DTC P006E: Turbocharger Wastegate Actuator Supply Voltage Circuit Low Voltage

CIRCUIT OPERATION

Power is supplied from the MFI relay to the ECM terminal WGMB.

TECHNICAL DESCRIPTION

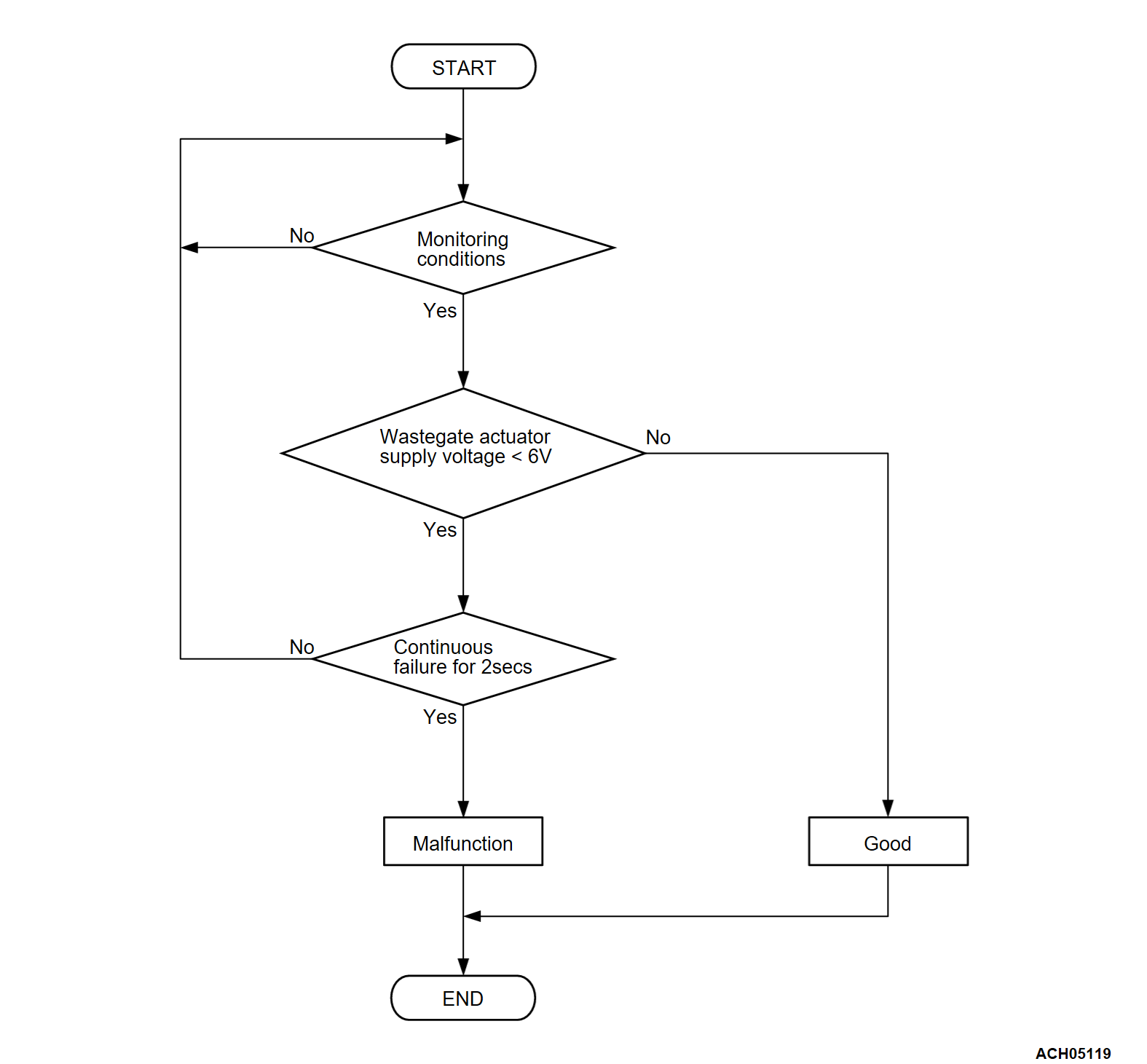

ECM checks the turbocharger wastegate actuator control motor supply voltage for abnormal conditions.

DESCRIPTIONS OF MONITOR METHODS

Turbocharger wastegate actuator source voltage is smaller than the specified value.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- More than 2 seconds have passed since the engine starting sequence was completed.

- Battery positive voltage is more than 8.3 volts.

Judgment Criterion

- Supply voltage for turbocharger wastegate actuator control motor is less than 6 volts for 2 seconds.

FAIL-SAFE AND BACKUP FUNCTION

- Stop driving the turbocharger wastegate actuator control motor.

- Torque is restricted.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are: )

- Blown fuse.

- Open or shorted turbocharger wastegate actuator control motor power supply circuit, harness damage or connector damage.

- ECM failed.

DIAGNOSIS

STEP 1. Measure the power supply voltage at ECM harness side connector.

(1) Disconnect the ECM connector and measure at the harness side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal WGMB and ground.

- Voltage should be battery positive voltage.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is battery positive voltage (approximately 12 volts) present?

STEP 2. Check the power supply fuse.

Is the fuse in good condition?

STEP 3. Check of harness damage in WGMB line between MFI relay connector and ECM connector.

Is the harness wire in good condition?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)