DTC P219A: Air-fuel Ratio Imbalance

TECHNICAL DESCRIPTION

It is thought that the air-fuel ratio between cylinders is uneven due to a deviation or a difference in combustion environment between cylinders.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Not applicable

Sensor (The sensor below is determined to be normal)

- Not applicable

Check Conditions

- Under the closed loop air-fuel control.

- Engine speed is between 1,500 r/min and 3,000 r/min.

- Volumetric efficiency is between 50 and 160 percent.

- Linear air-fuel ratio sensor output is between 13.5 and 15.5.

- Fuel injection mode is not MFI-mode.

- Short-term fuel trim is between -25 and +25 percent.

- Engine coolant temperature is higher than 60°C (140°F).

- 0.2 second or more has elapsed after the above mentioned conditions have been met.

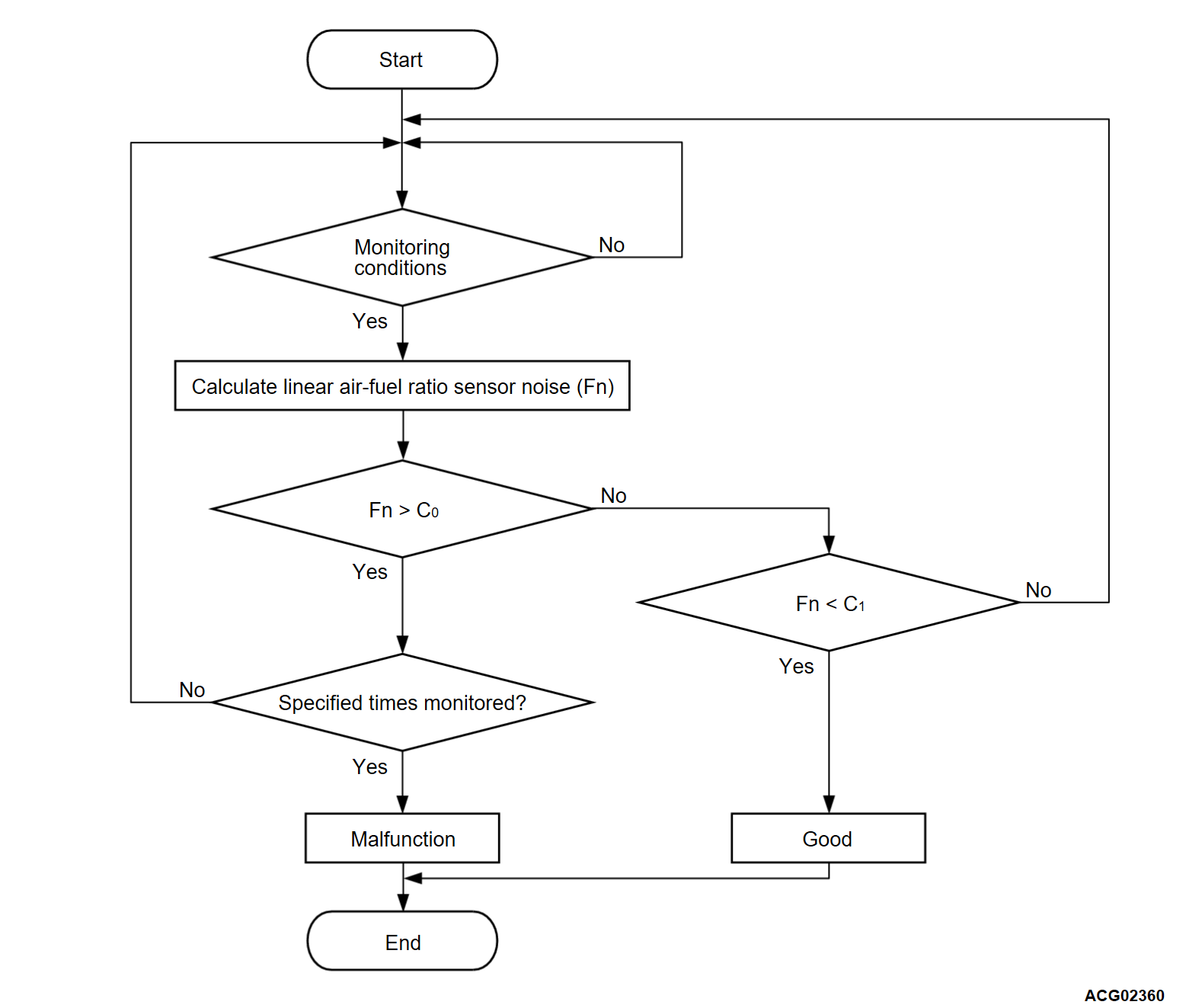

Judgment Criteria

- The number of rich/lean air-fuel ratio peak is more than the specified amount.

- During the drive cycle, the ECM performs monitoring with the accumulated total ignition of 400, 5 times.

FAIL-SAFE AND BACKUP FUNCTION

- None.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Injector failed.

- Injector (high pressure) failed.

- Contaminated intake ports.

- There is some foreign matter around intake and exhaust valves.

- Ignition system related part(s) failed.

- Poor compression.

- Linear air-fuel ratio sensor failed.

- ECM failed.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), read the diagnostic trouble code (DTC).

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(2) Turn the ignition switch to the "ON" position.

(3) Read the DFI and MFI-DTC.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Is the diagnostic trouble code other than P219A set?

STEP 2. Visual check of ignition spark.

(1) Remove the spark plug and install it to the ignition coil.

(2) Connect the ignition coil connector.

(3) Remove all injector connector.

(4) At the engine start, check each spark plug produces a spark.

Did it spark?

STEP 3. Check the compression.

STEP 5. Check the intake manifold contamination and the intake ports contamination.

Are the intake manifold and the intake ports clogged?

STEP 6. Check for foreign matter being around the intake and exhaust valves.

STEP 7. Check the injector (high pressure).

STEP 8. Check high-pressure fuel line.

By a visual inspection and odor inspection, check around the high-pressure fuel line from the fuel pump (high pressure) to the injector (high pressure). Ensure that there is not fuel seepage and fuel leaks.

Are there any abnormalities?

STEP 9. Check of harness damage in LHFL, LRL, LSFL, LEFL and LPFL line between linear air-fuel ratio sensor and ECM connector.

Is the harness wire in good condition?

STEP 10. Replace the linear air-fuel ratio sensor.

(1) Replace the linear air-fuel ratio sensor.

(2) Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 8  .

.

.

.(3) Check the diagnostic trouble code (DTC).

Is DTC P219A set?

The inspection is complete.

The inspection is complete.STEP 11. Replace the injector.

(1) Replace the injector.

(2) Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 8  .

.

.

.(3) Check the diagnostic trouble code (DTC).

Is DTC P219A set?

The inspection is complete.

The inspection is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)