DTC P0490: EGR Valve (Stepper Motor) Circuit Malfunction (Battery Short)

CIRCUIT OPERATION

- The EGR valve power is supplied from the MFI relay.

- The ECM terminals EGRA, EGRB, EGRC and EGRD drives the stepper motor by sequentially turning "ON" the power transistors in the ECM and providing ground to the EGR valve.

TECHNICAL DESCRIPTION

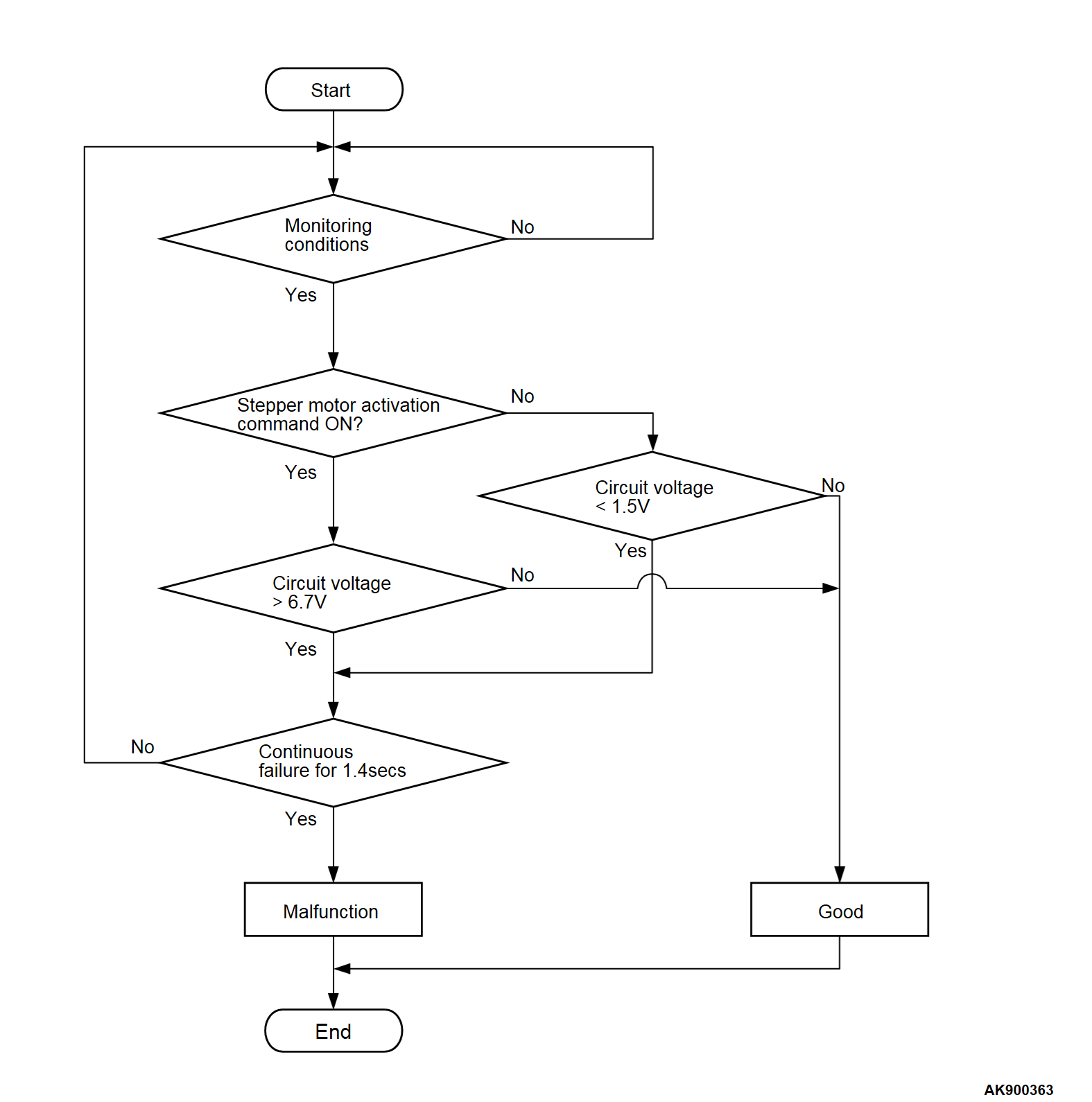

The ECM checks whether a short circuit to the power supply exists or not by measuring the EGR valve (stepper motor) drive circuit voltage when the current not flowing through the coils of the EGR valve (stepper motor).

DESCRIPTIONS OF MONITOR METHODS

When the EGR valve (stepper motor) drive circuit voltage is over the specified range, it is judged that a malfunction exists.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- EGR stepper motor monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Manifold absolute pressure sensor

- Accelerator pedal position sensor

Check Conditions

- Ignition switch is "ON" position.

- Battery positive voltage is at between 10 and 16.5 volts.

Judgment Criterion

- When the EGR valve is energized, the ECM voltage should be 6.7 volts or more for 1.4 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be stored are: )

- EGR valve (stepper motor) failed.

- Harness damage.

- Connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle Communication Interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite Main Harness A

- MB992747: V.C.I.-Lite USB Cable Short

- MB992748: V.C.I.-Lite USB Cable Long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

- MB991658: Test Harness Set

STEP 1. Measure the EGR valve motor coil resistance.

(1) Disconnect the EGR valve connector and measure at EGR valve side.

(2) Measure the resistance between EGR valve connector terminal power supply line and either terminal EGRA line or terminal EGRB line.

Standard value: 20 - 24 Ω [at 20°C (68°F)]

(3) Measure the resistance between EGR valve connector terminal power supply line and either terminal EGRC line or terminal EGRD line.

Standard value: 20 - 24 Ω [at 20°C (68°F)]

Is the measured resistance between 20 and 24 ohms [at 20°C (68°F)]?

STEP 2. Check of short circuit to power supply in power supply line between EGR valve connector and ECM connector.

Is the harness wire in good condition?

STEP 3. Check the EGR valve operation using special tool MB991658.

(1) Remove the EGR valve.

(2) Connect special tool MB991658 to the EGR valve. (All terminals should be connected.)

(3) Use the jumper wires to connect terminal power supply line of the EGR valve connector to the positive battery terminal.

(4) Check to ensure that the motor operates when the terminal EGRA line and EGRB line of the EGR valve connector are respectively connected to the negative battery terminal using a jumper wire.

- Vibration should be present at each application of voltage to test clip combination.

(5) Then, use jumper wires to connect the terminal power supply line of the EGR valve connector to the positive battery terminal.

(6) Check to ensure that the motor operates when terminal EGRC line and EGRD line of the EGR valve connector are respectively connected to the negative battery terminal using a jumper wire.

- Vibration should be present at each application of voltage to test clip combination.

(7) Reinstall the EGR valve, using a new gasket, and tighten to the specified torque.

Tighten torque: 23 ± 6 N·m [17 ± 4 ft·Ib]

Is the EGR valve operating properly?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)