BRAKE DISC CHECK

| caution | Disc brakes must be kept within the allowable service values in order to maintain normal brake operation. |

Before turning the brake disc, the following conditions should be checked.

| INSPECTION ITEM | REMARK |

| Scratches, rust, saturated lining materials and wear |

|

| Run-out | Excessive run-out of the discs will increase the pedal depression resistance due to piston kick-back. |

| Change in thickness (parallelism) | If the thickness of the disc changes, this will cause pedal pulsation, shuddering and surging. |

| Inset or warping (flatness) | Overheating and improper handling while servicing will cause warping or distortion. |

BRAKE DISC THICKNESS CHECK

1. Remove contaminants or corrosion from the brake disc surface.

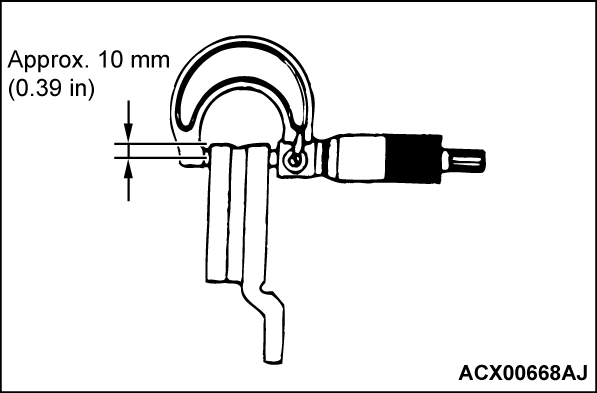

2. Use a micrometer to measure the brake disc thickness at minimum eight points which are 10 mm (0.39 in) inward from its circumference.

- <Front>

- Standard value: 24.0 mm (0.94 in)

- Limit: 22.4 mm (0.88 in)

- <Rear>

- Standard value: 10.0 mm (0.39 in)

- Limit: 8.4 mm (0.33 in)

3. If the brake disc thickness is worn beyond the limit value at more than one point, replace the brake disc and check its run-out.

BRAKE DISC THICKNESS UNEVENNESS CHECK AND CORRECTION

1. Remove contaminants or corrosion from the brake disc surface.

2. Use a micrometer to measure the brake disc thickness at minimum eight points which are 10 mm (0.39 in) inward from its circumference. Then record the measurements.

3. If the brake disc thickness unevenness (the difference between the maximum and minimum values measured above) is 0.015 mm (0.0006 in) or less, it is within the standard value.

4. If the brake disc thickness unevenness exceeds the standard value, grind it according to the procedure below while it is mounted on the vehicle.

| note | If it is suspected that the brake disc thickness will become less than the limit value after the grinding, replace the brake disc and check its run-out. |

(1) Check for wheel bearing looseness in the axial direction (Refer to GROUP 26 - On-vehicle Service, Wheel bearing end play check  <Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check

<Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check  <Rear>).

<Rear>).

<Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check

<Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check  <Rear>).

<Rear>).(2)

| caution |

|

Correct the brake disc uneven thickness by grinding it while in place on the vehicle.

BRAKE DISC RUN-OUT CHECK AND CORRECTION

1. Check for wheel bearing looseness in the axial direction (Refer to GROUP 26 - On-vehicle Service, Wheel bearing end play check  <Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check

<Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check  <Rear>).

<Rear>).

<Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check

<Front>, GROUP 27 - On-vehicle Service, Wheel bearing end play check  <Rear>).

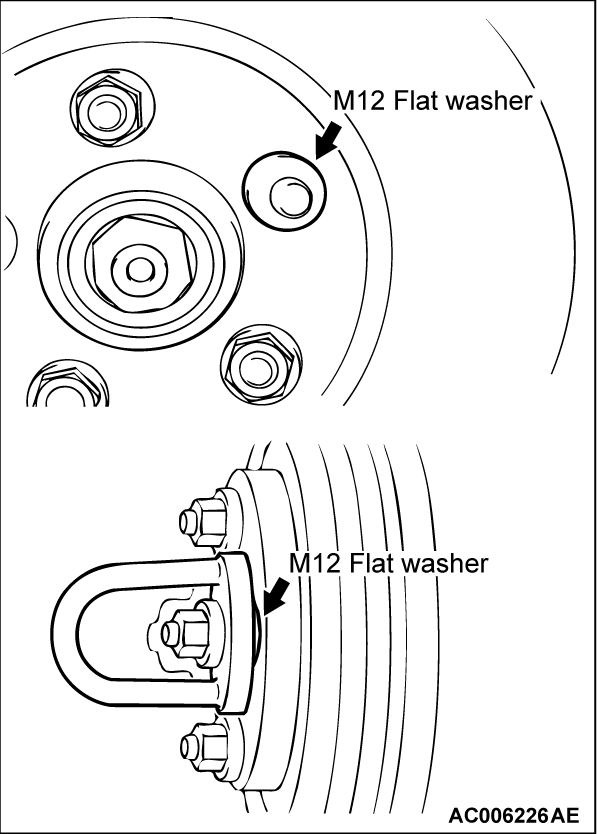

<Rear>).2. If the end play is within the limit value, secure the brake disc by tightening the nut (M12×1.5) evenly to the specified torque [100 N·m (74 ft-lb)]. If the end play still exceeds the limit value, replace the wheel bearing. Then secure the brake disc by tightening the nut (M12×1.5) evenly to the specified torque [100 N·m (74 ft-lb)].

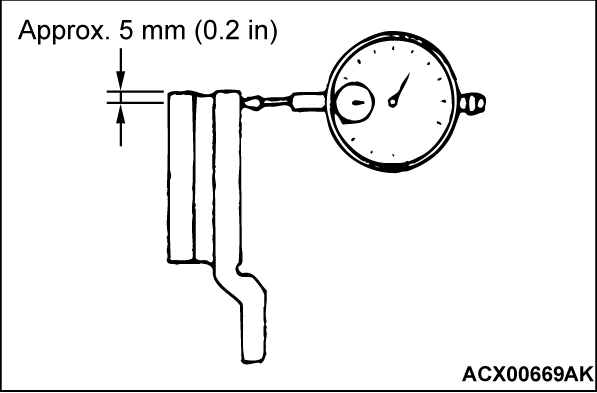

3. Place a dial gauge ca. 5 mm (0.2 in) inward from the circumference of the brake disc to measure its run-out.

Limit:

- 0.06 mm (0.0024 in) <Front>

- 0.08 mm (0.0031 in) <Rear>

4. If the brake disc run-out exceeds the limit value, rephase the brake disc to the hub so that the minimum brake disc run-out is obtained.

5.

| caution |

|

If the brake disc run-out exceeds the limit value after rephasing, grind the disc while in place on the vehicle so that the brake disc run-out is within the limit value.

| note | If it is suspected that the brake disc thickness will be below the limit value, replace the brake disc. Then rephase the brake disc so that the minimum brake disc run-out is obtained, or grind the disc while in place on the vehicle so that its run-out is below the limit value. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)