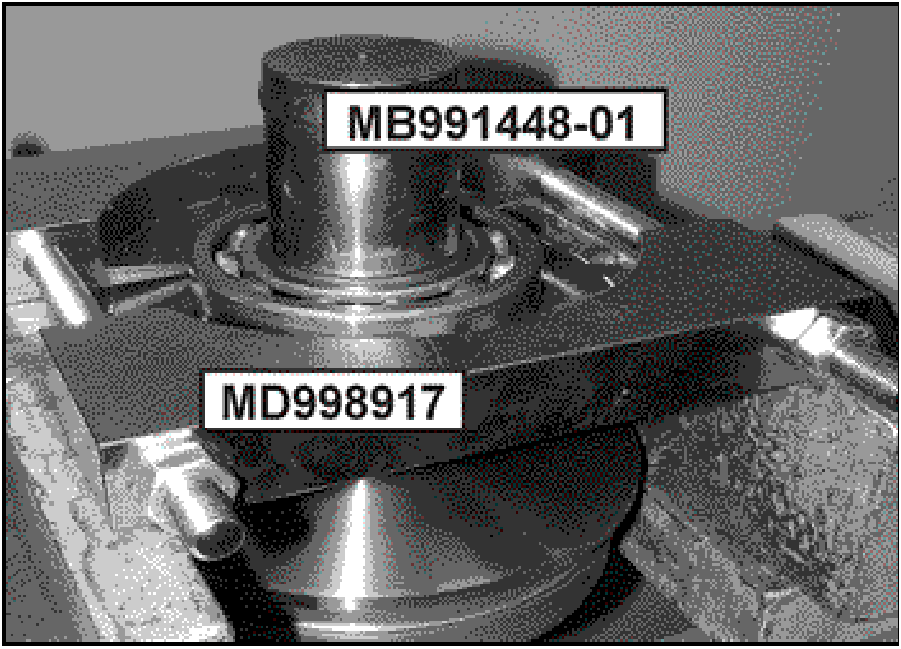

BEARING REPLACEMENT

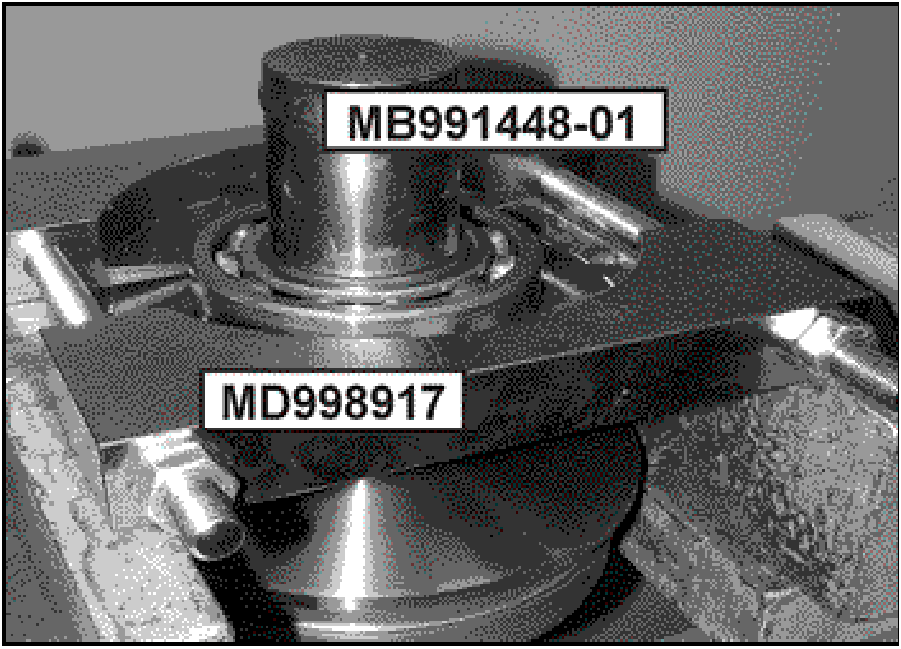

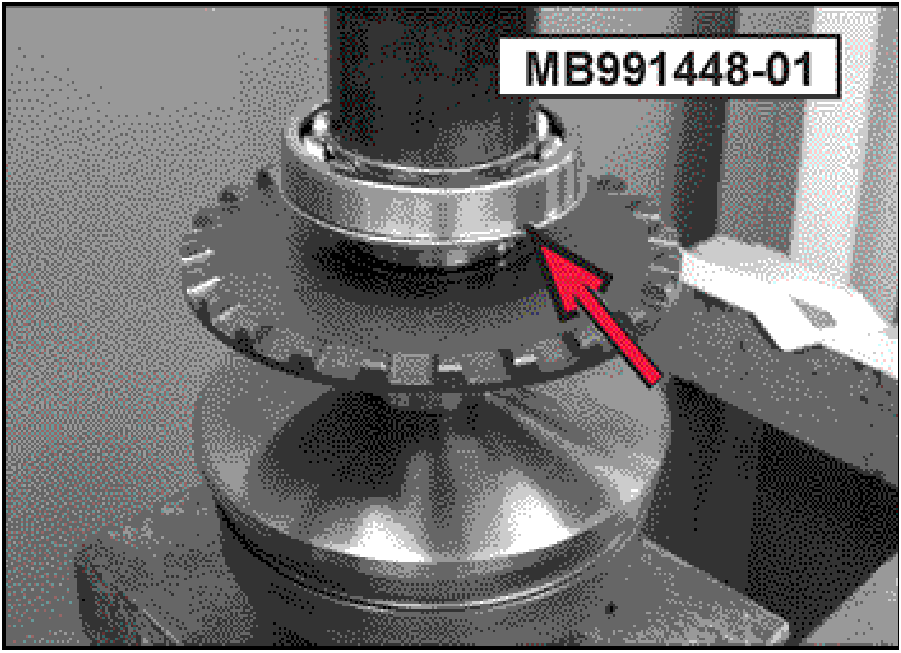

- Press the primary pulley’s front bearing from the shaft

using special tools MD998917 and MB991448-01 as

shown. Discard the bearing.

NOTE: Ensure the bearing splitter's jaws are fully

seated under the bearing outer race. Do not use the

bearing’s C-ring groove to perform this step.

|

|

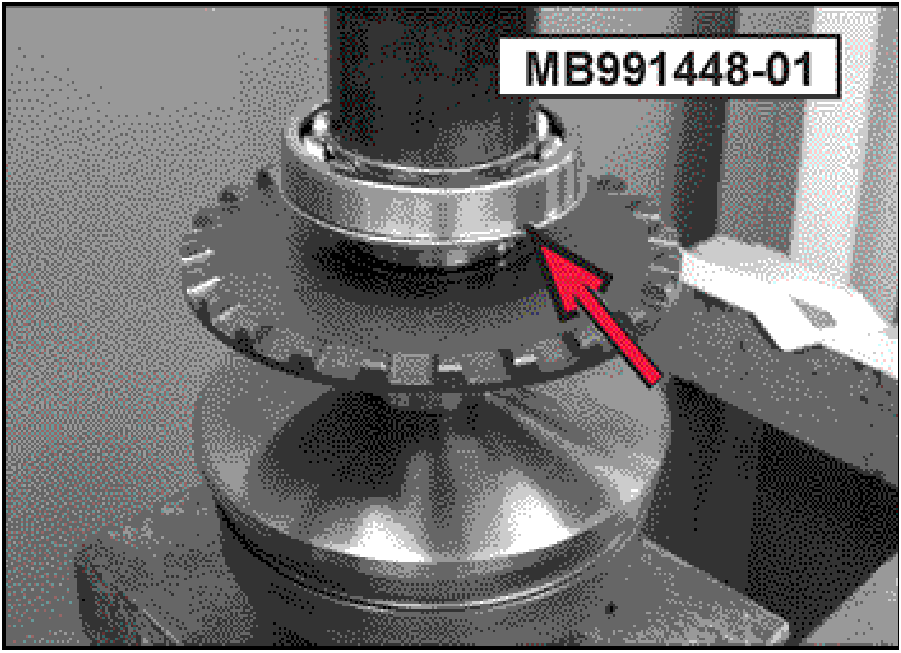

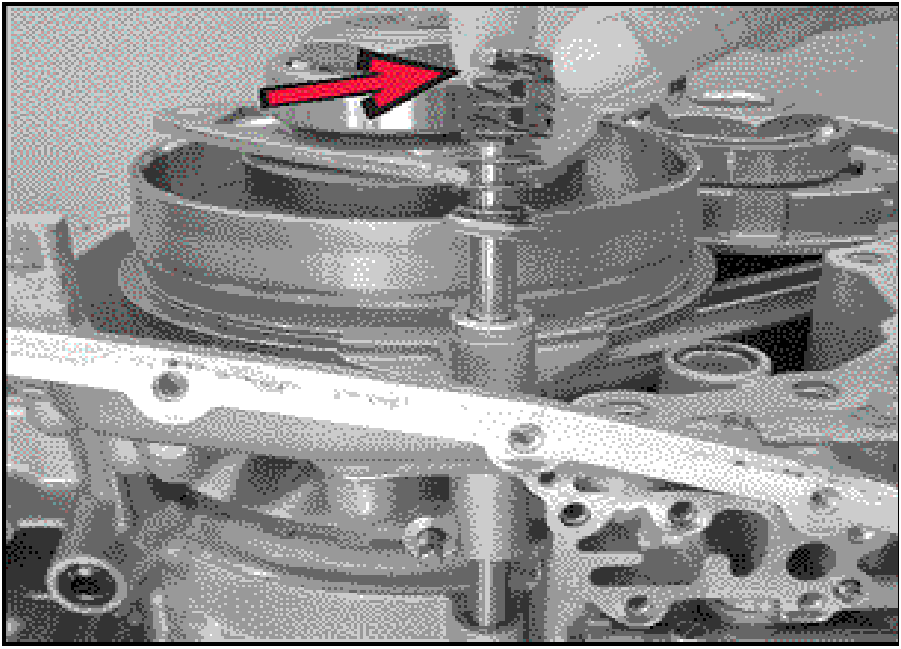

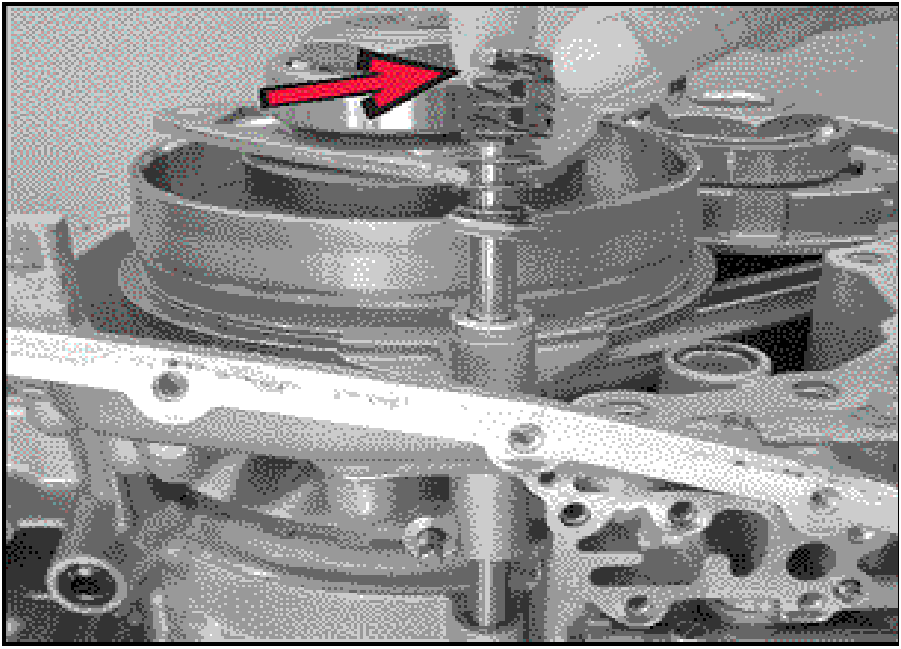

- Ensure all surfaces are free of debris. Use special tool

MB991448-01 to press the new bearing (2950A049)

onto the primary pulley shaft.

Ensure the bearing's C-ring groove faces the pulley

flange as indicated by the arrow.

|

|

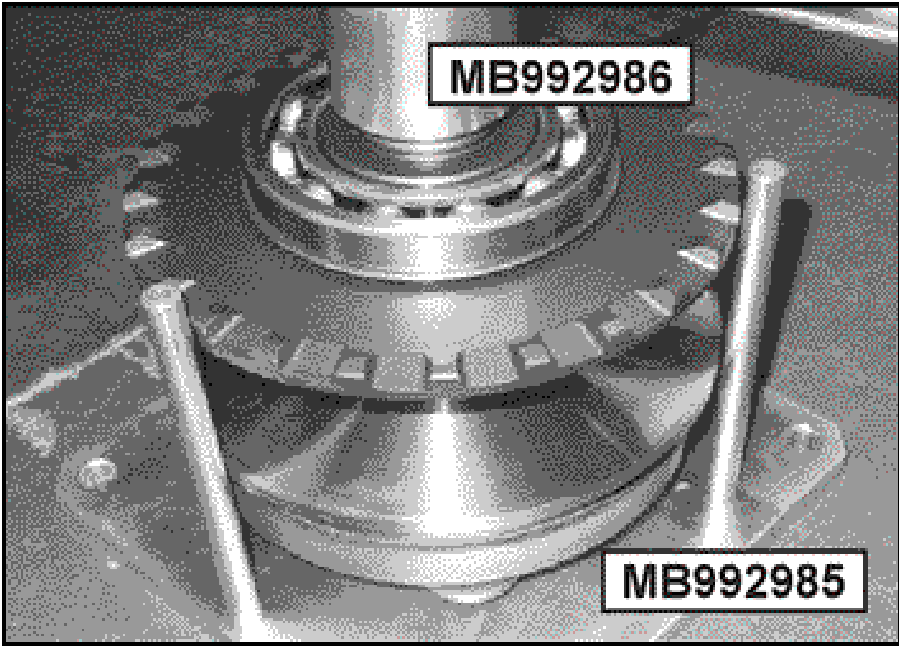

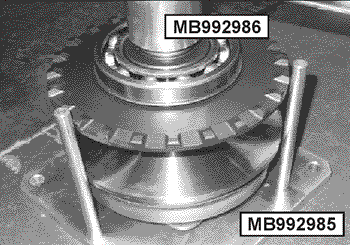

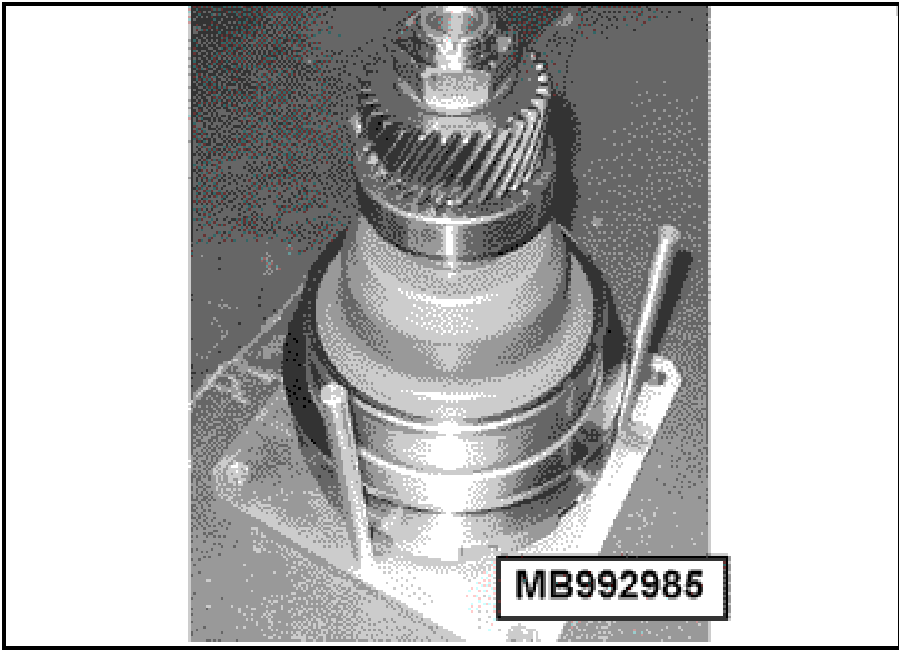

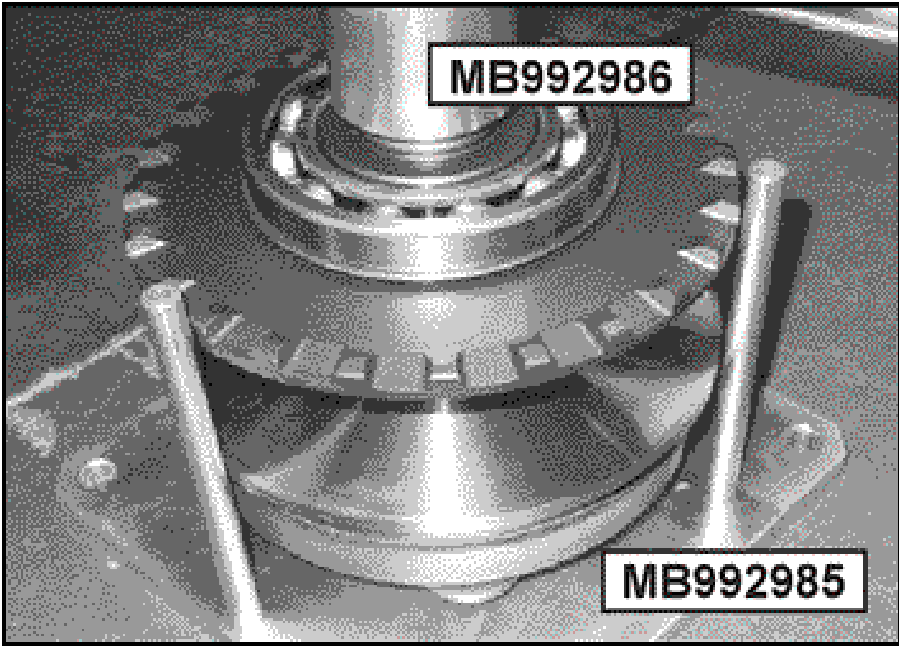

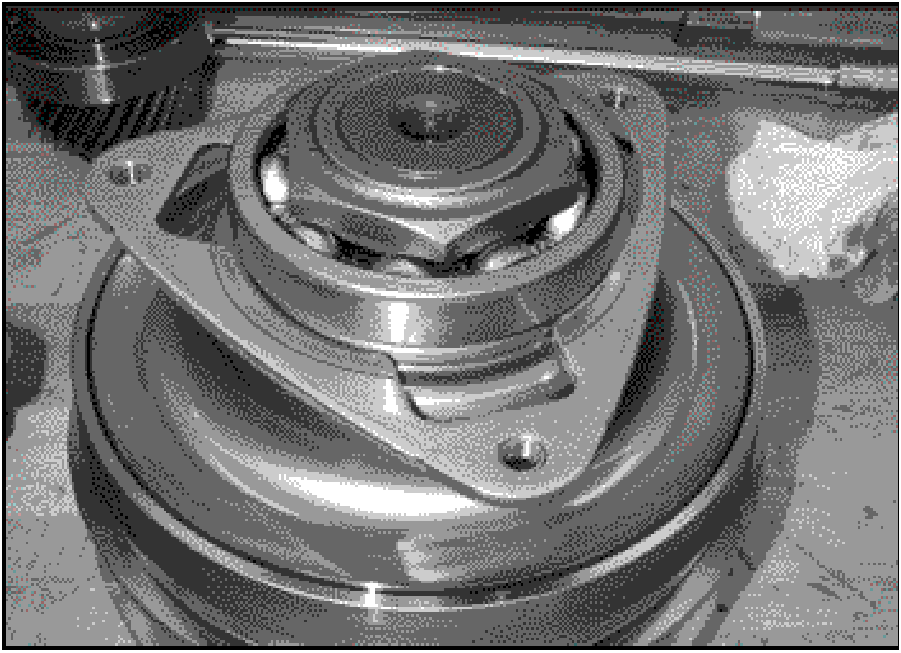

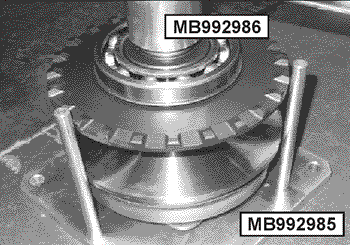

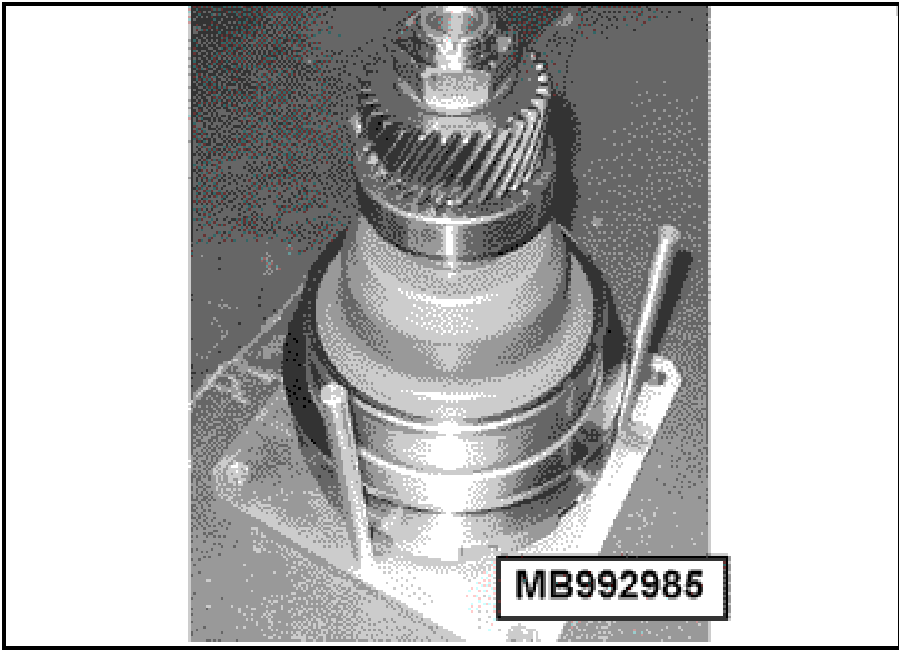

- Clamp the holding fixture (MB992985) to the

workbench. Place the primary pulley assembly (lock

nut down) into the 50mm hexagonal opening in the

fixture as shown.

Place the primary pulley holder (MB992986) onto the

splines. Using a breaker bar, loosen the lock nut.

Turn the assembly over, remove the lock nut and

discard it.

|

|

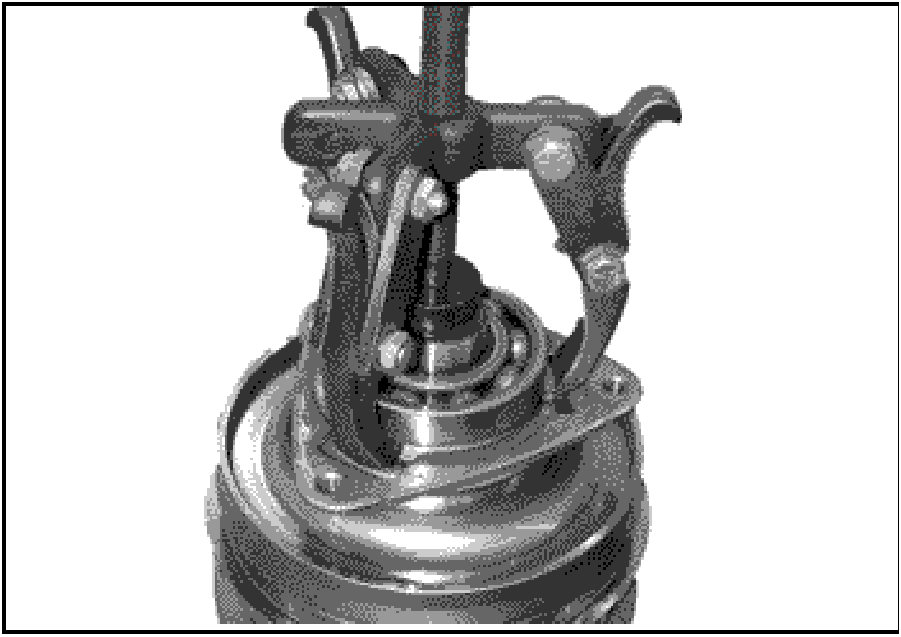

- Use a 3-jaw puller to remove the primary pulley's rear

bearing. Discard the bearing and bearing retainer

|

|

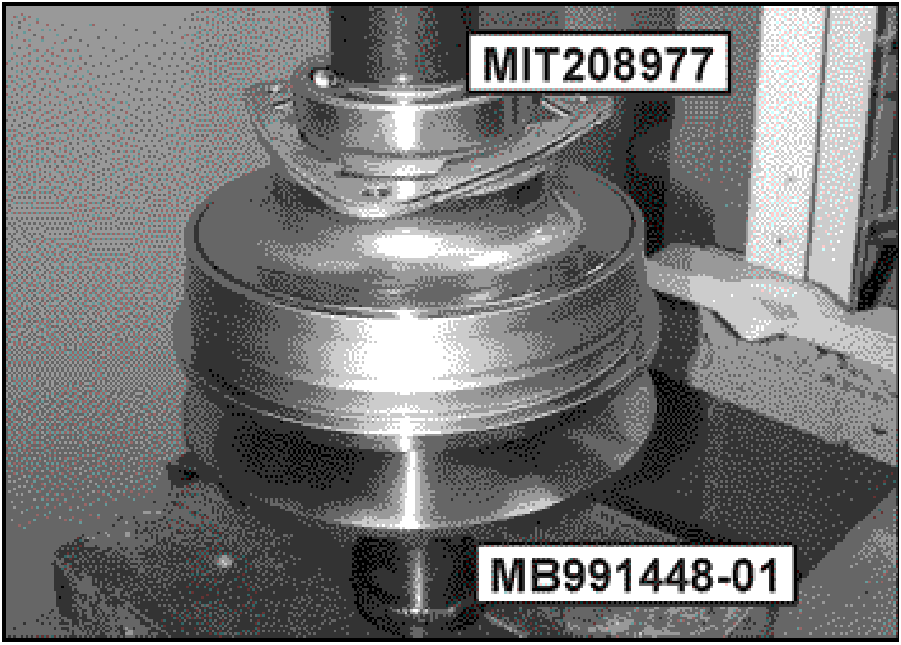

- Clean all surfaces of any debris. Position the new

bearing retainer (2771A001) as shown here.

Do not install the retainer upside down.

|

|

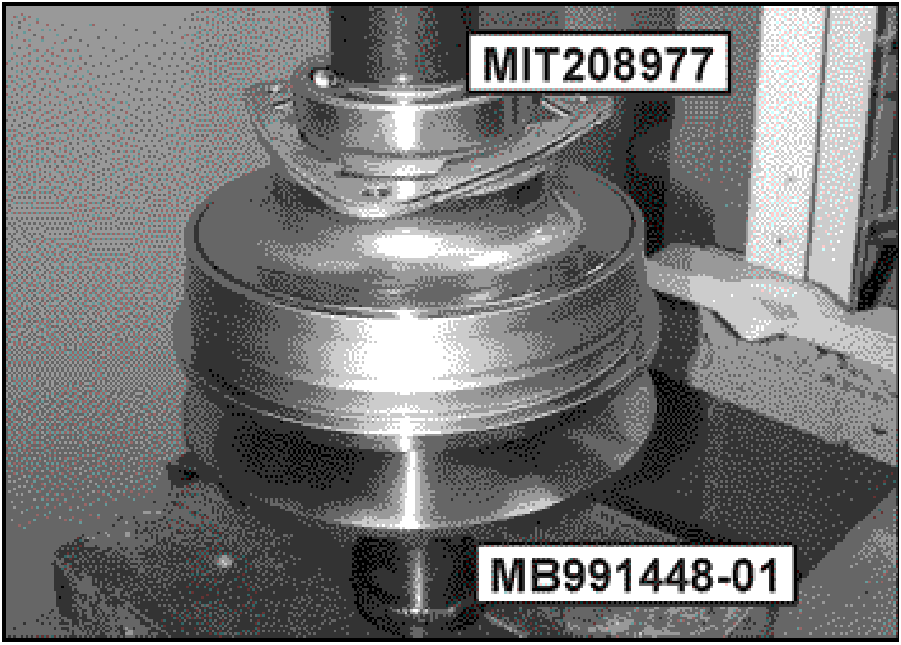

- Set a new primary pulley bearing (2950A047) in place.

Using special tool MB991448-01 to support the

assembly on the press table, seat the new bearing

onto the primary pulley shaft with MIT-208977.

|

|

- Thread the new 50mm lock nut (2771A004) in place.

|

|

- Insert the assembly into the holding fixture

(MB992985).

Use the primary pulley holder (splined socket)

(MB992986) to tighten the 50mm lock nut to 130Nm

(96 ft-lbs.).

|

|

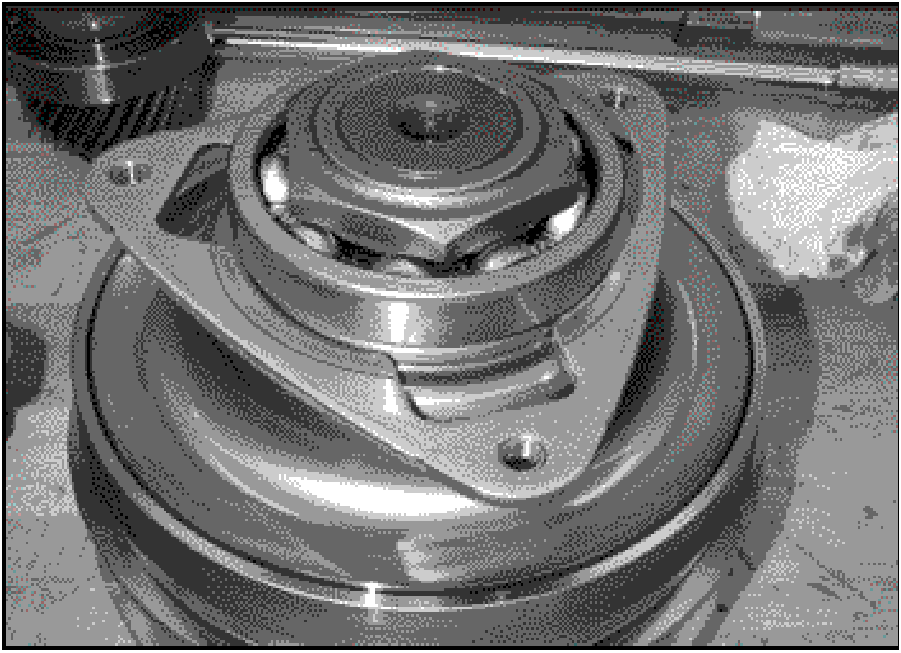

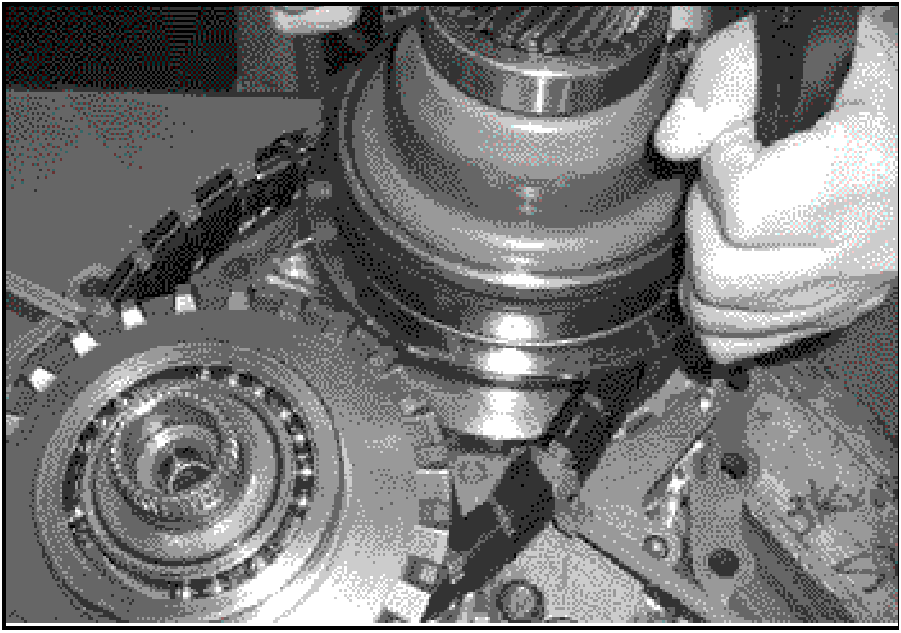

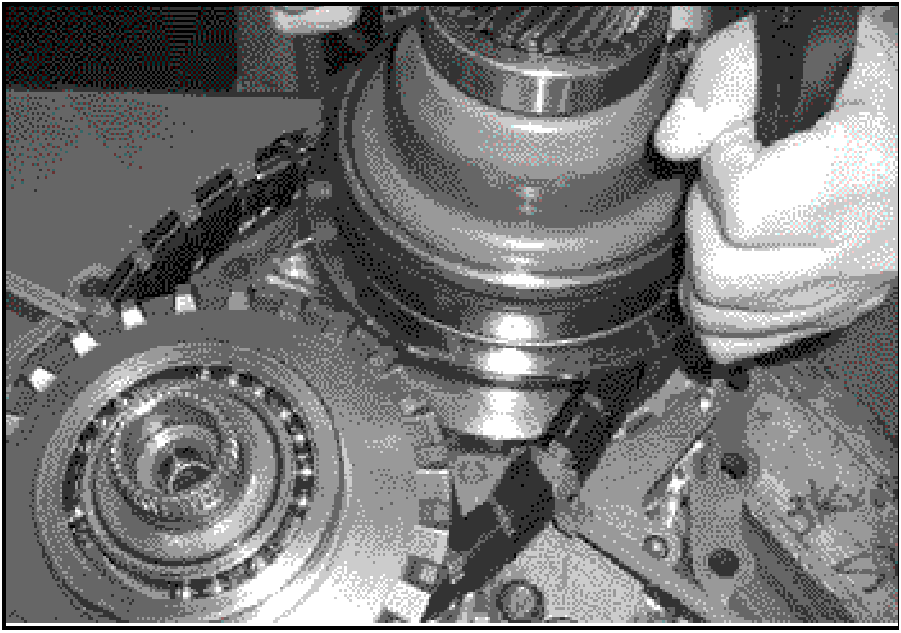

- Position the secondary pulley assembly (lock nut

down) in the holding fixture (MB992985) as shown.

Use a 40mm socket and breaker bar on the staked nut

to loosen the 50mm lock nut being held by the fixture.

|

|

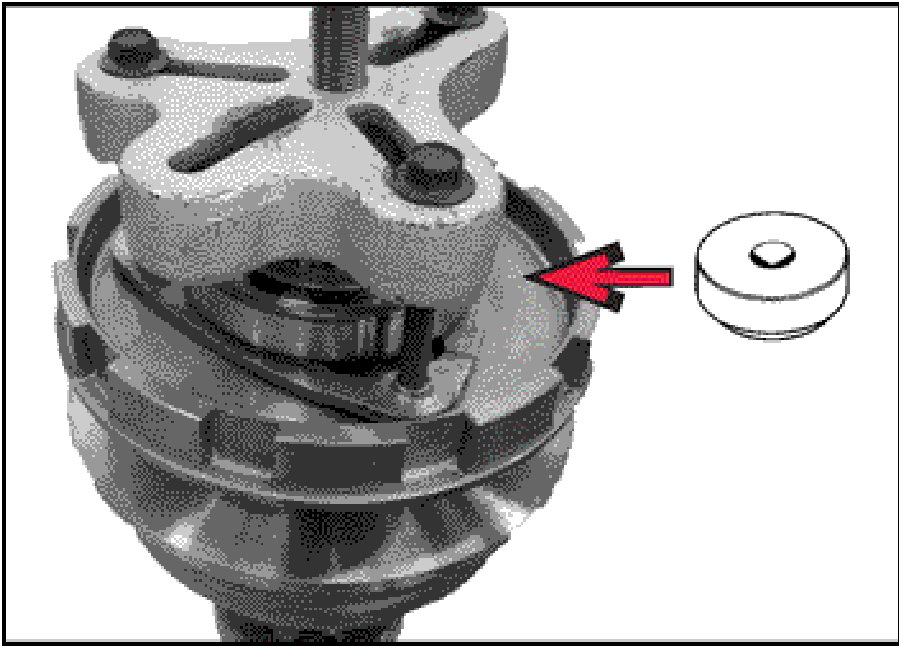

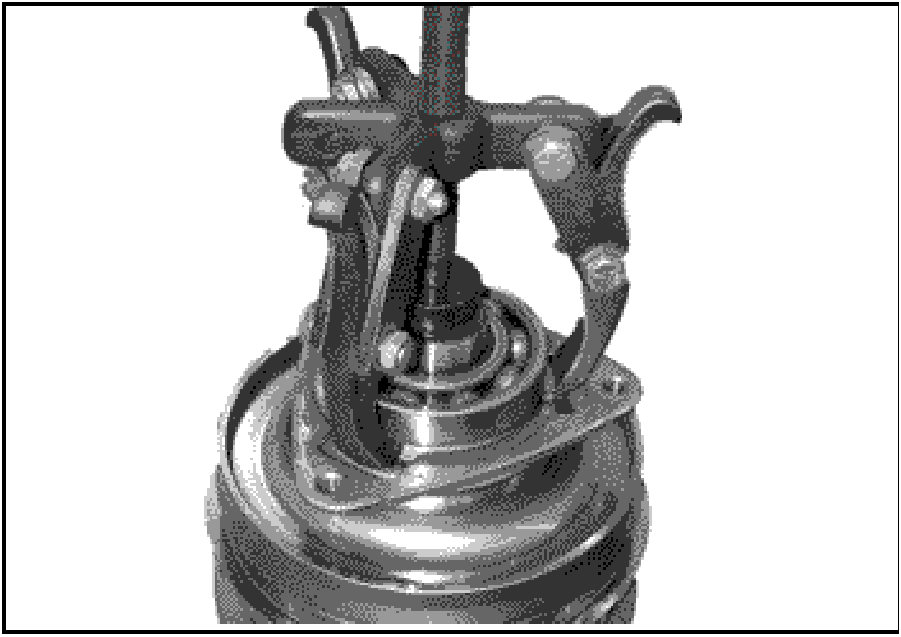

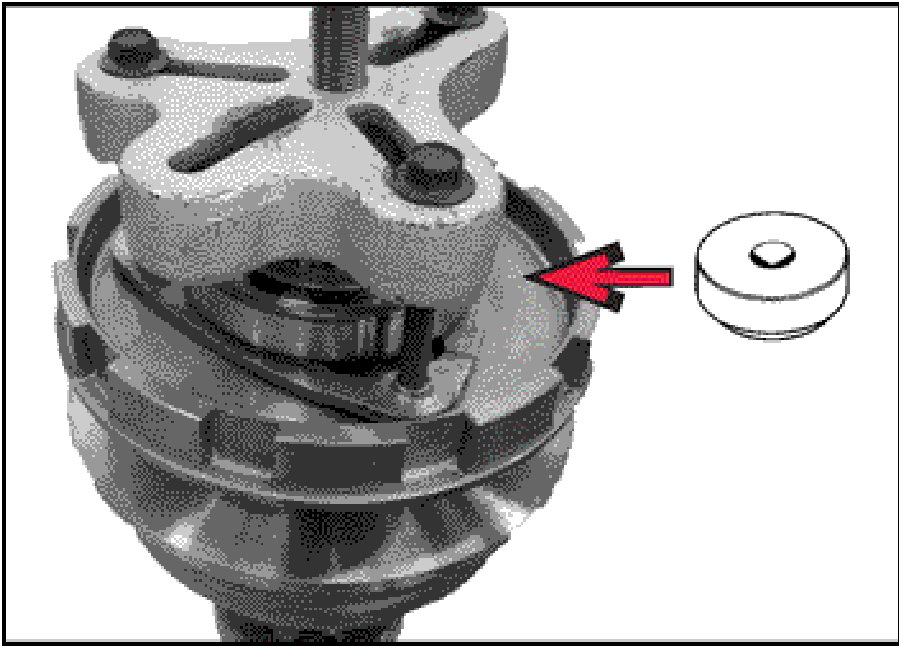

- Before attaching a flange puller, place the press button

(MB995049-01) onto the shaft.

Use three 8mm x 1.25mm screws to attach the puller

to the bearing retainer. Turn the forcing screw against

the press button to remove the secondary pulley's front

bearing.

Discard the bearing and bearing retainer.

Retainer may be deformed during this step.

|

|

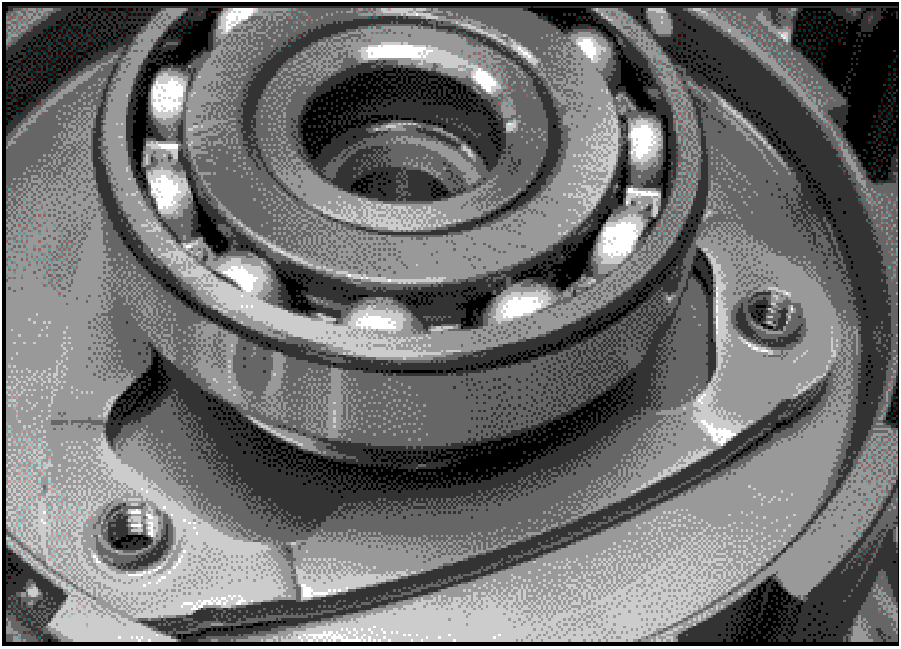

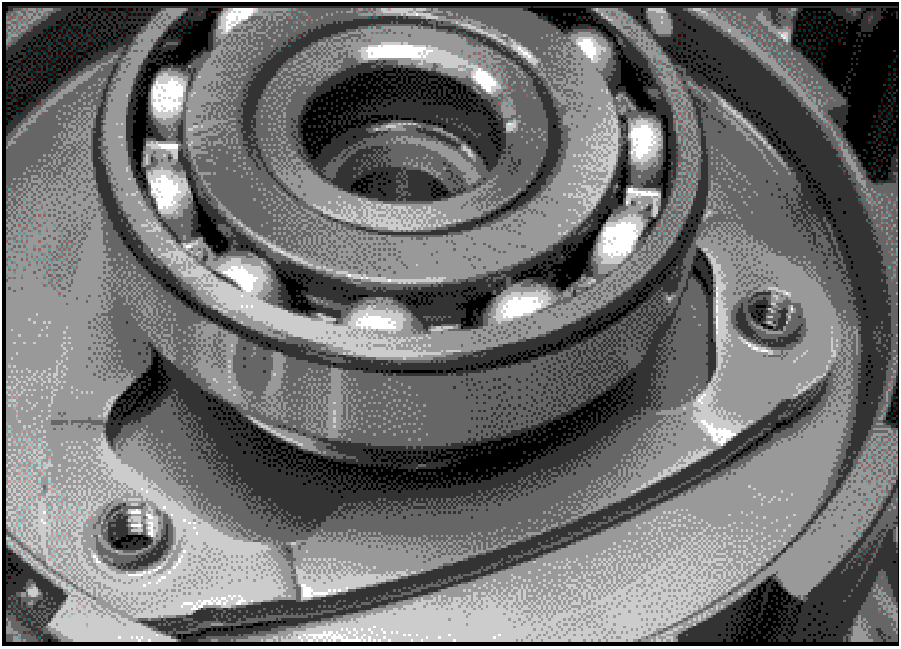

- Position the new bearing retainer (2771A002) and new

bearing (2950A048) onto the secondary shaft as

shown here.

Do not install the bering retainer upside down.

|

|

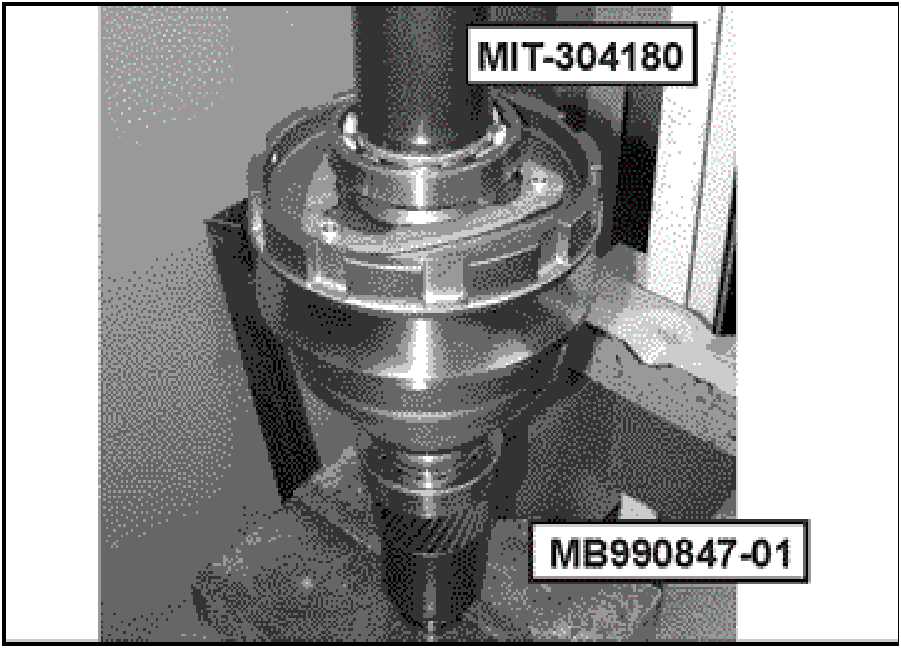

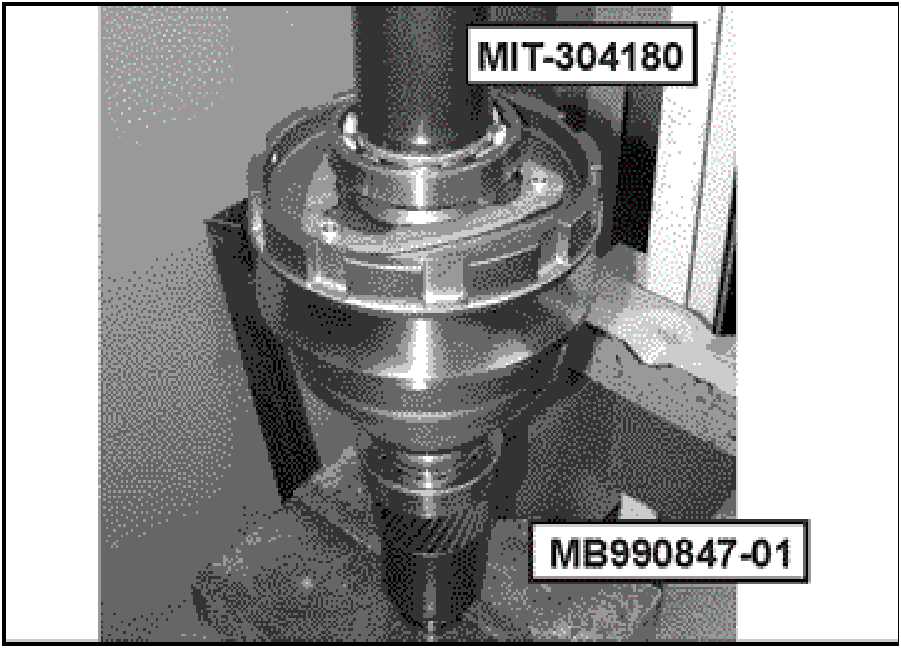

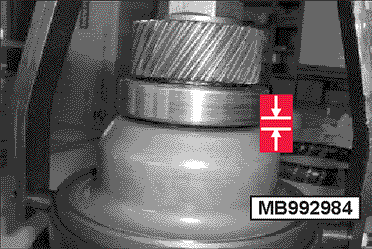

- Support the output gear on the press table with special

tool MB990847-01.

Use special tool MIT-304180 to press the bearing onto

the secondary pulley shaft.

|

|

- Thread a new 50mm lock nut (2771A003) onto the

shaft and return the secondary pulley assembly to the

holding fixture (MB992985) as shown.

Use a 40mm socket and torque wrench on the staked

nut to tighten the new lock nut (held by the holding

fixture) to 310Nm

(228 ft-lbs.).

|

|

- Install a new sealing ring (2931A005) as shown here.

NOTE: There may be 2 sealing rings depending

upon design. If so, replace both.

|

|

- To make component installation easier, level the side

cover with wood block(s).

|

|

- Install the primary pulley into the side cover.

|

|

- With slight downward pressure, shake the primary

pulley assembly until the bearing is fully seated in the

side cover.

Check the installed position by measuring the

dimension as shown.

The pulley flange should protrude above the side

cover mating surface by 1.5mm to 2.0mm (0.059” to

0.078”).

|

|

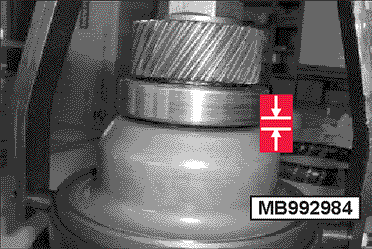

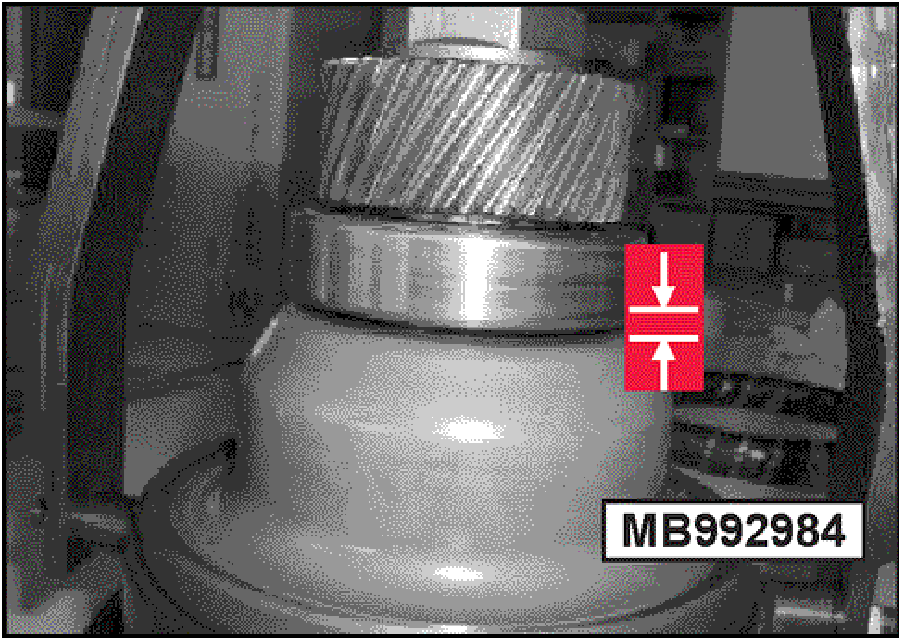

- Attach the compressor (MB992984) over secondary

pulley as shown in Step 39. Turn the forcing screw

clockwise. STOP turning when 3mm (.118”) is

measured at the location shown.

Overtightening the forcing screw will damage the

secondary return spring.

|

|

- Install the belt around the secondary pulley. Note the

directional arrow.

|

|

- Verify the arrow's direction matches the drawing

shown here.

|

|

- Hold the compressor close to the primary pulley while

another technician slides the belt into the primary

pulley groove.

|

|

- Once the belt is in position, install the secondary pulley

assembly into the side cover.

Like the primary pulley installation, shake the

assembly until the bearing is seated.

|

|

- The pulley flange should stand 12mm (.472”) above

the side cover when the bearing is fully seated.

Once the secondary pulley assembly is fully seated,

remove the compressor (MB992985).

Remove the protective convolute tubing and tie-wraps

from the belt.

|

|

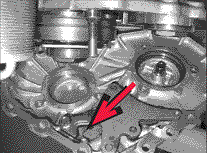

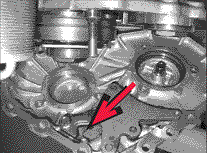

- Shift to PARK position. Align the park rod into position,

shown by the arrow, and lower the converter housing

onto the side cover.

|

|

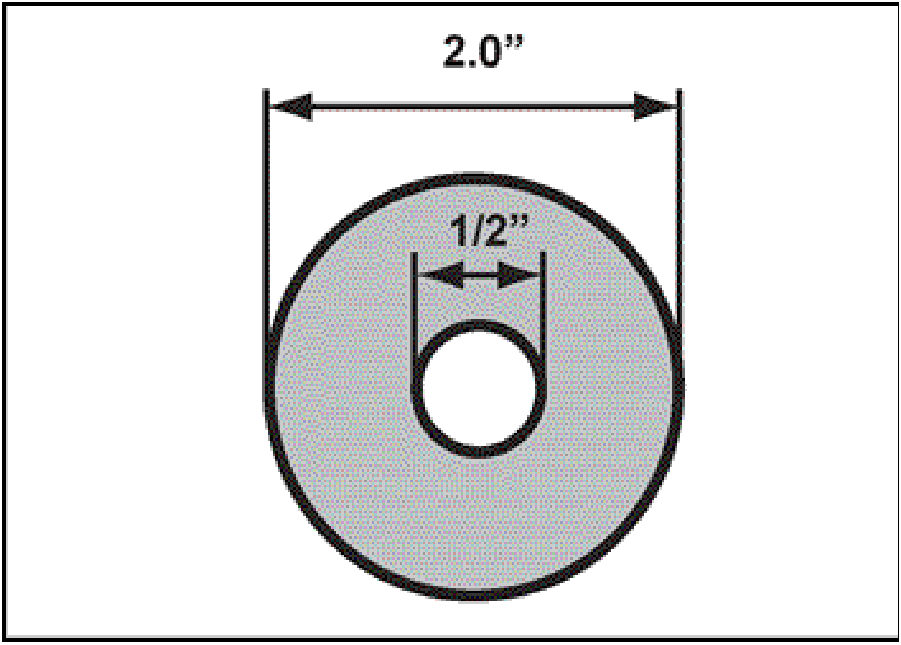

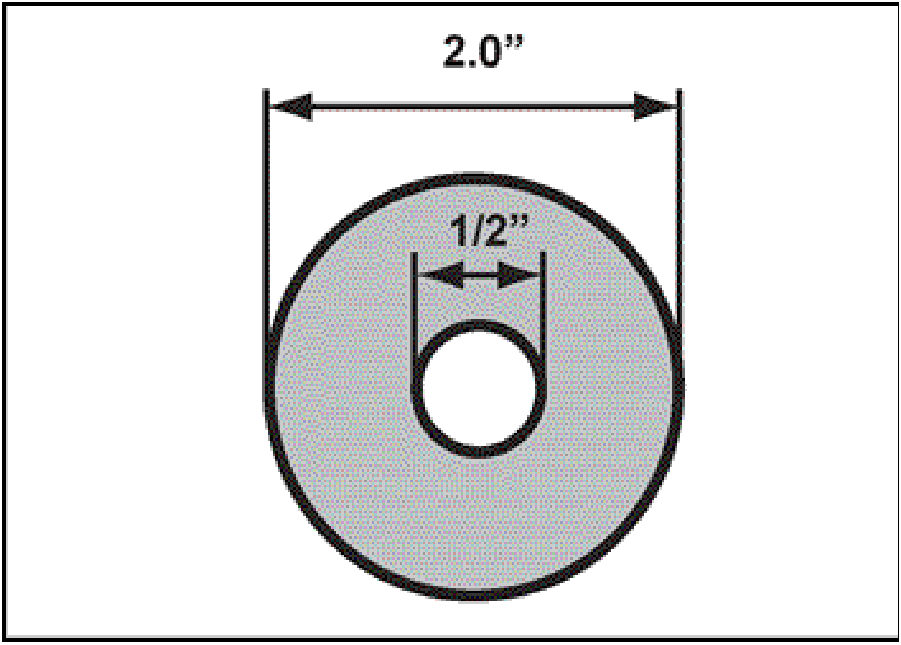

- To hold the secondary pulley assembly stationary in

the side cover as the transaxle is flipped over in step

83, use a 2” x 1/2 fender washer.

|

|

- Insert fender washer into the space between the

output gear and the bearing.

Use flat washers underneath the fender washer to

level it.

Secure with a bolt, finger tight only.

|

|

- Install two bolts to hold the transaxle case and side

cover together temporarily.

Turn the transaxle over and position on wood blocks

with the side cover facing up. Verify the output gear

clears the workbench.

Remove the two bolts and remove the side cover.

|

|

- Install the primary pulley sensor. Note the spring

installation direction as shown by the arrow.

|

|

- Install the manual shaft locating pin.

Remove the fuel hose installed in step 23

|

|

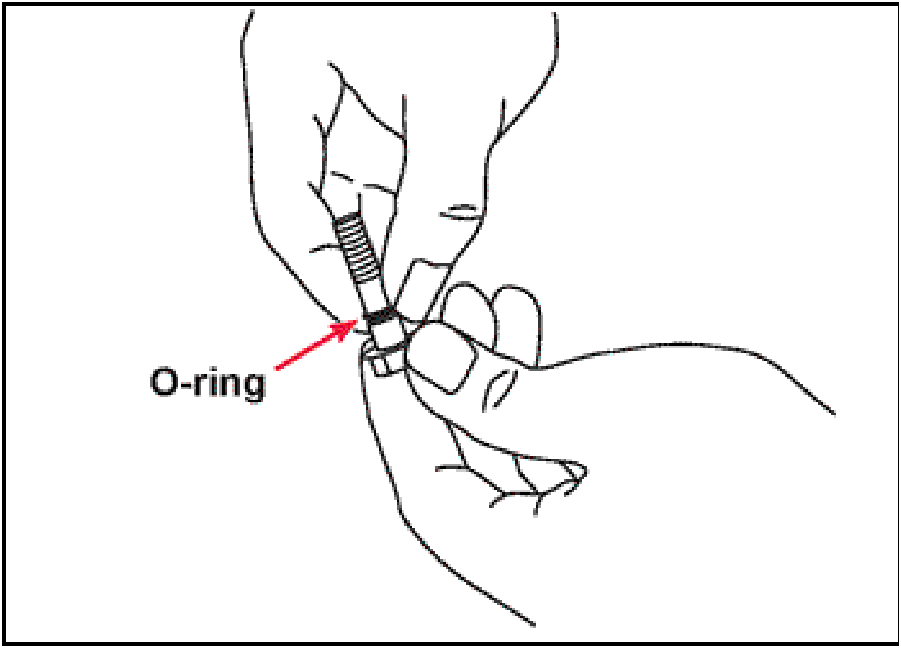

- Install new o-ring (270A078) as shown.

|

|

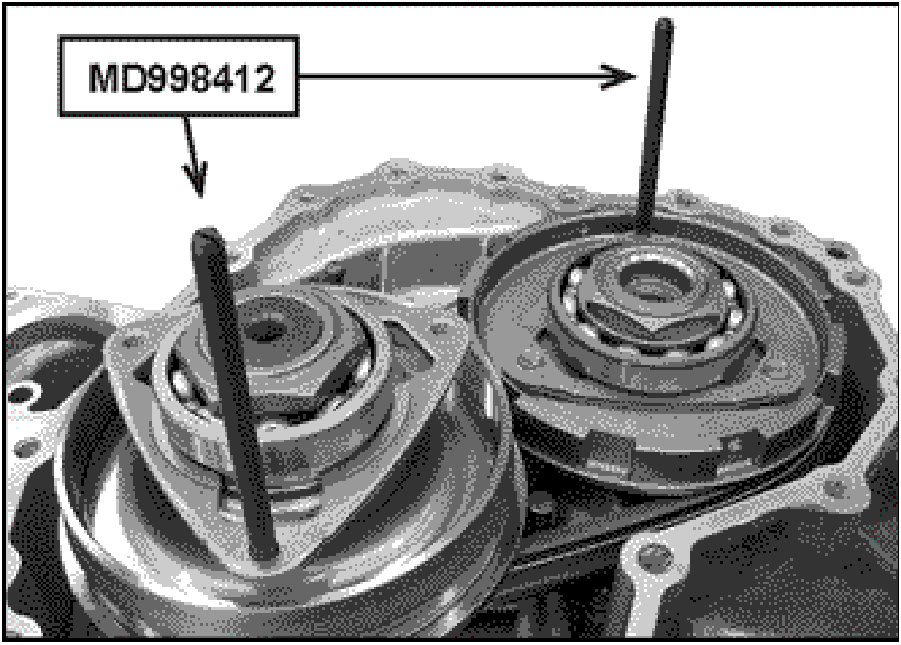

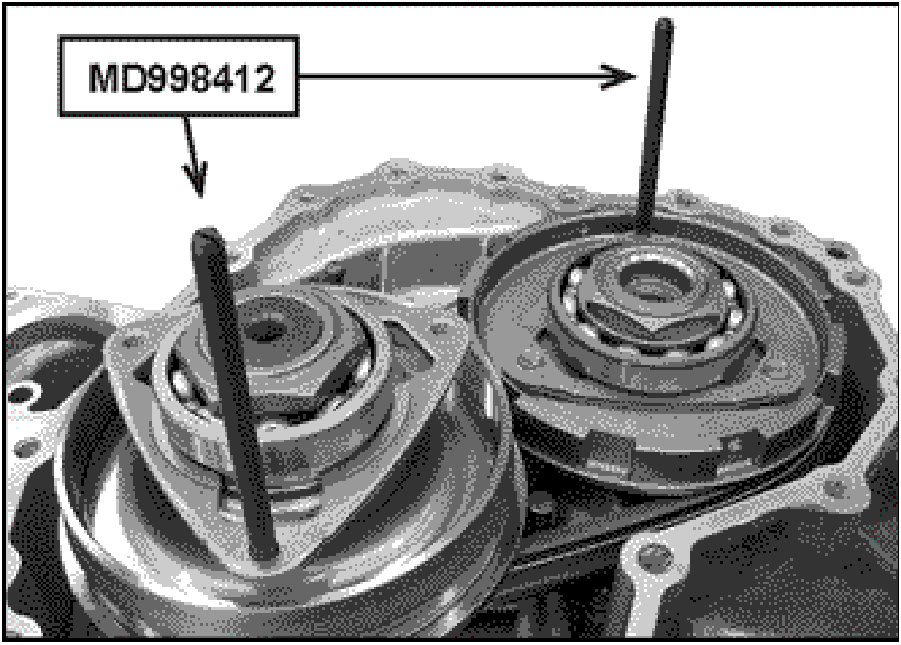

- To simplify aligning the bearing retainers with the side

cover bolt holes, loosely install guide pins (MD998412)

as shown.

NOTE: As the guide pin threads are different than

the retainer's threads, do not tighten the guide

pins.

|

|

- Apply a 1.5mm (0.060”) bead of Loctite 509 (or

equivalent) to the mating surface of the side cover.

|

|

- Install the secondary pulley side cover shim.

Because the side cover will be turned over in the next

step, use petroleum jelly to keep the shim in place.

|

|

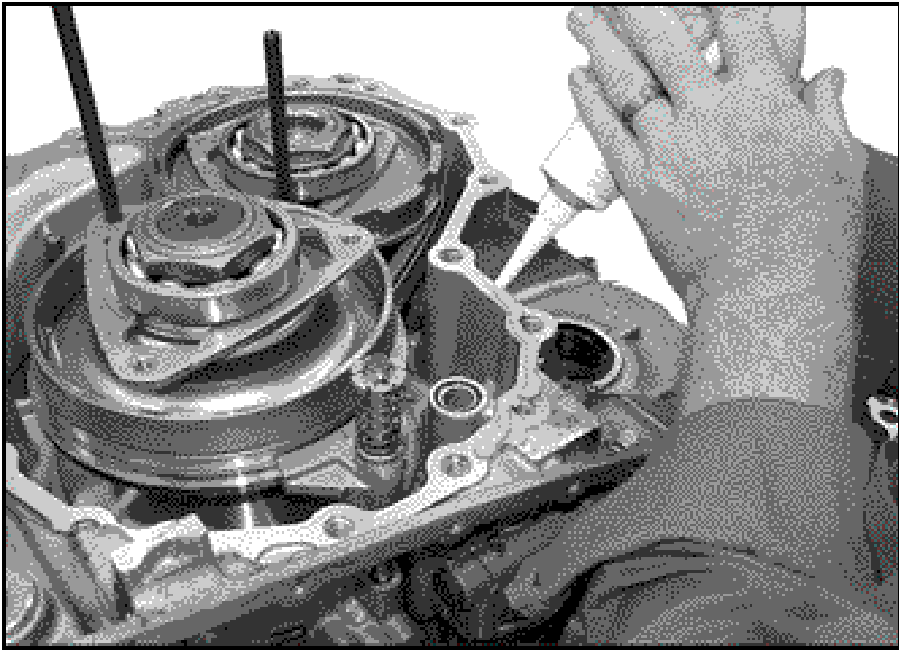

- Verify the shift linkage is in PARK. Lower the side cover

onto the transaxle case using the guide pins

(MD998412) to position the bearing retainers with their

bolt holes.

Take care to guide the park rod and speed sensor into

their locations in the side cover.

When properly aligned, seat the converter housing to

the side cover with a deadblow mallet.

|

|

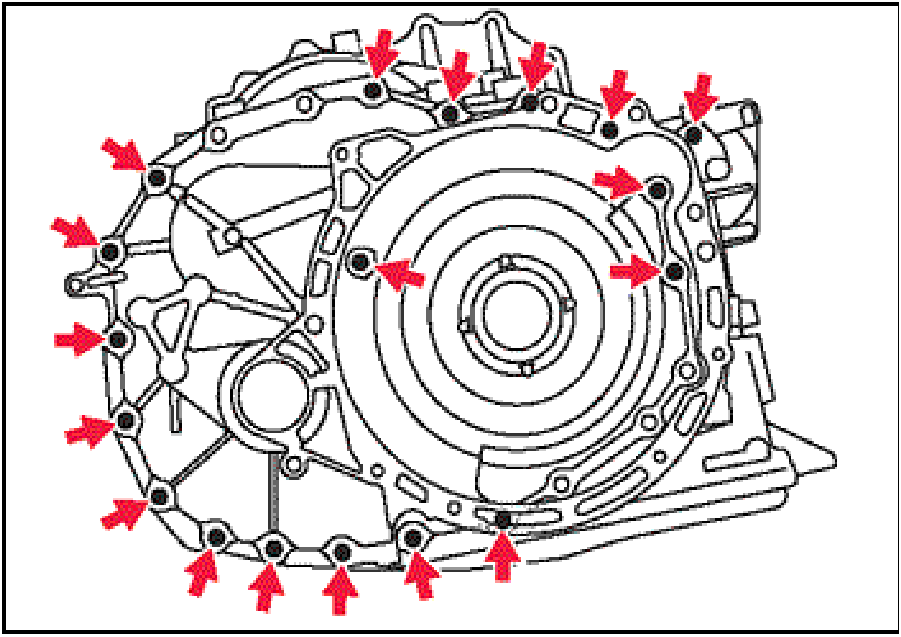

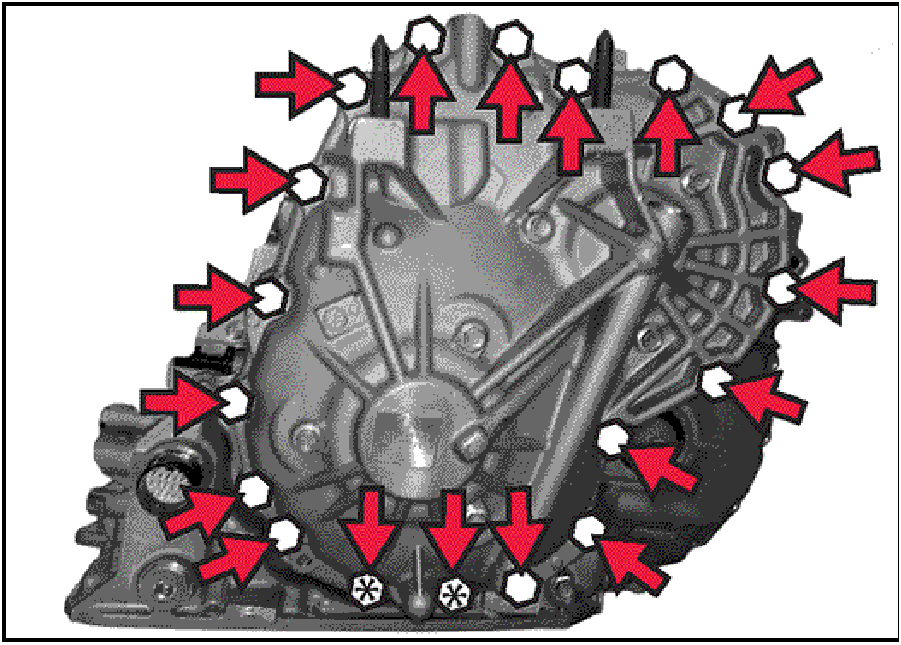

- Install the 19 case bolts and tighten to 45Nm (33

ft-lbs.) in the numbered sequence shown.

Make certain to install the two longer 35mm bolts at

locations 14 and 15.

|

|

- Install new o-rings (2791A012) on the six bearing

retainer bolts.

|

|

- After verifying the bearing retainers are properly

aligned, thread one bolt into each retainer to maintain

their positions.

Remove the guide pins.

Install the remaining bolts and tighten to 28Nm (21

ft-lbs.)

|

|

REASSEMBLY PROCEDURES

- Turn the transaxle over on the workbench as shown,

supporting the side cover with blocks.

Installed in step 81, remove the fender washer from

under the output gear.

|

|

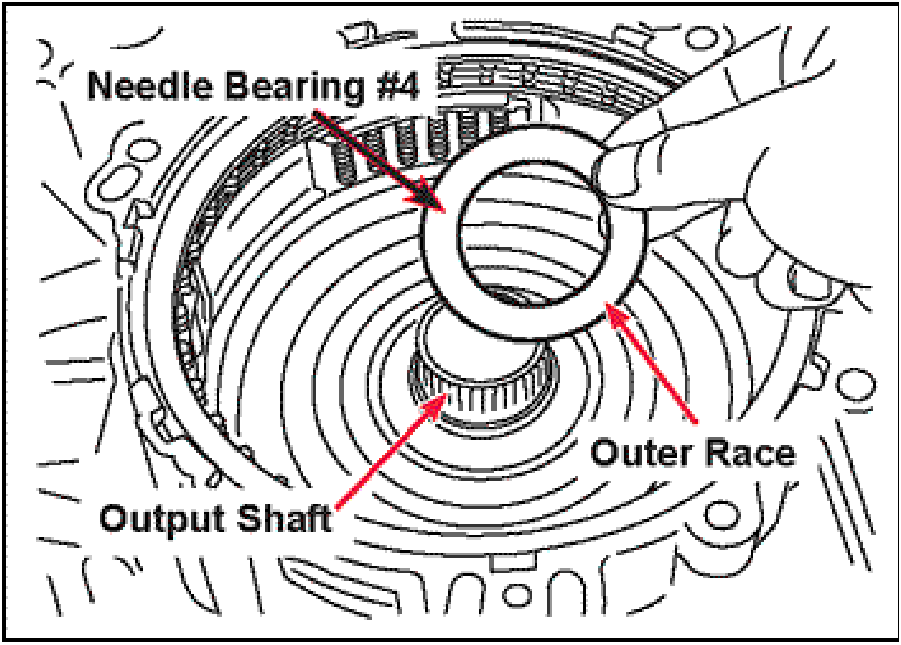

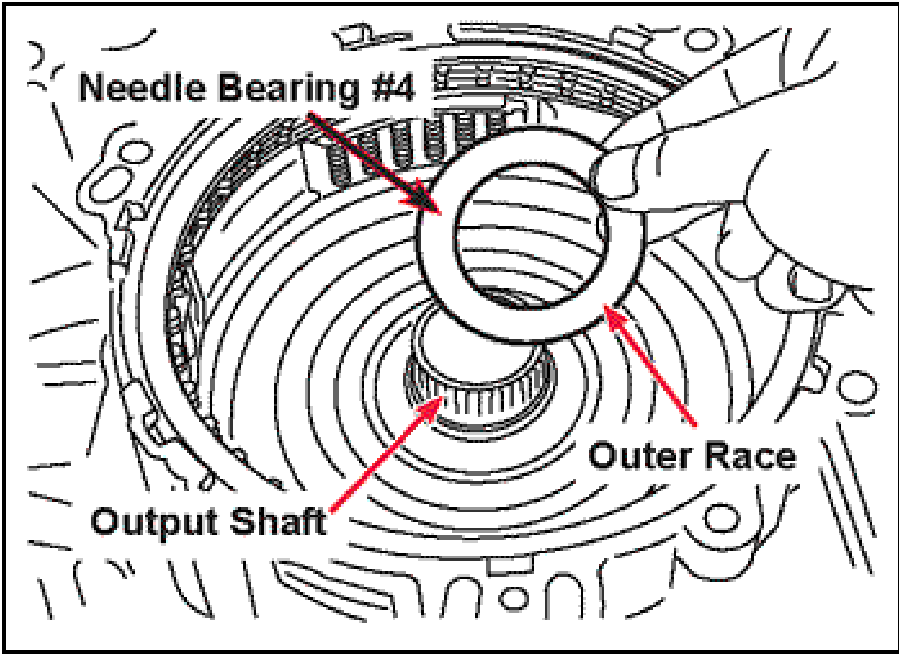

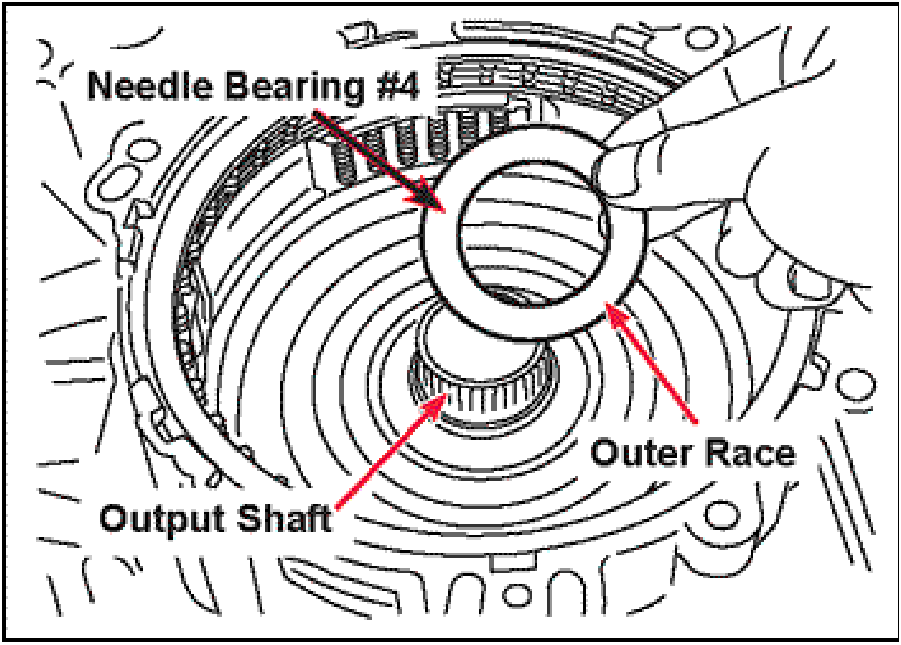

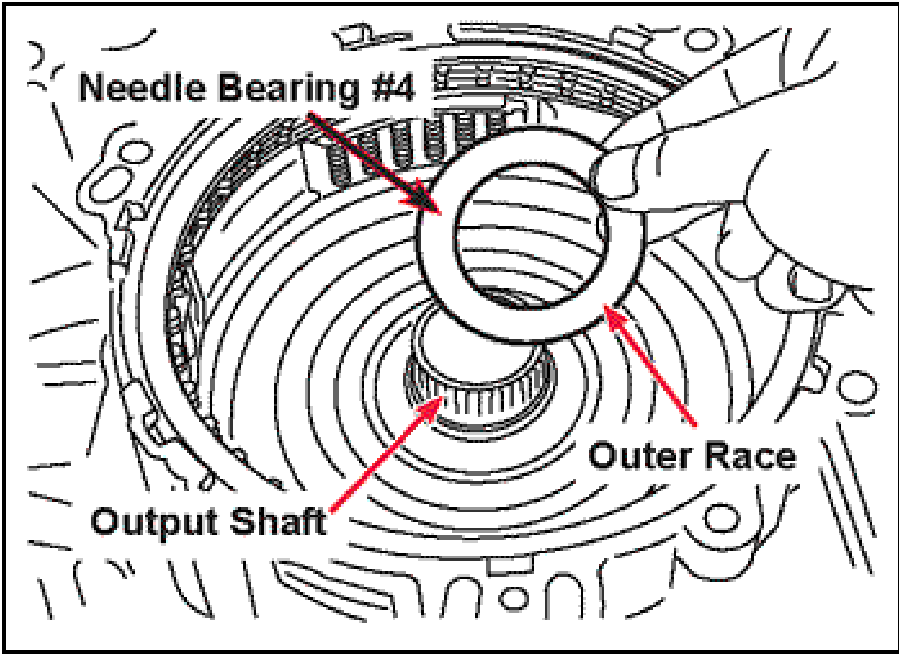

- Install the needle bearing assembly #4 located

between the output shaft and planet carrier with the

OUTER bearing race facing upward, over top of the

primary pulley drive splines.

|

|

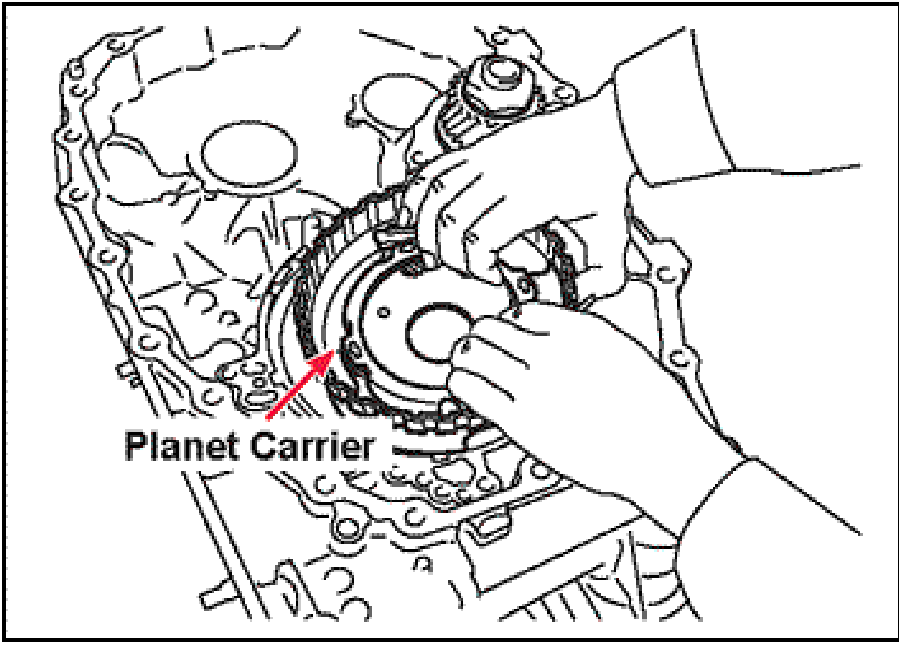

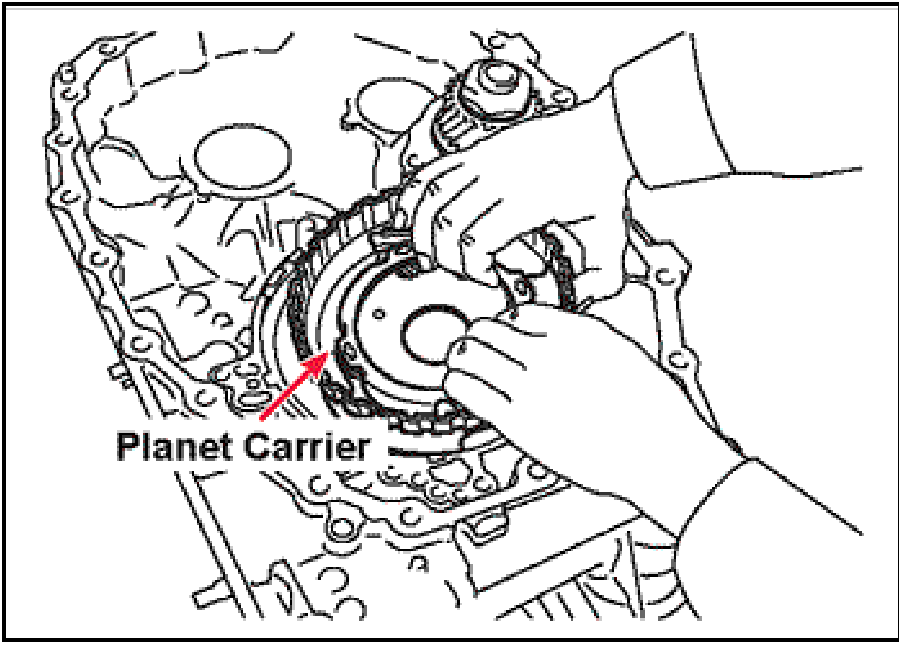

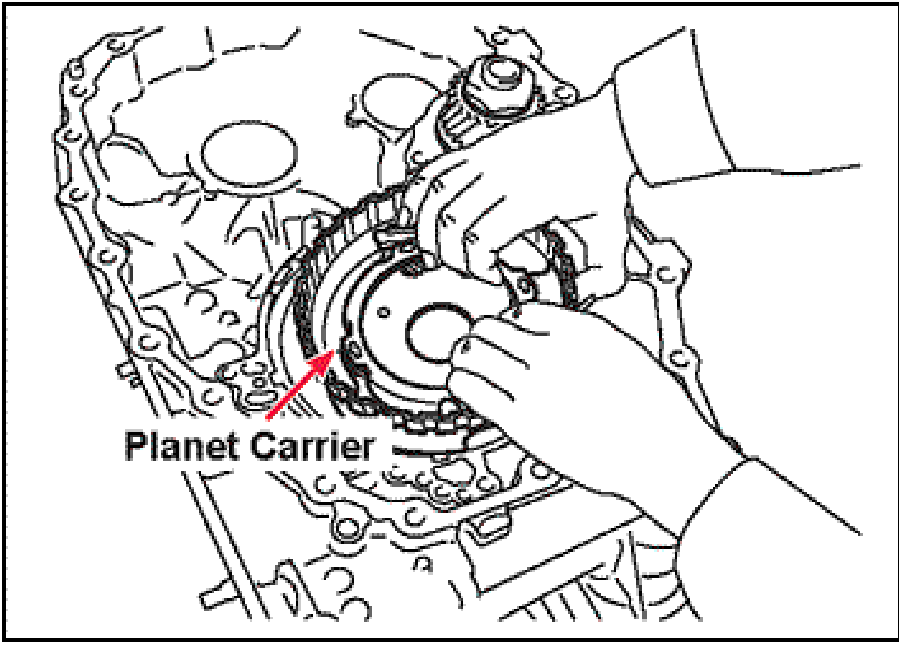

- Install the planet carrier into the transaxle case. Rotate

the planet carrier back and forth to make sure all clutch

friction discs are engaged with the hub. Continue until

the planet carrier is sitting down against the needle

thrust bearing.

|

|

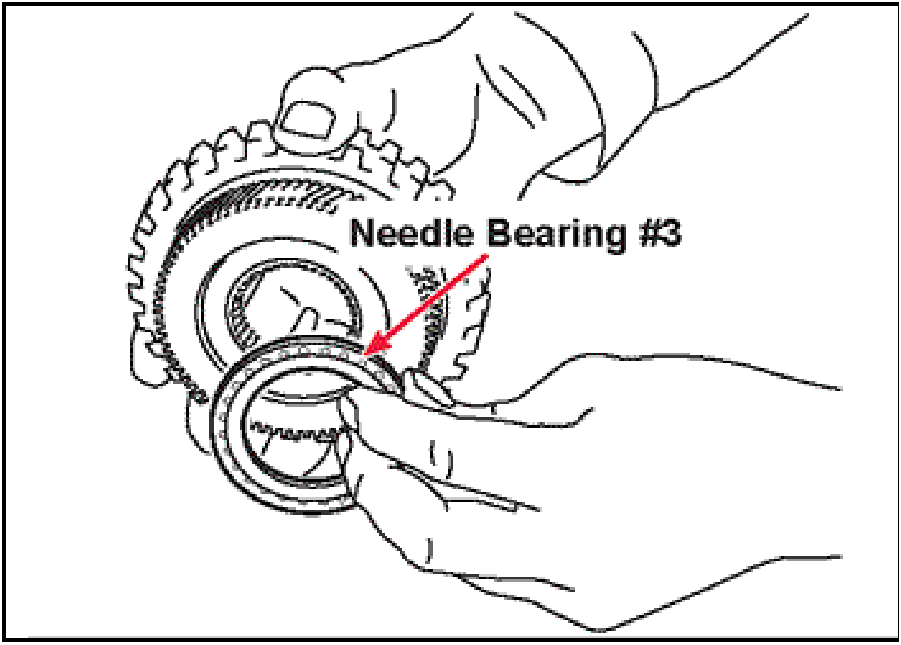

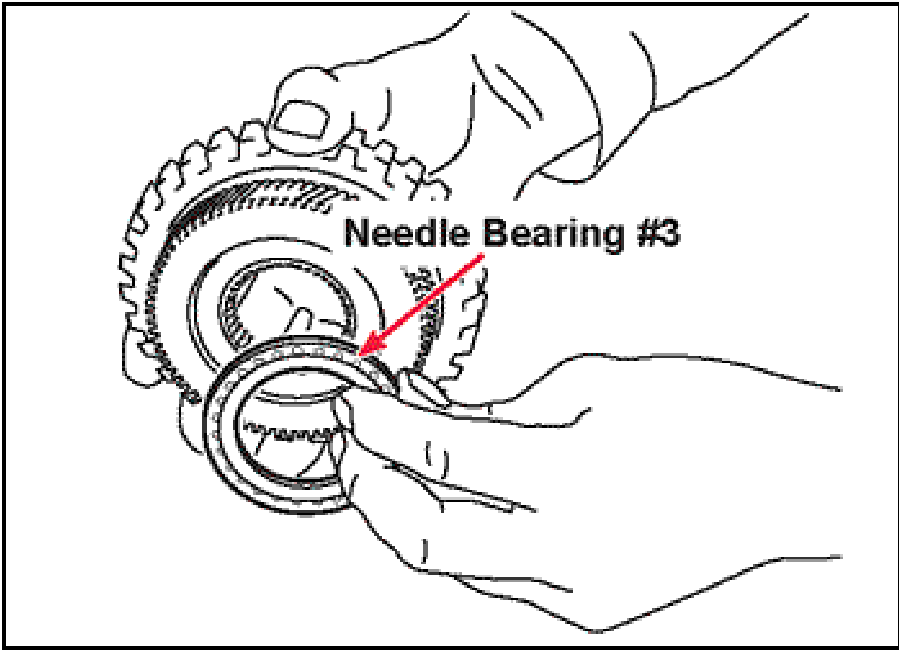

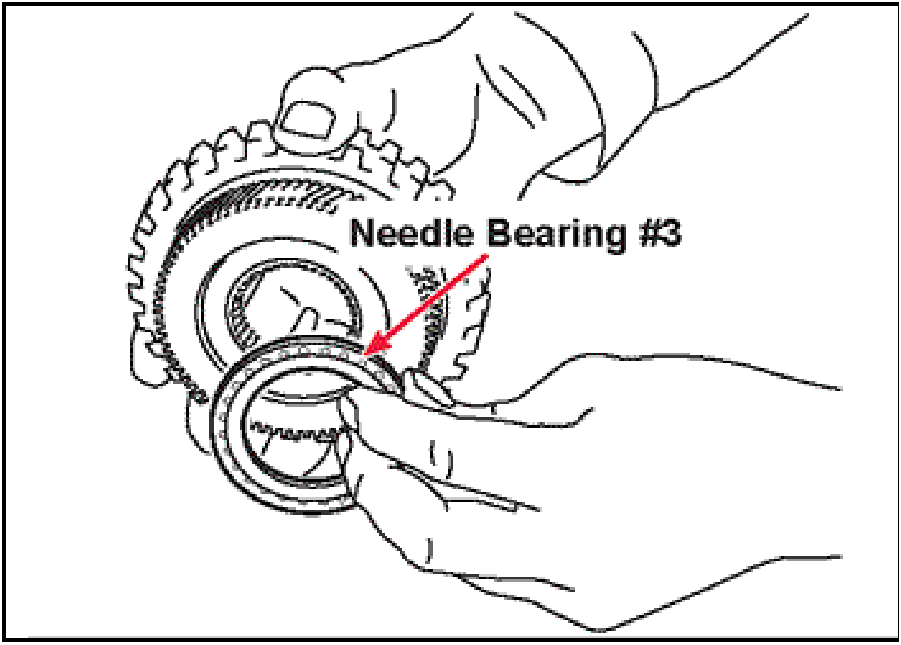

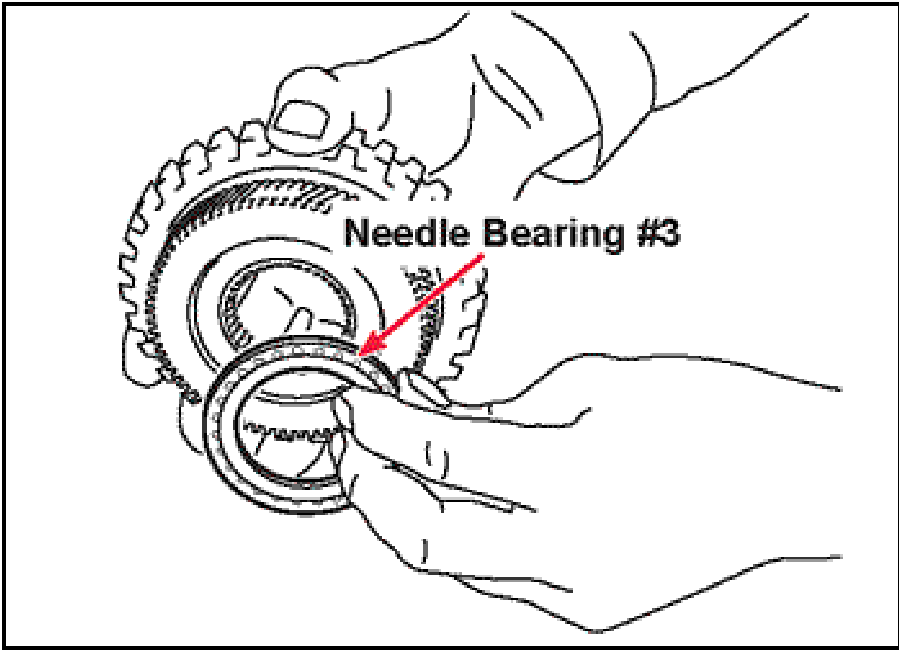

- Install the needle bearing assembly #3 located

between the planet carrier and the sun gear using

petroleum jelly to hold it onto the bottom side of the sun

gear with its OUTER race facing the sun gear.

|

|

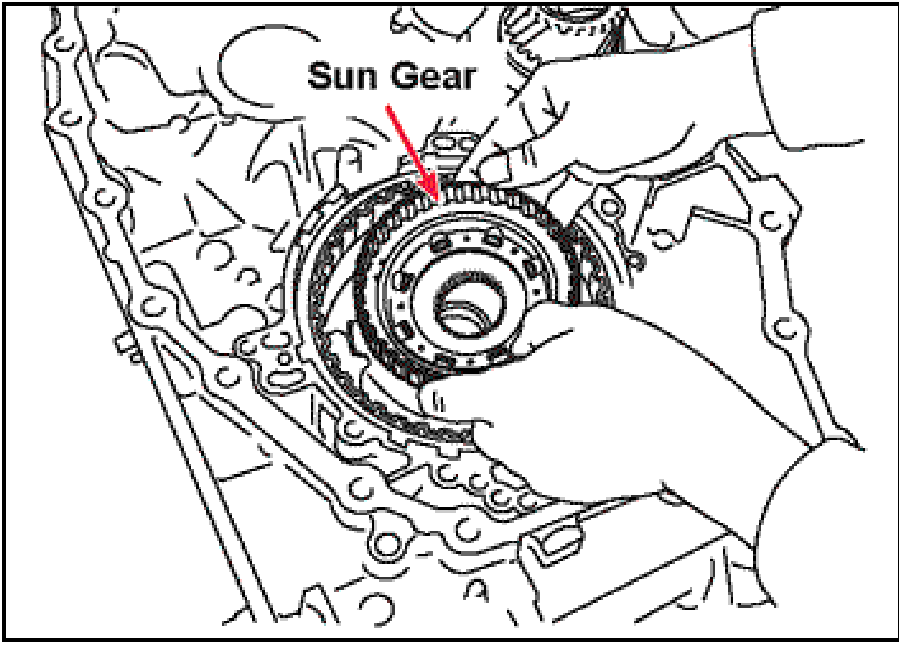

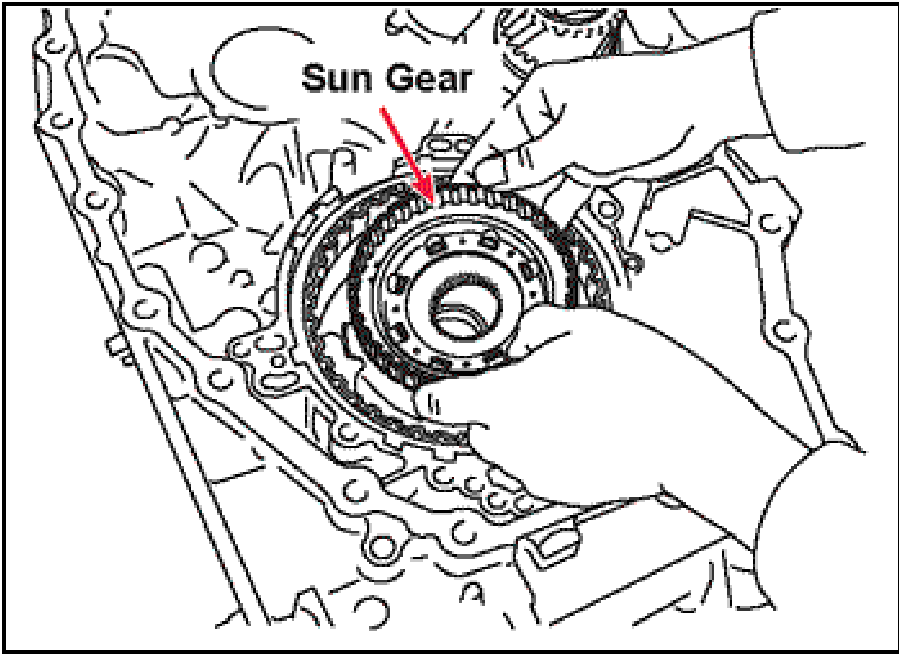

- Install the sun gear down into the planet carrier, rotate

it back and forth until it seats on top of the needle

bearing.

|

|

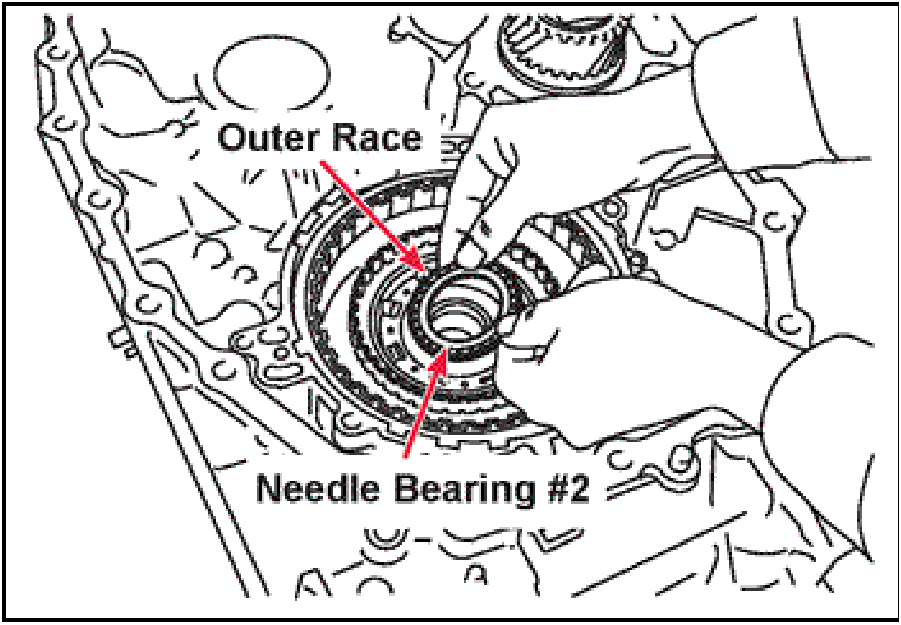

- Install the needle bearing assembly #2 between the

sun gear and forward clutch drum down into the top

side of the sun gear with the OUTER race facing

downward toward the sun gear.

|

|

- Apply a coating of petroleum jelly to the sealing rings

and bushing surface on the back of the input shaft.

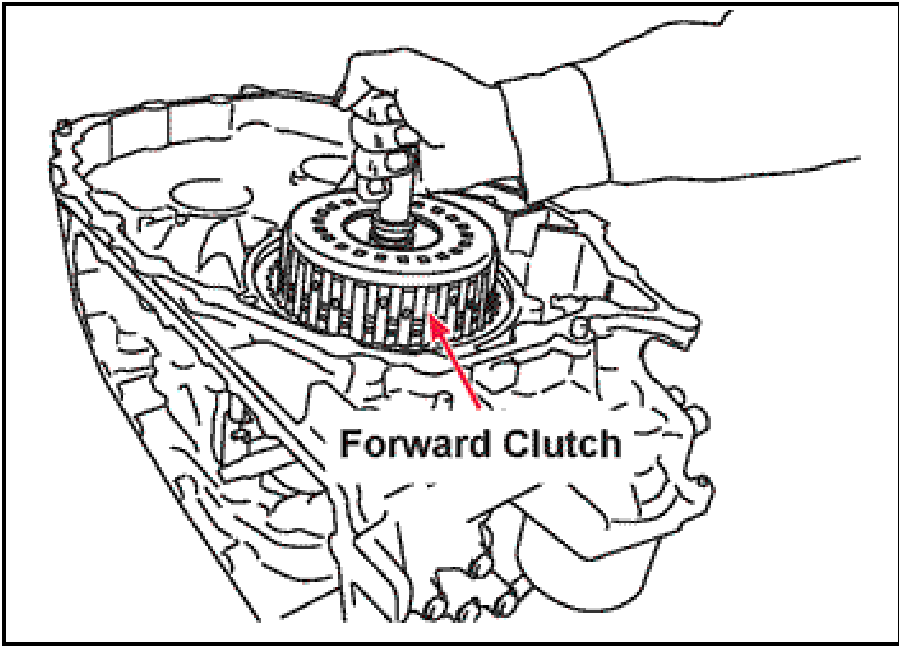

- Install the forward clutch assembly into the transaxle

case. Rotate the assembly back and forth until it is

drops down and is seated against the needle thrust

bearing.

|

|

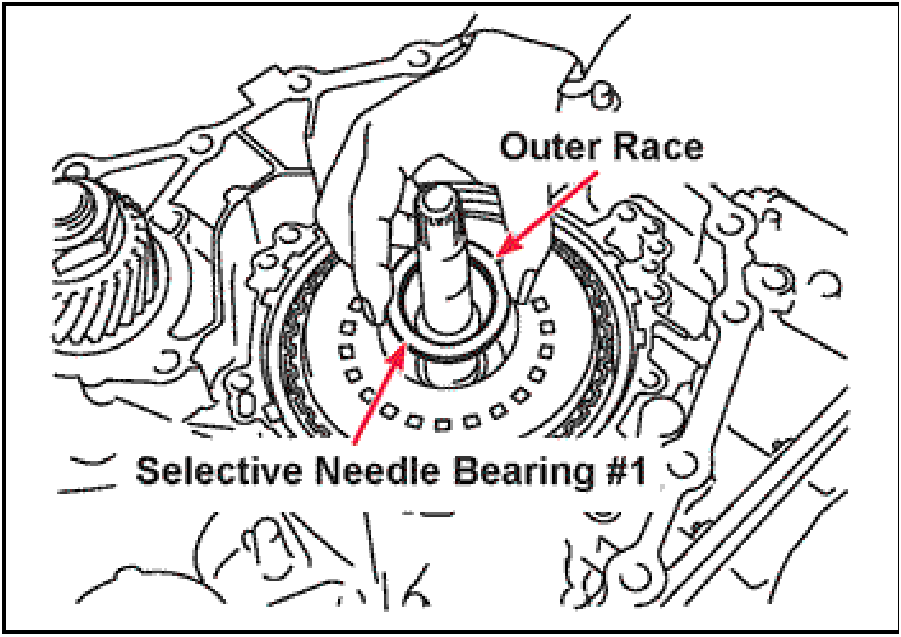

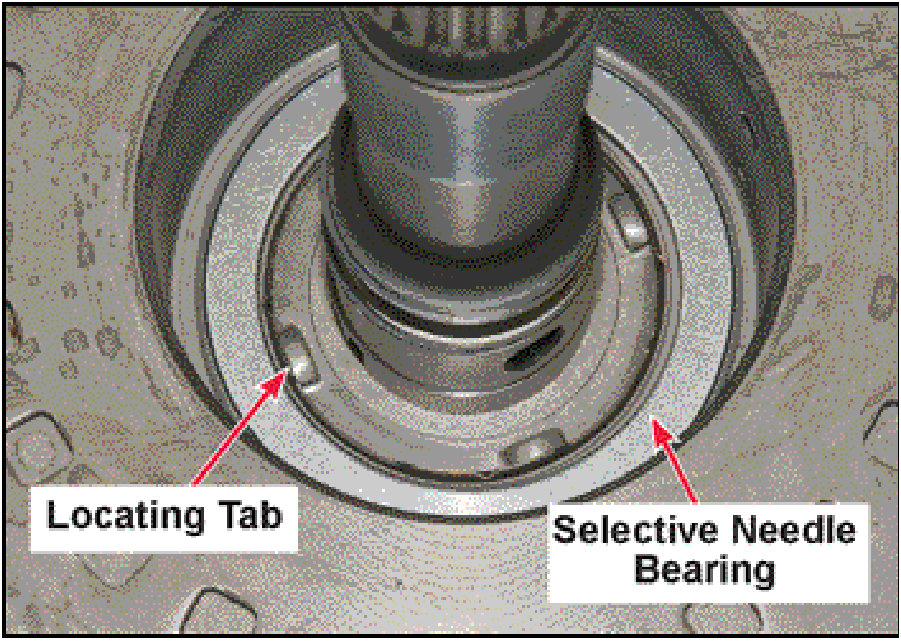

- Install the selective needle bearing assembly #1 down

into the forward clutch drum with the OUTER race

facing up.

|

|

- Verify the bearing is not sitting on top of any of the

locating tabs on the forward clutch drum.

|

|

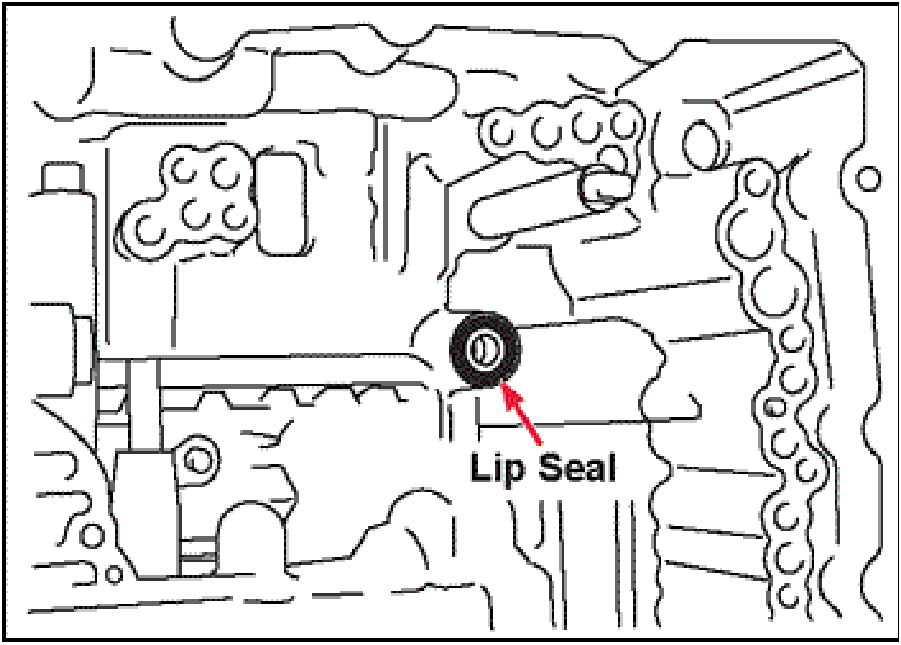

- Install a new oil pump metal clad lip seal (2791A014)

into the recess in the transaxle case using petroleum

jelly to hold it in position.

|

|

- Lower the oil pump into the transaxle case.

Install the three allen head oil pump mounting bolts

finger tight only at this time.

3 — Long Bolts — 70 mm (2.75 in.)

|

|

- Install a new o-ring (2791A012) onto the rear pump

mounting bolt. Then apply a coating of petroleum jelly

to the o-ring.

|

|

- Install the rear oil pump mounting bolt into the back

side of the transaxle case finger tight only at this time.

- Tighten the three allen head oil pump mounting bolts

to 19Nm (14 ft-lbs.)

Tighten the rear mounting bolt to 28Nm (21 ft-lbs.)

|

|

- Apply a coating of petroleum jelly to the new sealing

rings (2791A029) and bushing surfaces on the input

shaft and pump cover (stator support).

- Install the pump cover (stator support) and the five

mounting bolts into the locations indicated, finger tight

only at this time.

5 — Long Bolts — (30mm (1.18in.)

|

|

- Install the oil pump chain baffle in the location shown

using two mounting bolts.

Tighten all of the pump cover (stator support) and oil

pump chain baffle mounting bolts to 19Nm (14 ft-lbs.)

2 — Long Bolts — 30mm (1.18 in.)

|

|

- Install the differential baffle plate and the two

mounting bolts.

Tighten the bolts to 5.8Nm (52 in-lbs.)

2 — Short Bolts — 16mm (.630 in.)

|

|

- Install the oil pump bracket with the two bracket

mounting bolts.

Tighten the bolts to 25Nm (19 ft-lbs.)

2 — Short Bolts — 16mm (.630 in.)

|

|

- Install the three tang Thrust Washer on the pump

cover (stator support) making sure the three tangs on

the thrust washer are in the three holes in the pump

cover (stator support).

|

|

- Install the new driven sprocket ball bearing retaining

snap ring (2791A018) into the oil pump housing with

the opening in the snap ring aligned with the cutout in

the oil pump housing.

|

|

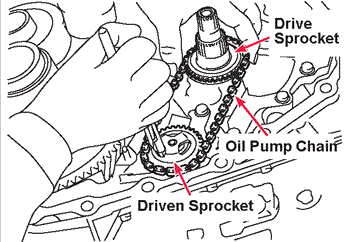

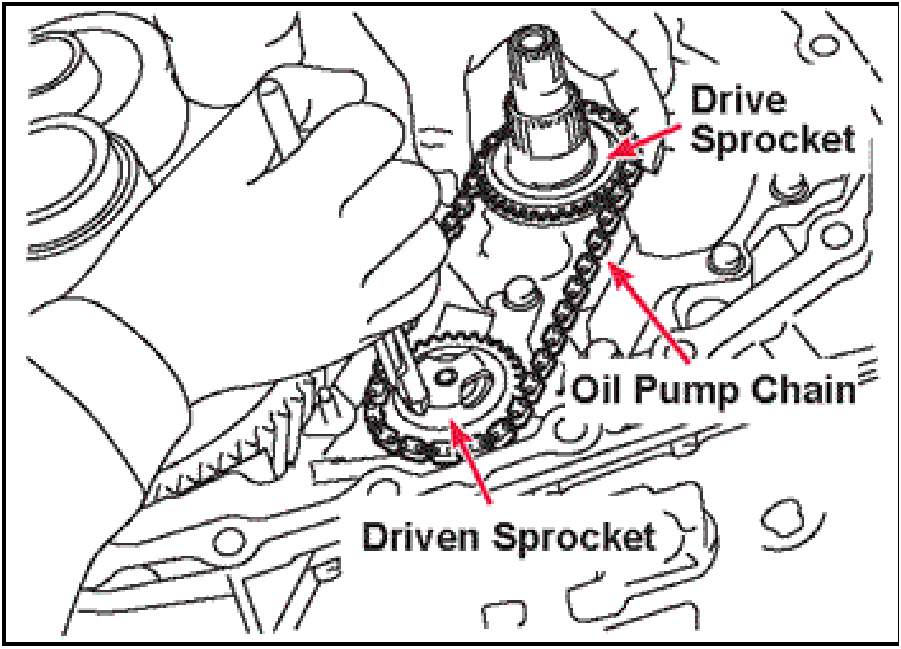

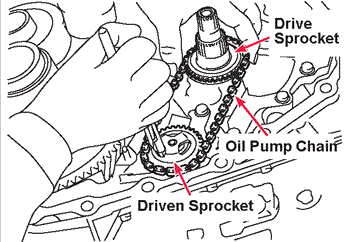

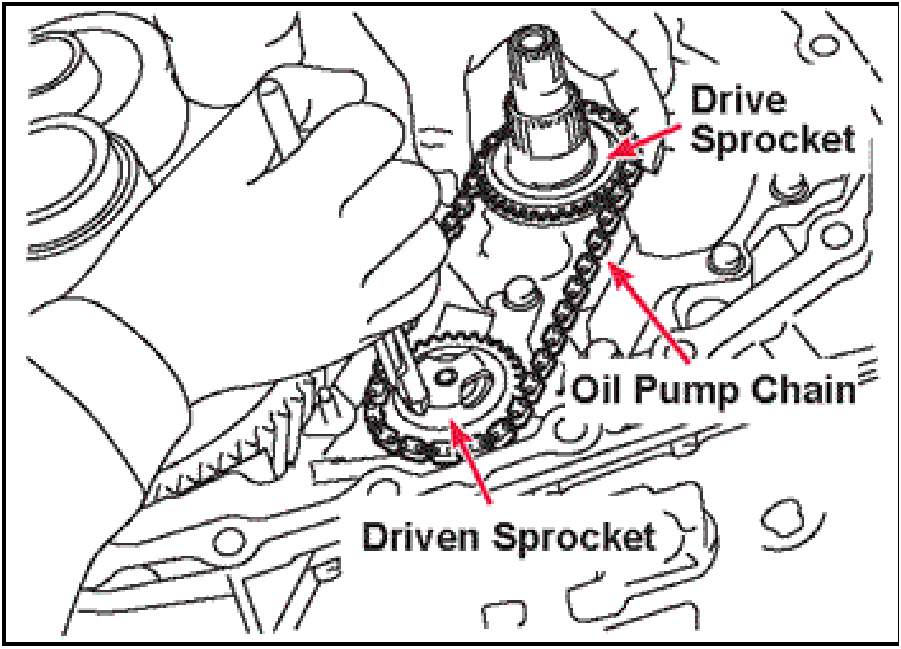

- Set the drive sprocket on the bench with the DEEP

RECESS FACING UP. Set the driven sprocket on the

bench with the ball bearing FACING DOWN.

Wrap the new chain (2791A024) around the sprockets

making sure the colored chain link is FACING UP.

|

|

- With the sprockets and chain as positioned in step

115, slide the assembly down over the shafts.

|

|

- Rotate the oil pump driven sprocket until one of the

three cutouts in the driven sprocket lines up with the

opening in the snap ring.

|

|

- Using a pair of external snap ring pliers, expand the

snap ring, at the same time slide both the drive and

driven sprockets downward along with the chain until

the drive sprocket fully seats on the three tang thrust

washer.

- While expanding the snap ring carefully move the oil

pump driven sprocket up and down until the snap ring

seats in the groove in the outer race of the ball

bearing.

|

|

- Install the oil pump driven sprocket baffle on the studs

in the transaxle case.

Install the two 10mm mounting nuts and tighten to

5.8Nm (52 in-lbs.).

|

|

- Install a new o-ring (2761A009) into the groove on the

input shaft.

|

|

- Install the differential assembly into the transaxle

case.

If bearings were replaced, verify proper shim

thickness using Service Manual selection

procedures.

|

|

- Install the reduction gear assembly into the transaxle

case.

If bearings were replaced, verify proper shim

thickness using Service Manual selection

procedures.

|

|

- Place a 1.5mm (0.60”) bead of Loctite 509 (or

equivalent) on the transaxle case mating surface.

Install the converter housing onto the transaxle case,

then install the five LONG converter housing

mounting bolts identified by the Dimple located in the

center of the hex head into the indicated locations.

5 — Long Bolts — (35mm (1.38in.)

|

|

- Install eighteen SHORT converter housing mounting

bolts into the indicated locations.

Tighten all bolts to 45Nm (33 ft-lbs.)

18 — Short Bolts — (30mm (1.18in.)

|

|

- Apply petroleum jelly to the new reverse brake clutch

passage lip seal (2800A031) and install it into the

transaxle case.

|

|

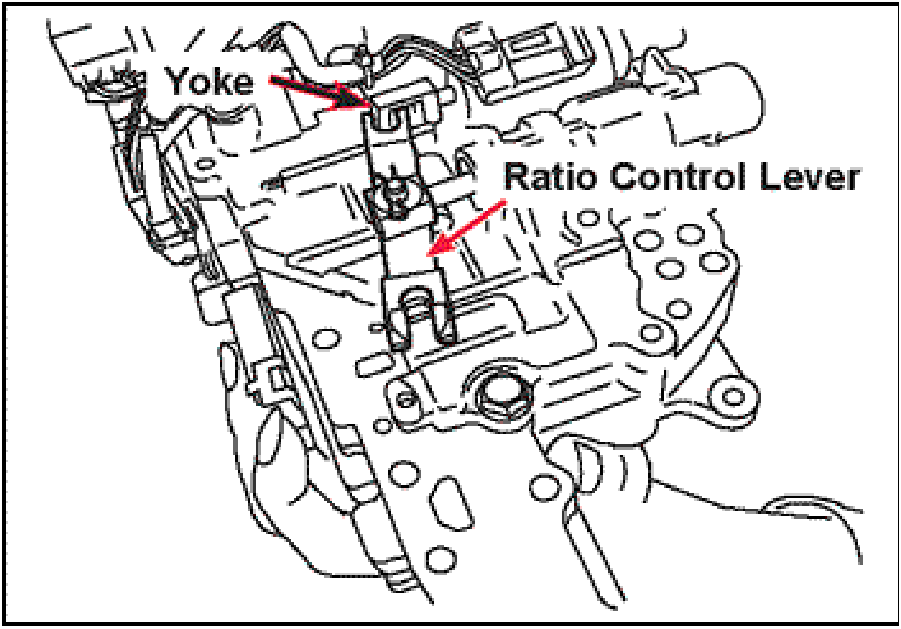

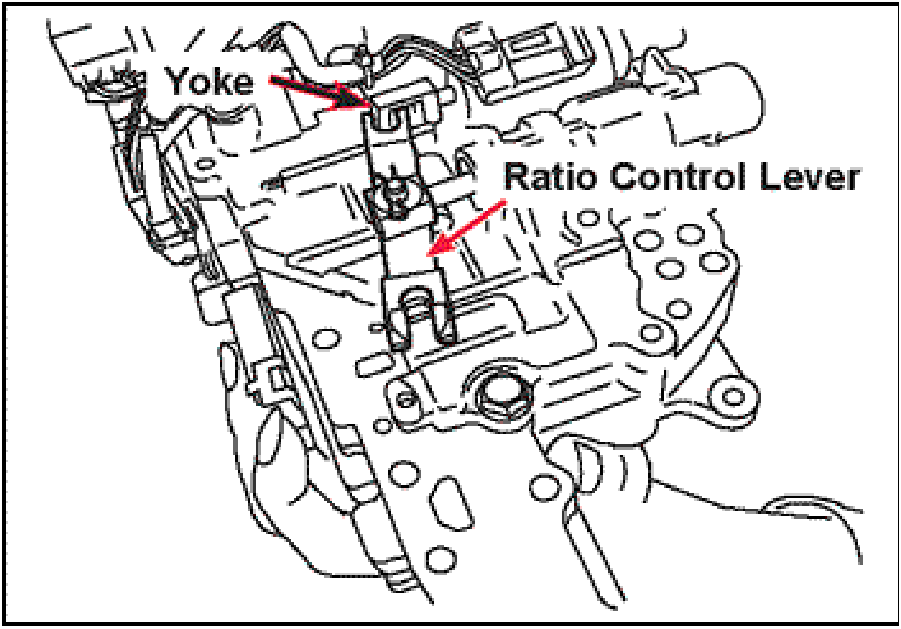

NOTE: If the ratio control valve and spring were to

fall out of the valve body during the disassembly

process, this drawing indicates the correct location

of the spring.

|

|

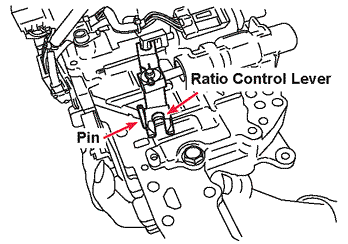

- Position the ratio control valve lever so that it is

engaged over the yoke on the stepper motor. Push

the ratio control lever inward toward the valve body.

|

|

- While holding the ratio control lever in, insert the long

pin used in disassembly into the hole in the valve body.

|

|

- Verify the ratio control valve lever is securely

positioned behind the pin.

|

|

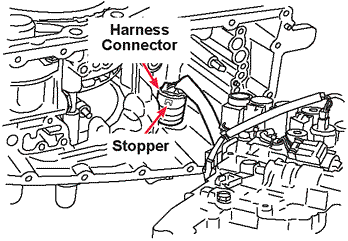

- Install the harness connector into the transaxle case.

Push the harness connector toward the outside of the

transaxle case until the stopper is fully seated.

Be careful not to damage the 0-ring.

|

|

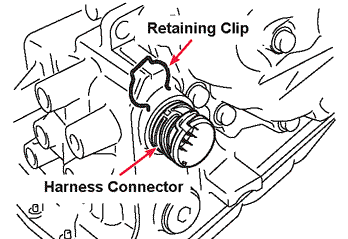

- Install the retaining clip into the groove on the harness

connector.

|

|

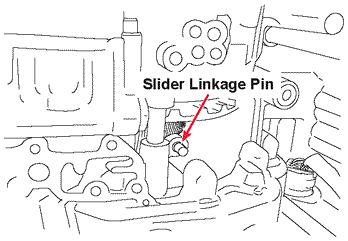

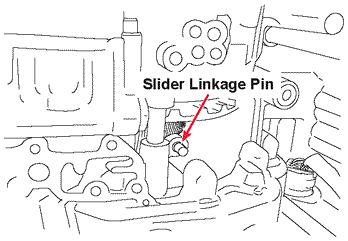

- Locate the slider linkage pin. When installing the

valve body, the cutout in the ratio control lever must

engage with the slider linkage pin.

|

|

- While holding the end of the long pin, install the valve

body into the case making sure the ratio control valve

linkage engages the pin on the slider linkage and that

the valve body seats on to the dowel pins mounted in

the transaxle case.

|

|

- While holding the valve body against the transaxle

case surface, install the one SHORT valve body

mounting bolt into the location indicated and tighten it

just enough to keep the valve body on the dowel pins

1 — Short Bolt — 44 mm (1.73 in.)

|

|

- Install the remaining ten LONG valve body mounting

bolts into the locations indicated finger tight only at this

time.

10 — Long Bolts — 54 mm (2.13 in.)

Remove the long pin (installed in step 128) from the

valve body.

Tighten all valve body bolts to 7.9Nm (70 in-lbs.).

|

|

- Install the oil strainer mounting bracket onto the valve

body with its mounting bolts.

Tighten the two bolts to 7.9Nm (70 in-lbs.).

2 — Long Bolts — 25 mm (.984 in.)

|

|

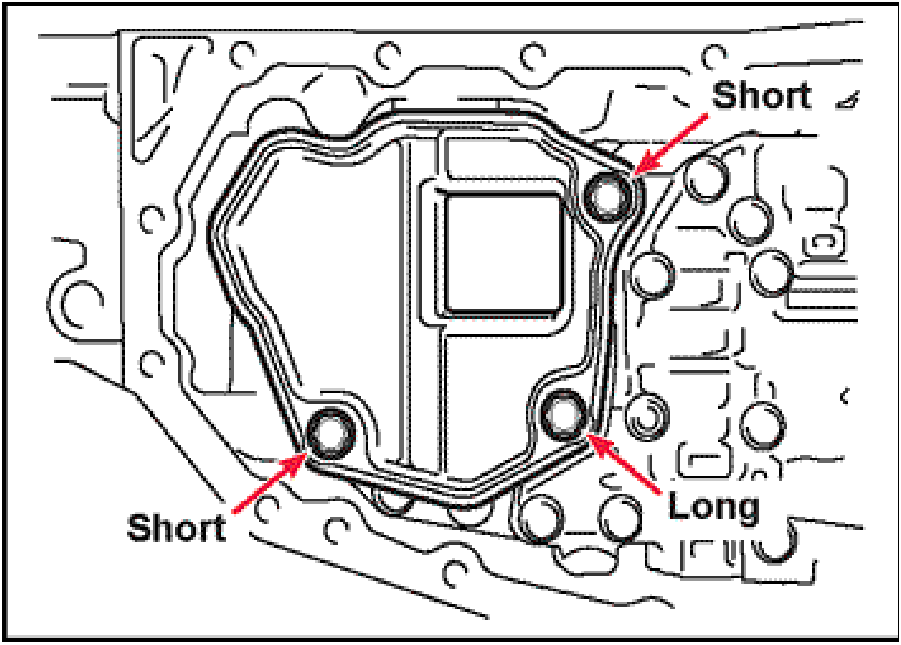

- Verify the new o-ring is attached on the new oil

strainer (2824A007). Coat the new o-ring with

petroleum jelly, then install the new oil strainer onto

the valve body.

Install the one LONG and two SHORT oil strainer

mounting bolts into the locations indicated. Tighten oil

strainer mounting bolts to 7.9Nm (70 in-lbs.).

1 — Long Bolt — 44 mm (1.73 in.)

2 — Short Bolts — 12 mm (.470 in.)

|

|

- Verify the manual control shaft sleeve is flush with the

valve body surface.

|

|

- Install the manual control valve lever onto the manual

control shaft, while at the same time, position the

manual control valve to ensure the lever engages the

cutout on the manual control valve.

Install the lock washer and nut.

Tighten the nut to 21 Nm (16 ft-lbs.).

|

|

- Install the new pan gasket (2705A015) and oil pan

onto the two dowel pins on the transaxle case. Install

the eighteen pan bolts and tighten to 7.9Nm (70

in-lbs.).

18 — Short Bolts — 15 mm (.590 in.)

Install a new drain plug gasket (2705A013). Install the

drain plug into the pan.

|

|

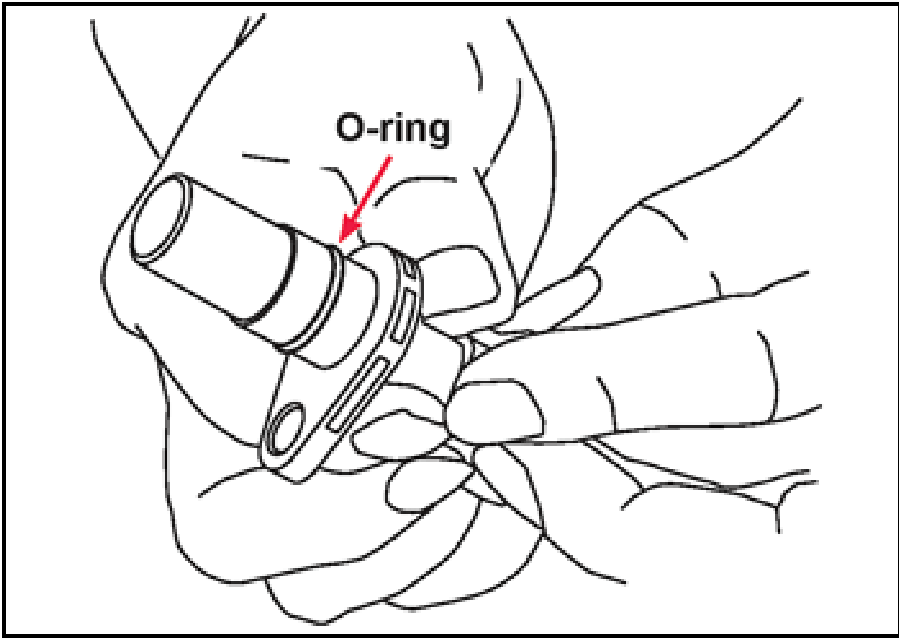

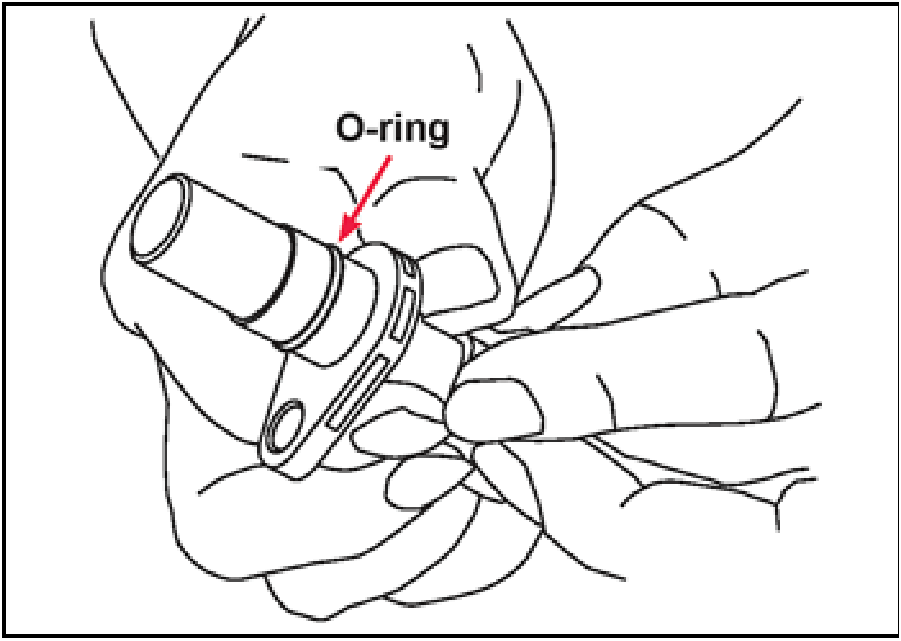

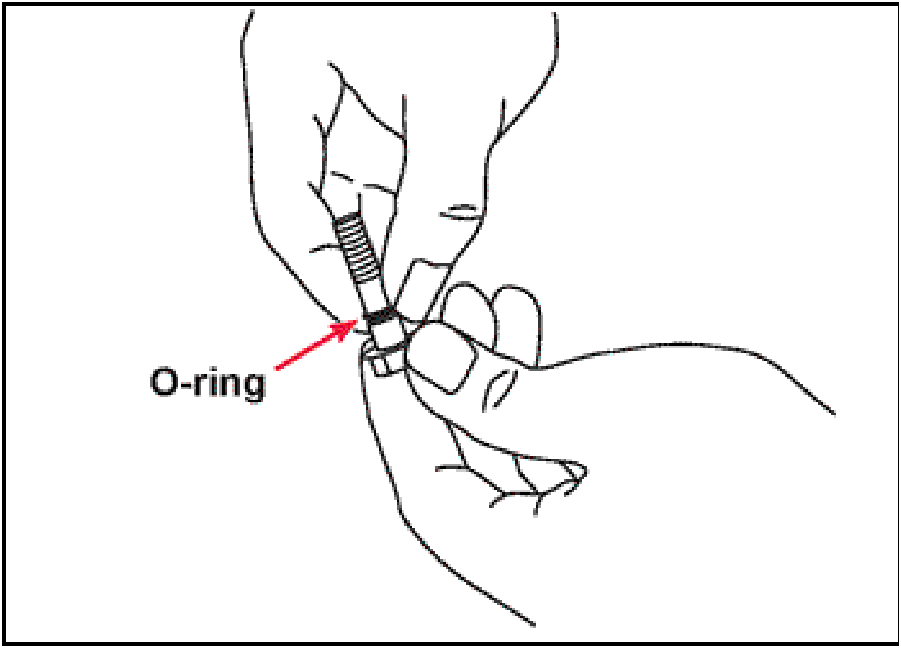

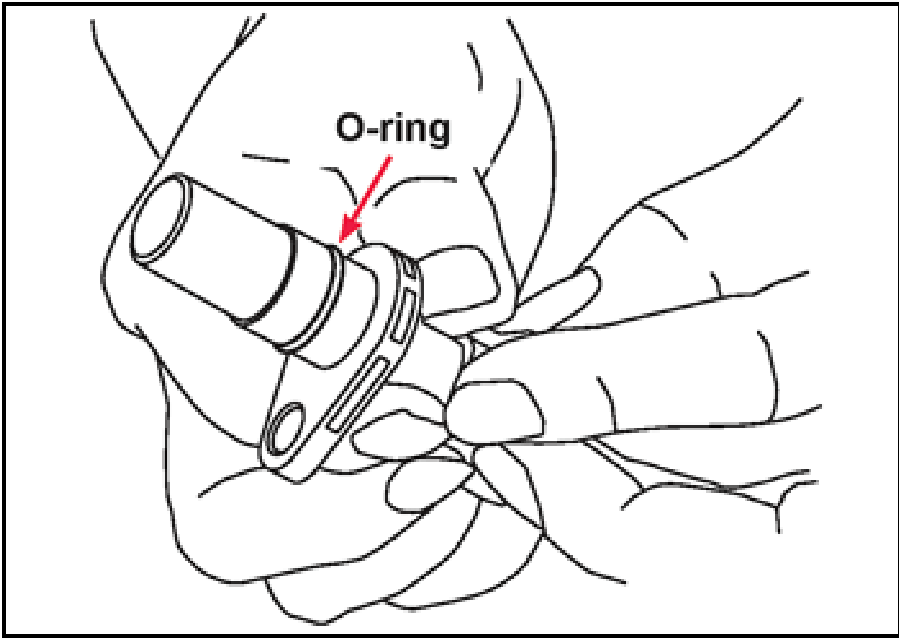

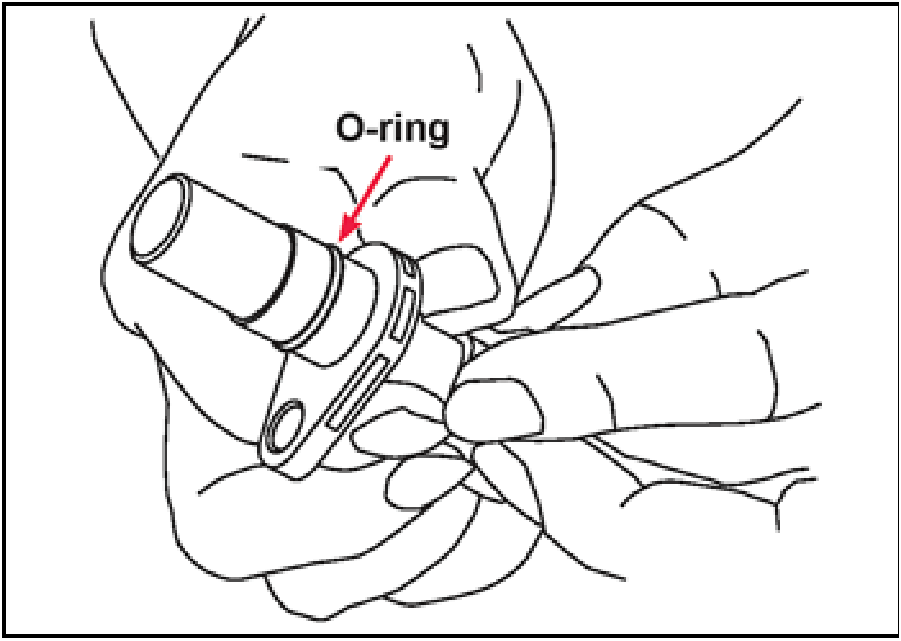

- Install a new o-ring (8652A017) into the groove on the

secondary pulley speed sensor. Coat the o-ring with

petroleum jelly.

|

|

- Using a stick magnet, hold the shim into position under

the secondary pulley speed sensor mounting tab

while installing the speed sensor into the transaxle

case.

|

|

- Install the secondary pulley speed sensor mounting

bolt.

Tighten the bolt to 5.8Nm (52 in-lbs.).

1 — Short Bolt — 17 mm (.669 in.)

|

|

- Install a new o-ring (8652A017) into the groove on the

primary pulley speed sensor. Coat the o-ring with

petroleum jelly.

|

|

- Install the primary pulley speed sensor

Tighten the bolt to 5.8NM (52 in-lbs).

1 — Short Bolt — 17 mm (.669 in.)

|

|

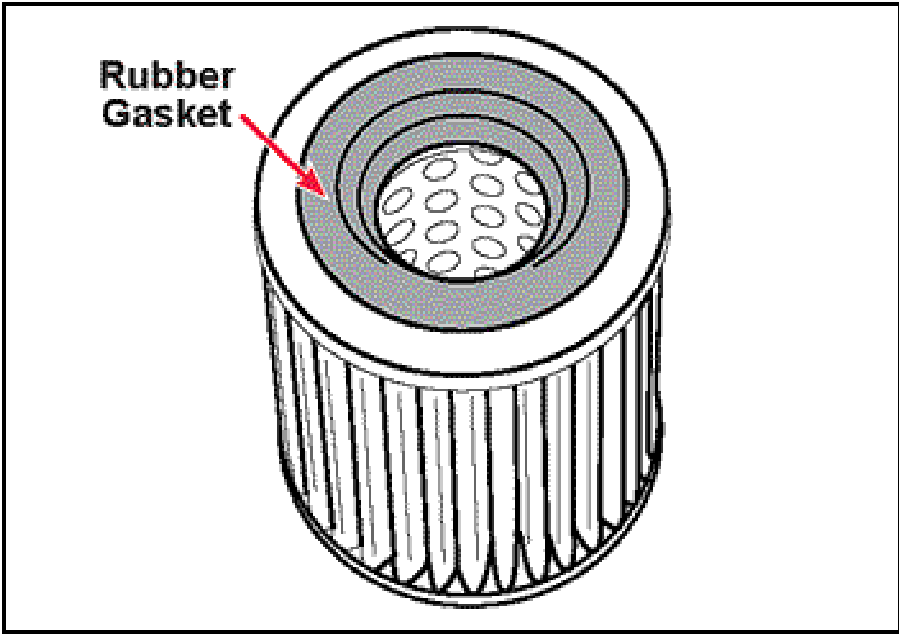

- Verify the rubber gasket is installed on the new ATF

warmer / cooler filter (2824A006). Apply a coating of

petroleum jelly to the seal.

|

|

- Install the new ATF warmer / cooler filter into the

opening in the transaxle case as shown.

|

|

- Install a new rubber o-ring (2920A096) in the groove

on the new ATF warmer / cooler. Coat the o-ring with

petroleum jelly.

|

|

- Install the ATF warmer / cooler onto the case with the

four mounting bolts.

Tighten the bolts to 4.1 Nm (37 in-lbs.).

4 — Short Bolts — 24 mm (.944 in.)

|

|

- Apply a coating of petroleum jelly to the input shaft

o-ring then install the torque converter into the

transaxle case. While lightly pushing inward rotate the

converter back and forth until it is fully seated.

TRANSAXLE FLUSHING

- Once the CVT has been reinstalled in the vehicle,

follow these steps to flush any remaining debris from

transaxle. Do not use an automatic transmission

flushing machine.

|

|

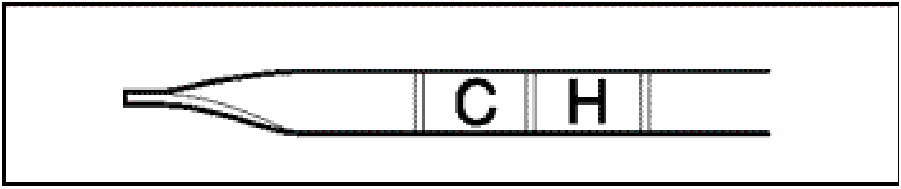

- With the engine running, add sufficient

DIA-QUEEN CVTF-J4 transmission fluid to raise

the level above the COLD range on the dipstick.

- Drive the vehicle until the fluid temperature has

reached at least 158°F. (Monitor Data List Item

#5.)

- Drain the fluid from the transaxle.

- Refill the transaxle with CVTF-J4 fluid.

- Drive the vehicle for 5 minutes.

- Drain the fluid from the transaxle.

- Refill the transaxle with CVTF-J4 fluid

|

This bulletin is supplied as technical information only and is not an authorization to repair. If an affected

vehicle is reported with the described condition, diagnose the condition, repair as described in this bulletin

and submit a normal warranty claim using the following information.