REMOVAL AND INSTALLATION

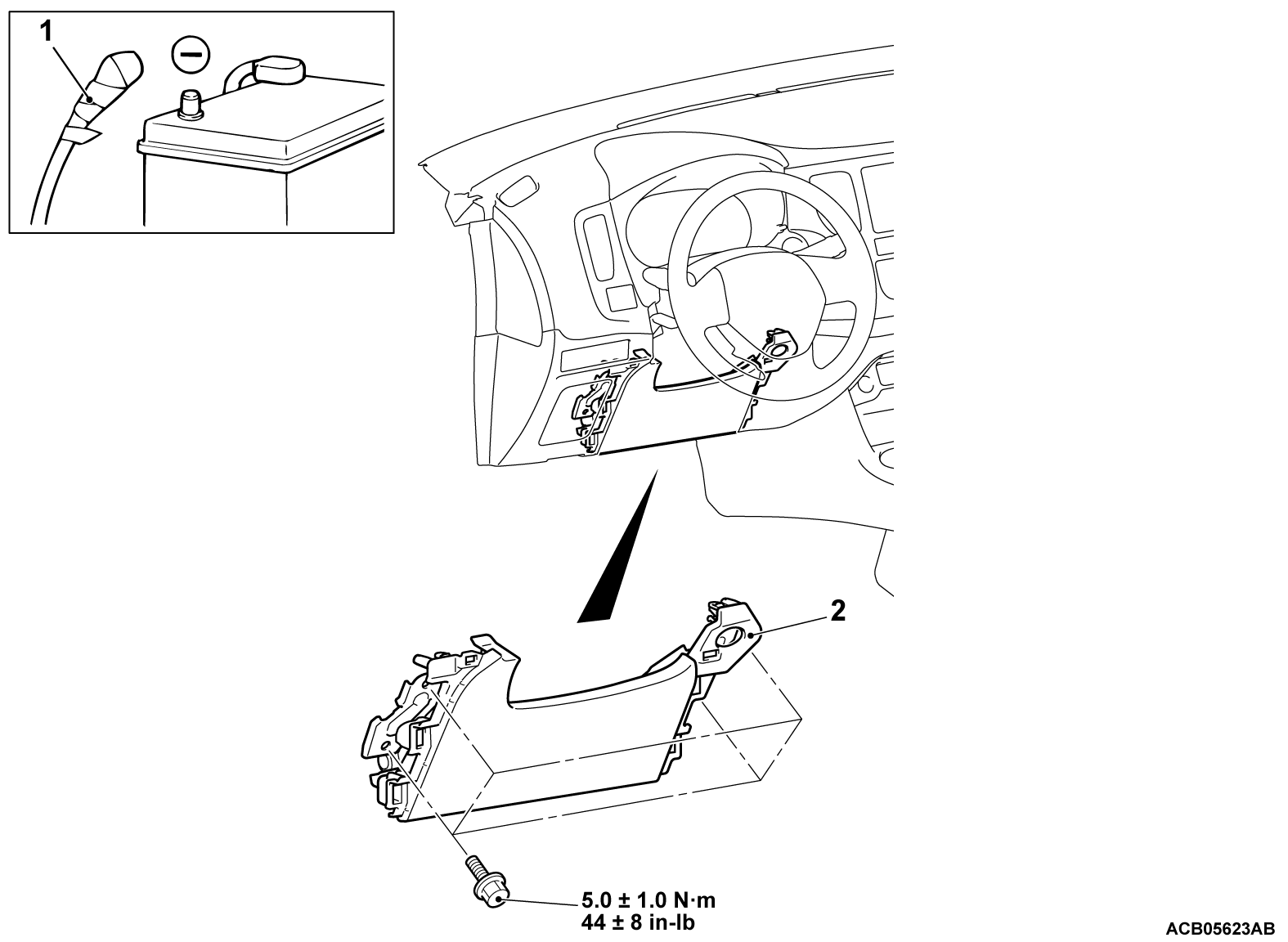

Pre-removal operation

|

REMOVAL SERVICE POINTS

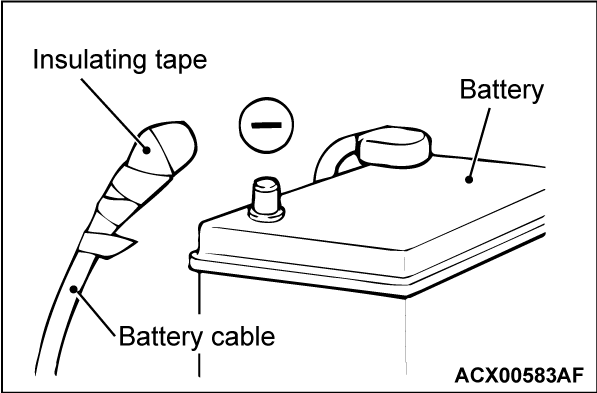

<<A>> NEGATIVE (-) BATTERY CABLE DISCONNECTION

| danger | Wait at least 60 seconds after disconnecting the battery cable before doing any further work (Refer to  ). ). |

| warning | Battery posts, terminals and related accessories contain lead and lead compounds. WASH HANDS AFTER HANDLING. |

Disconnect the negative (-) battery cable from the battery and tape the terminal to prevent accidental connection and air bag(s) deployment.

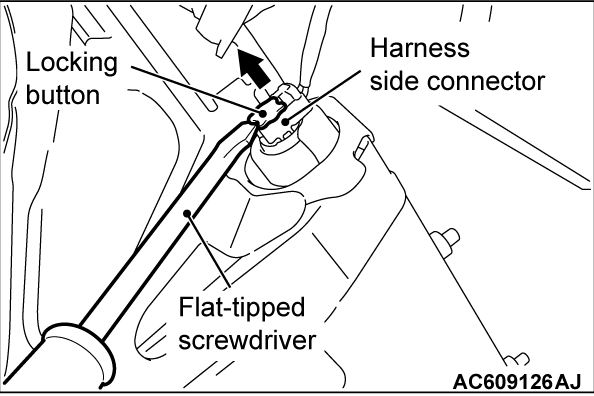

<<B>> KNEE AIR BAG MODULE REMOVAL

| caution |

|

Use the flat-tipped screwdriver to pull out the locking button of wiring harness side connector, and release the lock.

INSTALLATION SERVICE POINTS

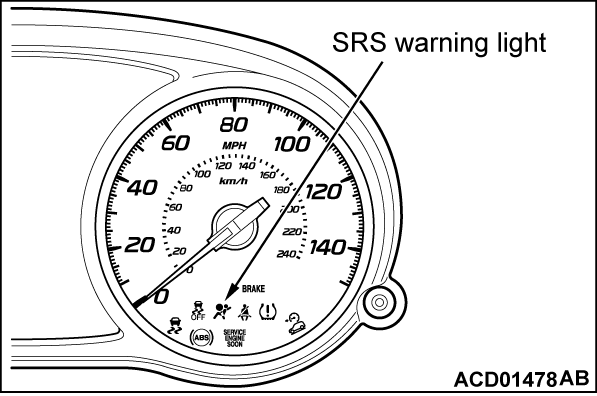

>>A<< PRE-INSTALLATION INSPECTION

2. Connect the negative (-) battery cable.

3.

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn off the power supply mode of the electric motor switch before connecting or disconnecting scan tool (M.U.T.-IIISE). |

Connect scan tool (M.U.T.-IIISE) to the data link connector.

4. Turn on the power supply mode of the electric motor switch.

5. Check DTCs using scan tool (M.U.T.-IIISE) to ensure entire SRS operates properly.

6.

| danger | Wait at least 60 seconds after disconnecting the battery cable before doing any further work (Refer to  ). ). |

| warning | Battery posts, terminals and related accessories contain lead and lead compounds. WASH HANDS AFTER HANDLING. |

Turn off the power supply mode of the electric motor switch. Disconnect the negative (-) battery cable and tape the terminal to prevent accidental connection and air bag deployment.

>>B<< KNEE AIR BAG MODULE INSTALLATION

| caution |

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)