HEADLIGHT AIMING

PRE-AIMING INSTRUCTION (LOW-BEAM)

1. Inspect for badly rusted or faulty headlight assemblies.

2. These conditions must be corrected before a satisfactory adjustment can be made.

3. Inspect tire inflation, and adjust if it is necessary.

4. If the fuel tank is not full, place a weight in the trunk of the vehicle to simulate weight of a full tank [3 kg (6.6 pounds) per gallon].

5. There should be no other load in the vehicle other than driver or substituted weight of approximately 68 kg (150 pounds) placed in driver's position.

6. Turn the headlight leveling switch to the switch position "0." <Vehicles with headlight manual leveling system>

7. Thoroughly clean the headlight lenses.

8.

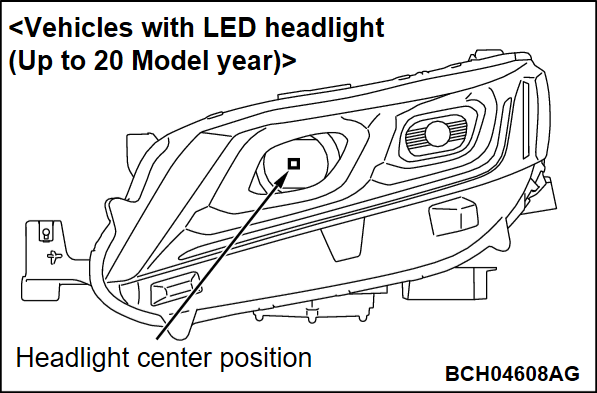

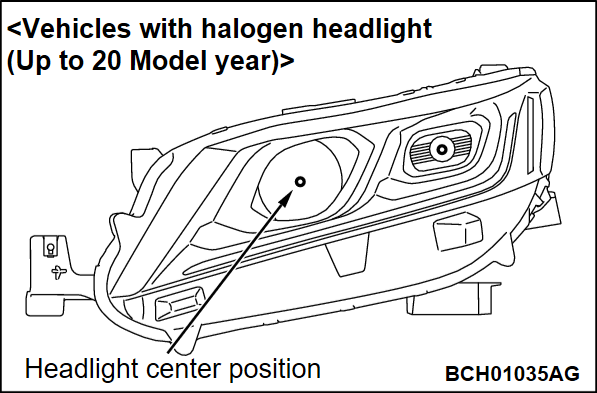

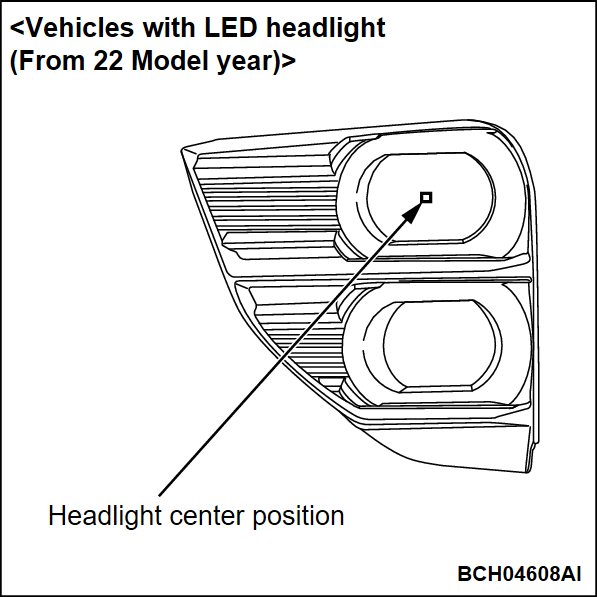

| caution | Check that the square shaped marking (LED headlight) or round shaped marking (halogen headlight) is on the lens surface. |

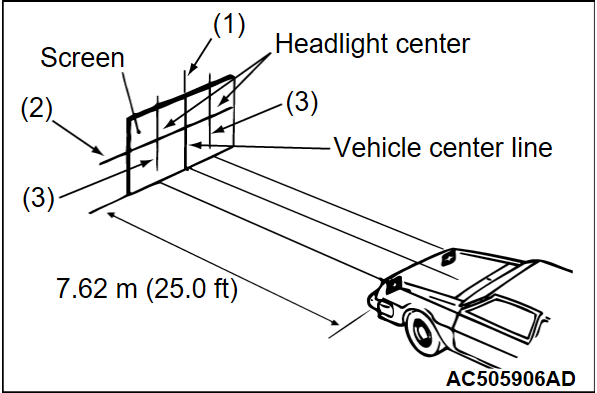

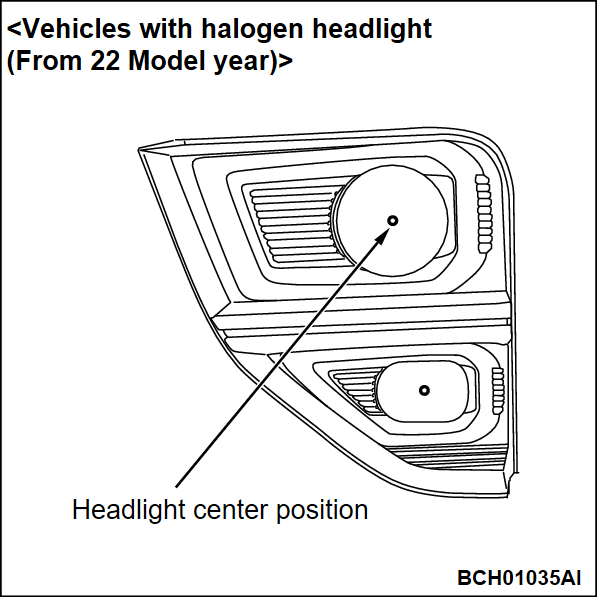

Place the vehicle on a level floor, perpendicular to a flat screen 7.62 m (25.0 ft) away from the headlight center-marks on the headlight lens.

9. Rock vehicle sideways to allow vehicle to assume its normal position.

10. Bounce the front suspension through three (3) oscillations by applying the body weight to hood or bumper.

11. Set the distance between the screen and the headlight center marks of the headlight as shown in the illustration.

12. Four lines of adhesive tape (or equivalent markings) are required on screen or wall:

(1) Position a vertical tape or mark so that it is aligned with the vehicle center line.

(2) Measure the distance from the headlight center position to the floor. Transfer the measurement to the screen. Horizontal tape or mark on the screen is for reference of vertical adjustment.

(3) Measure the distance from the center line of the vehicle to the center of each headlight. Transfer the measurement to the screen. Vertical tape or mark on the screen with reference to the center line of each headlight.

HEADLIGHT ADJUSTMENT (LOW-BEAM)

1.

| caution |

|

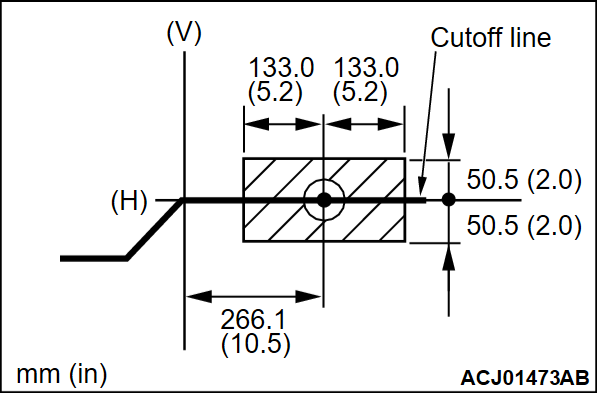

The low-beam headlight should project on the screen upper edge of the beam (cut-off).

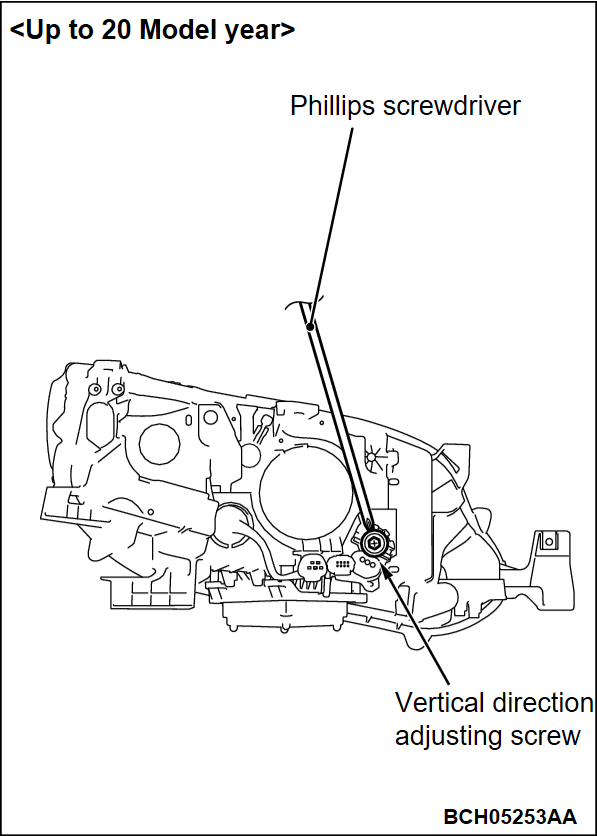

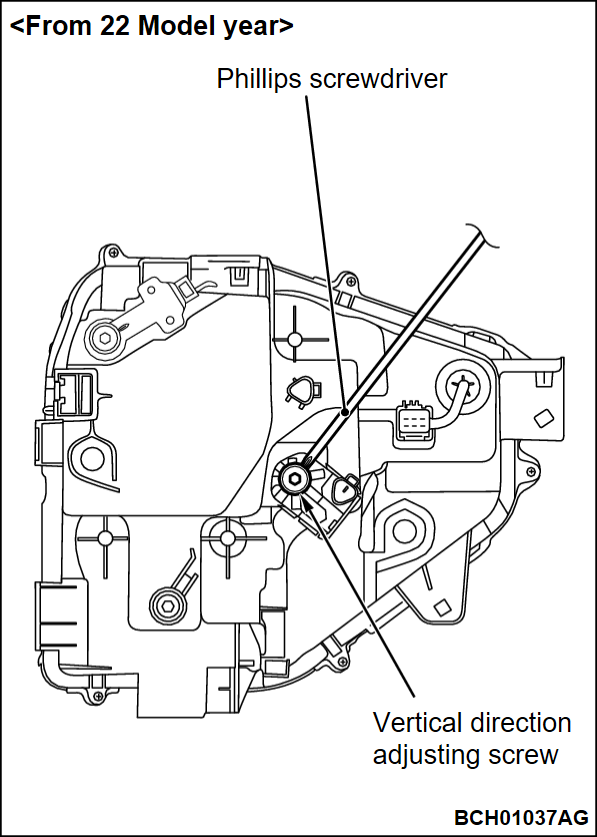

2. Turn the adjusting screws to achieve the specified low-beam cut-off location on the aiming screen.

Standard value:

- (Vertical direction) Horizontal line (H) ± 50.5 mm (± 2.0 in) (± 0.38 degrees angle)

- (Horizontal direction): ± 133.0 mm (± 5.2 in) (± 1 degrees angle) from the axis, which is 266.1 mm (10.5 in) (2 degrees angle) rightward from the vertical line (V)

| note | High-beam pattern should be correct when the low-beams are adjusted properly. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)