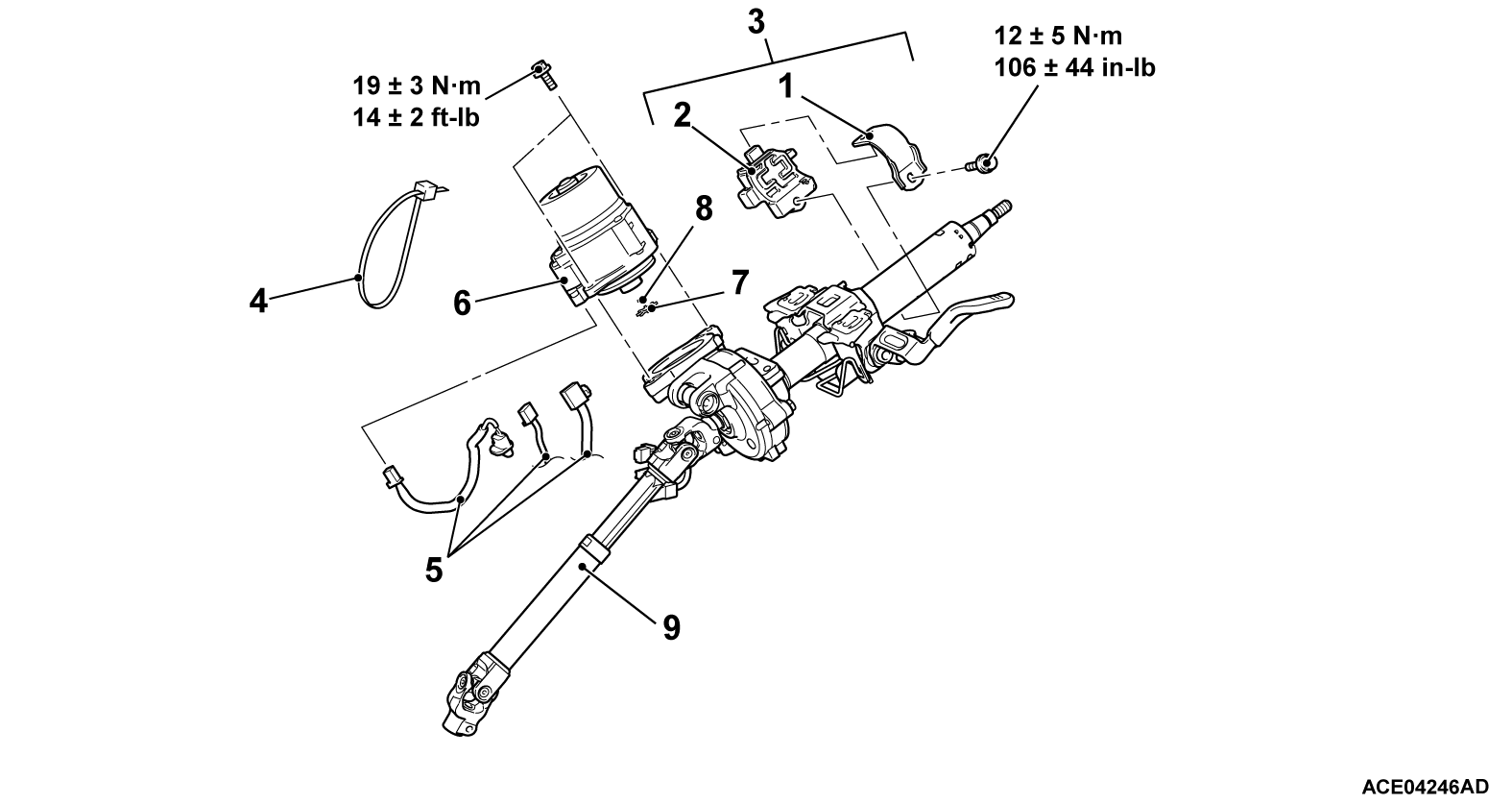

DISASSEMBLY AND REASSEMBLY

| caution |

|

| note |

|

Required Special Tools:

- MB990326: Preload socket

- MB992678: Screw extractor

DISASSEMBLY SERVICE POINT

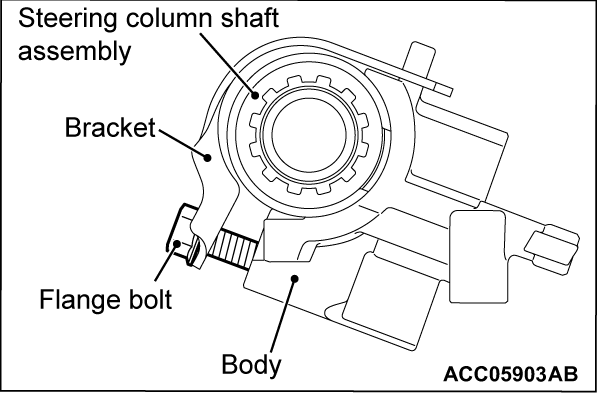

<<A>> MOTOR (EPS-ECU) REMOVAL

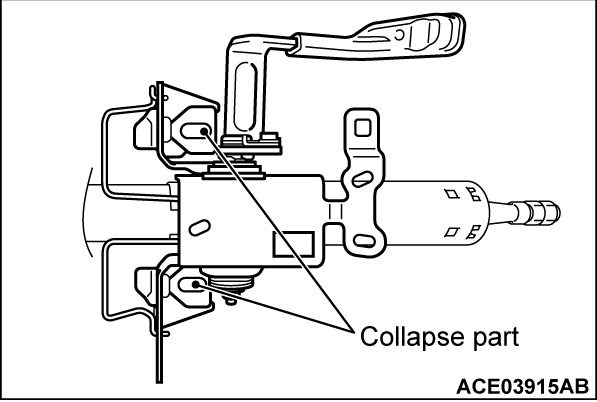

| caution | Do not remove the collapse part (shown in the illustration). |

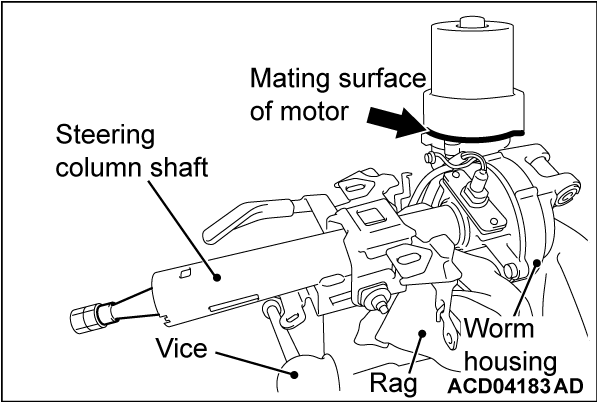

1. Remove the wiring harness.

2. Adjust the electric motor so that its mating surface is horizontal, and then secure the worm gear housing on the steering column shaft with a vice.

| caution |

|

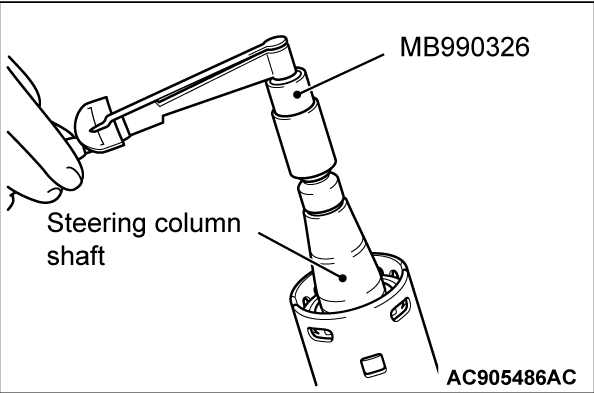

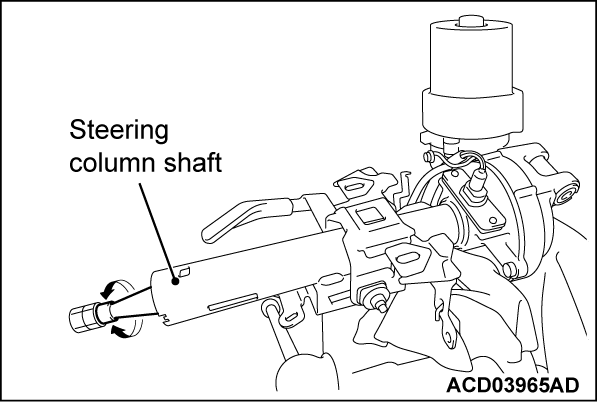

3. Install the nut to the end of the steering column shaft. Then use the preload socket (Special tool: MB990326) to rotate the shaft at a rate of one turn per 4 to 6 seconds, and then measure the total rotation torque.

| note |

|

4. Remove the motor mounting bolts.

REASSEMBLY SERVICE POINTS

>>A<< MOTOR (EPS-ECU) INSTALLATION

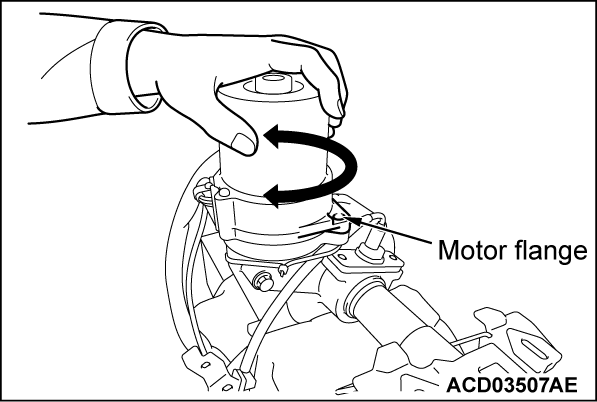

1. Insert the motor, and check that the motor flange moves with the bolts not tightened.

| caution |

|

2. Rotate the steering column shaft at a speed of approximately one turn per second. While doing so, tighten the electric motor mounting bolts alternately by hand.

| note | The steering column shaft can be rotated in either direction (right and left). |

3. Tighten the electric motor mounting bolts to the specified torque.

Tightening torque: 19 ± 3 N·m (14 ± 2 ft-lb·)

4. Install the two nut to the end of the steering column shaft. Then use the preload socket (Special tool: MB990326) to rotate the shaft at a speed of one turn per 4 to 6 seconds, and then measure the total rotation torque.

| note |

|

| caution | If the total rotation torque fluctuation compared with the value measured at removal is ±10% or more, remove the motor again and repeat installation steps 1, 2 and 3. |

5. Connect the wiring harness.

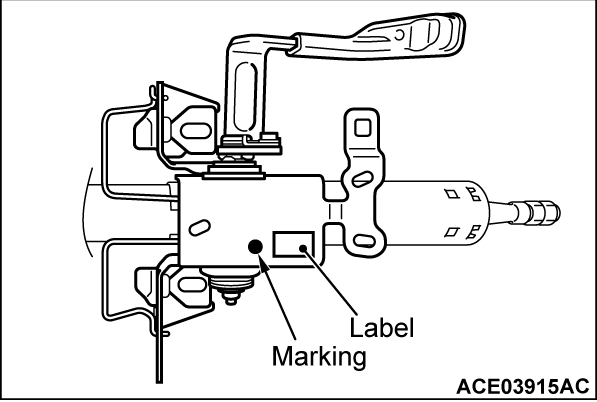

6. Use a black felt pen to apply a mark near the label as shown as a visual indication that this work has been completed.

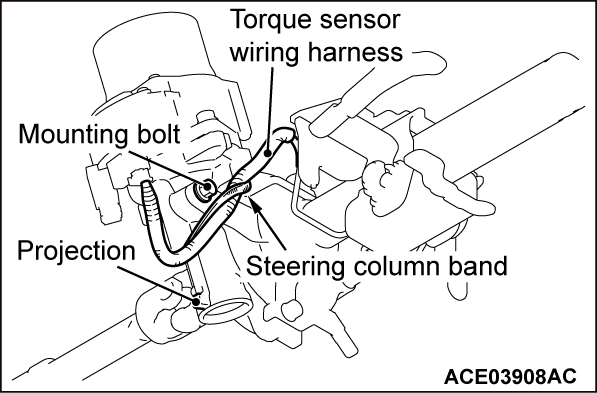

>>B<< STEERING COLUMN BAND INSTALLATION

| caution |

|

Tie the wiring harness wires with the steering column band.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)