DTC P023D: Abnormal Correlation Between Manifold Absolute Pressure Sensor And Boost Pressure Sensor

TECHNICAL DESCRIPTION

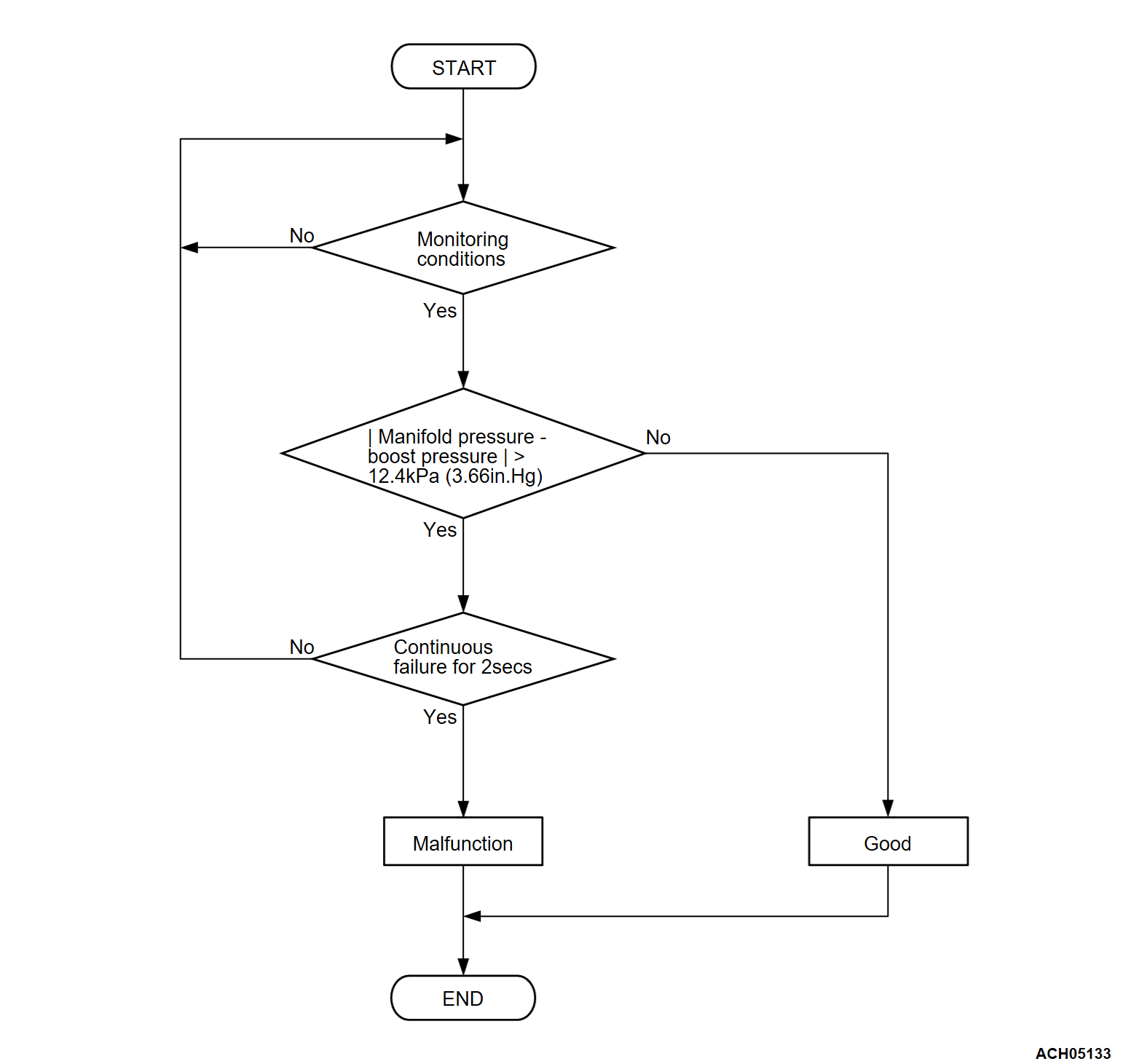

The ECM detects abnormality in the sensor by comparing the manifold absolute pressure sensor output with the boost pressure sensor output.

DESCRIPTIONS OF MONITOR METHODS

The ECM compares the manifold absolute pressure sensor output with the boost pressure sensor output after the ignition switch is in "LOCK" (OFF) position. When the difference exceeds the specified value between them, the ECM determines whether the manifold absolute pressure sensor / the boost pressure sensor has malfunction or not.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Engine coolant temperature sensor

- Manifold absolute pressure sensor

- Boost pressure sensor

DTC SET CONDITIONS

Check Conditions

- Ignition switch is in "LOCK" (OFF) position.

- After 2 seconds pass from the time when the engine is stopped.

- Engine coolant temperature is higher than 0°C (32°F).

Judgment Criterion

- Difference between manifold absolute pressure sensor output and boost pressure sensor output is more than 12.4 kPa (3.66 in.Hg) for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- None.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Boost pressure sensor circuit harness damage, or connector damage.

- Manifold absolute pressure sensor circuit harness damage, or connector damage.

- Boost pressure sensor failed.

- Manifold absolute pressure sensor failed.

- ECM failed.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), check data list item 8: Manifold Absolute Pressure Sensor.

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(1) Connect scan tool (M.U.T.-IIISE) to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool (M.U.T.-IIISE) to the data reading mode for item 8, Manifold Absolute Pressure Sensor.

- When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg).

- When altitude is 600 m (1,969 feet), 95 kPa (28.1 in.Hg).

- When altitude is 1,200 m (3,937 feet), 88 kPa (26.0 in.Hg).

- When altitude is 1,800 m (5,906 feet), 81 kPa (23.9 in.Hg).

(4) Start the engine.

- When the engine is idling, 27 - 47 kPa (8.0 - 13.9 in.Hg).

- When the engine is suddenly revved, manifold absolute pressure varies.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

STEP 2. Using scan tool (M.U.T.-IIISE), check data list item 125: Boost Pressure Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool (M.U.T.-IIISE) to the data reading mode for item 125, Boost Pressure Sensor.

- When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg).

- When altitude is 600 m (1,969 feet), 95 kPa (28.1 in.Hg).

- When altitude is 1,200 m (3,937 feet), 88 kPa (26.0 in.Hg).

- When altitude is 1,800 m (5,906 feet), 81 kPa (23.9 in.Hg).

(3) Start the engine.

- When the engine is idling, 70 - 110 kPa (20.7 - 32.4 in.Hg) (Near the atmospheric).

- When the engine is suddenly revved, boost pressure varies.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)