DTC P1310: Low Speed Pre-ignition Detected

TECHNICAL DESCRIPTION

- The ECM detects abnormal combustion (LSPI) at low engine rotation.

- Using engine oil other than genuine goods, oil dilution, or fuel deterioration may cause LSPI. In rare cases, it may occur when intake air temperature is high and high load operation is performed with low rotation.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

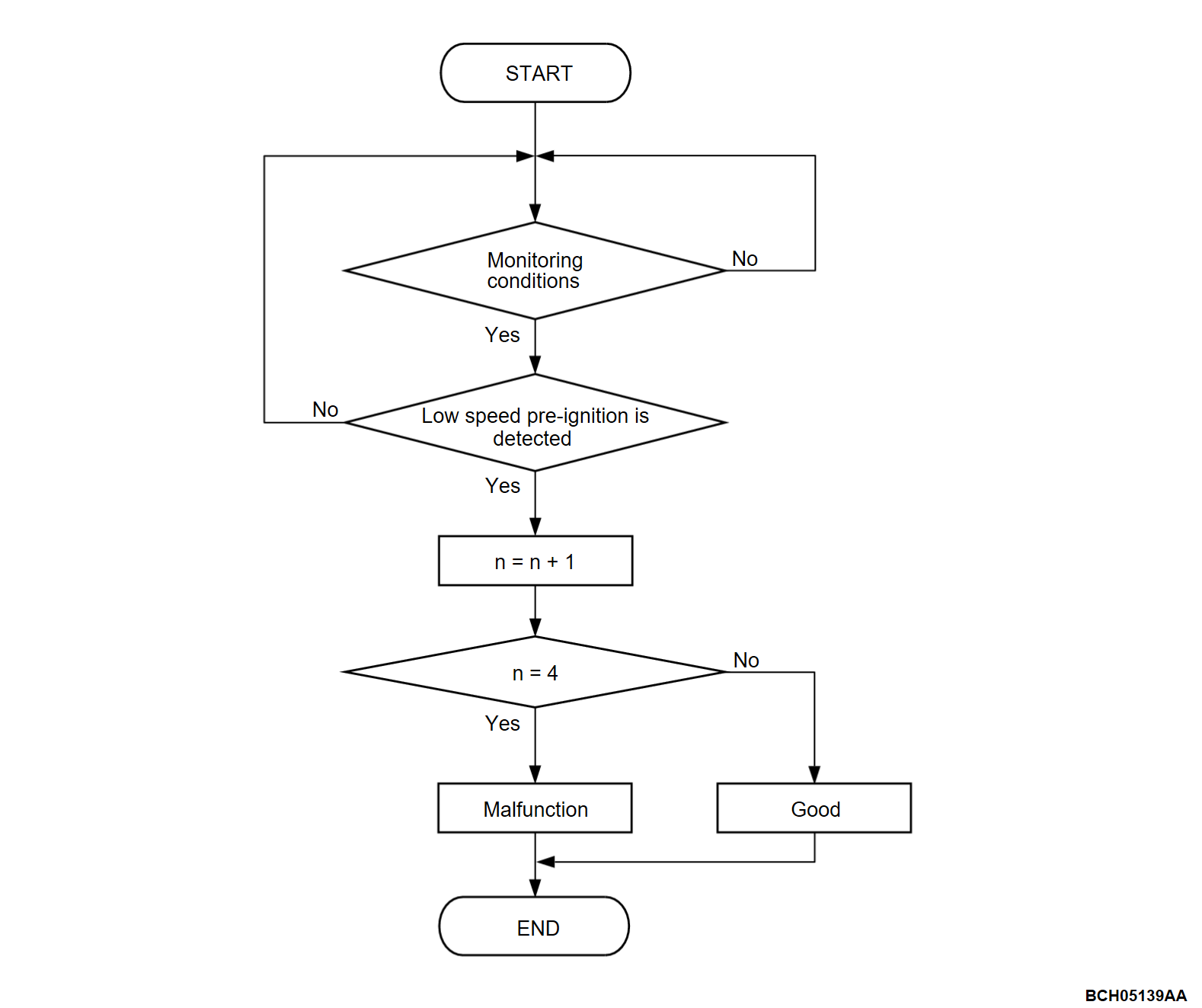

DTC SET CONDITIONS

Check Conditions

- After predetermined times since the completion of engine start.

- Engine speed is lower than 3,000 r/min.

- Volumetric efficiency is higher than 160 percent.

Judgment Criterion

- Detection times of low speed pre-ignition is more than 4 times.

FAIL-SAFE AND BACKUP FUNCTION

- Limit the torque that is at low engine speed and high load.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Engine oil failed.

- Fuel deteriorated.

- Engine failed.

- Spark plug failed.

- Turbocharger failed.

| note | If excessive LSPI occurs, the engine, turbocharger, etc. may get damaged. |

DIAGNOSIS

Preparation to carry out troubleshooting

- Check with the user whether specified engine oil is used, about the supply source of fuel, fueling timing, fueling amount, and car usage status (how long has the car not been used, the driving situation at the time of DTC occurrence, or whether short distance driving in a cold condition occurred).

STEP 1. Check the compression.

Are there any abnormalities?

STEP 2. Check the spark plugs.

Refer to GROUP 16, Ignition System - On-vehicle Service - Spark Plug Check And Cleaning  .

.

.

.Is the spark plug normal?

STEP 3. Check the turbocharger assembly.

Refer to GROUP 15, Turbocharger Assembly - Turbocharger Assembly Inspection  .

.

.

.Is the turbocharger assembly normal?

STEP 4. Refill or replace fuel

- Check when fuel was refilled and the amount of the fuel, and refill or replace fuel as shown in the table.

|

| note | *: Extract fuel so that the specified amount can be replenished. |

| note | For the details of the fuel tank capacity, refer to the relevant Technical Information Manual. Refer to GROUP 13B, General Information). |

Is refilling or replacement of fuel necessary?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)