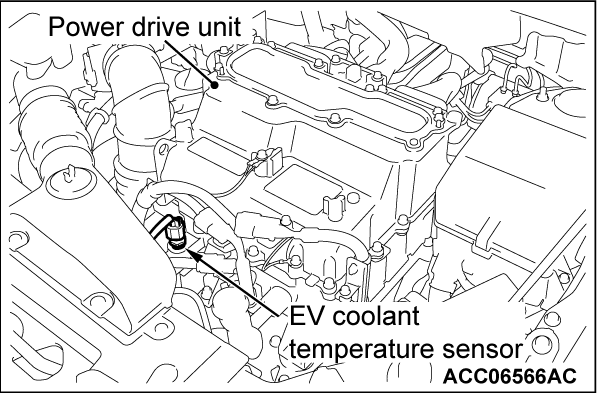

EV COOLANT TEMPERATURE SENSOR CHECK

1. EV coolant temperature sensor connector is separated.

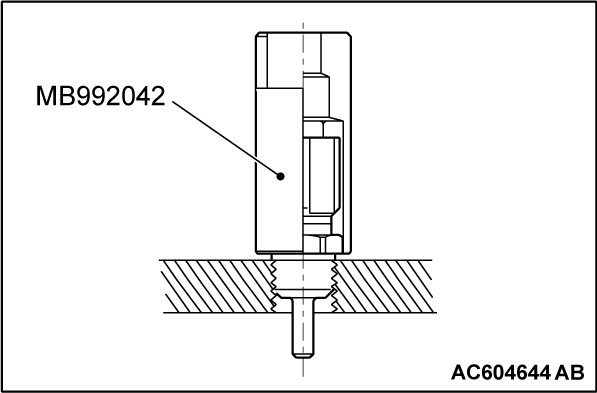

2. Special tool "Water temperature sensor wrench (MB992042)" It is used and EV coolant temperature sensor is removed.

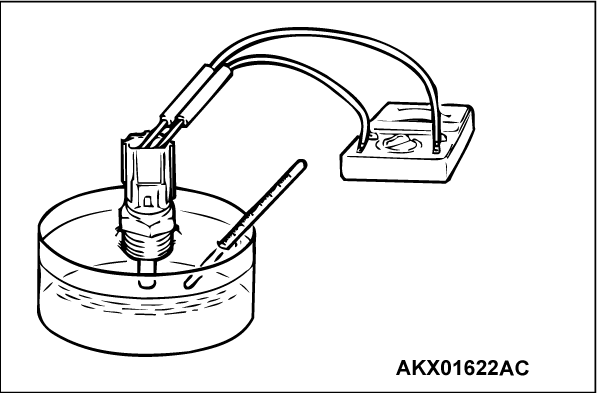

3. While immersing the temperature sensing part of the EV coolant temperature sensor into hot water, measure the resistance between connector terminals.

Standard value:

- 14 to 17 kΩ [-20°C (-4°F) ]

- 5.1 to 6.5 kΩ [0°C (32°F) ]

- 2.1 to 2.7 kΩ [20°C (68°F) ]

- 0.9 to 1.3 kΩ [40°C (104°F) ]

- 0.48 to 0.68 kΩ [60°C (140°F) ]

- 0.26 to 0.36 kΩ [80°C (176°F) ]

4. When having deviated from the standard value, EV coolant temperature sensor is exchanged.

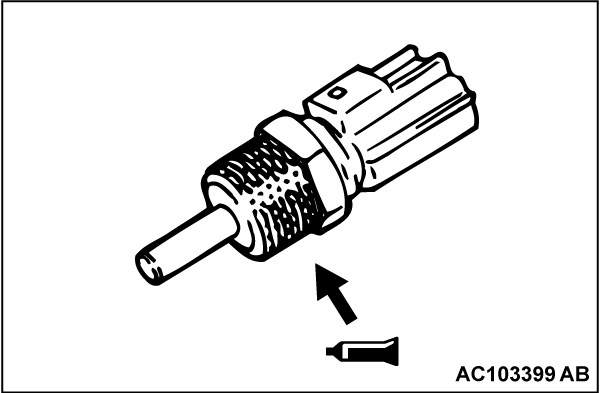

5. The seal agent adhering to power drive unit is removed.

Moreover, when reusing EV coolant temperature sensor, the seal agent adhering to EV coolant temperature sensor is removed once.

Moreover, when reusing EV coolant temperature sensor, the seal agent adhering to EV coolant temperature sensor is removed once.

6. A seal agent is applied to the screw part of EV water temperature sensor.

Sealant: Loctite 262 or equivalent

| note | Attach EV coolant temperature sensor quickly after applying sealant. |

7.

Using a special tool "Water temperature sensor wrench (MB992042)" as with the time of removal, EV water temperature sensor is tighten with specified torque.

| caution | After the EV coolant temperature sensor is installed, the sealant application location must be free of water or oil until a certain period (approx. one hour) elapses. Do not turn on the power supply mode of the electric motor switch (do not activate the electric motor). |

Tightening torque: 30 ± 9 N·m (22 ± 6 ft-lb)

8. EV coolant temperature sensor connector is connected.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)