DTC P0998: Low Clutch Shift Solenoid Valve System (Short circuit)

DTC P0999: Low Clutch Shift Solenoid Valve System (Open circuit)

DTC P0999: Low Clutch Shift Solenoid Valve System (Open circuit)

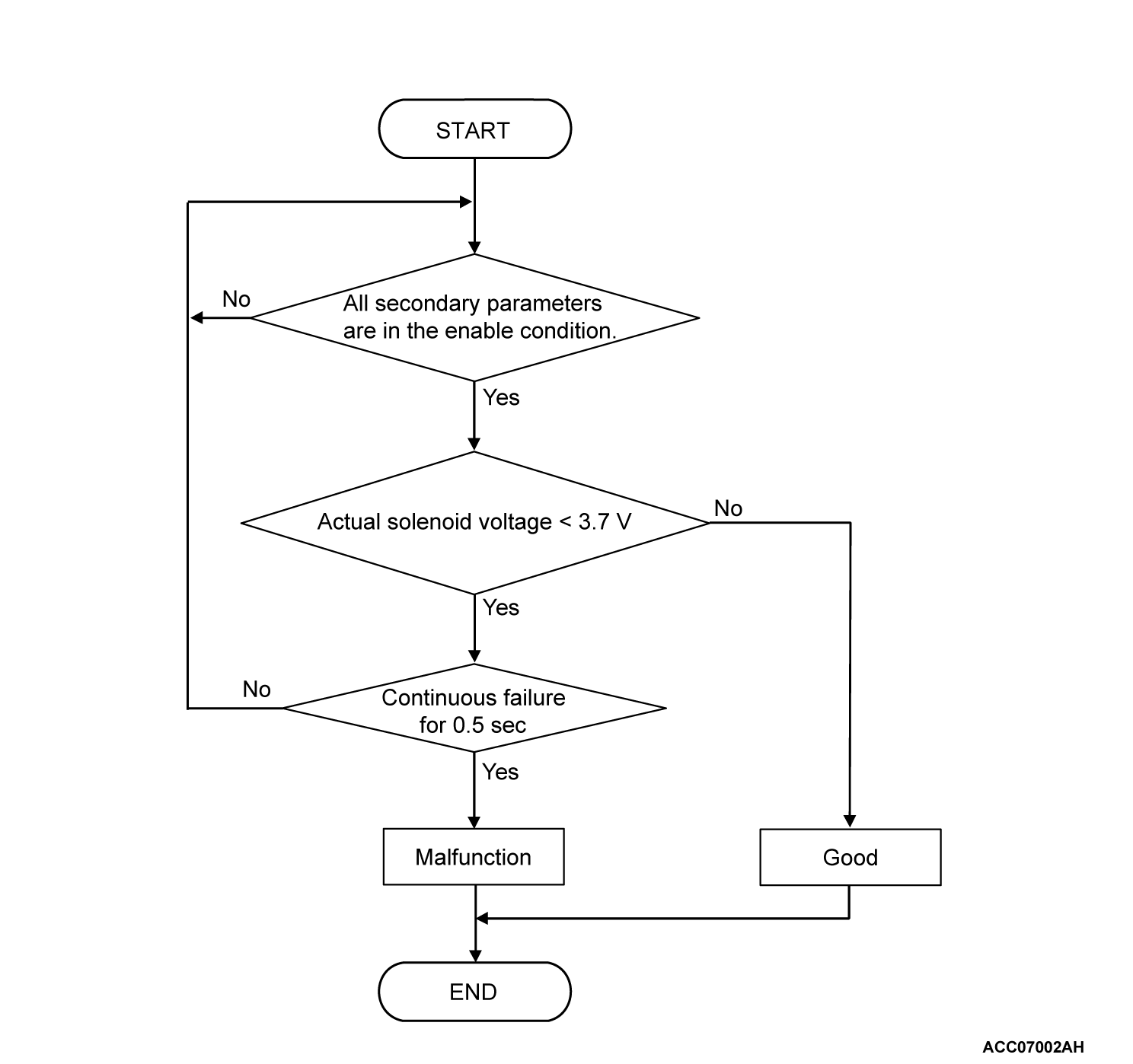

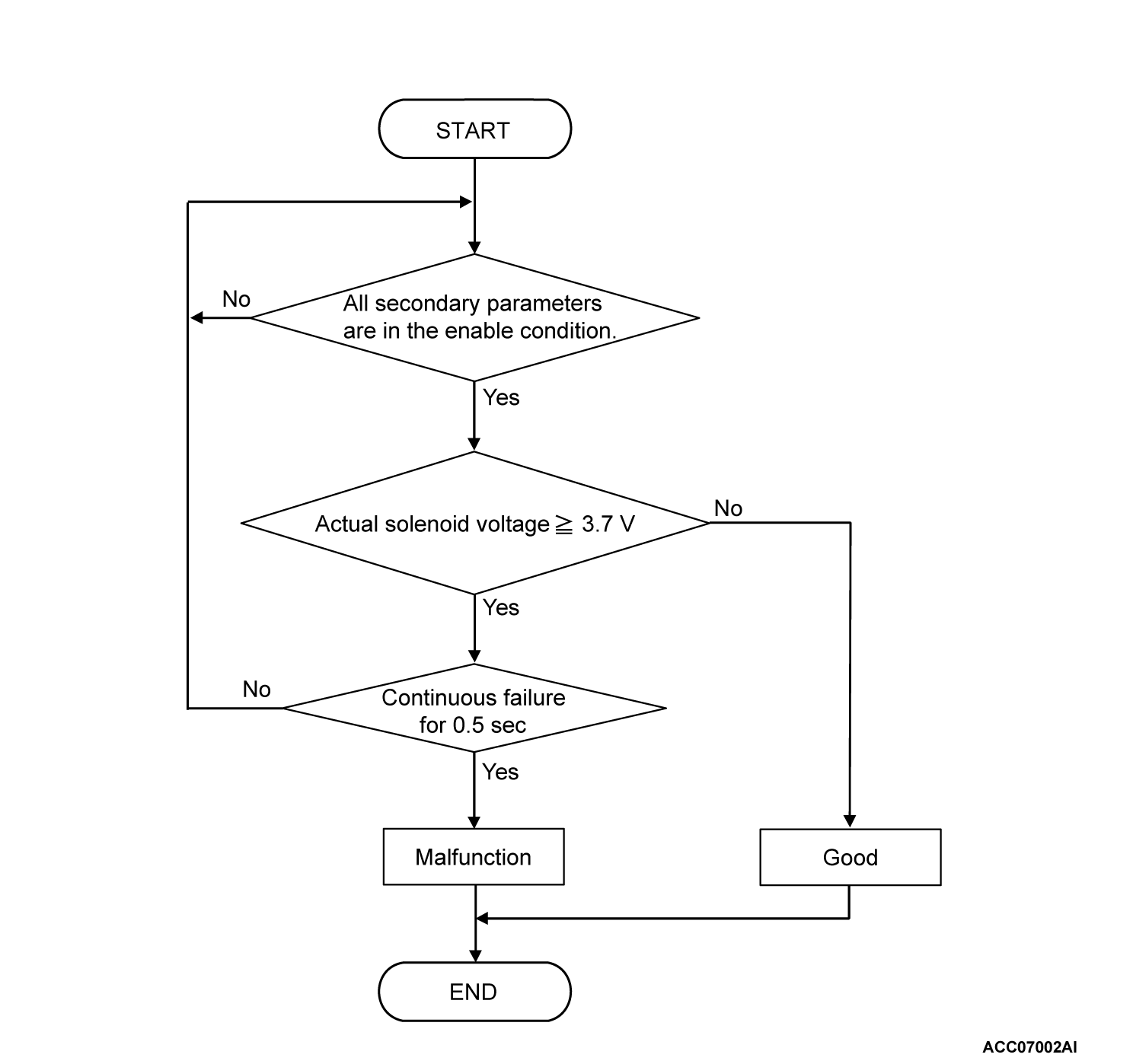

DESCRIPTIONS OF MONITOR METHODS

- During the 5th to 6th driving, and with the lock-up function deactivated, a short circuit is detected for 0.5 second. <P0998>

- During 1st to 4th driving, and with the lock-up function deactivated, an open circuit is detected for 0.5 second. <P0999>

MONITOR EXECUTION

- During with the lock-up deactivated

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0731: 1st gear incorrect ratio

- P0732: 2nd gear incorrect ratio

- P0733: 3rd gear incorrect ratio

- P0734: 4th gear incorrect ratio

- P0735: 5th gear incorrect ratio

- P0729: 6th gear incorrect ratio

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions <P0998>

- Gear position: 5th or 6th.

Judgment Criteria <P0998>

- Low clutch shift solenoid valve actual voltage: less than 3.7 V (0.5 second)

Check Conditions <P0999>

- Gear position: 1st to 4th.

Judgment Criteria <P0999>

- Low clutch shift solenoid valve actual voltage: 3.7 V or more (0.5 second)

OBD-II DRIVE CYCLE PATTERN

Drive at 55 km/h (34.2 mph) or less with the shift ranges of 1st, 2nd, 3rd, and 4th gear. Driving at 48 ± 2 km/h (29.8 ± 1.2 mph) with the 5th gear. Maintain each shift range for 1 second or more.

PROBABLE CAUSES

- Malfunction of the low clutch shift solenoid valve system circuit

- Damaged harness or connector

- Malfunction of the TCM

- Malfunction of the low clutch shift solenoid valve (valve body Assembly)

DIAGNOSIS

STEP 1. Check the TCM terminal voltage.

[TCM connector (harness side, connected)]

Measure the voltage between LCSS terminal and body ground.

- 5th and 6th: Battery positive voltage

- Other than above: 0 V

Is the check result normal?

STEP 2. Check for continuity in LCSS line between the TCM connector and the A/T control solenoid valve assembly.

When the continuity check result is OK, check that the wiring harness is not shorted to the body and other wiring harness. Repair the connector(s) or wiring harness.

Repair the connector(s) or wiring harness.

Is the check result normal?

Repair the connector(s) or wiring harness.

Repair the connector(s) or wiring harness.STEP 3. Check the low clutch shift solenoid.

STEP 4. Check for continuity in signal line between the A/T control solenoid valve assembly connector and the low clutch shift solenoid valve connector.

Is the check result satisfactory?

Replace the valve body assembly.

Replace the valve body assembly. Repair the connector(s) or wiring harness.

Repair the connector(s) or wiring harness.STEP 5. Check the TCM and A/T control solenoid valve assembly connector pin terminals and the connection status.

STEP 6. Check the TCM and A/T control solenoid valve assembly connector pin terminals and the connection status.

Is the check result normal?

Replace the TCM.

Replace the TCM. Repair or replace the failure section.

Repair or replace the failure section.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)