DTC P0107: Manifold Absolute Pressure Circuit Low Input

CIRCUIT OPERATION

- A 5-volts voltage is supplied to the manifold absolute pressure sensor power terminal from the ECM terminal MAP5. The ground terminal is grounded with ECM terminal MAPE.

- A voltage that is proportional to the intake manifold pressure is sent to the ECM terminal MAP from the manifold absolute pressure sensor output terminal.

TECHNICAL DESCRIPTION

- The manifold absolute pressure sensor outputs a voltage which corresponds to the intake manifold pressure.

- The ECM checks whether this voltage is within a specified range.

DESCRIPTIONS OF MONITOR METHODS

- Manifold absolute pressure sensor output voltage is out of specified range.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Engine coolant temperature sensor

- Throttle position sensor

- Mass airflow sensor

- Intake air temperature sensor 1

- Barometric pressure sensor

- Boost pressure sensor

DTC SET CONDITIONS

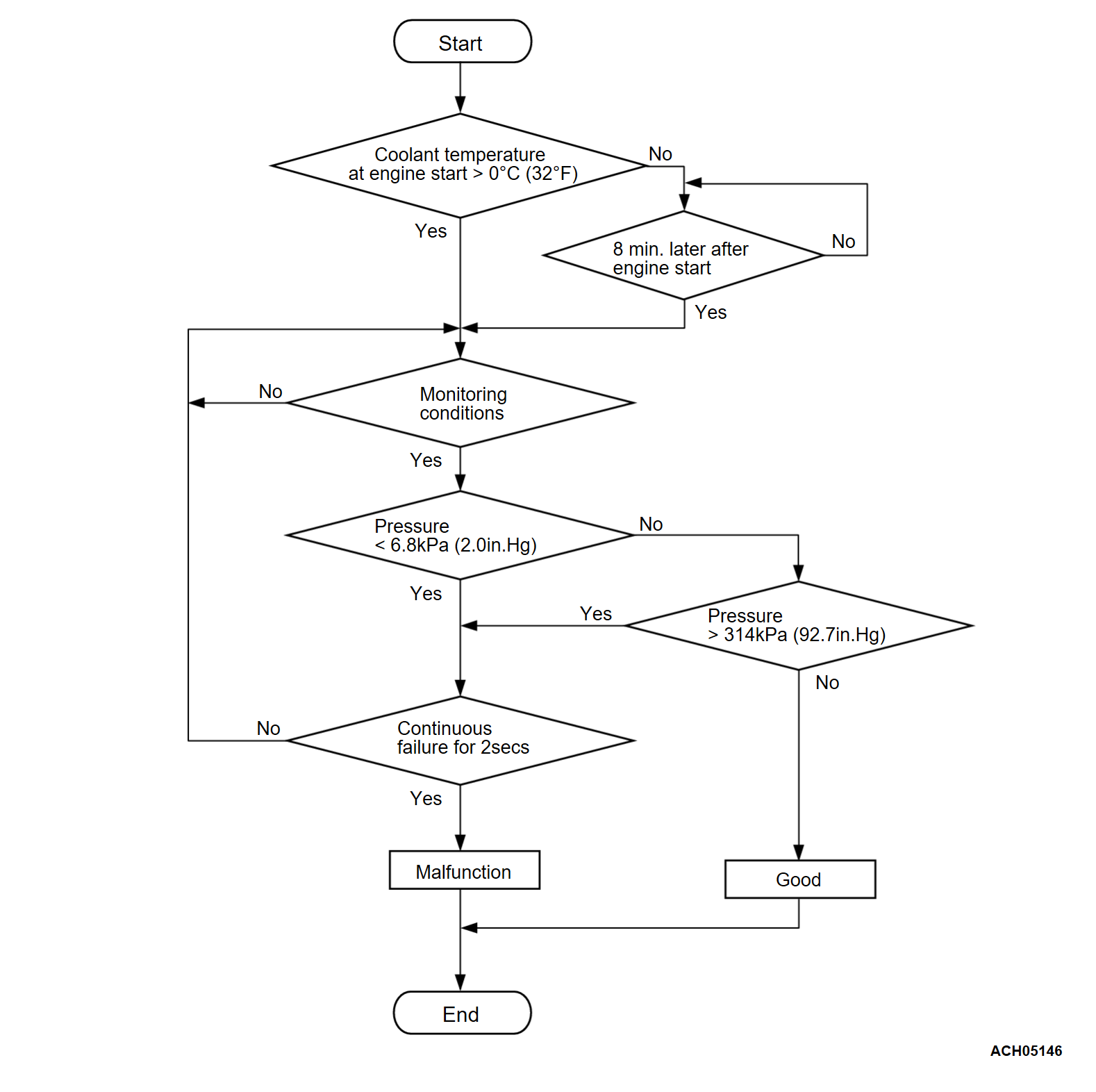

Check Conditions

- 8 minutes or more have passed since the engine starting sequence was completed, when the engine coolant temperature at engine start is 0°C (32°F) or lower.

- Volumetric efficiency is higher than 20 percent.

Judgment Criterion

- Manifold absolute pressure sensor output voltage is less than 0.1 volt [corresponding to a manifold absolute pressure of 6.8 kPa (2.0 in.Hg)] for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Estimate the throttle opening degree and the intake manifold pressure given by a normal sensor, and then carry out the fuel control.

- Intake charge pressure is restricted.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Manifold absolute pressure sensor failed.

- Open or shorted manifold absolute pressure sensor circuit, or connector damage.

- ECM failed.

DIAGNOSIS

Required Special Tool:

- MB991709: Test Harness

STEP 1. Using scan tool (M.U.T.-IIISE), check data list item 8: Manifold Absolute Pressure Sensor.

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool (M.U.T.-IIISE) to the data reading mode for item 8, Manifold Absolute Pressure Sensor.

- When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg).

- When altitude is 600 m (1,969 feet), 95 kPa (28.1 in.Hg).

- When altitude is 1,200 m (3,937 feet), 88 kPa (26.0 in.Hg).

- When altitude is 1,800 m (5,906 feet), 81 kPa (23.9 in.Hg).

(4) Start the engine.

- When the engine is idling, 27 - 47 kPa (8.0 - 13.9 in.Hg).

- When the engine is suddenly revved, manifold absolute pressure varies.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 2. Measure the sensor supply voltage at manifold absolute pressure sensor connector.

(1) Disconnect the connector and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal MAP5 line and ground.

- Voltage should be between 4.9 and 5.1 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage between 4.9 and 5.1 volts?

STEP 3. Check of open circuit and short circuit in MAP5 line between manifold absolute pressure sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 4. Using scan tool (M.U.T.-IIISE), check data list item 8: Manifold Absolute Pressure Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool (M.U.T.-IIISE) to the data reading mode for item 8, Manifold Absolute Pressure Sensor.

- When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg).

- When altitude is 600 m (1,969 feet), 95 kPa (28.1 in.Hg).

- When altitude is 1,200 m (3,937 feet), 88 kPa (26.0 in.Hg).

- When altitude is 1,800 m (5,906 feet), 81 kPa (23.9 in.Hg).

(3) Start the engine.

- When the engine is idling, 27 - 47 kPa (8.0 - 13.9 in.Hg).

- When the engine is suddenly revved, manifold absolute pressure varies.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 5. Check of harness damage in MAP line between manifold absolute pressure sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 6. Measure the sensor output voltage at manifold absolute pressure sensor connector.

(1) Using test harness special tool MB991709 to connect connector, and measure at pick-up harness.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal MAP and ground.

- When altitude is 0 m (0 foot), voltage should be between 1.4 and 1.6 volts.

- When altitude is 600 m (1,969 feet), voltage should be between 1.3 and 1.5 volts.

- When altitude is 1,200 m (3,937 feet), voltage should be between 1.2 and 1.4 volts.

- When altitude is 1,800 m (5,906 feet), voltage should be between 1.1 and 1.3 volts.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the measured voltage normal?

STEP 7. Check of short to ground in MAP line between manifold absolute pressure sensor connector and ECM connector.

Is the harness wire in good condition?

STEP 8. Check of open circuit and harness damage in MAP line between manifold absolute pressure sensor connector and ECM connector.

Is the harness wire in good condition?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)