DTC B1625 Lap pre-tensioner (RH) (squib) system (short circuit between squib circuit terminals)

| caution | If DTC B1625 is set in SRS-ECU, be sure to diagnose the CAN bus line. |

OPERATION

Only when the frontal collision impact that exceeds the threshold is simultaneously detected (turned ON) by the front impact sensor as well as by the analog G-sensor and safing G-sensor in SRS-ECU, the electric current is supplied from SRS-ECU to the lap pre-tensioner (RH) (squib).

TROUBLE JUDGMENT

The code is set when the short circuit occurs to between the terminals of SRS-ECU lap pre-tensioner (RH) (squib) circuit.

PROBABLE CAUSES

- Damaged short spring *

- Short circuit between terminals of lap pre-tensioner (RH) (squib) circuit

- Damaged connector(s)

- Malfunction of SRS-ECU

- Insufficient press of locking button or locking button not pressed

| note | *: The squib connectors integrate a short spring (which prevents the air bags from being unintentionally deployed because of static electricity by shorting the positive wire to the ground wire in the squib circuit when the connectors are disconnected). Therefore, when the above codes are set, the short spring may not be released due to the damaged connector even when the connectors are connected. |

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), diagnose the CAN bus line.

(1)

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the CAN bus line found to be normal?

STEP 2. Using scan tool (M.U.T.-IIISE), check whether the DTC is set again.

(1) Connect the negative battery terminal.

(2) After erasing the DTC memory, check the DTC again.

(3) Disconnect the negative battery terminal.

Is DTC B1625 set?

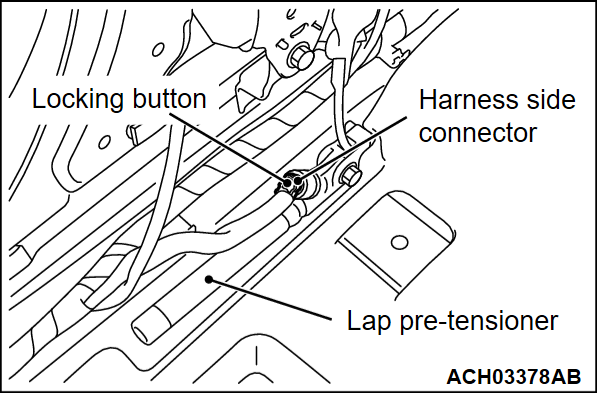

STEP 3. Connector check: lap pre-tensioner (RH)

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

(2) After disconnecting the lap pre-tensioner (RH) harness side connector, connect the connector again. For the lap pre-tensioner (RH) harness side connector disconnection, use the flat-tipped screwdriver to pull out the harness side connector locking button. After releasing the lock, disconnect the harness side connector.

(3) Connect the negative battery terminal.

(4) After erasing the DTC memory, check the DTC again.

(5) Disconnect the negative battery terminal.

Is DTC B1625 set?

Replace the connector concerned.

Replace the connector concerned.STEP 4. Diagnosis check by dummy resistor connection.

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

(2) Use the flat-tipped screwdriver to pull out the locking button of harness side connector. After releasing the lock, disconnect the lap pre-tensioner (RH) harness side connector.

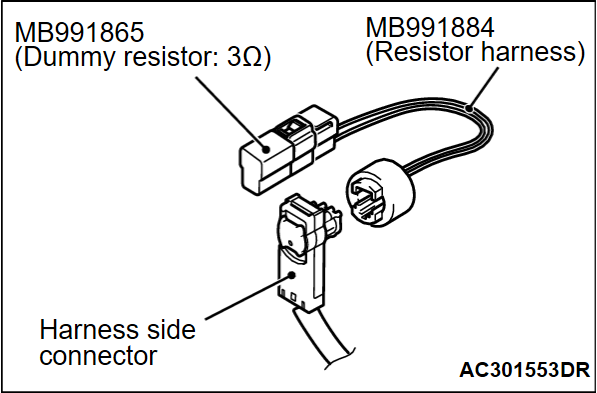

(3) Connect special tool dummy resistor (MB991865) to special tool resistor harness (MB991884).

(4) Connect resistor harness to the lap pre-tensioner (RH) harness side connector.

(5) Connect the negative battery terminal.

(6) After erasing the DTC memory, check the DTC again.

(7) Disconnect the negative battery terminal.

Is DTC B1625 set?

STEP 5. Resistance measurement at the SRS-ECU connector.

(1) Check that the negative battery terminal is disconnected. If the negative battery terminal is connected, disconnect it.

(2) Disconnect the SRS-ECU connector.

(3)

Use the flat-tipped screwdriver to pull out the locking button of harness side connector. After releasing the lock, disconnect the lap pre-tensioner (RH) harness side connector.

| danger | Disconnect this lap pre-tensioner (RH) connector, and keep the squib circuit shorted. |

(4) Take the measurements below at the SRS-ECU harness side connector.

- Continuity between PA2-, PA2+ line

OK: No continuity

Is the check result normal?

Repair the wiring harness PA2-, PA2+ line between the SRS-ECU connector and the lap pre-tensioner (RH) connector.

Repair the wiring harness PA2-, PA2+ line between the SRS-ECU connector and the lap pre-tensioner (RH) connector.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)