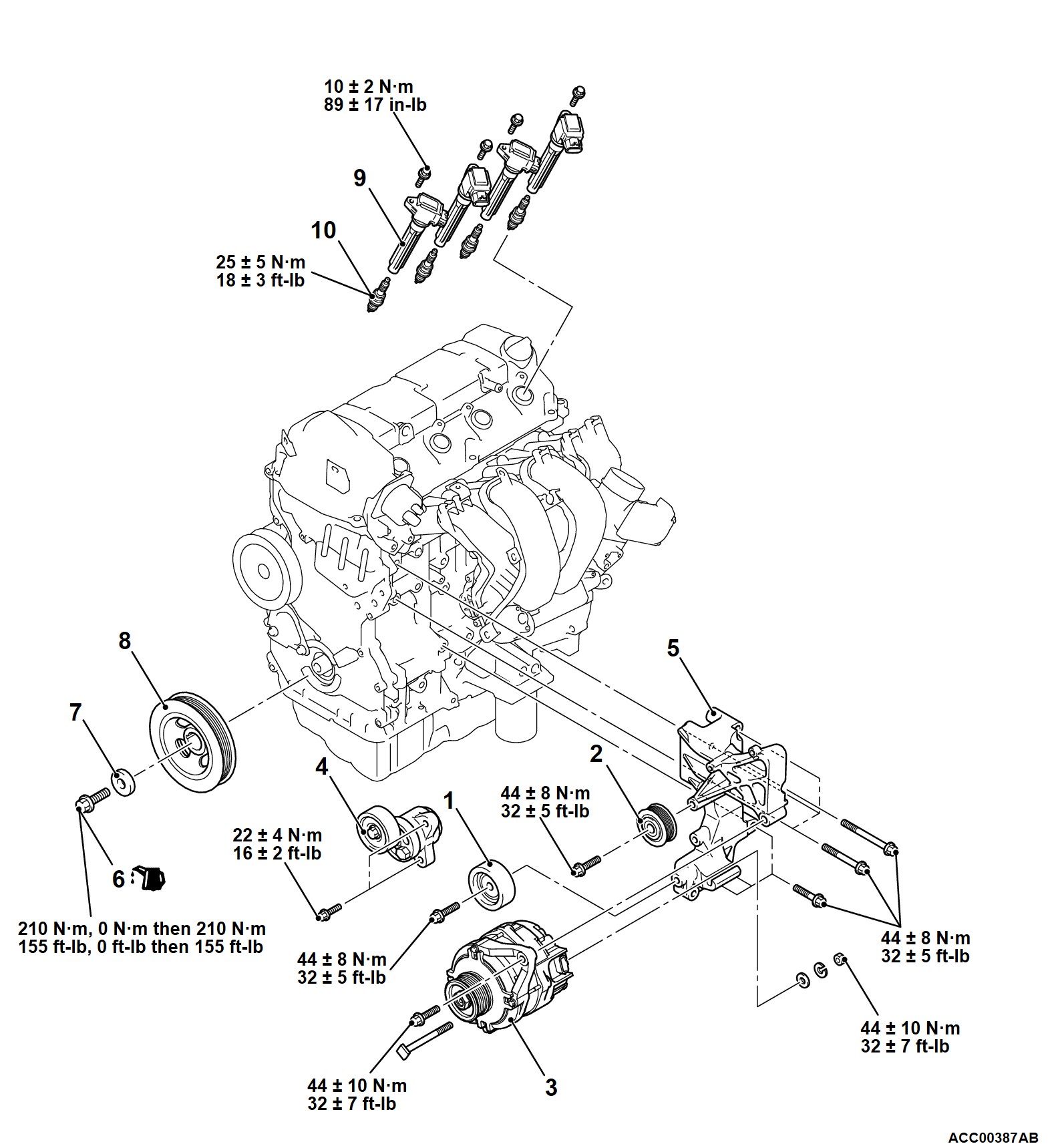

REMOVAL AND INSTALLATION

Required Special Tool:

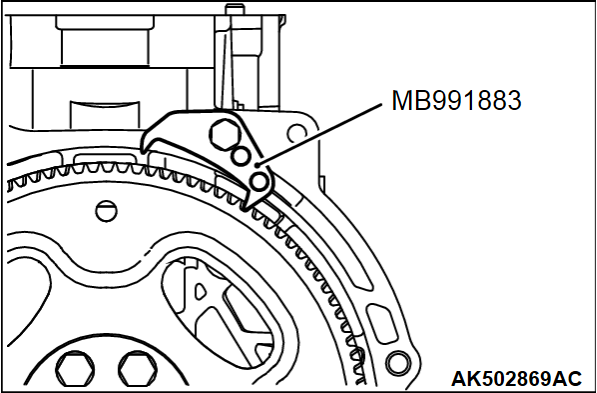

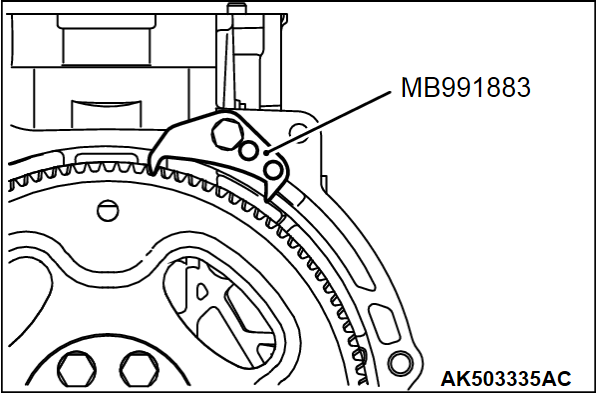

- MB991883: Flywheel Stopper

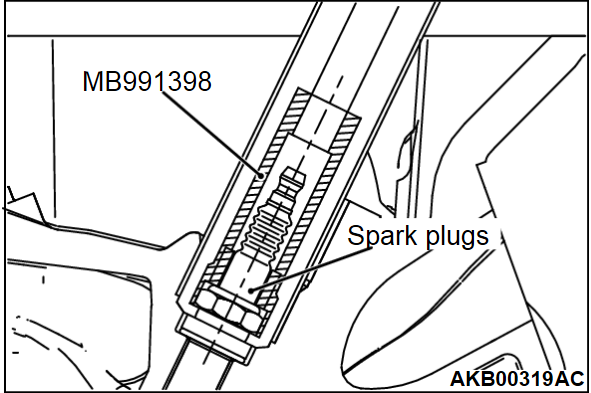

- MB991398: Spark plug wrench

REMOVAL SERVICE POINTS

<<A>> CRANKSHAFT PULLEY CENTER BOLT REMOVAL

1. Use special tool Flywheel stopper (MB991883) to secure the drive plate.

2. Remove the crankshaft pulley center bolt.

INSTALLATION SERVICE POINTS

>>A<< SPARK PLUG INSTALLATION

Use special tool Spark plug wrench (MB991398), tighten the spark plug to specified torque of 25 ± 5 N·m (18 ± 3 ft-lb).

>>B<< CRANKSHAFT PULLEY / CRANKSHAFT PULLEY WASHER / CRANKSHAFT PULLEY CENTER BOLT INSTALLATION

1. Use special tool Flywheel stopper (MB991883) to secure the drive plate.

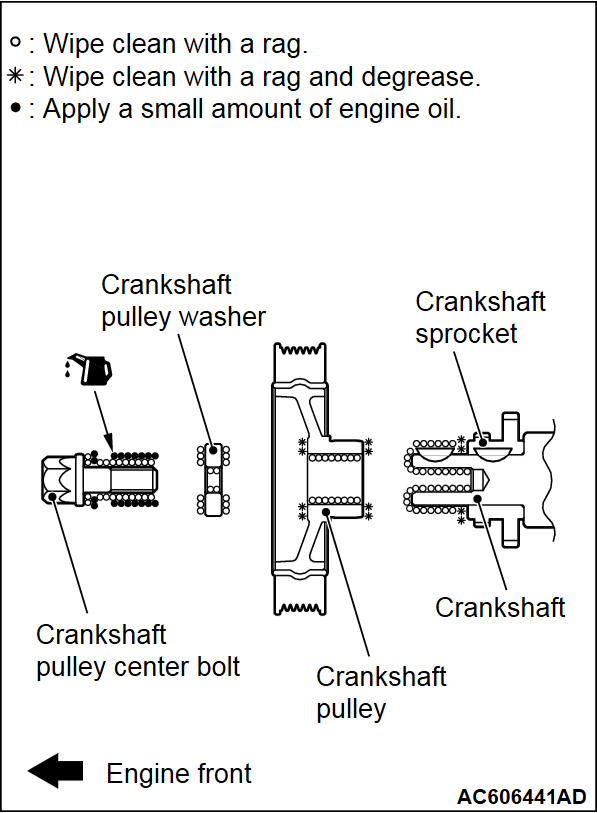

2. Wipe off the dirt on the crankshaft pulley washer and on the thread hole of the crankshaft using a rag.

3. Wipe off the dirt on the crankshaft pulley and the crankshaft sprocket using a rag, and then remove the grease from the portion shown in the illustration.

| note | Remove grease to prevent the coefficient of friction of the pressing portion from declining due to adhesion of oil. |

4. Install the crankshaft pulley.

5. Apply an appropriate and minimum amount of engine oil to the threaded portion of the crankshaft and lower part of the flange.

6. With the chamfered side on the inside of the washer facing the bolt top, install the crankshaft pulley washer to the crankshaft pulley center bolt.

7. Tighten the crankshaft pulley center bolt to the specified torque.

Tightening torque: 210 N·m (155 ft-lb)

8. Loosen the crankshaft pulley center bolt fully.

9. Tighten the crankshaft pulley center bolt to the specified torque again.

Tightening torque: 210 N·m (155 ft-lb)

>>C<< GENERATOR INSTALLATION

1. Temporarily tighten generator bolt and nut.

2. Tighten the nut on the lower side to the specified torque.

Tightening torque: 44 ± 10 N·m (32 ± 7 ft-lb)

3. Tighten the bolt on the upper side to the specified torque.

Tightening torque: 44 ± 10 N·m (32 ± 7 ft-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)