DTC P0606: Engine Control Module Main Processor Malfunction

ENGINE CONTROL MODULE MAIN PROCESSOR MALFUNCTION CIRCUIT

CIRCUIT OPERATION

TECHNICAL DESCRIPTION

The ECM check whether the microcomputer, which performs the drive control of the throttle valve and injector (high pressure), is normal.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS <Processor error>

Check Condition

- Ignition switch is "ON" position.

Judgment Criterion

- No surveillance pulse signals is inputted for 0.5 second.

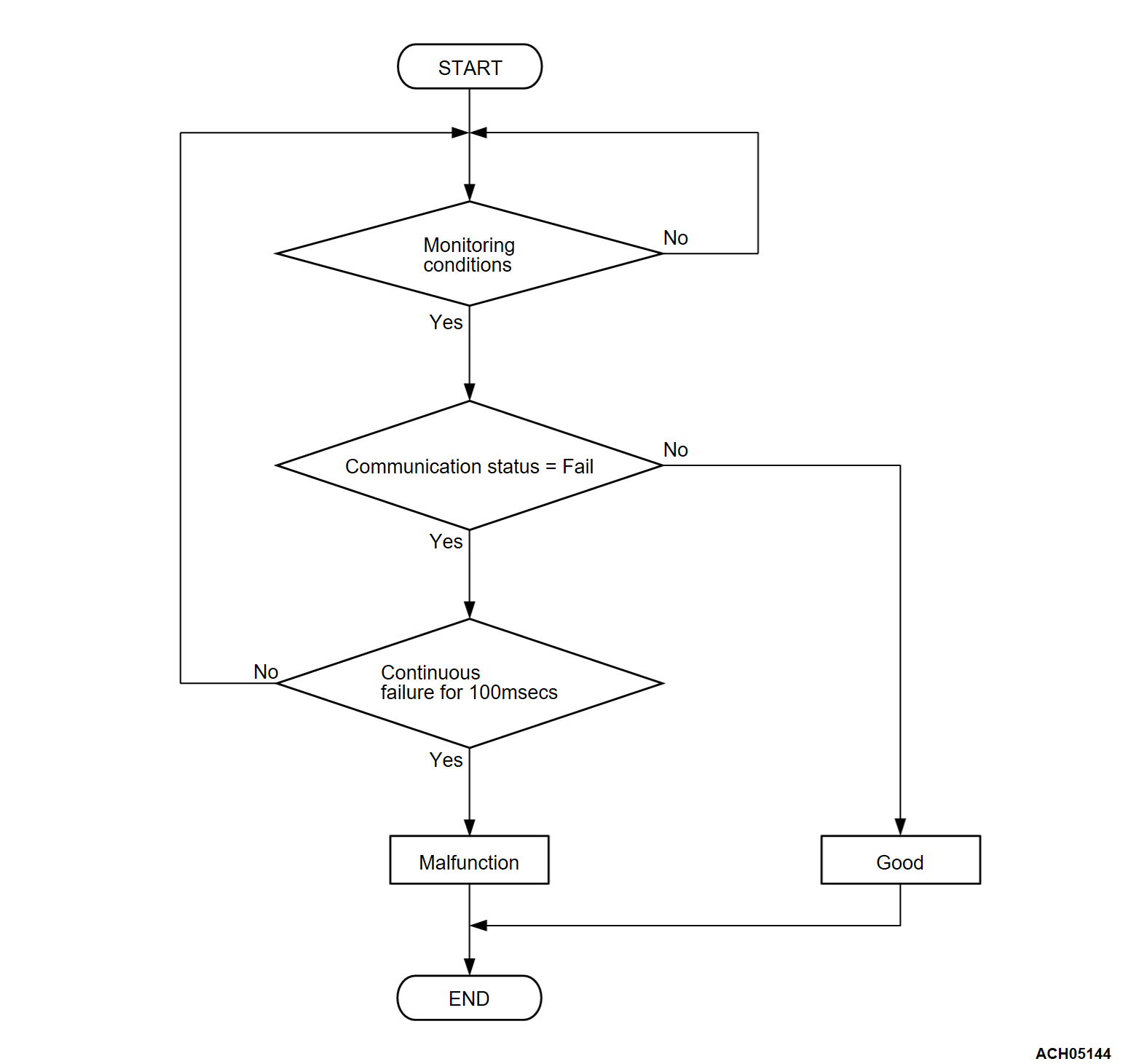

DTC SET CONDITIONS <Direct injection driver communication error (ECM and IC)>

Check Condition

- Ignition switch is "ON" position.

- Battery positive voltage is between 10 and 16.5 volts.

Judgment Criterion

- When communication error between the microcomputer and the direct fuel injection injector driver continues.

FAIL-SAFE AND BACKUP FUNCTION

- Throttle opening degree position is in default position.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- MFI relay failed.

- Shorted MFI relay circuit or connector damage.

- Open or shorted ignition switch-IG circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

STEP 1. Check the battery.

STEP 2. Measure the ignition switch-IG signal voltage at ECM harness side connector.

(1) Disconnect the ECM connector and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal IGN and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

STEP 3. Check of harness damage in IGN line between ETACS-ECU connector and ECM connector.

STEP 4. Check the MFI relay.

STEP 5. Check of short circuit to ground in C/R line between MFI relay connector and ECM connector.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)