DTC P0328: Knock Sensor Circuit High

CIRCUIT OPERATION

- The knock sensor sends a signal voltage to the ECM terminal K/S.

- The ground terminal is grounded with ECM terminal K/SE.

TECHNICAL DESCRIPTION

- The knock sensor converts the vibration of the cylinder block into a voltage and outputs it.

- The ECM checks whether the voltage is within a specified range.

DESCRIPTIONS OF MONITOR METHODS

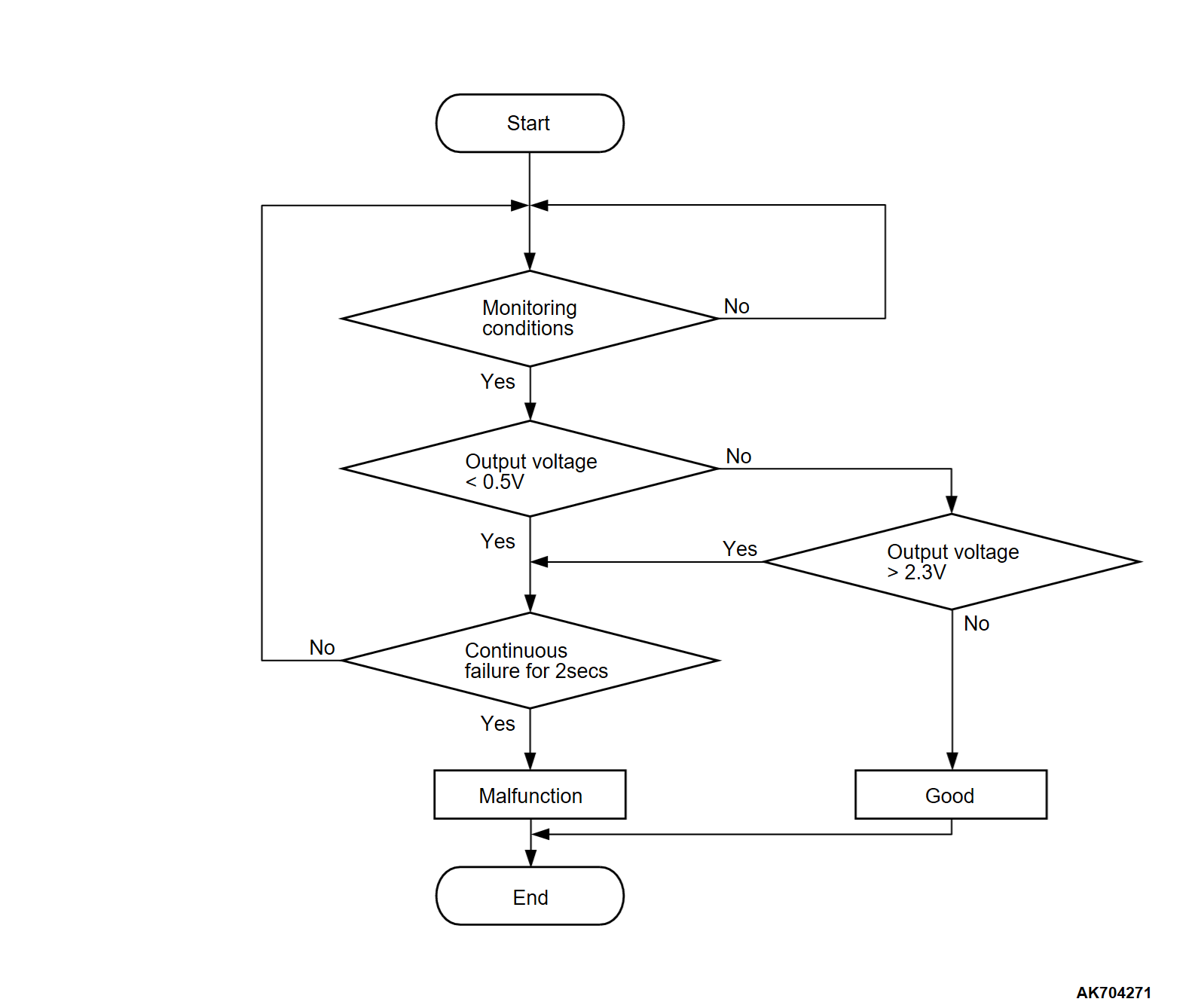

Knock sensor output voltage is out of specified range.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

Check Condition

- More than 2 seconds have passed since the engine starting sequence was completed.

Judgment Criterion

- Knock sensor output voltage has continued to be higher than 2.3 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Fix the ignition timing with an allowance against knock.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Shorted knock sensor circuit, or connector damage.

- ECM failed.

DIAGNOSIS

STEP 1. Check of short circuit to power supply in K/S line between knock sensor connector and ECM connector.

STEP 2. Check of short circuit to power supply in K/SE line between knock sensor connector and ECM connector.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)