DTC B1403: Driver's air bag module (1st squib) system (shorted to squib circuit power supply)

DTC B1483: Driver's air bag module (2nd squib) system (shorted to squib circuit power supply)

DTC B1483: Driver's air bag module (2nd squib) system (shorted to squib circuit power supply)

| caution |

|

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the front impact sensors and the G-sensor in the SRS-ECU. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, the SRS air bag will inflate.

- The ignition signal is input to the air bag module via the clock spring to inflate the air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the driver's air bag module (squib).

TROUBLESHOOTING HINTS

- Malfunction of the clock spring

- Damaged harness wires and connectors

- Short to the power supply in the driver's air bag module (squib) harness

- Malfunction of the SRS-ECU

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), diagnose the CAN bus line.

(1)

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn off the power supply mode of the electric motor switch before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(2) Turn on the power supply mode of the electric motor switch.

(3) Diagnose the CAN bus line.

(4) Turn off the power supply mode of the electric motor switch.

Is the CAN bus line found to be normal?

STEP 2. Recheck for DTC.

Check again if the DTC is set.

(1) Erase the DTC.

(2) Turn on the power supply mode of the electric motor switch.

(3) Check if the DTC is set.

(4) Turn off the power supply mode of the electric motor switch.

Is the DTC set?

STEP 3. Check the DTC by connecting a dummy resistor.

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

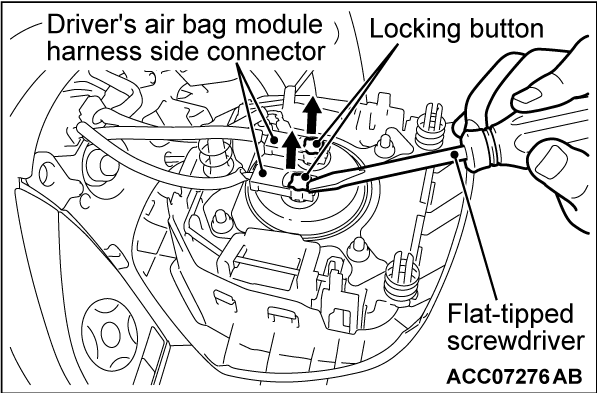

(2) Use the flat-tipped screwdriver to pull out the locking button of wiring harness side connector, and release the lock.

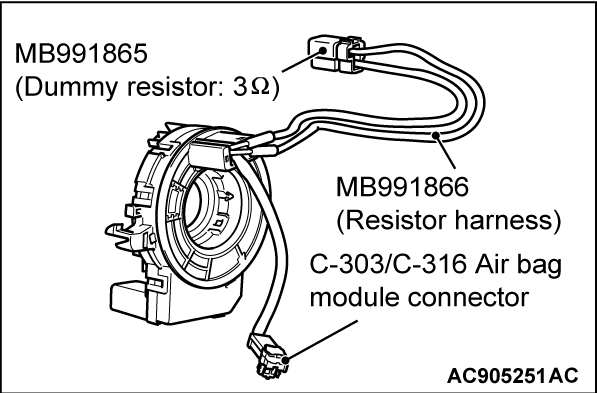

(3) Connect special tool dummy resistor (MB991865) to special tool resistor harness (MB991866).

(4)

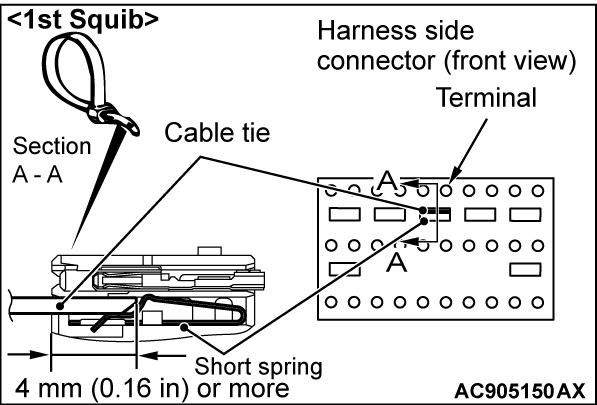

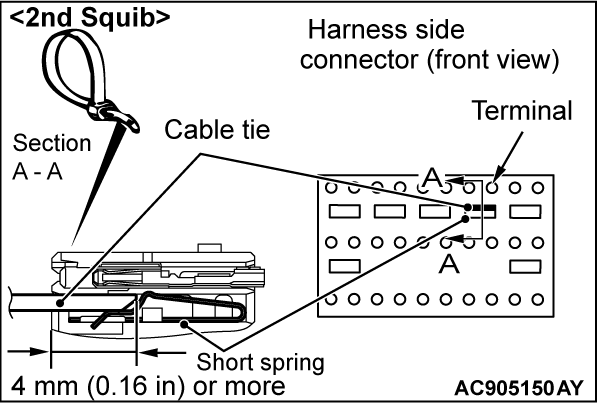

Insert the resistor harness probe (special tool) as shown.

| caution | Do not insert a probe directly into the terminal from the connector front side as the connector contact pressure may be weakened. |

(5) Connect the negative battery terminal.

(6) After erasing the DTC memory, check the DTC again.

(7) Disconnect the negative battery terminal.

(8)

| caution | Always DTC B1483 is set when checking DTC B1403. This is because the second side terminal is isolated when checking it. DTC B1483 is set but this is not a fault. In addition, always DTC B1403 is set when checking DTC B1483 because the first side terminal is isolated. |

Erase the DTC memory, and check the DTC.

Is the checked DTC set?

STEP 4. Diagnosis check by dummy resistor connection.

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

(2) Disconnect the clock spring connector.

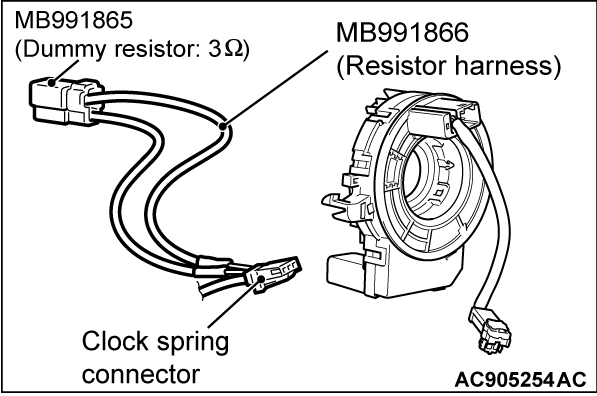

(3) Connect special tool dummy resistor (MB991865) to special tool resistor harness (MB991866).

(4)

| caution | Do not insert a probe directly into the terminal from the connector front side as the connector contact pressure may be weakened. |

Insert the resistor harness probe from the back of harness side connector DQ1-, DQ1+ line <B1403>.

Insert the resistor harness probe from the back of harness side connector DQ2-, DQ2+ line <B1483>.

(5) Connect the negative battery terminal.

(6) After erasing the DTC memory, check the DTC again.

(7) Disconnect the negative battery terminal.

(8)

| caution | Always DTC B1483 is set when checking DTC B1403. This is because the second side terminal is isolated when checking it. DTC B1483 is set but this is not a fault. In addition, always DTC B1403 is set when checking DTC B1483 because the first side terminal is isolated. |

Erase the DTC memory, and check the DTC.

Is the checked DTC set?

STEP 5. Voltage measurement at the SRS-ECU connector.

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

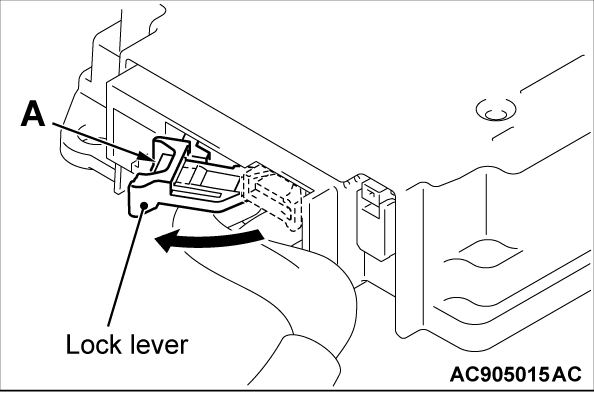

(2) While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the SRS-ECU connector.

(3)

| caution | To release SRS-ECU connector short spring in the following operations, disconnect this clock spring connector, and keep the squib circuit shorted. |

Disconnect the clock spring connector.

(4)

| caution | Insert an insulator such as a cable tie to a depth of 4mm (0.16 inch) or more, otherwise the short spring will not be released. |

Insert the insulator [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] such as cable tie between the DQ1-, DQ1+ line, and then release the short spring <B1403>.

Insert the insulator [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] such as cable tie between the DQ2-, DQ2+ line, and then release the short spring <B1483>.

(5) Connect the negative battery terminal.

(6) Electric motor switch: ON

(7) Take the measurements below at the harness side connector.

- Voltage between DQ1-, DQ1+ line and body ground <B1403>

OK: 1 V or less

- Voltage between DQ2-, DQ2+ line and body ground <B1483>

OK: 1 V or less

(8) Disconnect the negative battery terminal.

Is the check result normal?

Repair the wiring harnesses DQ1-, DQ1+ line <B1403> or DQ2-, DQ2+ line <B1483> between the clock spring connector and the SRS-ECU connector.

Repair the wiring harnesses DQ1-, DQ1+ line <B1403> or DQ2-, DQ2+ line <B1483> between the clock spring connector and the SRS-ECU connector.STEP 6. Recheck for DTC.

Check again if the DTC is set.

(1) Erase the DTC.

(2) Turn on the power supply mode of the electric motor switch.

(3) Check if the DTC is set.

(4) Turn off the power supply mode of the electric motor switch.

Is DTC B1403 (1st squib) or B1483 (2nd squib) set?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)