DTC P0340: Intake Camshaft Position Sensor Circuit

CIRCUIT OPERATION

- The intake camshaft position sensor power is supplied from the ECM terminal 5V.

- Terminal DGND line of the intake camshaft position sensor is grounded with ECM terminal DGND.

- A 5-volt voltage is applied on the intake camshaft position sensor output terminal from the ECM terminal CPIN. The intake camshaft position sensor generates a pulse signal when the output terminal is opened and grounded.

TECHNICAL DESCRIPTION

- The intake camshaft position sensor detects the position of the intake camshaft and inputs the pulse signal to the ECM.

- In response to the intake camshaft position sensor signal and the crankshaft position sensor signal, the ECM detects the compression top dead center of the No. 1 cylinder.

- Also, in response to the intake camshaft position sensor signal, the ECM controls variable valve timing (V.V.T.).

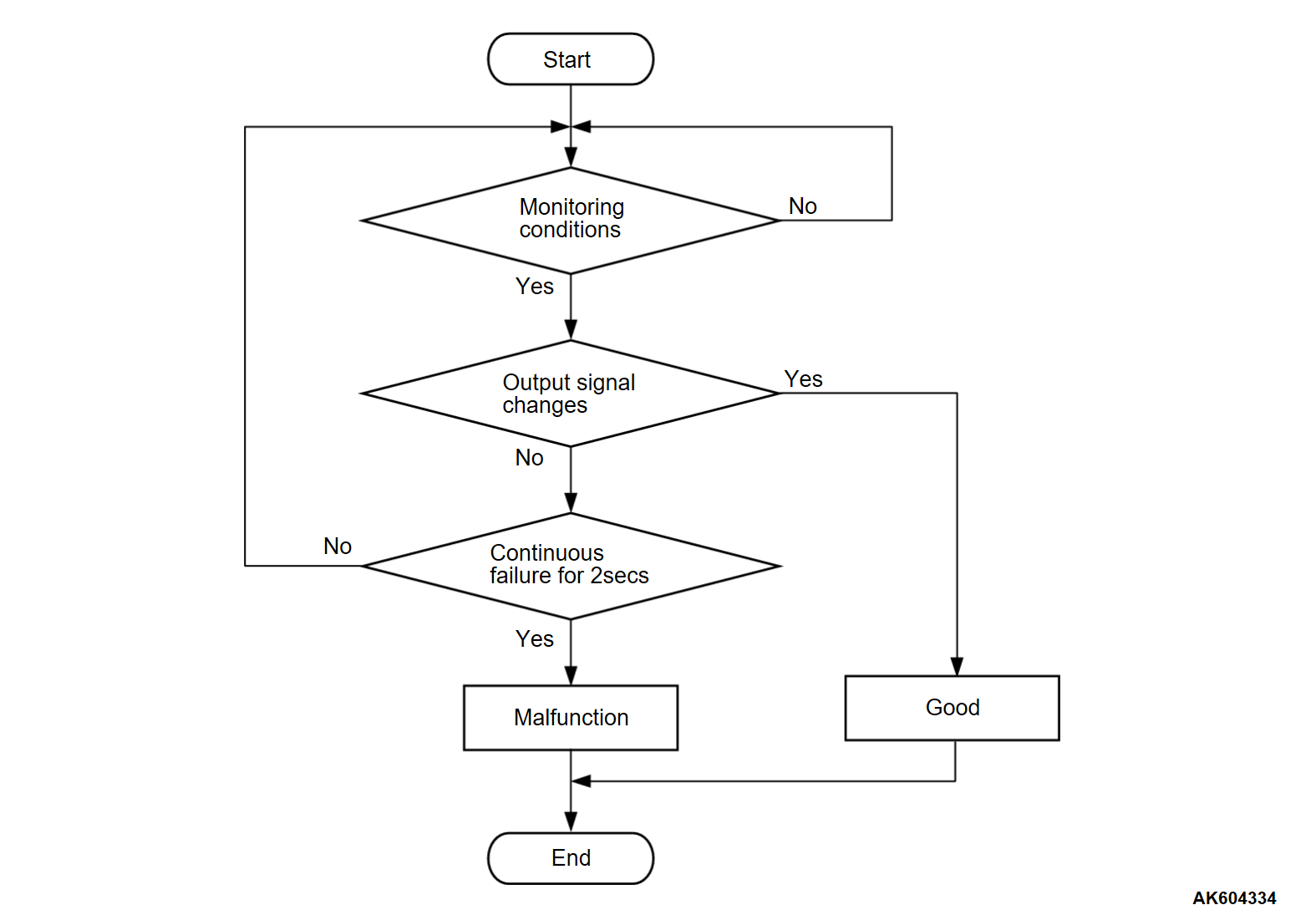

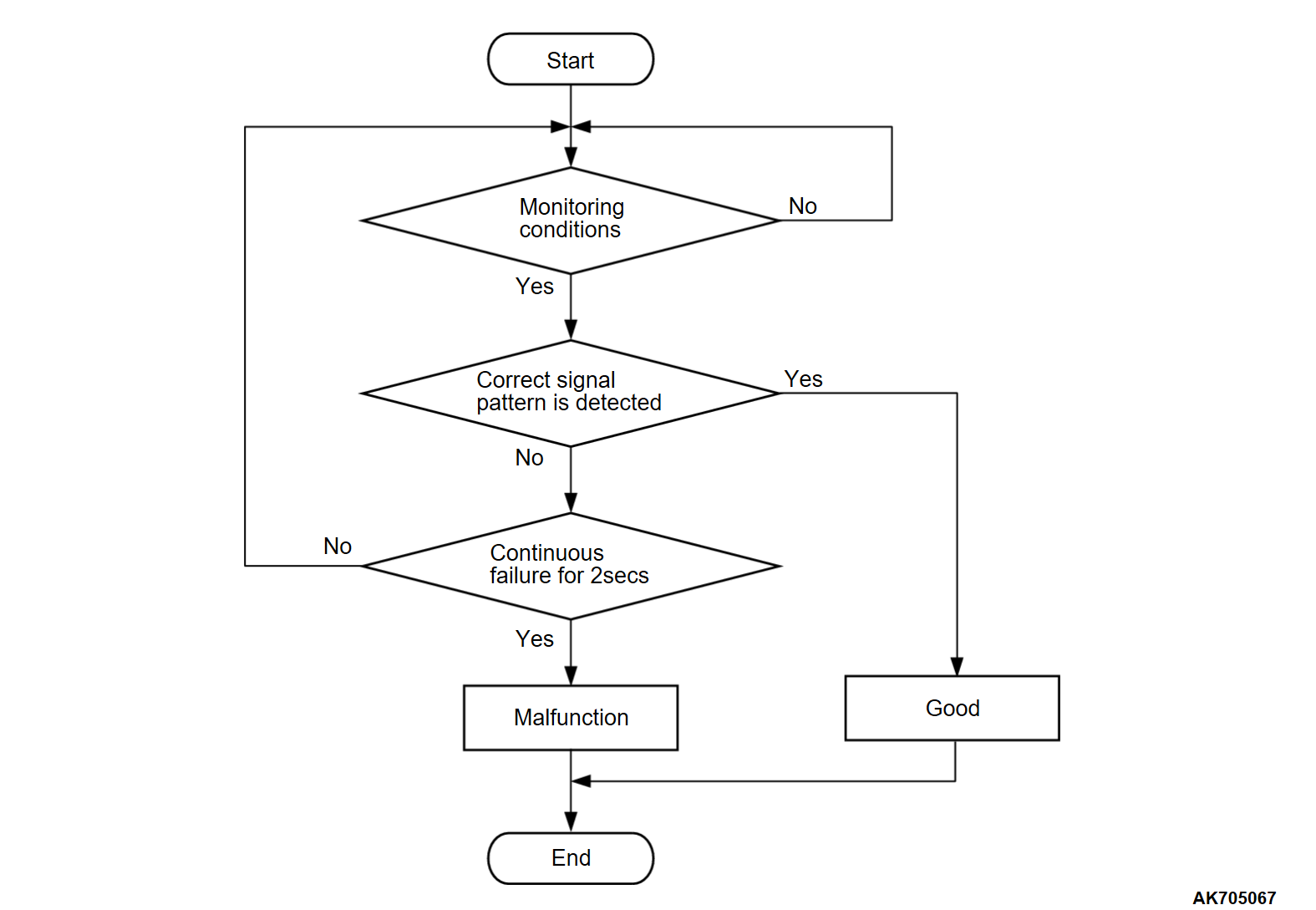

DESCRIPTIONS OF MONITOR METHODS

- Intake camshaft position sensor signal does not change.

- Intake camshaft position sensor signal is not normal pattern.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS <Circuit continuity>

Check Condition

- Engine is being cranked.

or

- Engine speed is more than 500 r/min excluding during cranking.

Judgment Criterion

- Intake camshaft position sensor output voltage does not change (no pulse signal is input) for 2 seconds.

DTC SET CONDITIONS <Range/Performance problem - alignment>

Check Condition

- Engine is being cranked.

or

- Engine speed is more than 500 r/min excluding during cranking.

Judgment Criterion

- Normal signal pattern is not inputted for cylinder identification from the crankshaft position sensor signal and intake camshaft position sensor signal for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Engine runs in learned pattern until engine stops.

- Does not control variable valve timing (V.V.T.).

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Intake camshaft position sensor failed.

- Open or shorted intake camshaft position sensor circuit, harness damage or connector damage.

- Intake camshaft failed.

- ECM failed.

DIAGNOSIS

Required Special Tool:

- MB991709: Test Harness

STEP 1. Using the oscilloscope, check the intake camshaft position sensor.

- Engine: Idling

- Selector lever: P range

- Voltage between terminal CPIN and ground.

Is the wave pattern normal?

STEP 2. Measure the sensor supply voltage at intake camshaft position sensor connector.

(1) Disconnect the intake camshaft position sensor connector and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal CPIN line and ground.

- Voltage should be between 4.9 and 5.1 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 4.9 and 5.1 volts?

STEP 3. Check of short to ground and open circuit in CPIN line between intake camshaft position sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 4. Measure the power supply voltage at intake camshaft position sensor connector.

(1) Disconnect the intake camshaft position sensor connector and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 5V line and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

STEP 5. Check of short to ground and open circuit in 5V line between intake camshaft position sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 6. Check the continuity at intake camshaft position sensor connector.

(1) Disconnect the intake camshaft position sensor connector and measure at the harness side.

(2) Check for the continuity between terminal DGND line and ground.

- Continuity (2 ohms or less).

Does continuity exist?

STEP 7. Check of open circuit and harness damage in DGND line between intake camshaft position sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 8. Check of harness damage in 5V line between ECM connector and intake camshaft position sensor connector.

Is the harness wire in good condition?

STEP 9. Check of harness damage in CPIN line between ECM connector and intake camshaft position sensor connector.

Is the harness wire in good condition?

STEP 10. Check the intake camshaft position sensing portion.

Is the intake camshaft position sensing portion in good condition?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)