DTC P0131: Linear Air-Fuel Ratio Sensor Circuit Low Voltage

CIRCUIT OPERATION

The linear air-fuel ratio sensor and the ECM are connected by the following three lines to detect the air-fuel ratio.

- The line between the linear air-fuel ratio sensor and the ECM terminal LPFL detects the air-fuel ratio.

- The auxiliary line between the linear air-fuel ratio sensor and the ECM terminal LSFL detects the air-fuel ratio.

- The line between the linear air-fuel ratio sensor and the ECM terminal LEFL is connected to ground.

TECHNICAL DESCRIPTION

- The ECM effects air/fuel ratio feedback control in accordance with the signals from the linear air-fuel ratio sensor.

- If the linear air-fuel ratio sensor has deteriorated, corrections will be made by the heated oxygen sensor (rear).

DESCRIPTIONS OF MONITOR METHODS

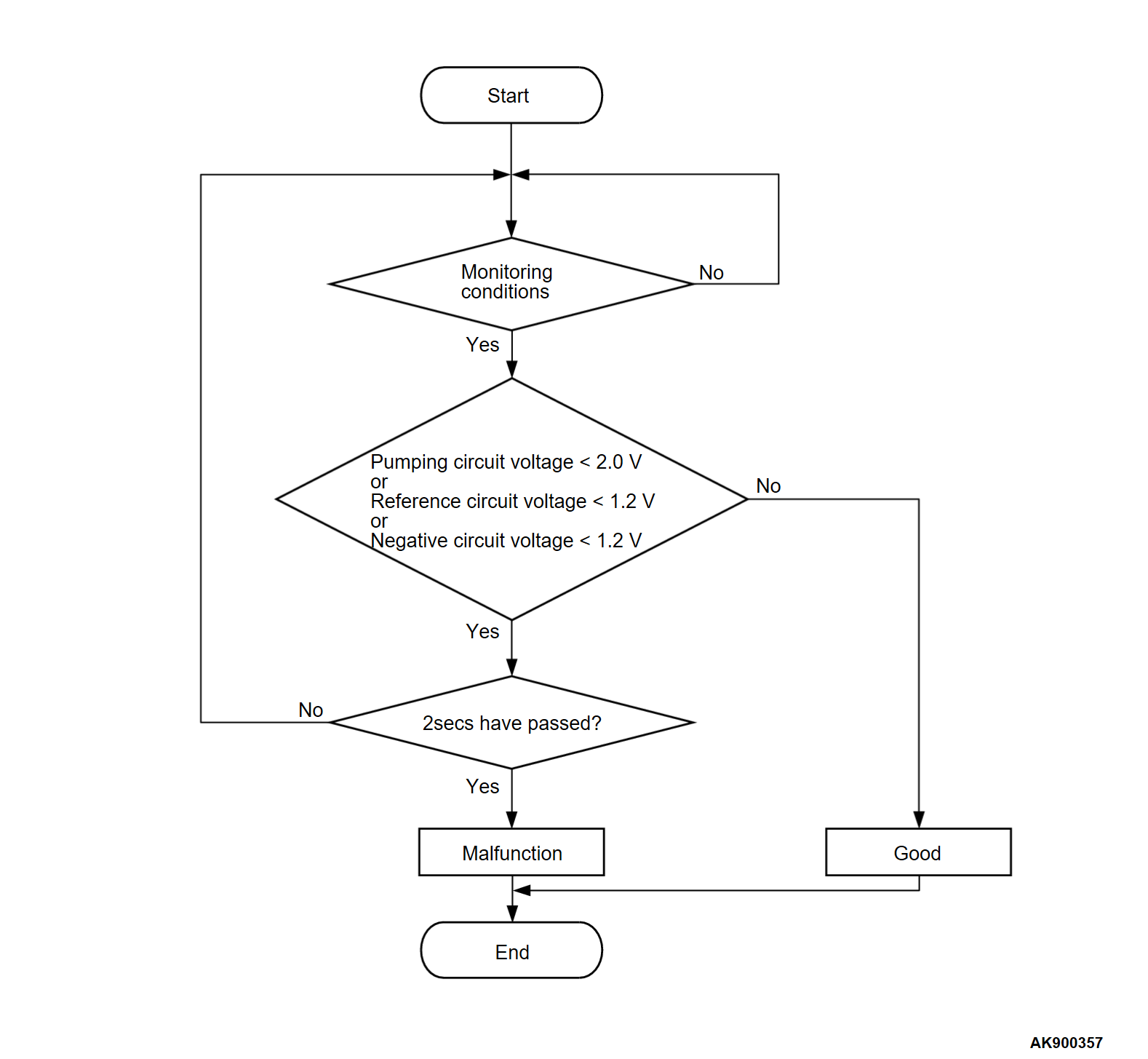

- If one of the three line voltages is excessively low or if all the three line voltages are excessively low, the DTC is set as a malfunction.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Linear air-fuel ratio sensor heater monitor

- Misfire monitor

- Fuel system monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor 1

- Barometric pressure sensor

- Throttle position sensor

- Accelerator pedal position sensor

Check Conditions

- Battery positive voltage is between 10 and 16.5 volts.

- More than 40 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- The pumping circuit voltage is be lower than 2 volts for 2 seconds.

or

- The reference circuit voltage is be lower than 1.2 volt for 2 seconds.

or

- The negative circuit voltage is be lower than 1.2 volt for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Does not control air-fuel ratio closed loop.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Linear air-fuel ratio sensor failed.

- Shorted linear air-fuel ratio sensor circuit, or connector damage.

- ECM failed.

DIAGNOSIS

STEP 1. Check of short circuit to ground in LSFL line between linear air-fuel ratio sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 2. Check of short circuit to ground in LPFL line between linear air-fuel ratio sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 3. Check of short circuit to ground in LEFL line between linear air-fuel ratio sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 4. Replace the linear air-fuel ratio sensor.

(1) Replace the linear air-fuel ratio sensor.

(2) Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 1  .

.

.

.(3) Check the diagnostic trouble code (DTC).

Is DTC P0131 set?

The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)