DISASSEMBLY AND ASSEMBLY

Required Special Tools:

- MB990326: Preload Socket

- MB990890: Rear Suspension Bushing Base

- MB990935: Installer Adapter

- MB990938: Installer Bar

- MB991000: Spacer

- MB991017: Front Hub Remover and Installer

- MB991355: Knuckle Arm Bridge

- MB991388: Bush Remover Base

- MB991576: Base

- MB992150: Oil Seal Installer

- MB992250: Knuckle Arm Bridge Attachment

- MD999528: Adapter

- MD998801: Remover

- MD998812: Installer Cap

- MD998813: Installer

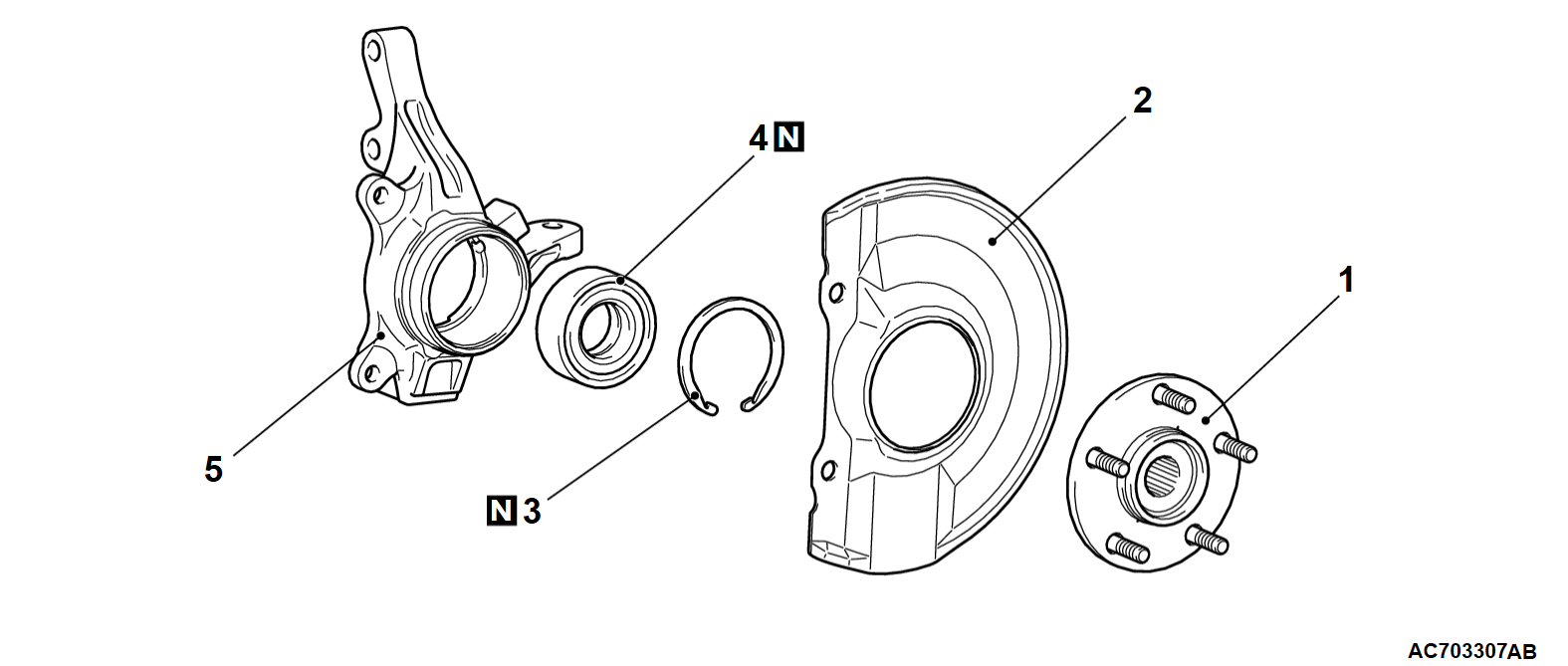

DISASSEMBLY SERVICE POINTS

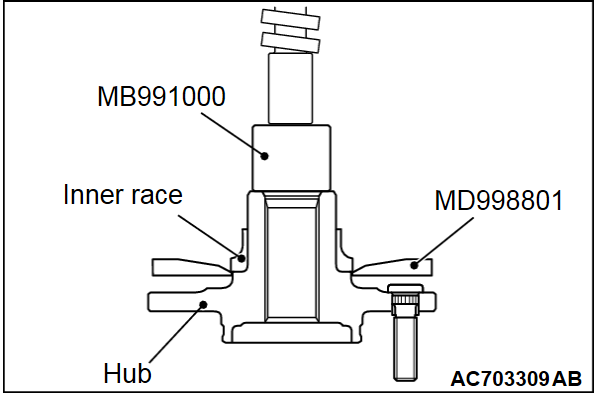

<<A>> HUB REMOVAL

| caution | In the hub removal operation, make sure to replace the wheel bearing with new one. |

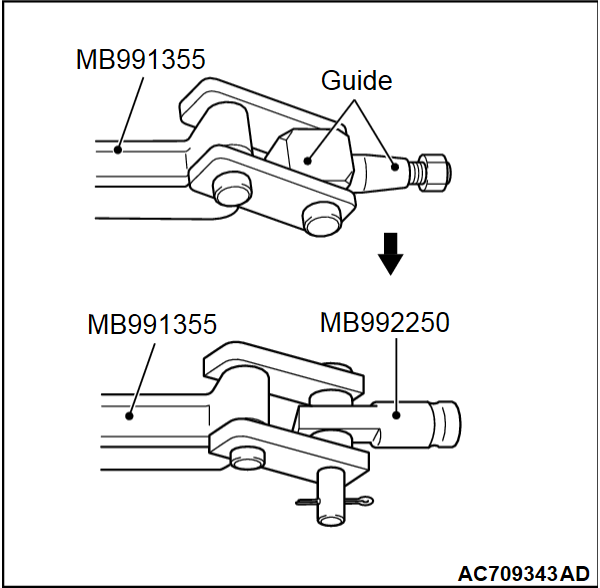

1. Replace special tool MB992250 with a guide of special MB991355 as shown in the figure.

2. Insert special tool MB992250 in the knuckle and tighten it with a bolt and nut.

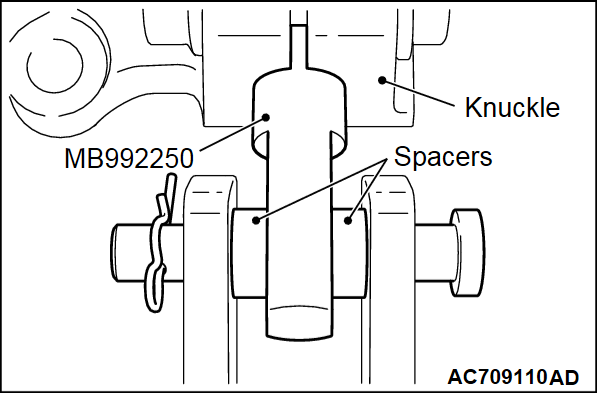

| note | Set the spacers of special tool MB992250 as shown in the figure. |

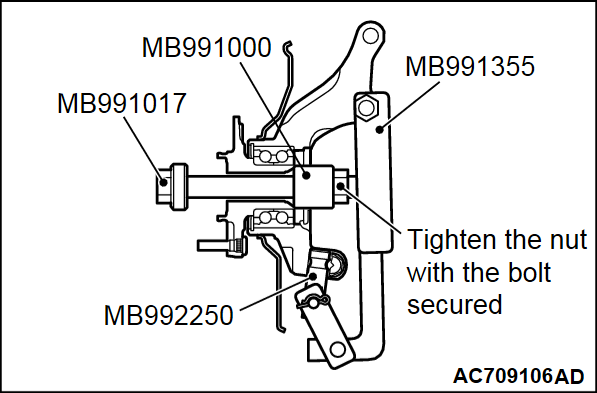

3. Use special tools MB991000, MB991017, MB991355 and MB992250 to remove the hub.

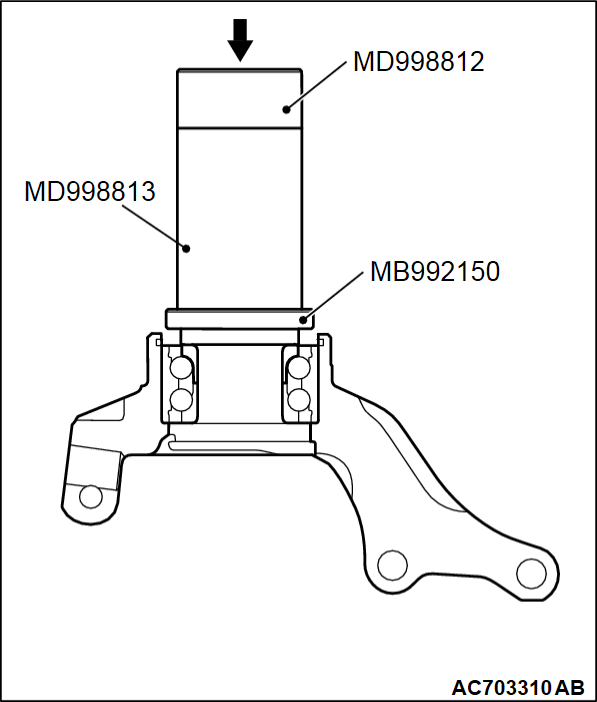

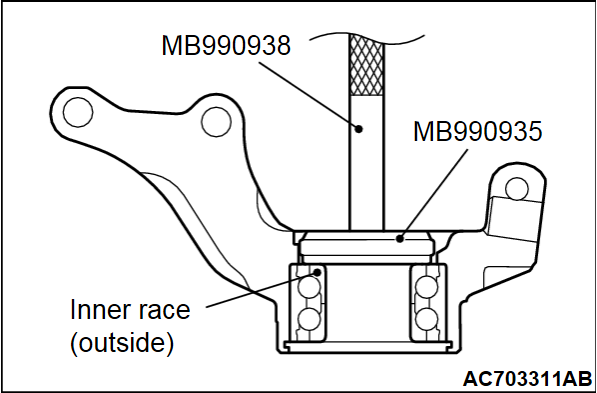

<<B>> WHEEL BEARING REMOVAL

1. Use special tools MD998801 and MB991000 to remove the wheel bearing inner race (outside) from the hub.

2. Use special tools MB992150, MD998812 and MD998813 to assemble the inner race (outside) removed from the hub to the wheel bearing.

3. Use special tools MB990935 and MB990938 to remove the wheel bearing.

ASSEMBLY SERVICE POINTS

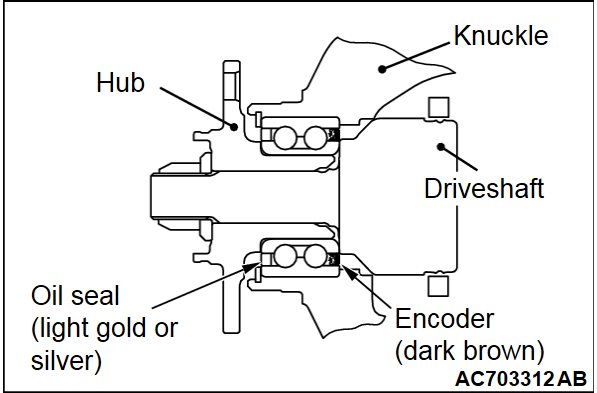

>>A<< WHEEL BEARING INSTALLATION

| caution |

|

1. Remove grease and foreign material cleanly from the inside of knuckle bore.

2. Apply the specified grease thinly and evenly to the inside of knuckle as shown in the figure.

Specified grease: DOW CORNING TORAY Molykote EP

Amount to use: as required {2.0 g (0.07 oz)}

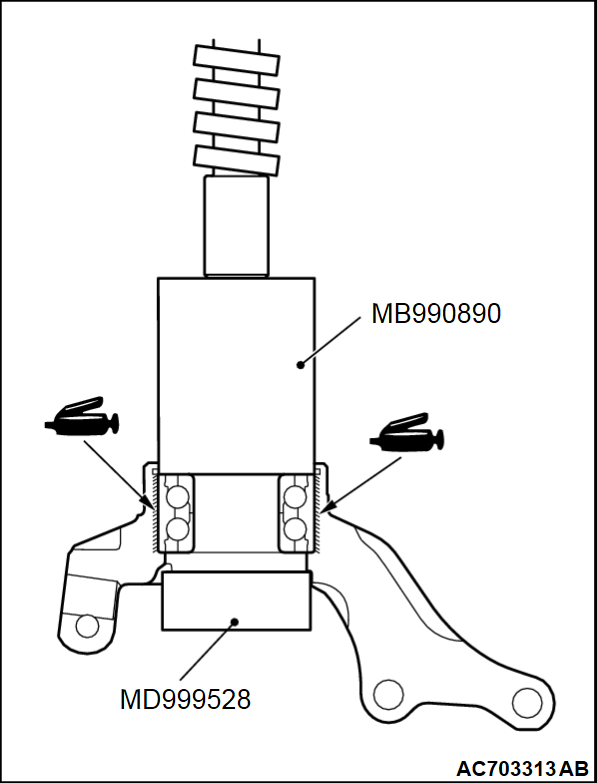

3. Use special tools MD999528 and MB990890 to press-fit the wheel bearing.

4. Remove excessive grease seeped out between knuckle and wheel bearing outer race after press-fitting the wheel bearing.

>>B<< DUST SHIELD INSTALLATION

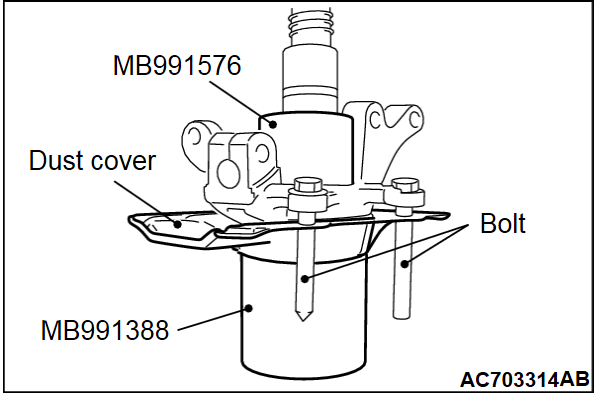

Use special tools MB991388 and MB991576 to press-fit the knuckle into the dust shield.

| note | Use the bolts (M12) to align the caliper mounting holes. |

>>C<< HUB ROTATION STARTING TORQUE CHECK

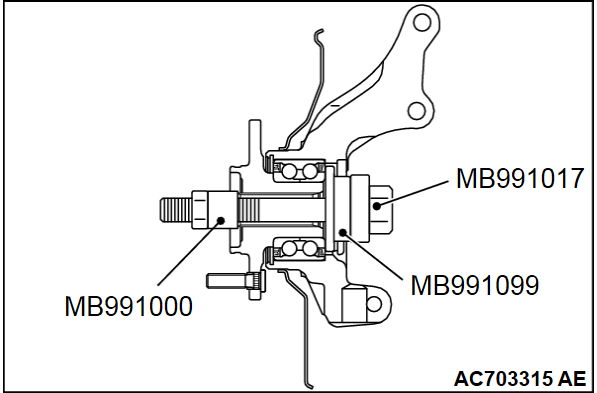

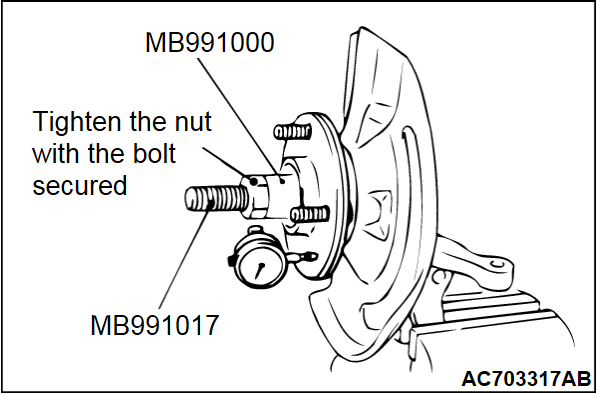

1. Set special tools MB991000, MB991017 and MB991099 as shown in the figure, tighten the nut to the specified torque, and press-fit the hub into the knuckle.

Tightening torque: 250 ± 25 N·m (184 ± 18 ft-lb)

2. Rotate the hub to make the bearing well-greased.

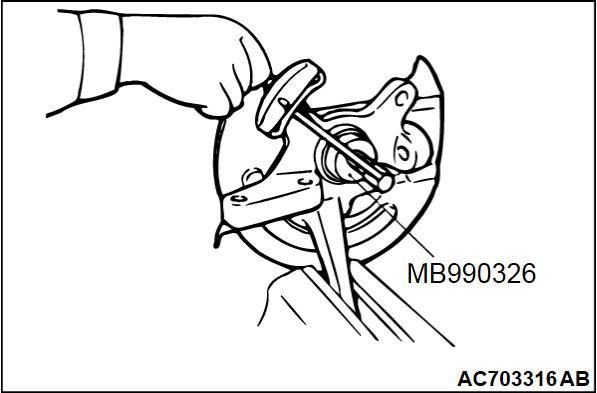

3. Use Special tool MB990326 to measure the hub rotation starting torque.

Limit: 1.5 N·m (13 in-lb)

4. Hub rotation starting torque should be within the limit value, and there should be no roughness and gritty feeling in rotation.

>>D<< WHEEL BEARING END PLAY CHECK

1. Use special tools MB991000 and MB991017 to measure to determine whether the wheel bearing end play is within the specified limit or not.

Limit: 0.05 mm(0.002 inch)

2. If the end play is not within the limit range while the nut is tightened to specified torque, the bearing, hub and/or knuckle have probably not been installed correctly. Replace the bearing and re-install.

Tightening torque: 250 ± 25 N·m (184 ± 18 ft-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)